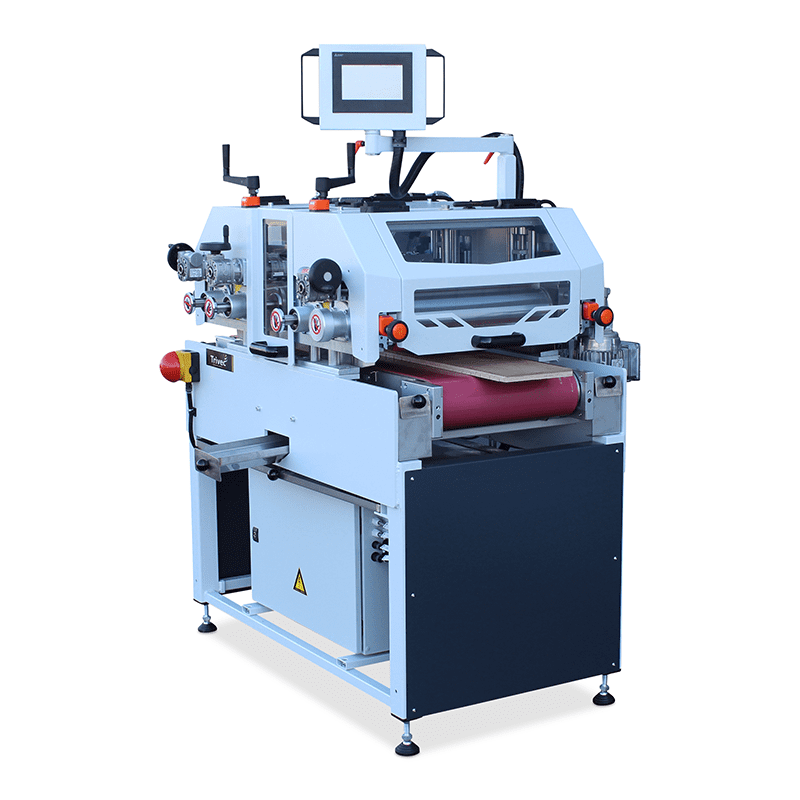

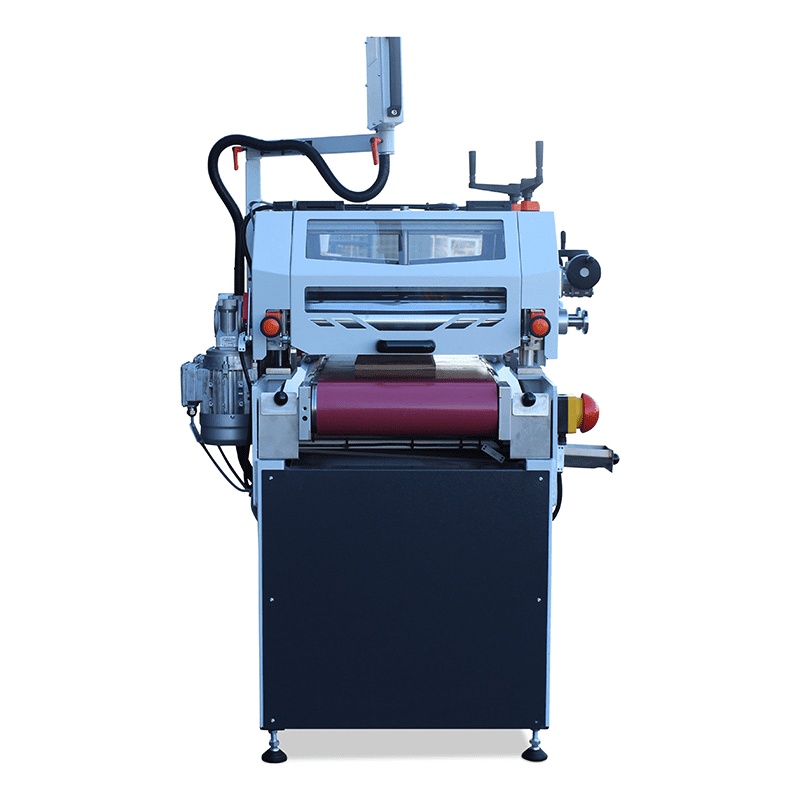

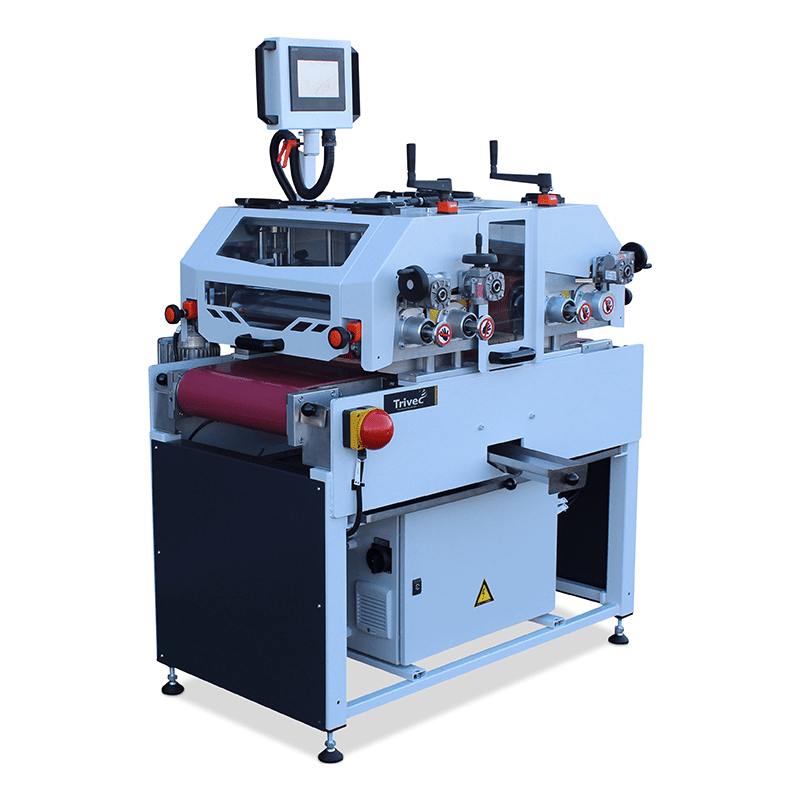

