Creating solutions together

to

innovate

improve

optimise

Trivec, specialist in machine solutions for surface treatment of many materials.

Our brands

Creating solutions together that help you grow, improve and become more efficient and sustainable.

Why choose Trivec?

“Creating solutions together” embodies our commitment to quality, innovation, and collaboration. Trivec machines are not just products; they are tailored solutions designed to enhance efficiency and make production processes more sustainable. Everything we do focuses on achieving the best finishing of product surfaces and optimizing handling within production processes. What is your challenge that we can help you with?

Strong

Strong

together

together

Strong together

We believe in the power of collaboration. Together with clients, glue and lacquer manufacturers and other partners and suppliers, we aim to find the best solution. Our team thinks along with you and guides you from concept to installation, always with your goals in mind.

Client-

Client-

focused

focused

Client-focused

Your needs and challenges are at the centre of what we do. We deliver high-quality sustainable solutions that meet your expectations and ensure efficient use of resources, materials and people.

Trusted

Trusted

Trusted

As a client, you can count on us and we act honestly and ethically. We do so proactively and with prompt service. We are ready when you need us, with solutions that contribute directly to the continuity of your business.

Sustainable

Sustainable

quality

quality

Sustainable quality

Trivec machines and machine lines are designed and manufactured with the greatest care and attention to detail. Offering quality and sustainable solutions is in our DNA from initial design to after-sales service. This guarantees machines that perform, are durable and provide a sustainable working environment.

Innovation

Innovation

and

customisation

and

customisation

Innovation and customisation

We strive for continuous improvement and new solutions. We confert knowledge and experience into innovative solutions and techniques that, where necessary, are custom designed and built. From standard machines to fully customised solutions, in close cooperation with you and our partners.

Trivec

Trivec

Experience

Center

Experience

Center

Trivec Experience Center

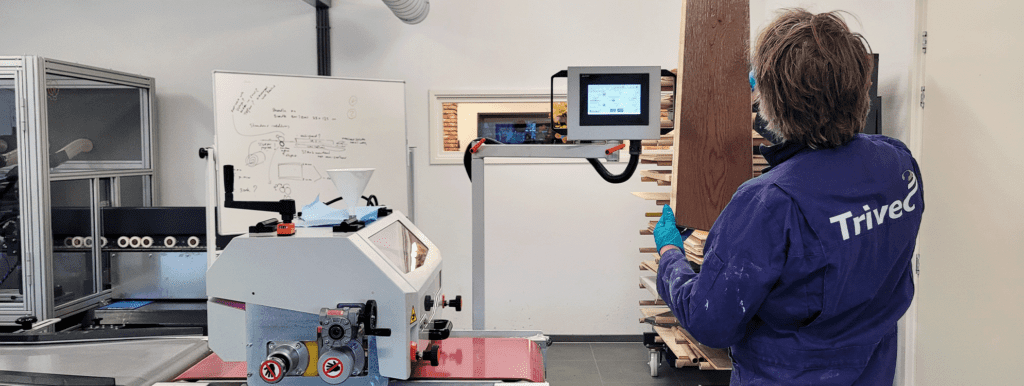

Trivec’s own test centre offers you a production setup that allows you to realise and experience your current or future production process in full control. By testing and fine-tuning your own application live, we find together, and in close cooperation with your paint or glue manufacturers, the best solutions tailored perfectly to your specific challenge.

Our expertise

We specialise in providing machinery solutions for surface finishing and treatment for a variety of industries. Explore how we support your branche or sector with our innovative approach and expertise.

Our techniques

Discover the innovative techniques we use to deliver high-quality solutions tailored to your needs.

Our services

Discover how we can help you with our service solutions and expert support. Explore our technical services, after sales support, training and consultancy and let us know how we can assist you.

Project showcase

Get inspired by some of our completed projects

Next-Gen sports floors, engineered by Trivec

Next-Gen sports floors, engineered by Trivec

In 2021, a client approached Trivec with an ambitious request: could their plastic tile sports floor be redesigned to be

Scaling smarter: Double efficiency without replacing production line

Scaling smarter: Double efficiency without replacing production line

Two and a half years ago, our customer started operating a finishing line based on oxidative oil. The line included

How texture and stain created premium façade wood

How texture and stain created premium façade wood

View ProjectTwo step UV-oil finishing line parquet flooring

Two step UV-oil finishing line parquet flooring

How a parquet wholesaler established its own high-quality UV-oil finishing line.

