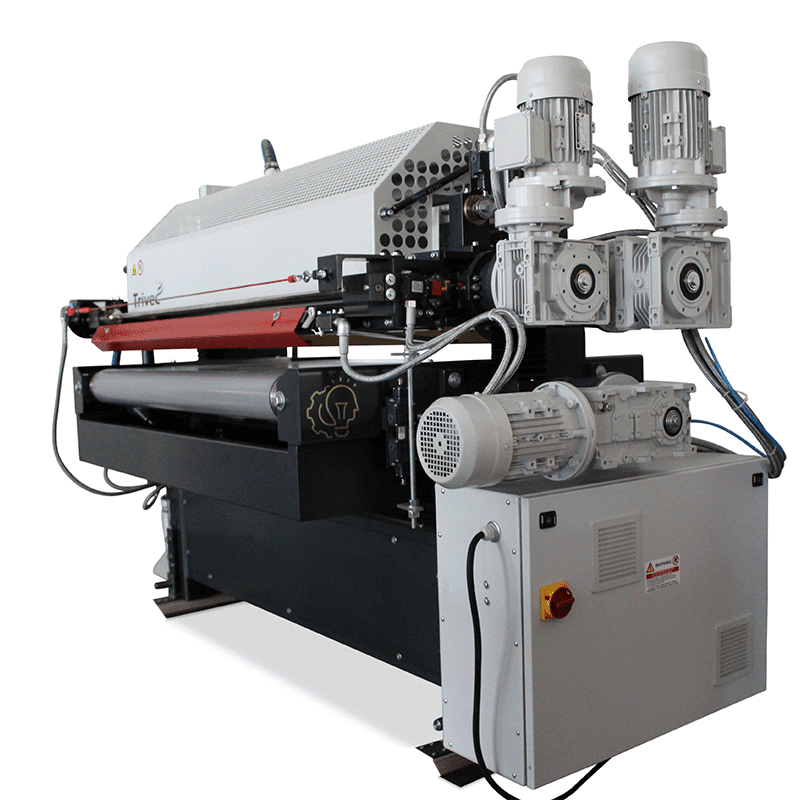

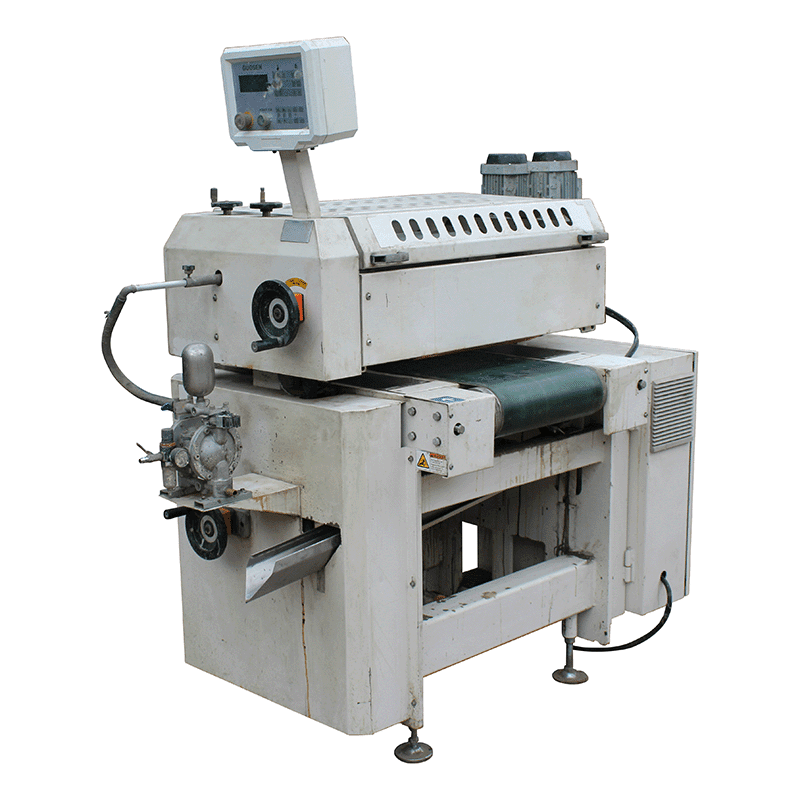

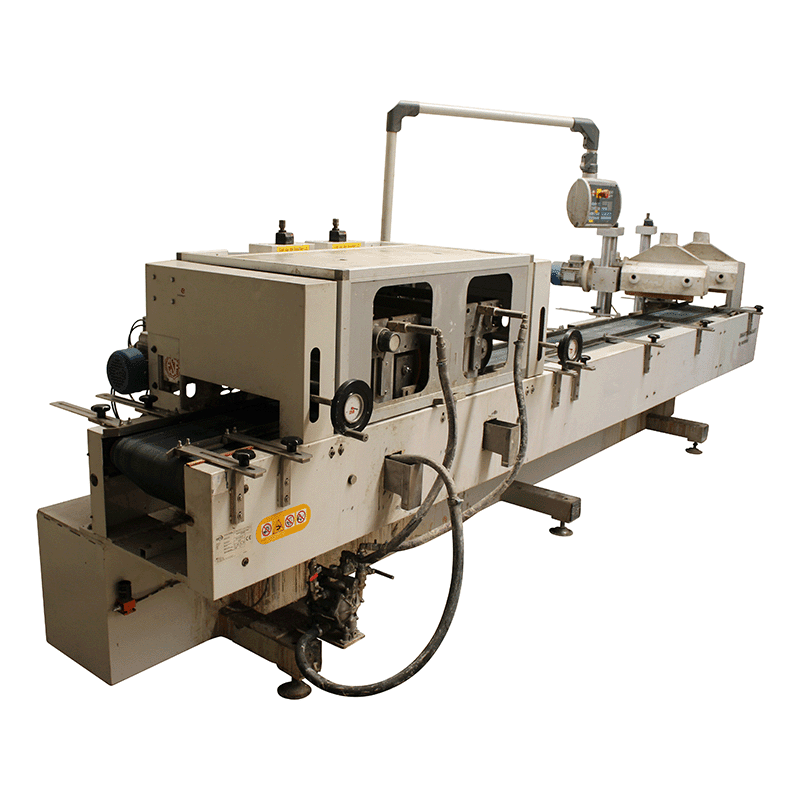

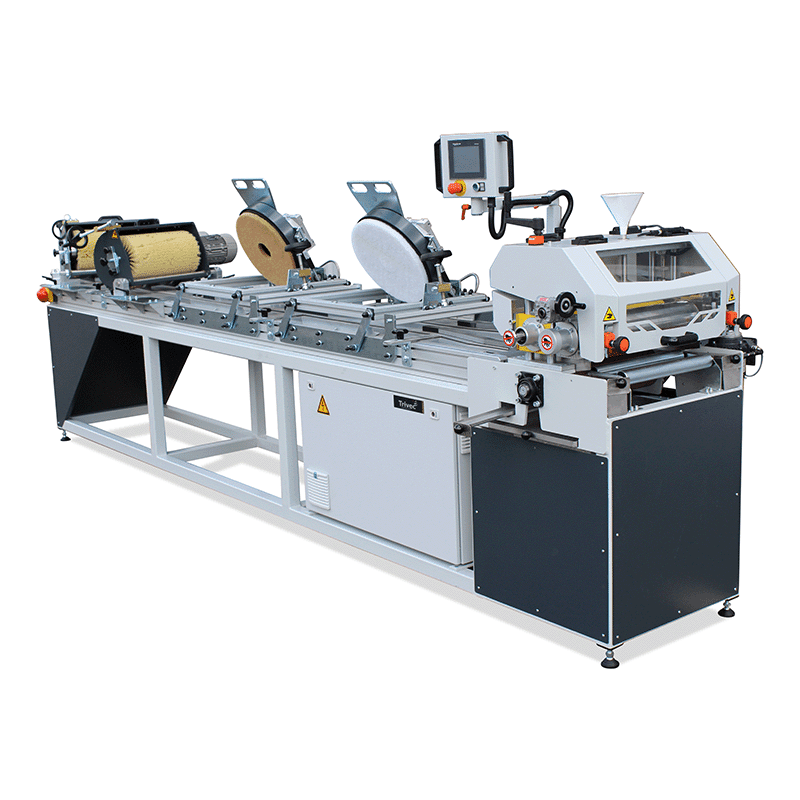