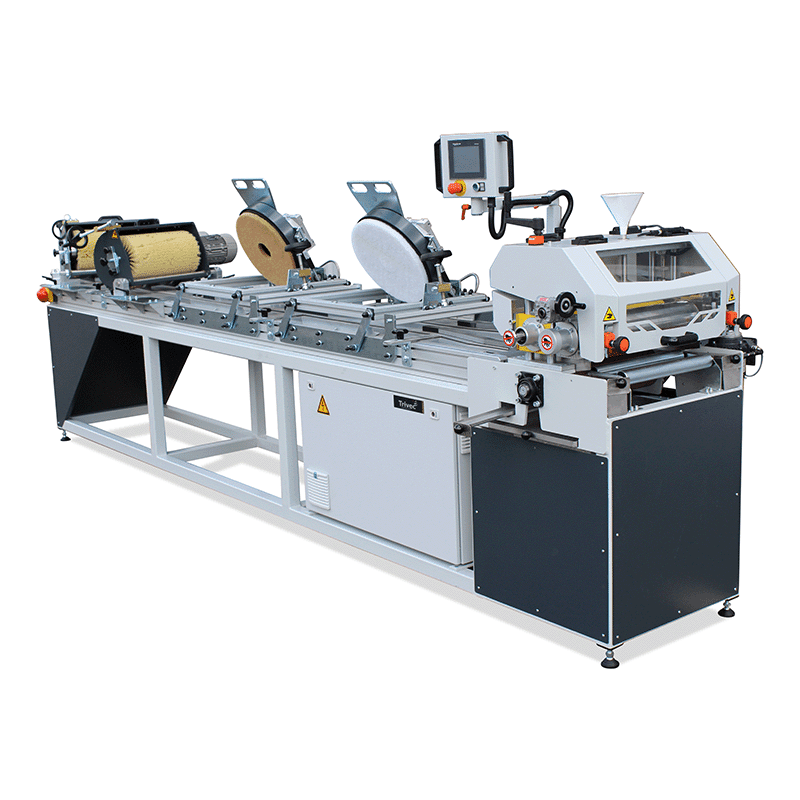

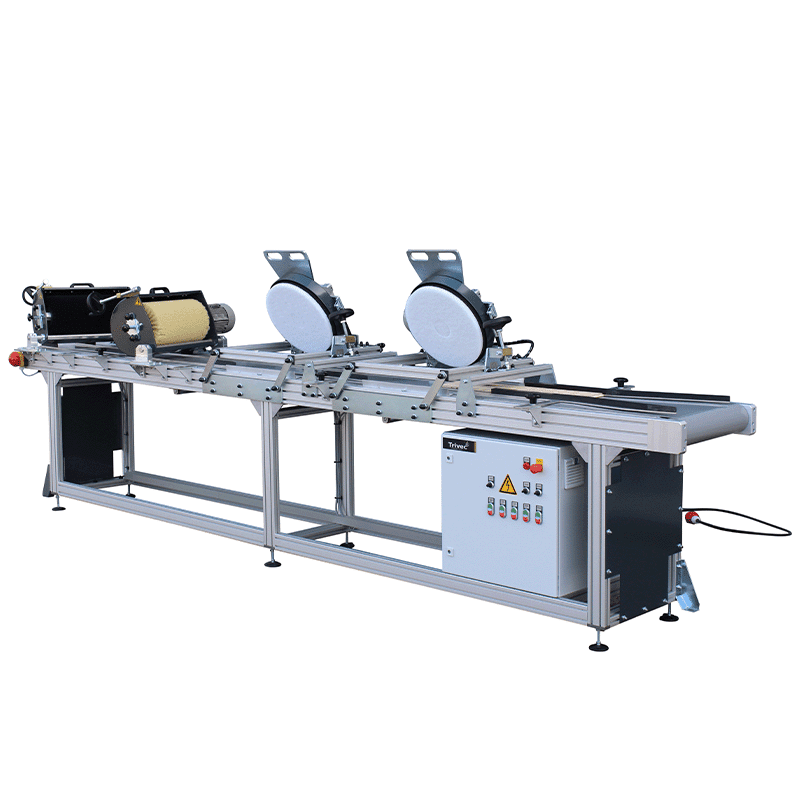

