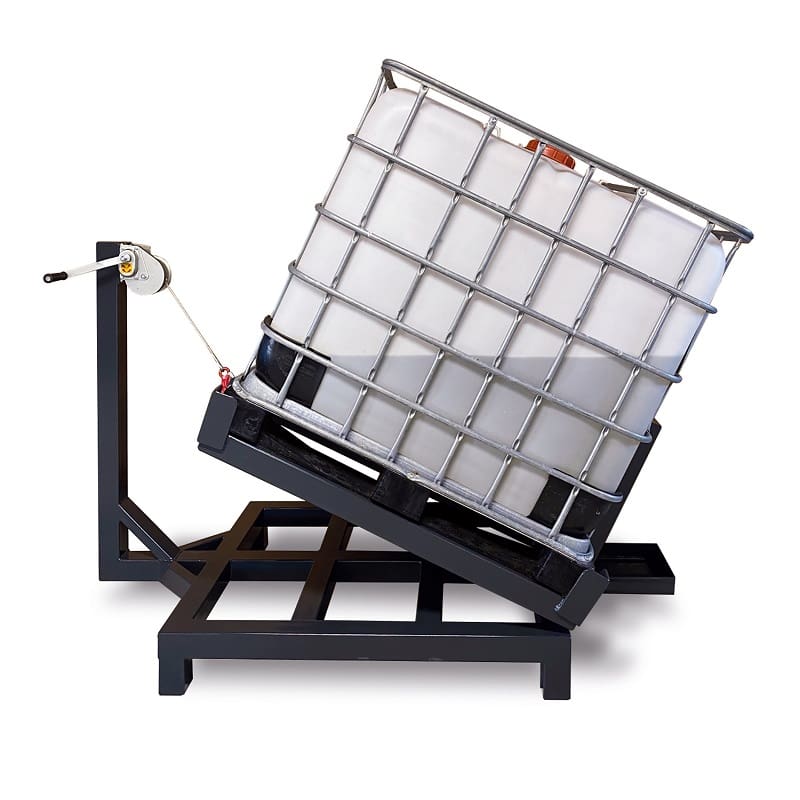

Optimise your IBC handling with our sturdy IBC Tilter, engineered for safe, efficient and complete emptying of 1,000 × 1,200 mm IBC containers. With an ergonomic manual tilt handle, this mechanism enables smooth and effortless tilting up to 35°, ensuring every last drop of product is utilised while reducing waste and maximising yield.

Designed to enhance both productivity and workplace safety, the IBC Tilter streamlines emptying cycles and helps lower product and operational costs. The automatic tilt at 35 % fill level protects workers from manual strain and prevents unnecessary accidents or spills. It integrates seamlessly into your setup, whether placed directly on the floor, atop a drip tray or mounted on a frame, and is available in galvanised steel or stainless steel upon request.

Available with flexible configuration options to meet your needs. Request a quote today to discover how the IBC Tilter can elevate efficiency, safety and cost-effectiveness in your warehouse or production facility.