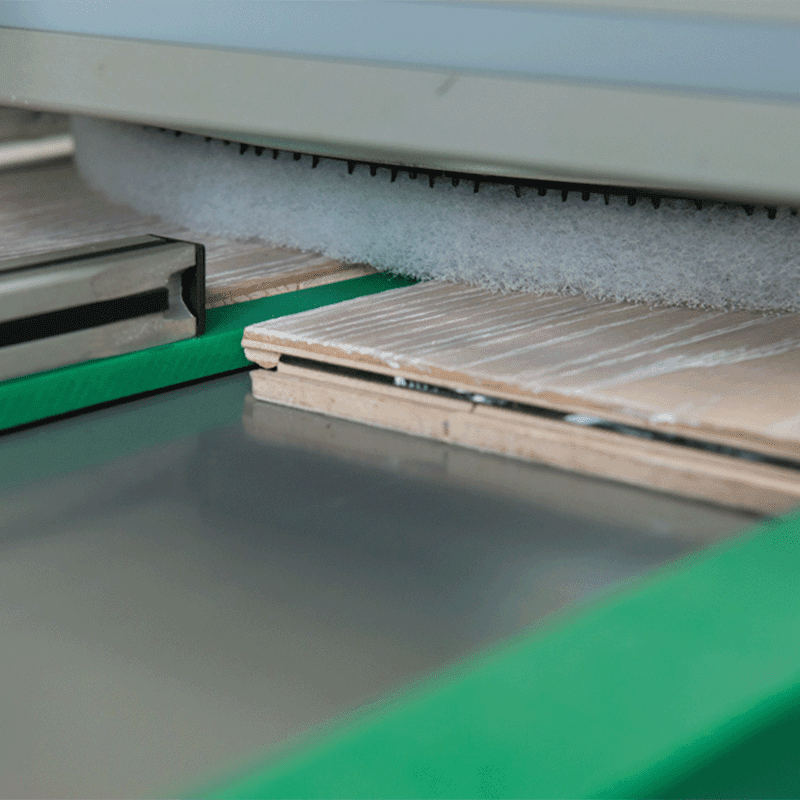

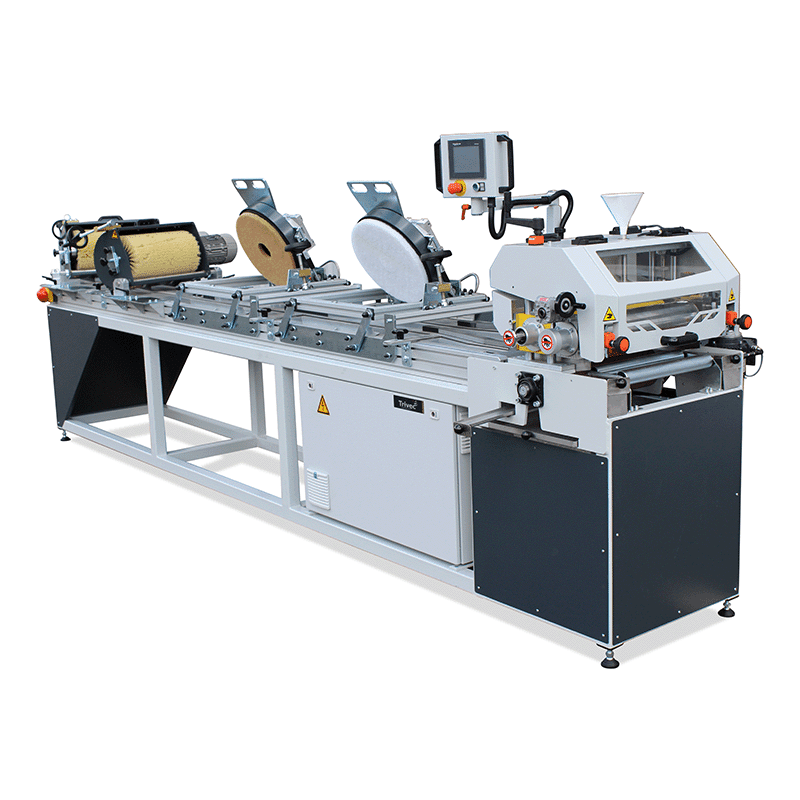

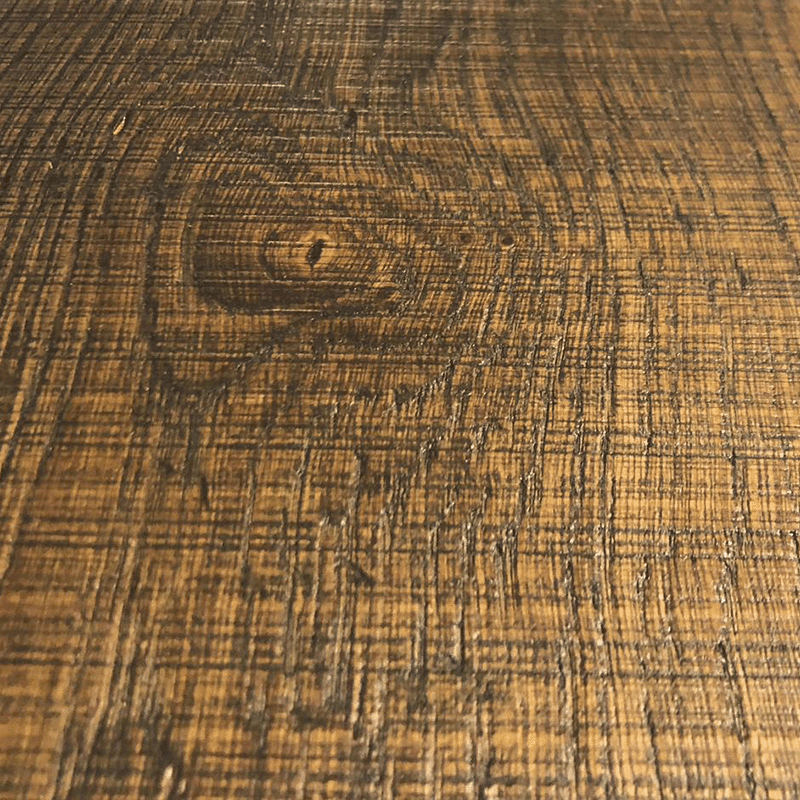

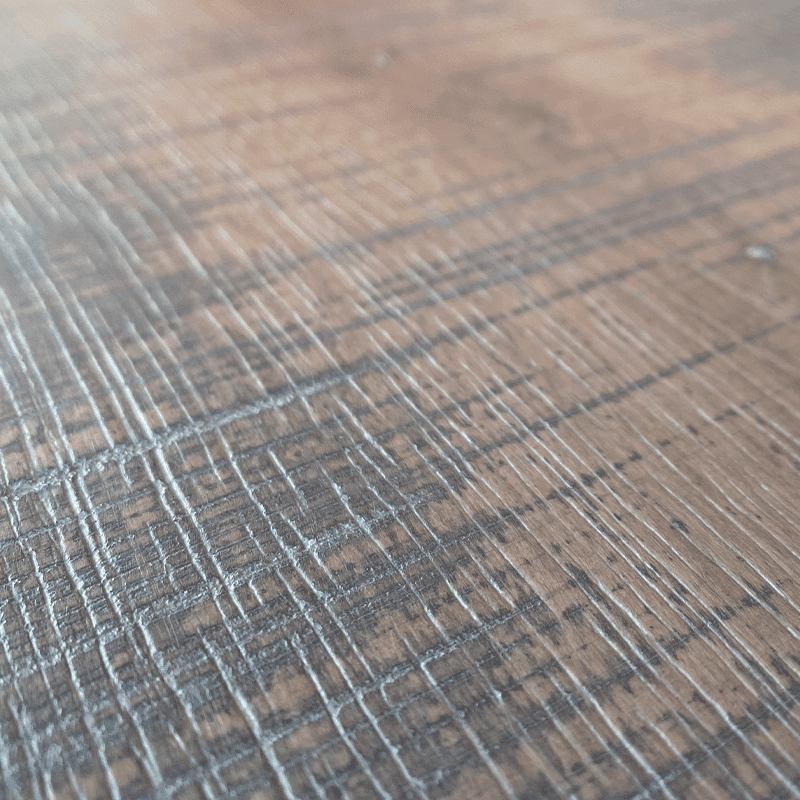