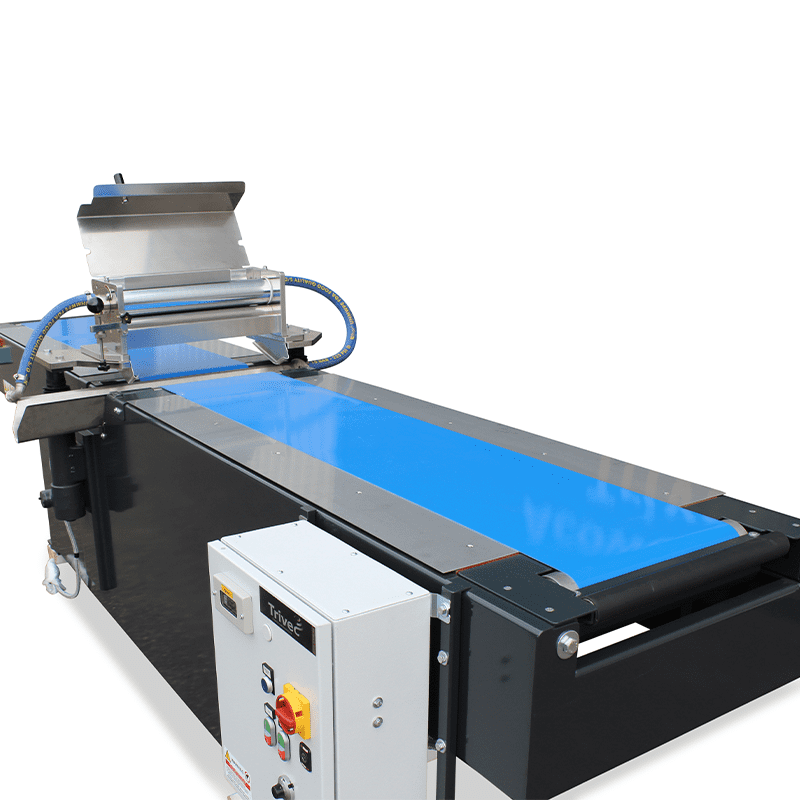

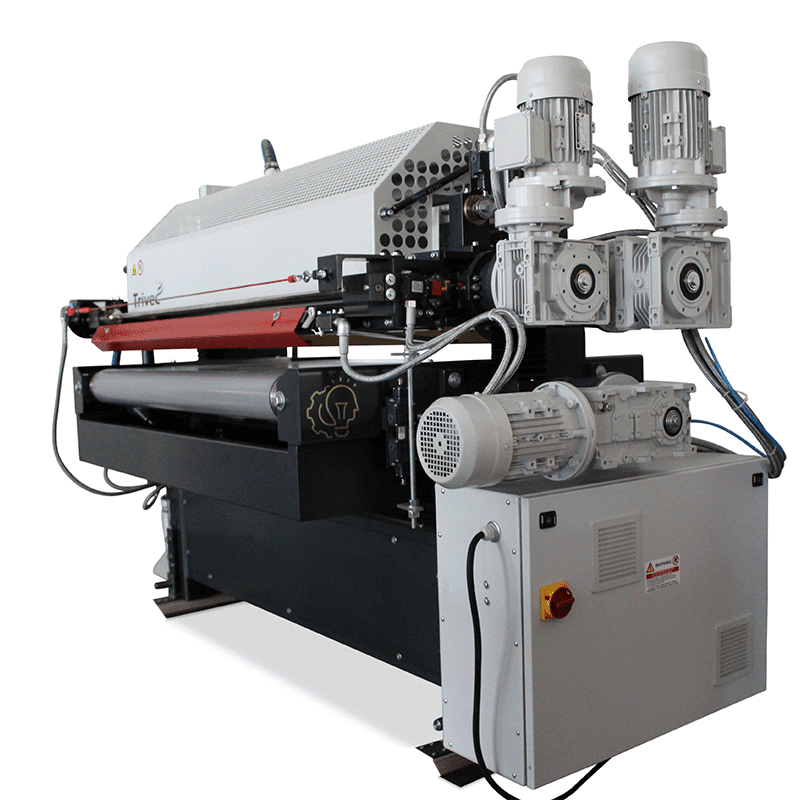

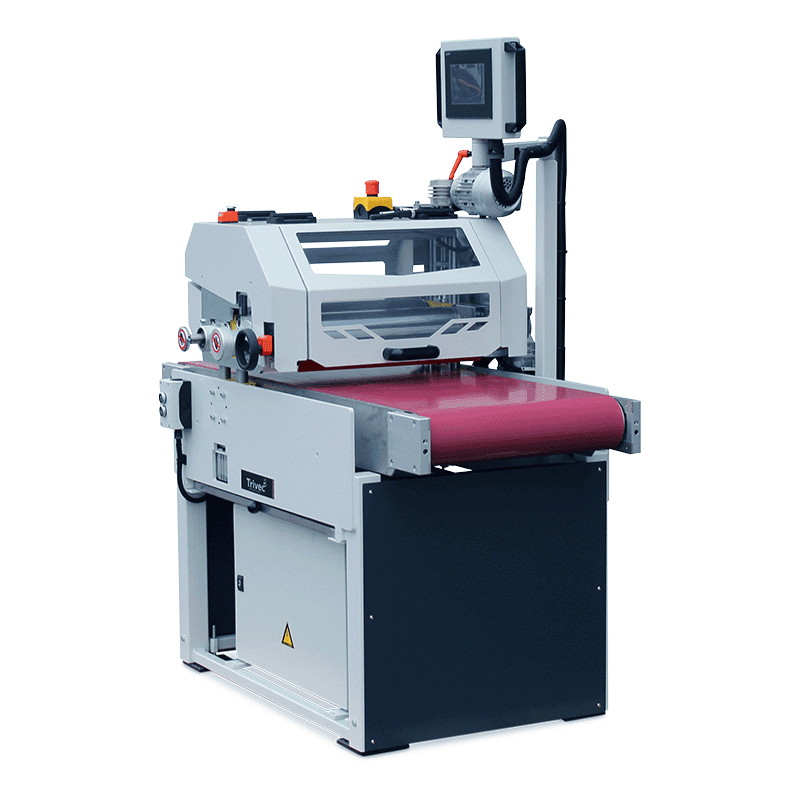