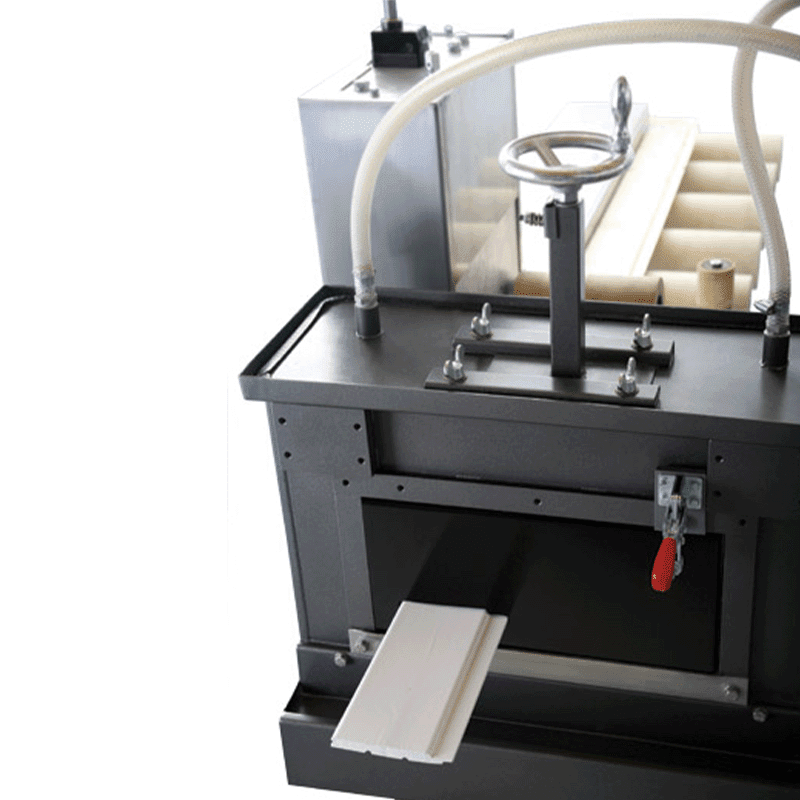

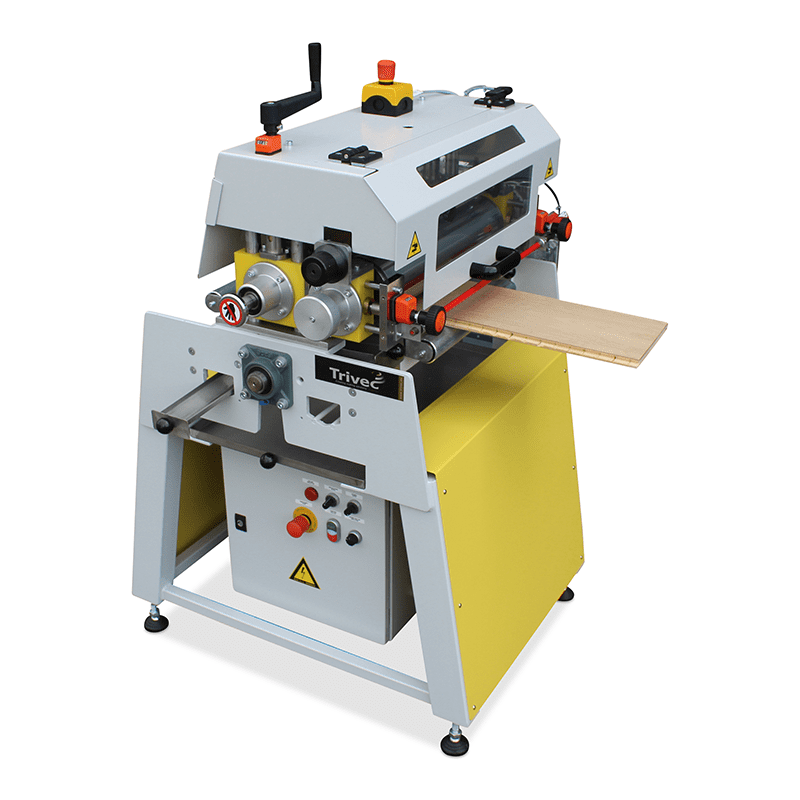

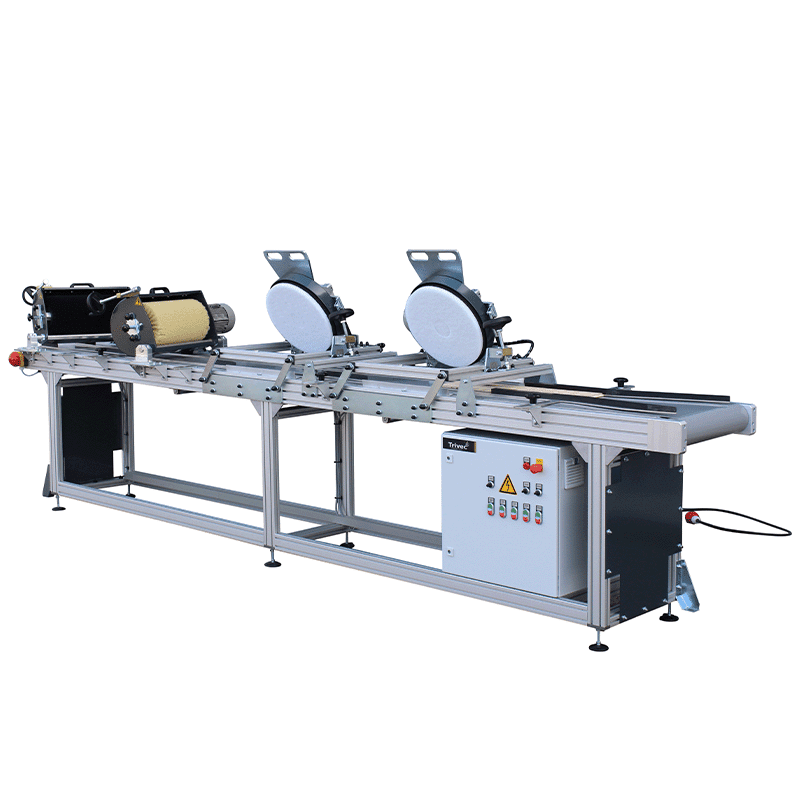

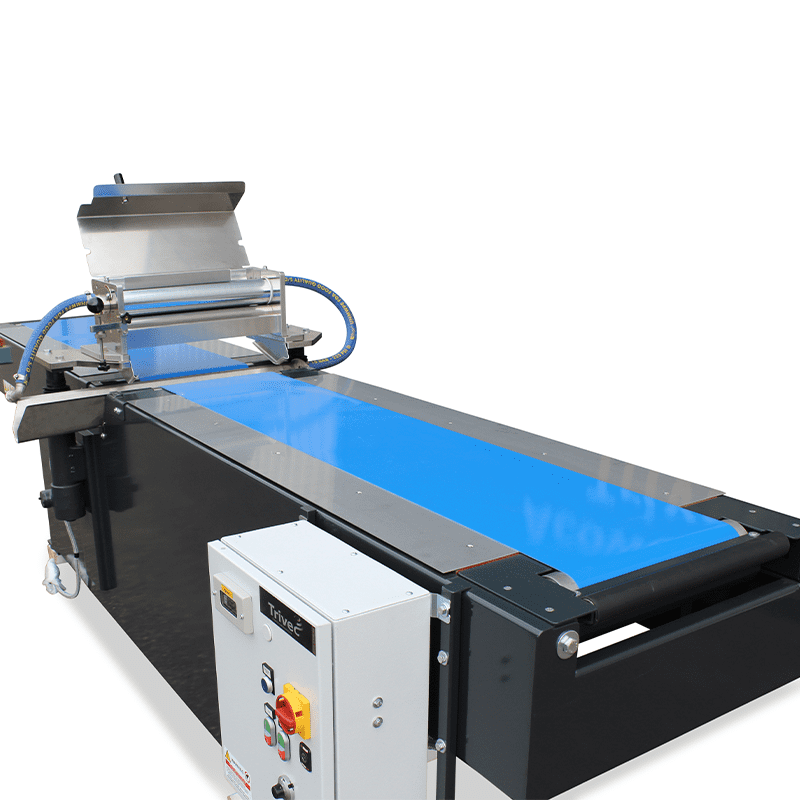