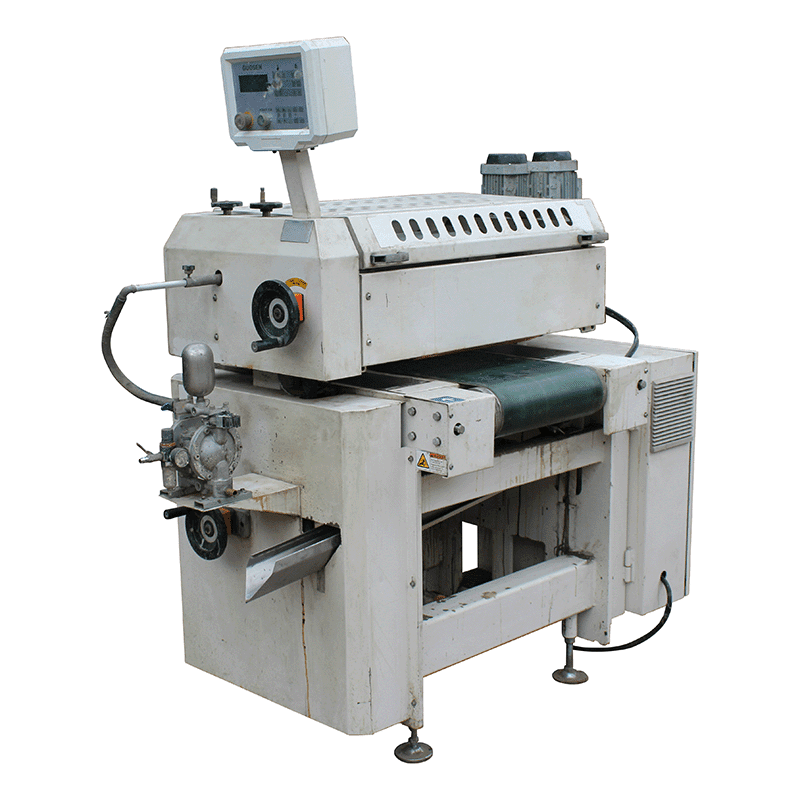

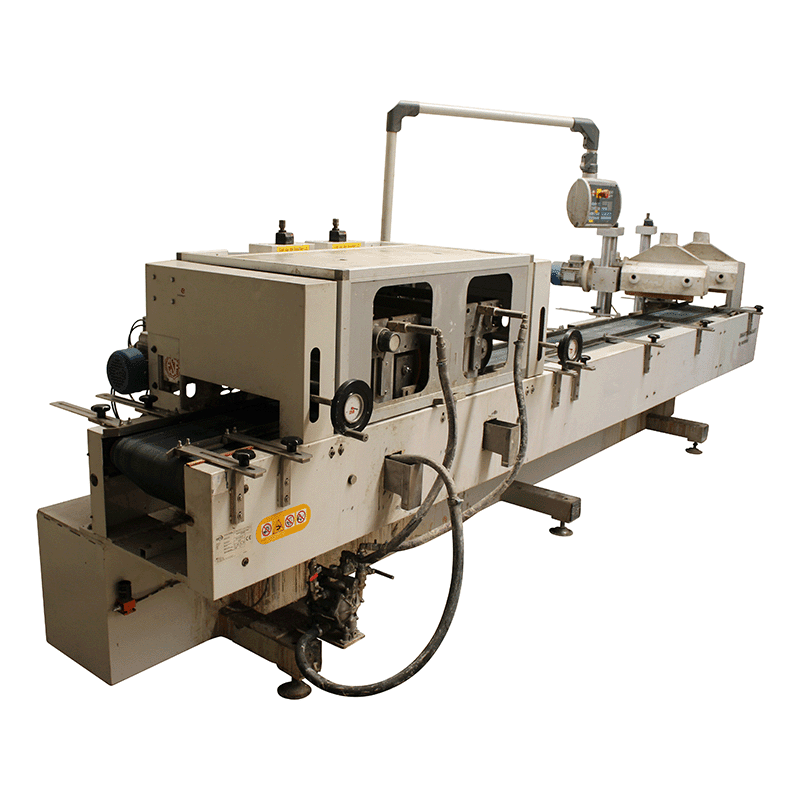

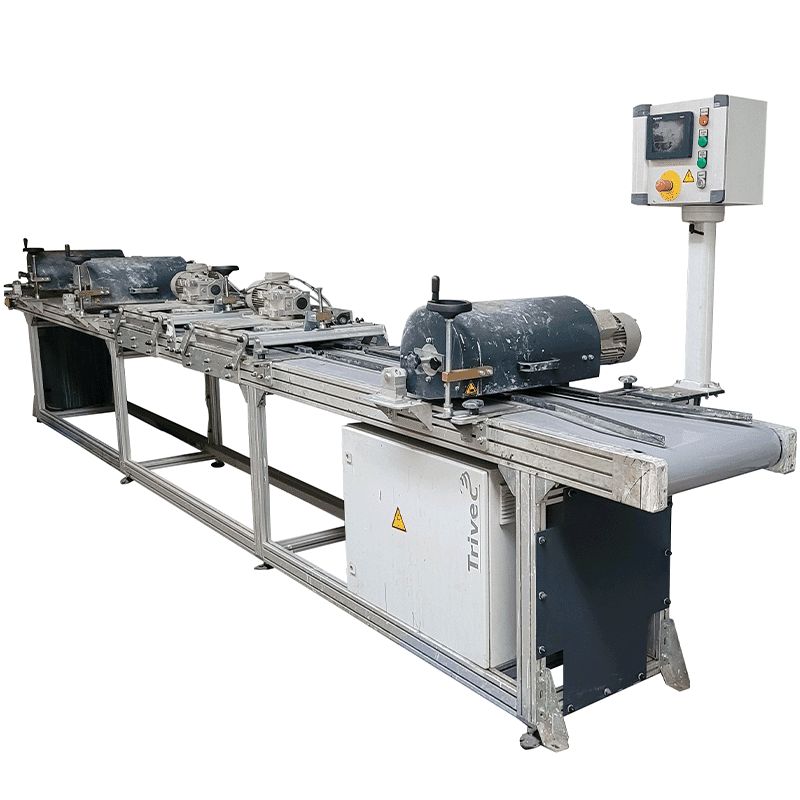

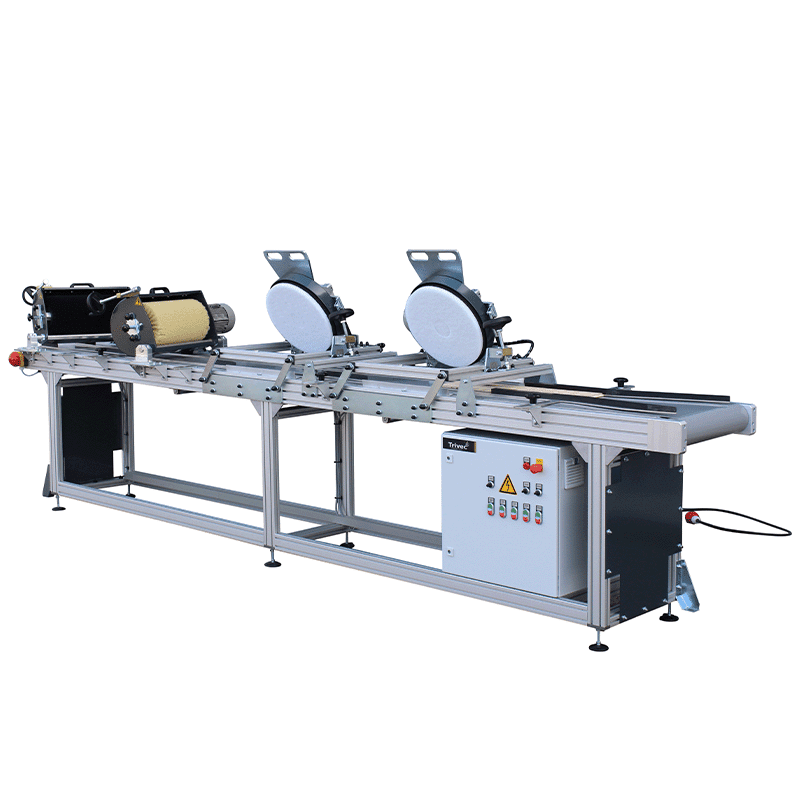