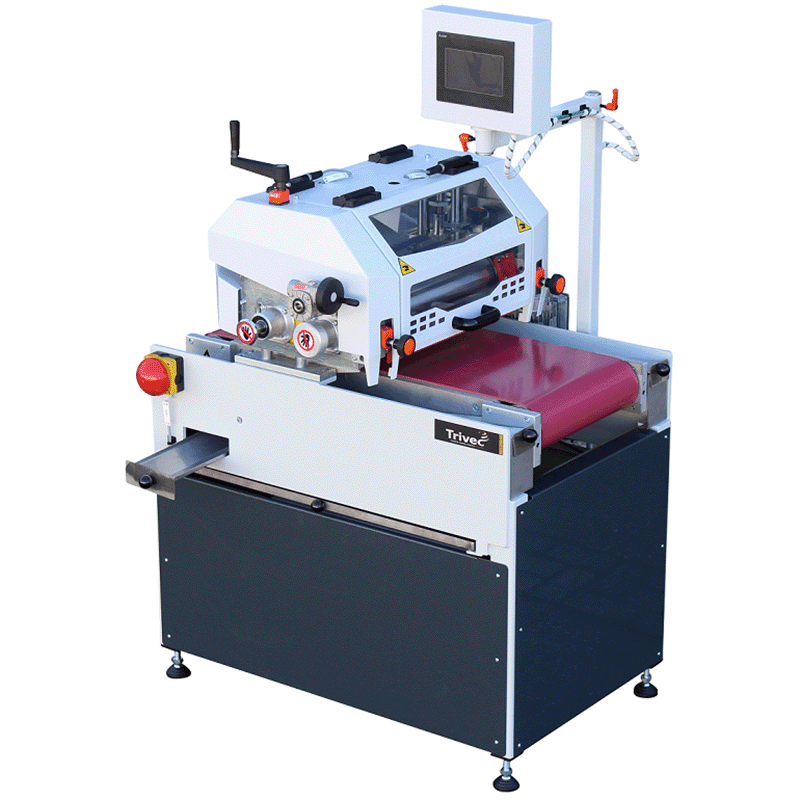

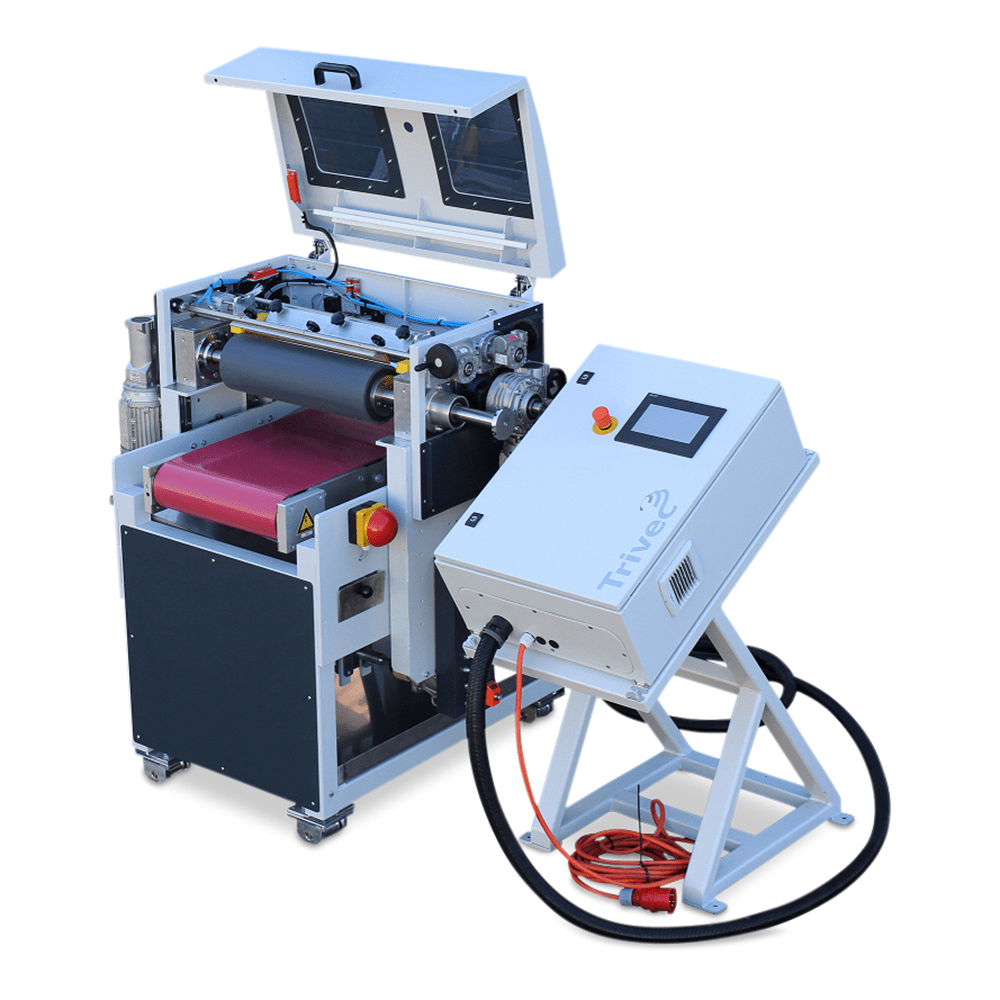