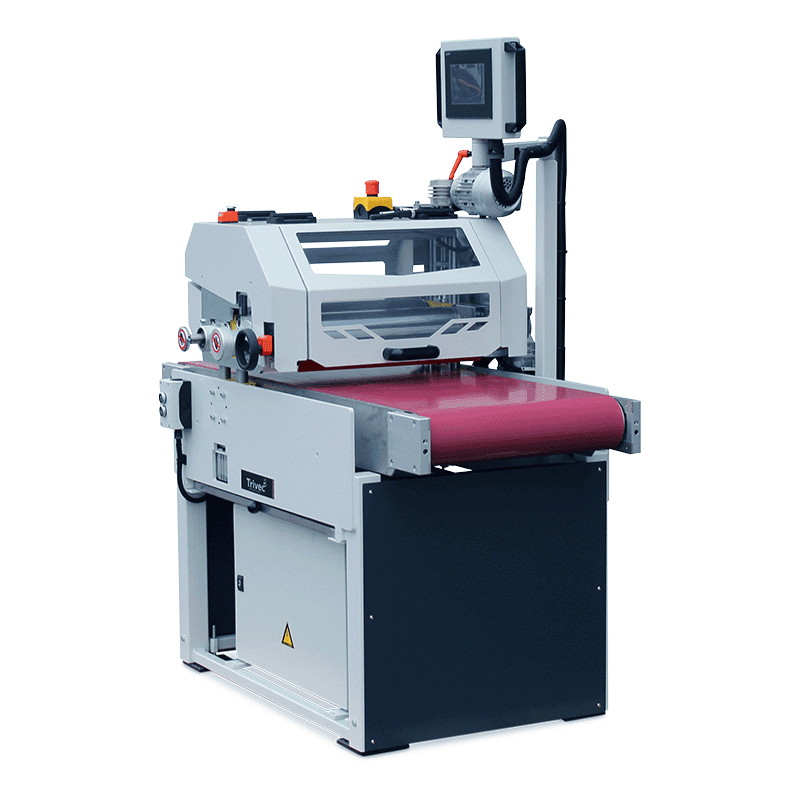

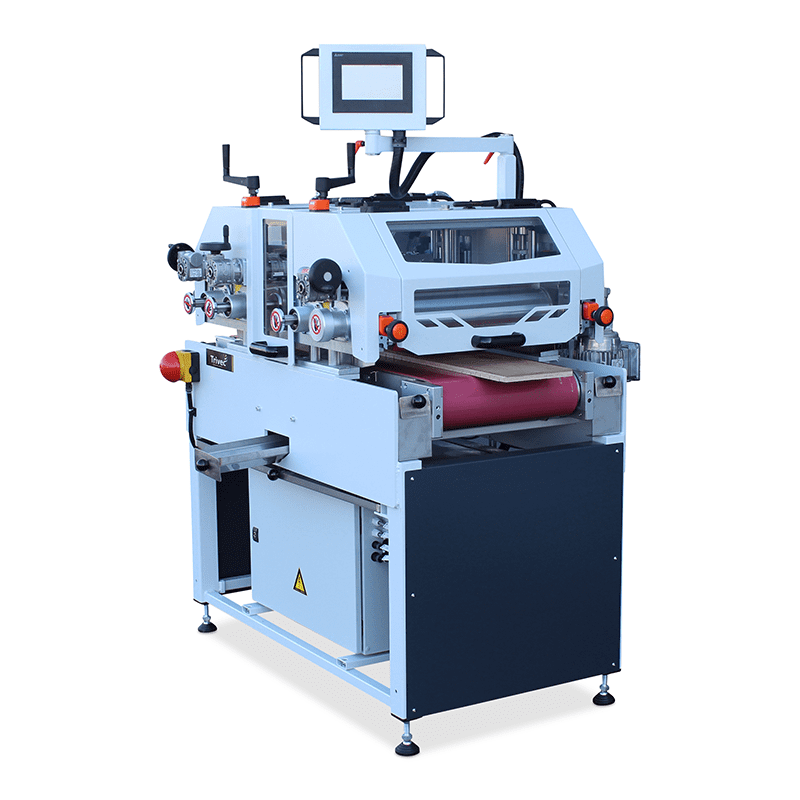

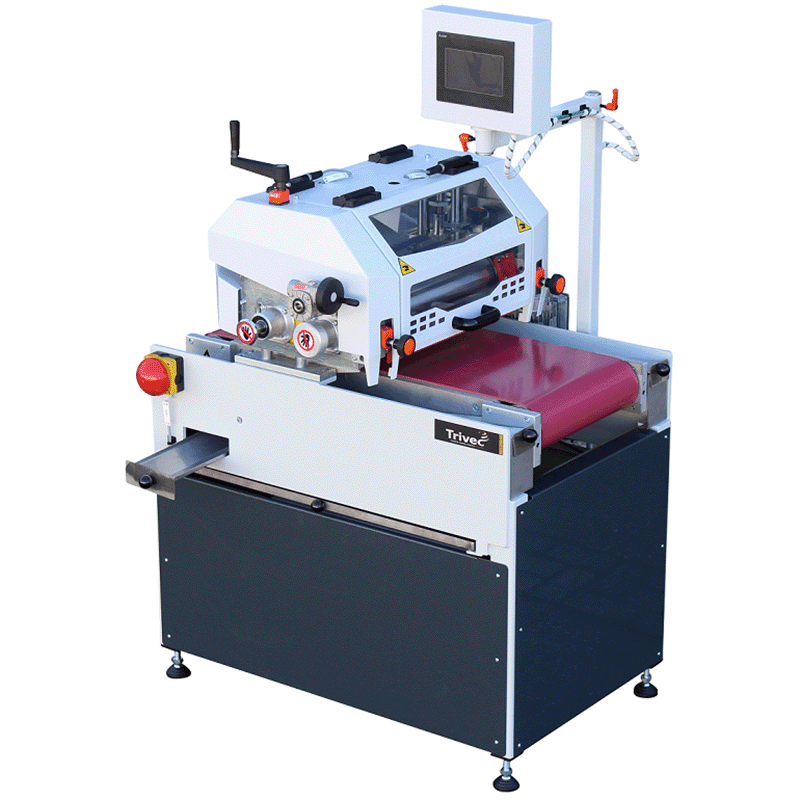

