7 Tips for flawless wood finishing with roller coaters (with video)

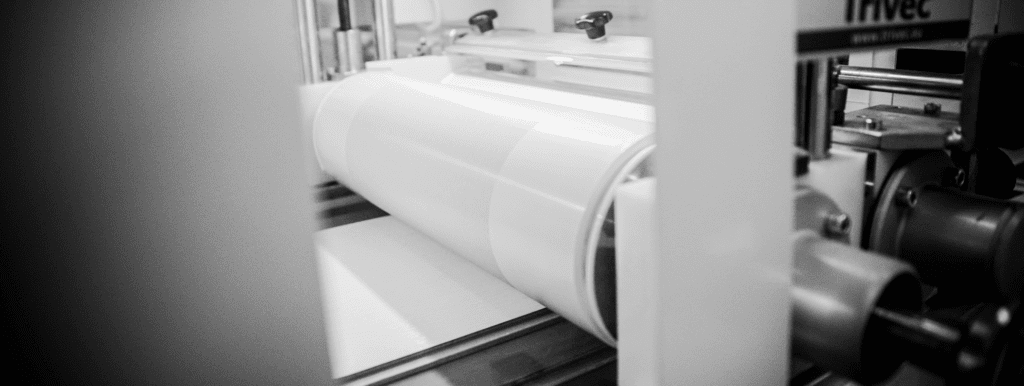

In the world of woodworking, the finish often distinguishes a project from good to exceptional. A critical technique in this process is the application of oil or varnish using a roller coating machine, a method that demands precision, craftsmanship, and attention to detail. In this article, we delve into the essence of roller coating techniques, focusing on single roller coating and double roller coating, as demonstrated by an expert in the accompanying instructional video. We highlight the importance of these techniques for both aesthetics and durability. For a complete and visual explanation, we recommend watching the instructional video, where the expert showcases these techniques in action.

Article continues below the video.

Why roller coating matters

Roller coating goes beyond merely applying a layer of oil or varnish. It is a technique that enhances the natural beauty of wood while providing protection against wear, moisture, and other elements. A well-executed roller coating technique ensures an even distribution of the finish, which is crucial for a professional result. Whether you’re finishing parquet, furniture, stair treads, or profiled surfaces, the right roller coating technique elevates your work to the next level.

Single roller coating: simplicity and precision

Single roller coating, as used in systems like the Trivec Single Roller Coater Experience, is ideal for applying an even finishing layer. This method employs one application roller (often soft rubber rollers for profiled surfaces) and a dosing roller (also known as a chrome roller).

Key aspects of single roller coating

- Speed control: The speed of the rollers determines the amount of product applied. A slow speed (e.g., 2 meters per minute) results in a thin layer (5-6 grams for topcoats), while a higher speed (up to 15 meters per minute) applies more product.

- Pressure adjustment: The adjustable pressure between the rollers and the wood is essential. Thinner oils require more pressure, while thicker oils need less. A standard pressure setting of approximately 0.3 mm is often a good starting point.

- Streak-free finish: The transport and application rollers must operate synchronously to prevent streaks. The dosing roller can be independently adjusted for added control.

- Reverse rotation for fine application: For an ultra-thin layer, the dosing roller can rotate in the opposite direction, using a rubber dosing blade and sealed sideplates to prevent leakage. This is ideal for delicate finishes on flat surfaces like parquet, furniture panels, or cork.

Single roller coating is perfect for smooth surfaces or delicate finishes and is widely used for base and topcoats on wood, as well as materials like glass, cardboard, and plastic.

Double roller coating: depth and control

For heavily textured wood, such as oak with deep grain, double roller coating, as implemented in systems like the Trivec Double Roller Coater Experience, is highly effective. This method uses two sets of rollers, each with an application roller and a dosing roller, arranged in a mirror-image configuration. The first set applies a generous amount of product, while the second set rotates in the opposite direction to remove excess oil or varnish, ensuring the product is well-absorbed into the wood and delivering a clean, even finish.

Wet-wet application

An advanced application of double roller coating is the wet-wet technique. In this method, both roller sets rotate in the same direction, and the second roller is also filled with product (oil or varnish). This results in a high grammage, ideal for heavy, durable finishes on textured wood or for special effects like ceruse finishes on parquet and furniture panels.

A ceruse finish, also known as “liming” or “pickling,” is a woodworking technique that creates a two-tone effect by highlighting the open grain of the wood with a contrasting base color. This method is popular for achieving an aged, weathered look and can be applied to various wood types, such as oak.

Advantages of double roller coating

- Thorough absorption: Ideal for textured wood where the product needs to be deeply absorbed into the pores, such as in parquet or exterior wood cladding.

- Clean finish: Removes excess oil, preventing later contamination of presses and brushes.

- Versatility: Suitable for both industrial applications and specialized finishes, supporting various materials like ceramics, concrete tiles, and plastics. The wet-wet configuration offers additional flexibility for intensive coatings.

Advanced techniques and tips

To fully master roller coating techniques, several advanced considerations make a difference:

- Oil viscosity: Adjust pressure and speed based on the viscosity of the oil or varnish used. Viscosity adjustments ensure consistent results.

- Rotation direction: The direction of the dosing rollers affects the outcome. Reverse rotation provides precision for thin layers, while simultaneous rotation, as in the wet-wet application, ensures heavy application.

- Sideplates: Use open sideplates for standard rotation and sealed sideplates for reverse rotation to prevent leakage.

- Speed synchronization: Synchronous speeds between transport and application rollers guarantee a streak-free finish.

Why watch the video?

While this blog post provides a detailed overview of roller coating techniques, seeing these methods in action is essential for a complete understanding. In the instructional video, one of our experts demonstrates the operation of the rollers, the fine-tuning of speed and pressure, and their application on various materials. The visual element helps you grasp the nuances of each technique and inspires you to enhance your own projects.

Conclusion: elevate the quality of your woodworking

Mastering roller coating techniques is an indispensable skill for any woodworker striving for perfection. With single roller coating, supported by systems like the Trivec Single Roller Coater Experience, you achieve an even, delicate finish. Double roller coating, powered by systems like the Trivec Double Roller Coater Experience, offers unparalleled control for textured wood and heavy coatings. By focusing on speed control, pressure adjustment, and proper setup, you can achieve a finish that is both beautiful and durable.

For a comprehensive and visual guide, we highly recommend watching the instructional video. Here, you’ll see the expert at work and gain practical insights you can directly apply to your own projects. Dive into the art of roller coating and take your woodworking to the next level!