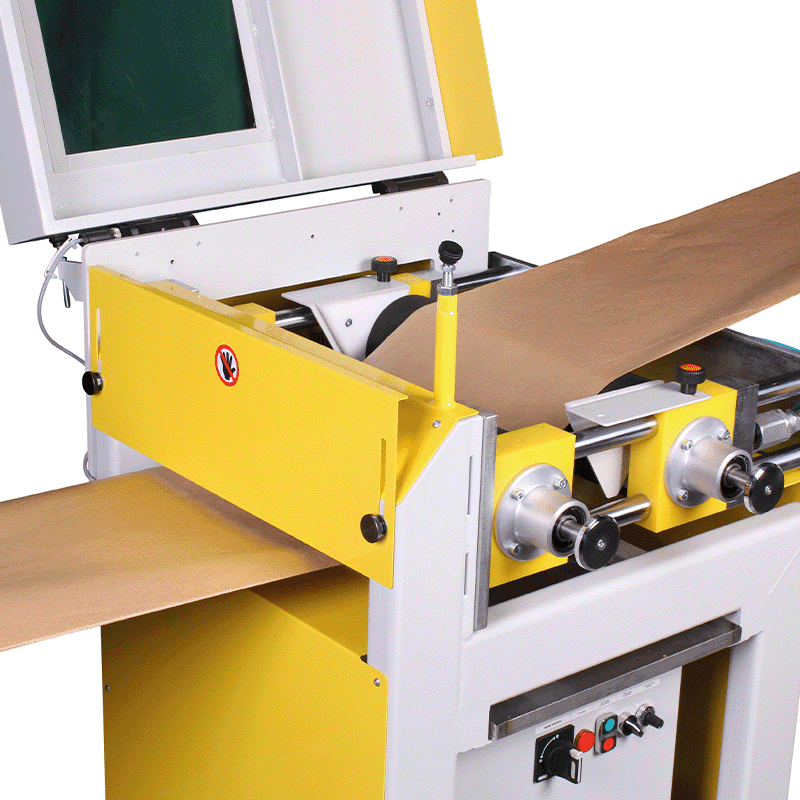

The Trivec Double Roller Coater Experience is equipped with two dosing- and application roller sets. Workpieces are fed into the system by use of an integrated conveyor belt.