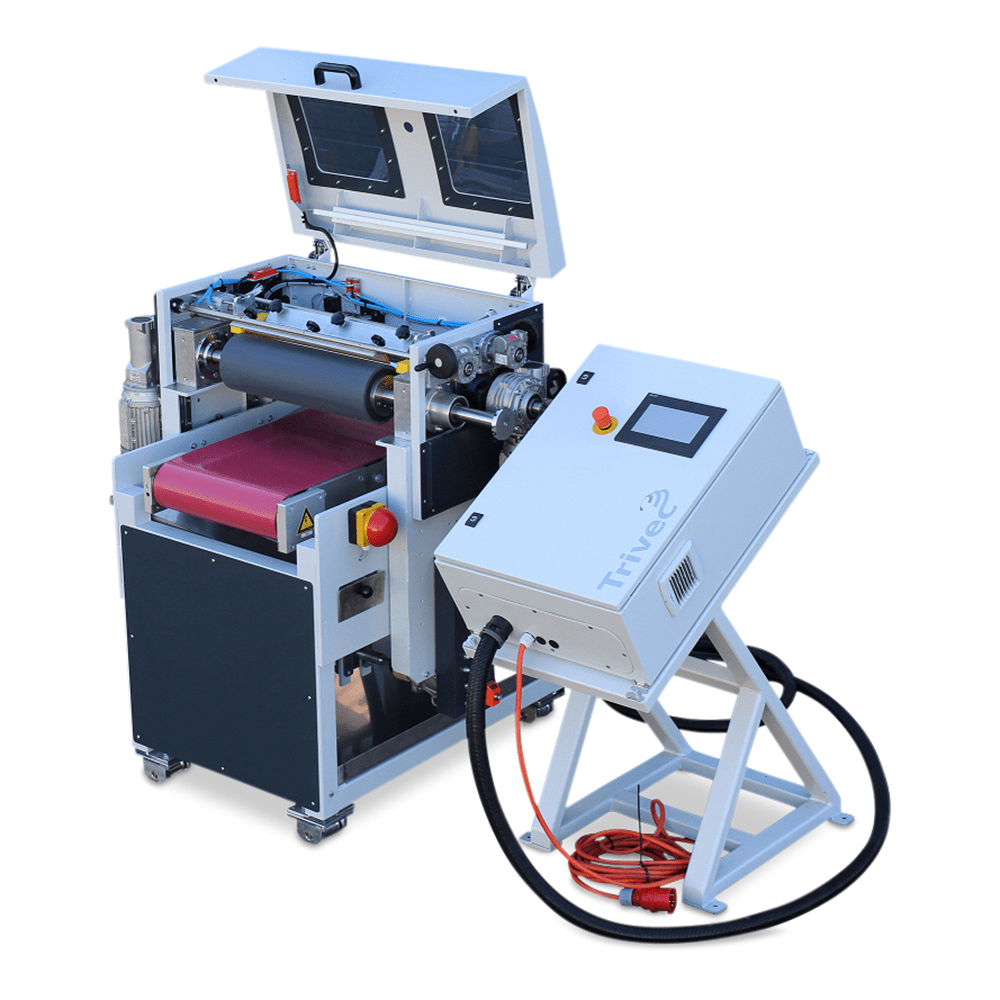

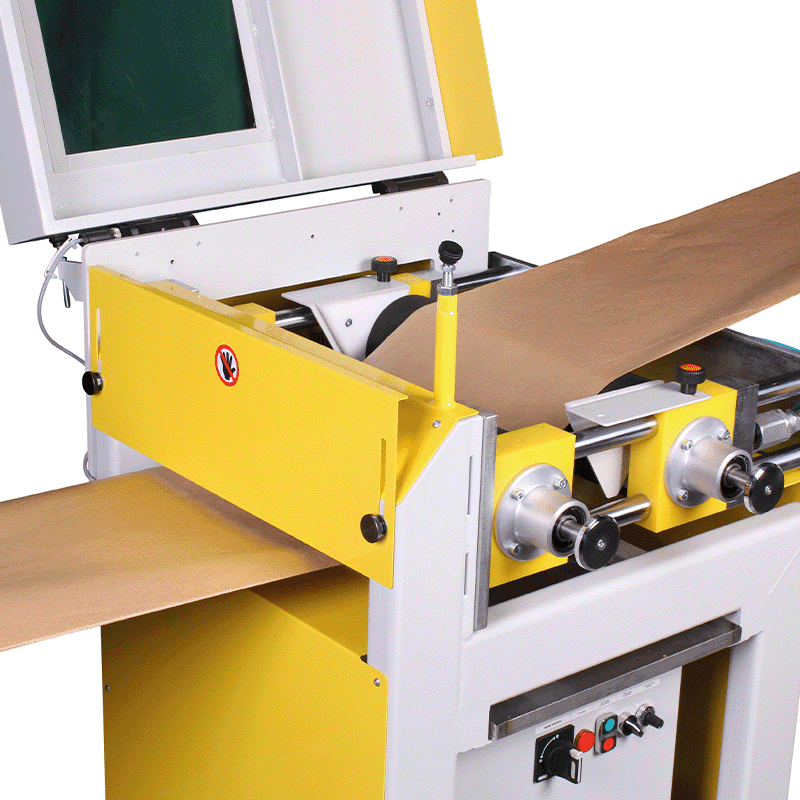

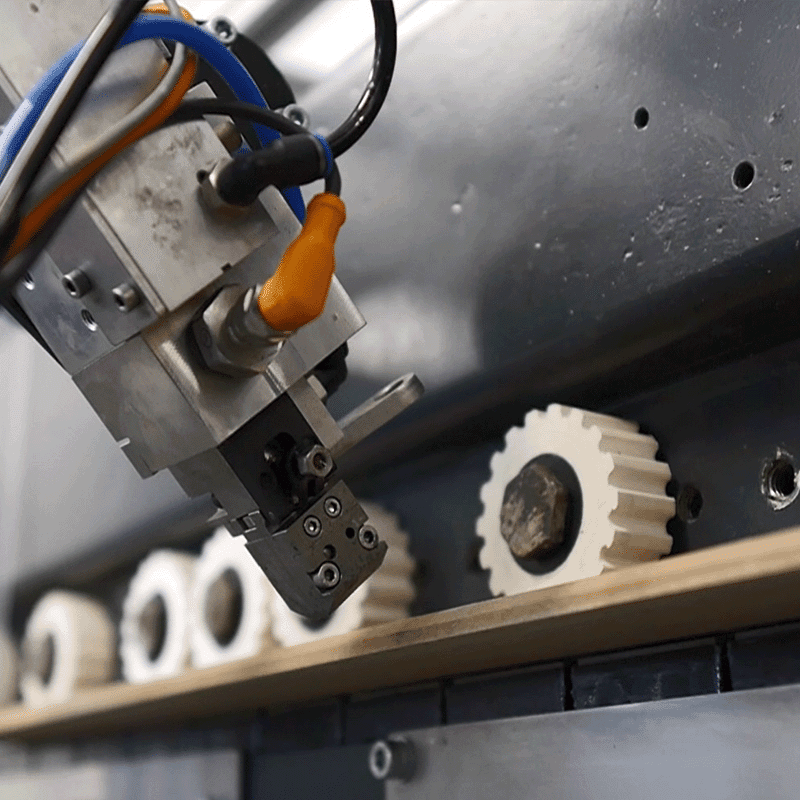

The Premium Industrial Roller Coater is designed with both a dosing and application roller for precise coating applications. Available as single or double coater. Workpieces are efficiently fed into the system via an integrated conveyor belt. Coating thickness is adjustable by modifying the pressure between the dosing and application rollers, the roller speed, and the rotation direction of the dosing roller, ensuring optimal results.

For added flexibility, the Industrial Roller Coater comes with optional features such as a touchscreen, feeding pump, rail system, single reverse function, and electrical height adjustment, making it ideal for a wide range of industrial coating applications.