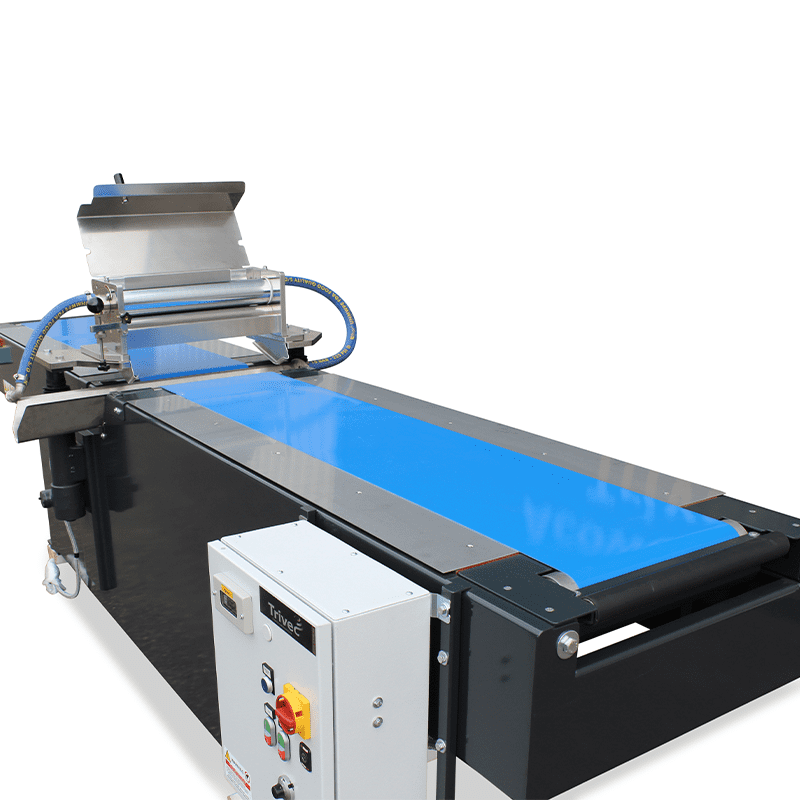

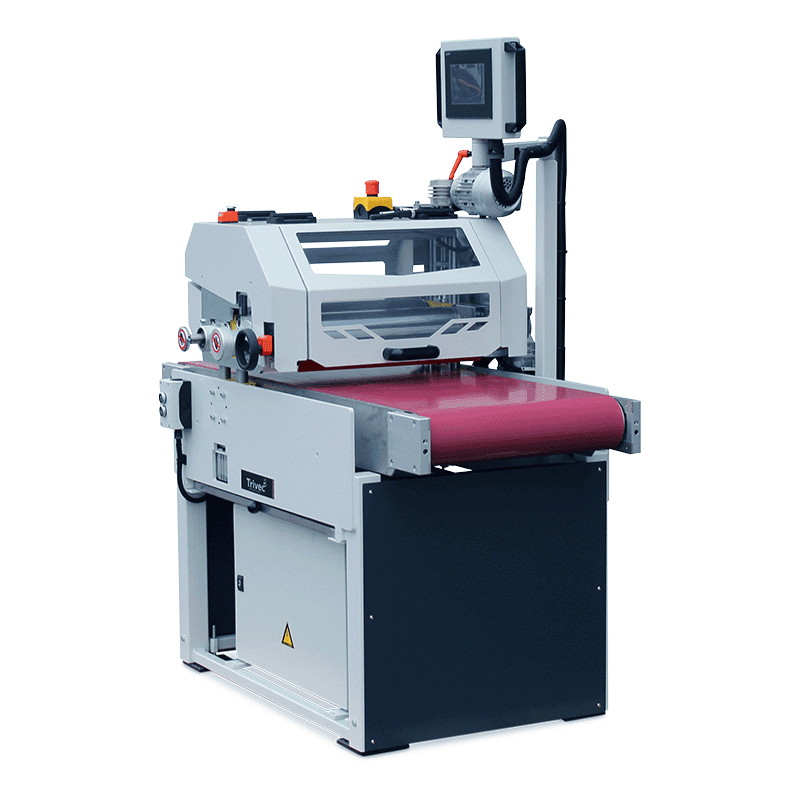

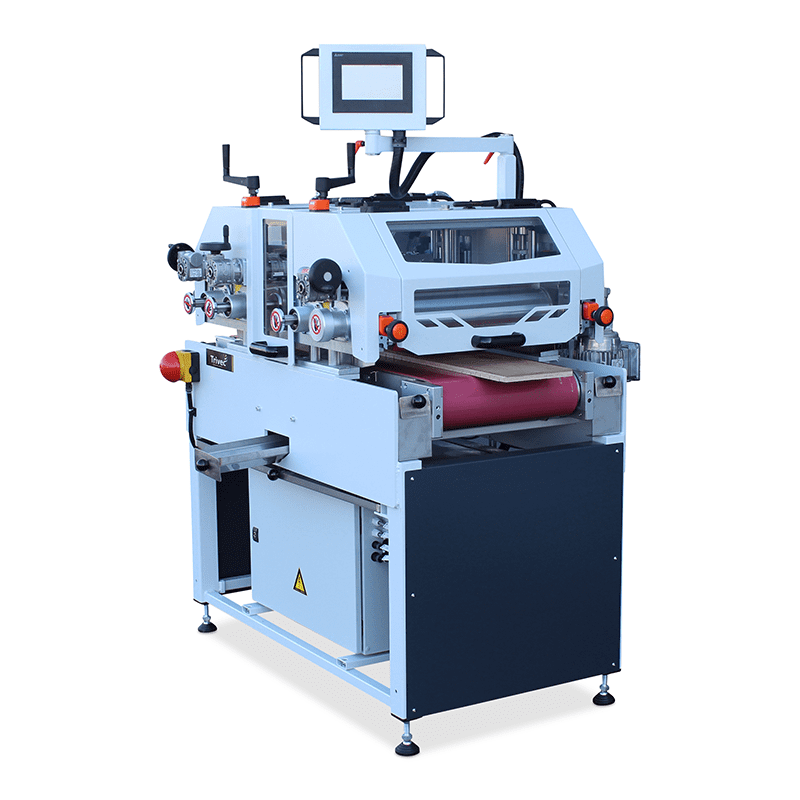

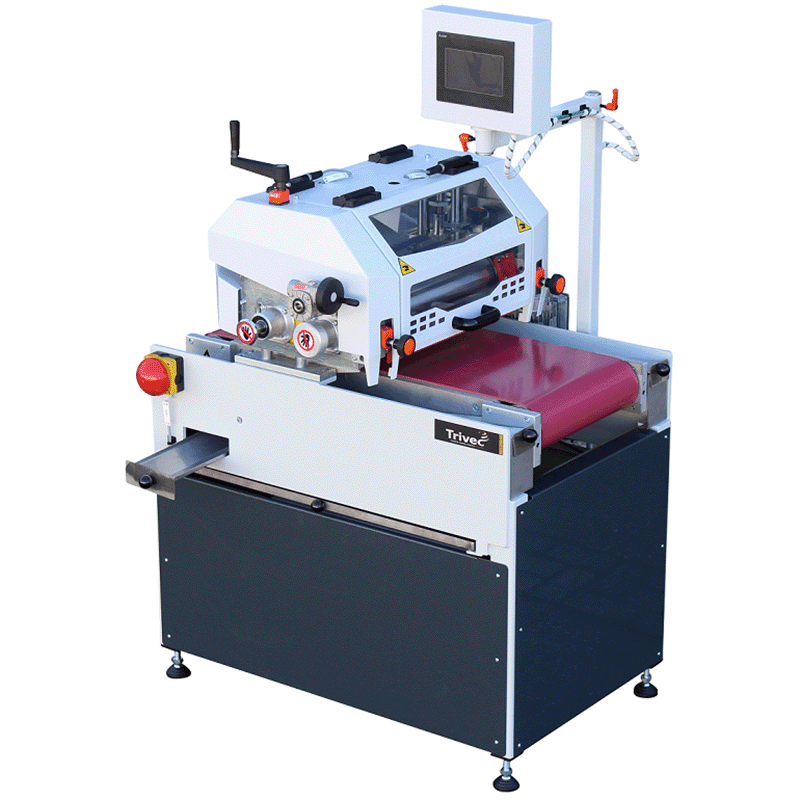