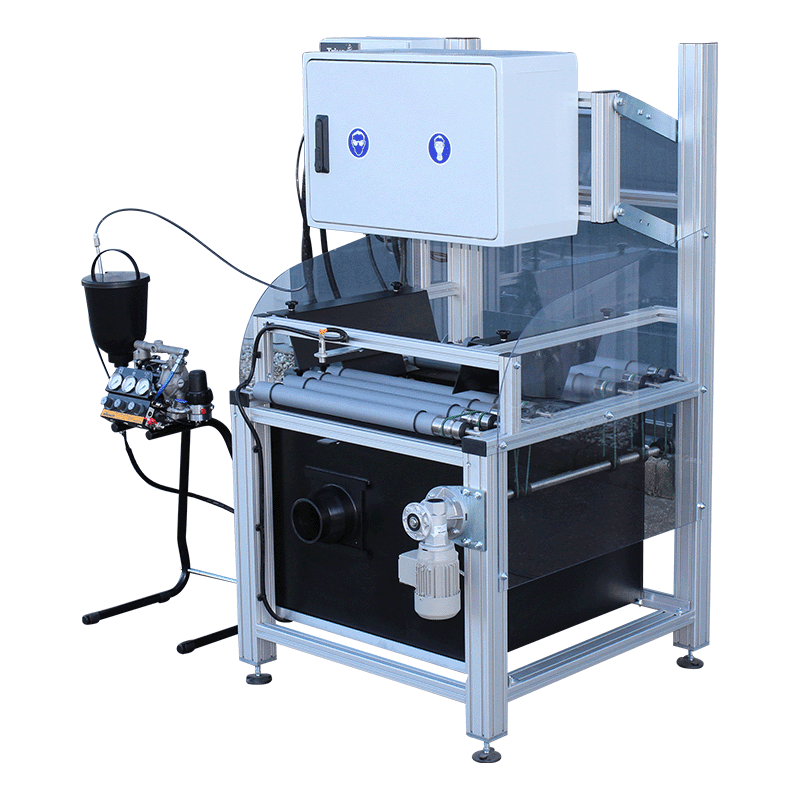

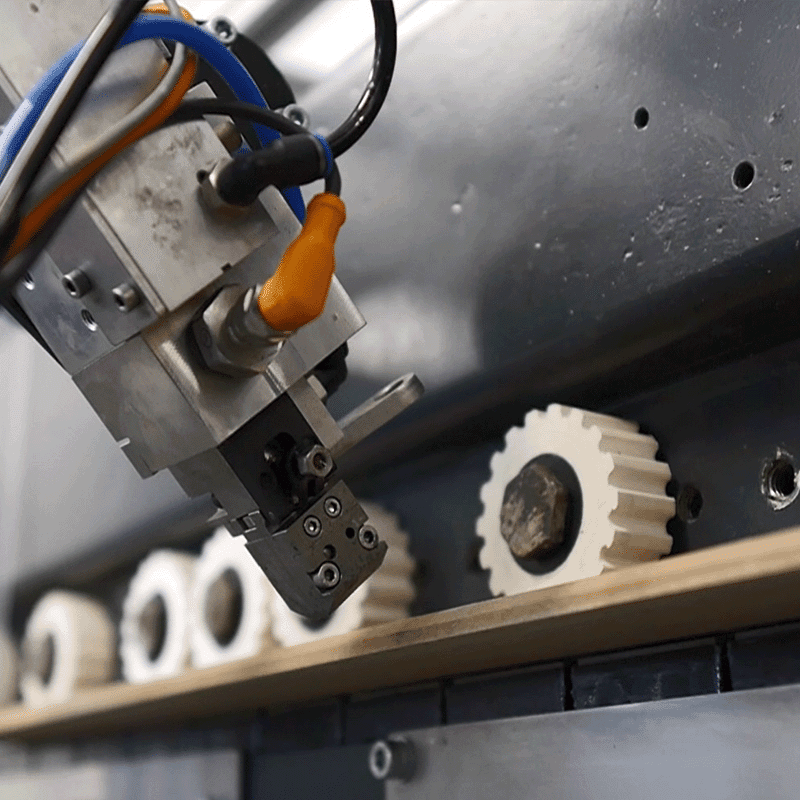

The application can be made precisely by changing the pressure between the application- and dosing rollers, the speed of the rollers and the rotational direction of the dosing rollers. The second set is used as a reverse roller, further increasing precision, and enabling additional finishing effects. The application rollers can be removed without the use of tools from the machine, for quick colour change or cleaning. Optional with touchscreen, feeding pumps, rail system, wet/wet configuration, and electrical height adjustment.