UV-resistant coating on printed concrete tiles

UV-resistant coating on printed concrete tiles

Transforming concrete into natural stone: UV-resistant coating.

Innovating together

Since 1974, we have been specialists in machines and accessories for surface treatment.

From our knowledge and experience and in close cooperation with clients we design and develop innovative solutions together. Where applicable, we also seek collaboration with partners to create the best outcome for your needs. These are solutions that combine existing techniques with new technologies and possibilities, truly advancing your business and customers. Our Engineering Solutions will enable you to genuinely differentiate yourself in your markets.

Our approach

We work closely together and approach your challenge via the process of innovation to find the solution you’re looking for.

Assessment

We begin our innovation process by assessing the problem or challenge you want to solve. What knowledge and experience do we collectively have to tackle this journey, and what additional resources are needed?

Co-creation

In this phase, we collaborate closely together to generate ideas and and explore possible solutions. By combining our expertise with your insights, we lay a solid foundation for the next steps.

Design

We transform the generated ideas into concrete designs. Your goals and requirements are the main focus for every desing made, ensuring the technical concept aligns perfectly with your vision and needs.

Prototyping

We create an initial version of the design by building and refining a working model to test the design, functionality, and usability. This prototype is used to evaluate and gather feedback, allowing us to refine the product further.

Testing

We test the prototype in real-world conditions to ensure the outcome meets the expectations. We learn and determine whether adjustments are needed, or if we can move forward. This is the final step before realizing the finished product.

Production

The solution becomes reality and we begin producing the final product. With care and precision, we ensure the final product is ready for use in your business and is perfectly tailored to your needs.

Testimonials

We have been using Trivec machines on our production line for some time now, and we couldn’t be more satisfied. The build quality is outstanding—robust, reliable, and clearly designed with long-term use in mind. The machines are also incredibly user-friendly, which has helped streamline our workflow and reduce training time.

Equally impressive is Trivec’s customer support. Their team is consistently responsive, knowledgeable, and genuinely helpful whenever we’ve needed assistance, and we are especially grateful to Wiebe for all his support. It’s clear they stand behind their products and are committed to their customers’ success.

We would highly recommend Trivec to any company looking for high-quality, dependable finishing equipment backed by excellent service.

Initially, we had doubts about choosing Trivec, particularly regarding the price and the robustness of the machines. However, we have purchased multiple machines from them and have always experienced a professional and pleasant collaboration. The support was prompt and helpful, and the service was solution-oriented. We appreciate Trivec as a reliable and customer-focused partner. That is why we would certainly recommend them to others.

We faced serious bottlenecks in our coating line, slowing down production and efficiency. Trivec Engineering provided the perfect solution with a custom-designed Coating Line that completely eliminated these issues. Our output has increased, and their proactive maintenance service prevents costly downtime. Trivec’s expertise, reliability, and commitment to customer satisfaction make them a trusted partner. We highly recommend them to any company looking to optimize production.

Trivec’s team is exceptional. Wiebe’s expertise and problem-solving skills keep our production running at peak performance, while Branko’s innovative approach ensures we stay ahead with new design concepts. Their commitment to quality and customer satisfaction makes them more than a supplier—they’re a true strategic partner. We highly recommend Trivec to any company looking to optimize its production.

Our Experience Center

At Trivec, we believe in developing and testing solutions together with our customers. With our Experience Center in Sumar, Friesland (The Netherlands) we have created our own test lab and demo center. Here, you can explore and experience our solutions and technologies and also collaborate with our team. Together we can determine in real-world circumstances how the meet your specific requirements.

Test and experience it yourself

Do you want to experience our solutions, or to explore what techniques can improve your business? You are welcome to visit our Experience Center in Sumar, Friesland (The Netherlands).

Innovating together

Together, we turn dreams into reality. Do you have ideas and want to know if we can help you innovate?