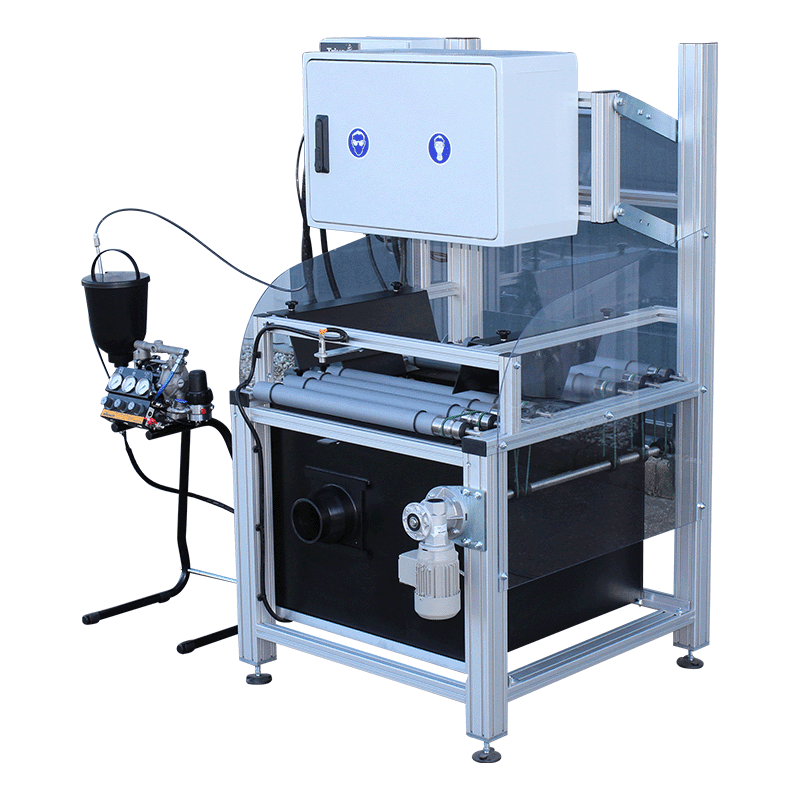

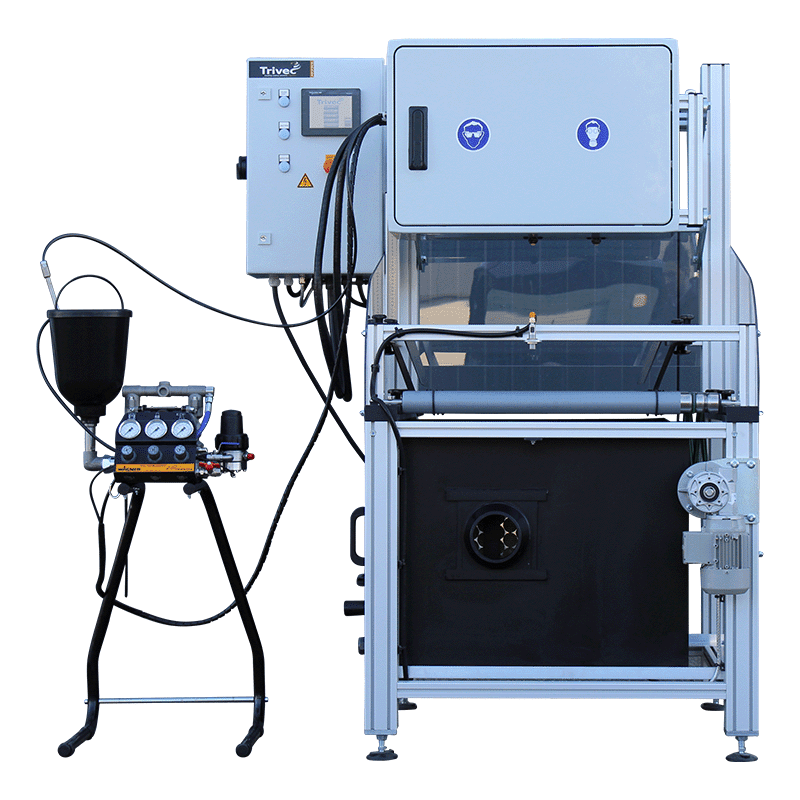