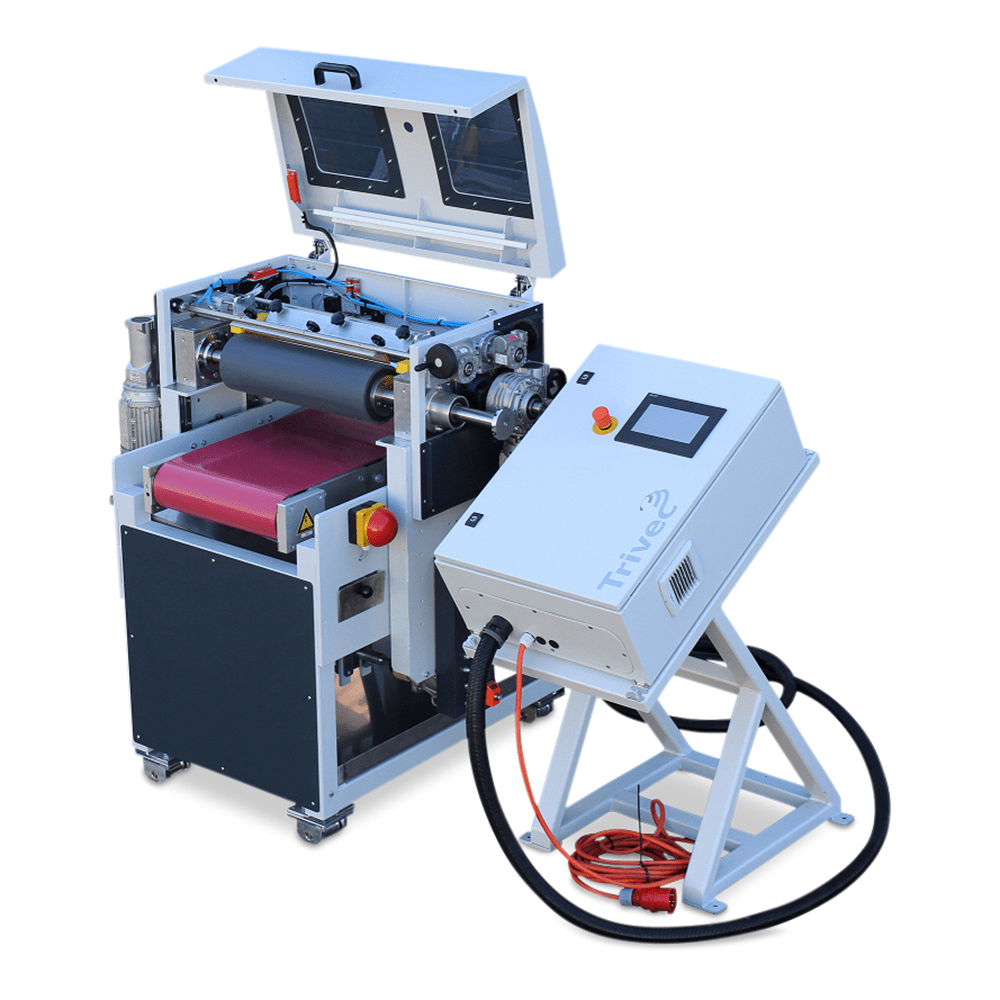

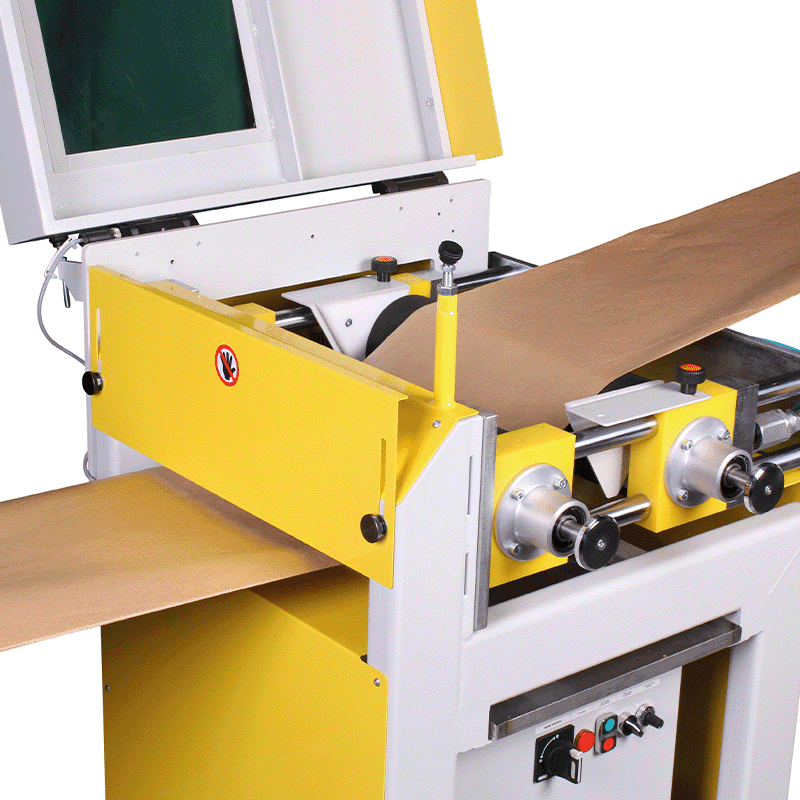

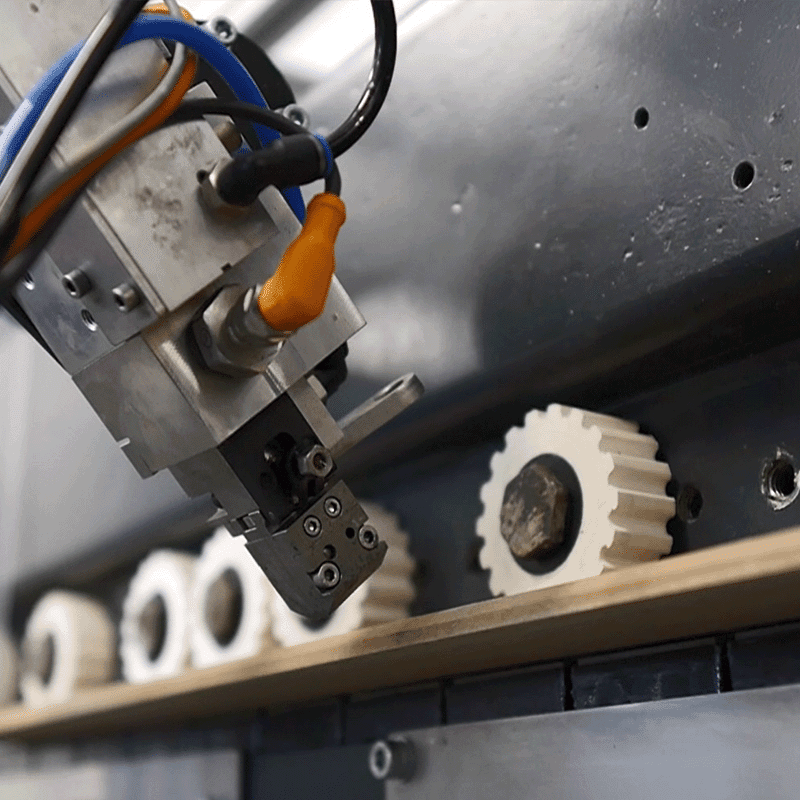

The Trivec All-In-One is used for smaller production series of applying oil, stains, and hard wax on parquet / flooring. This compact floor finishing line is ideal for smaller production areas. The All-In-One has four or five modules (roller coater – and three/four polishing units). The modules are integrated on the existing frame. The modules can work simultaneously or separately. It depends on the product to be applied. The control is via touchscreen, which enables precise work. The application roller can be removed quickly and without tools for changing and/or cleaning purposes. The desired result can be accurately adjusted using the pressure of the application roller in combination with the speed and direction for rotation of the dosing roller.