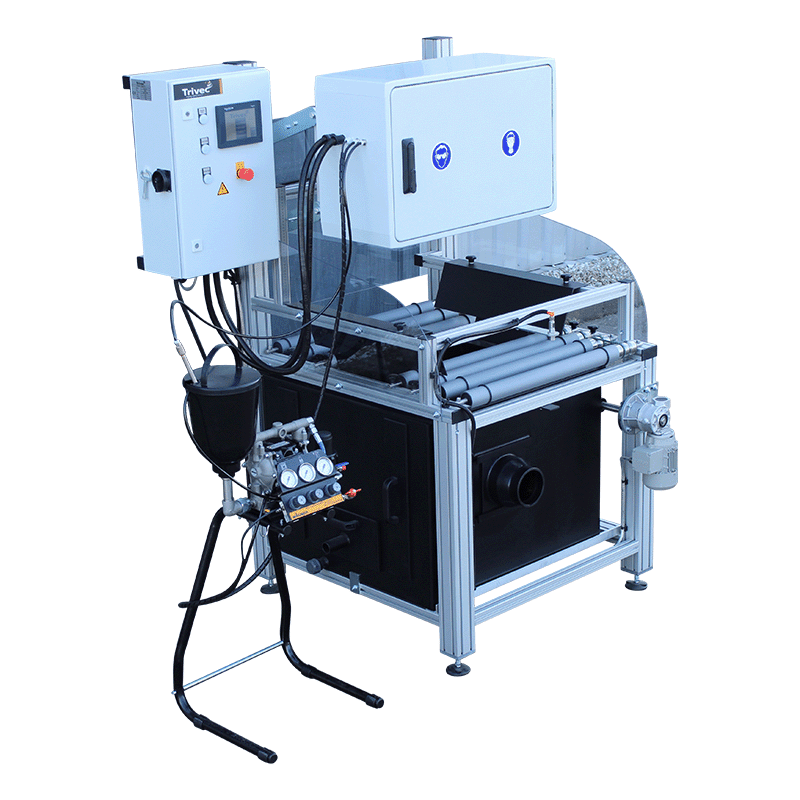

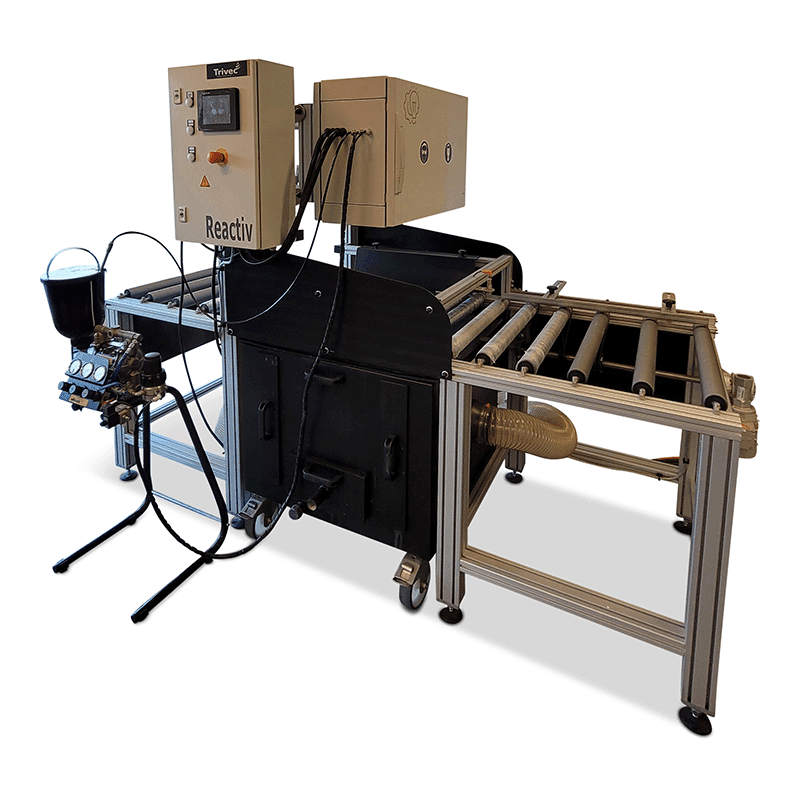

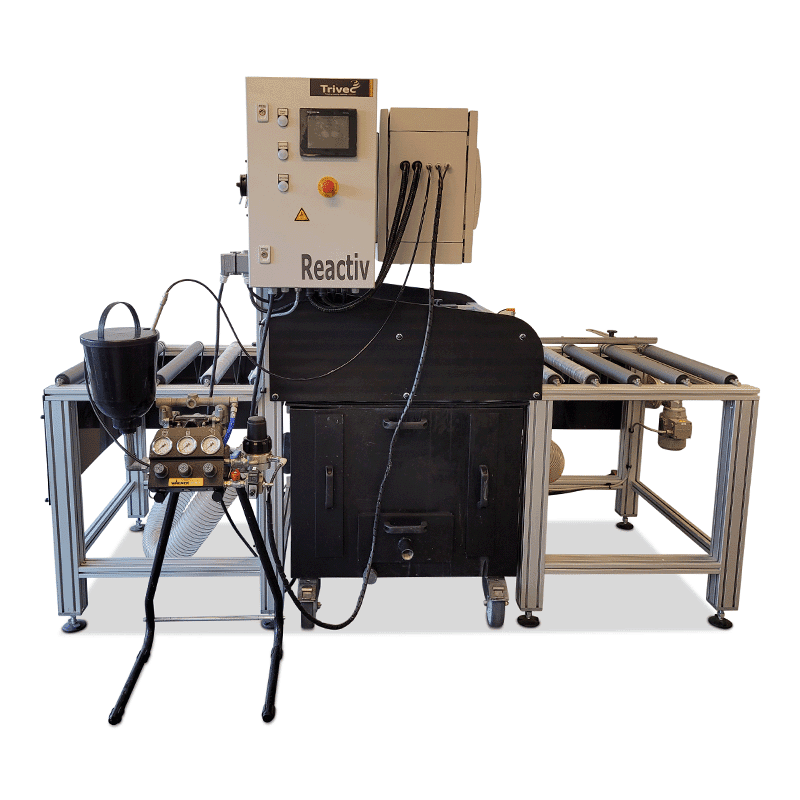

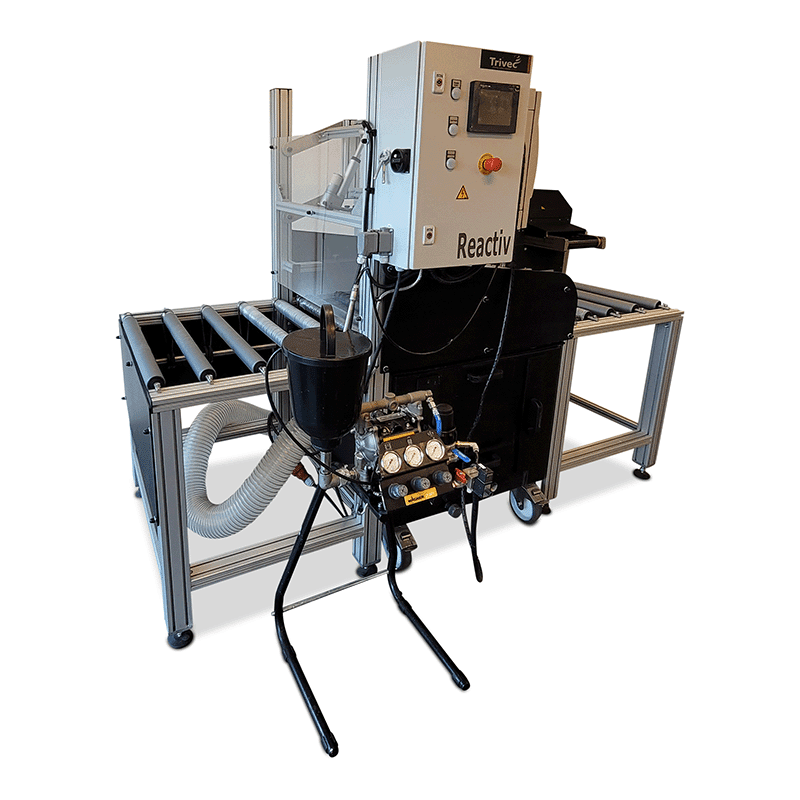

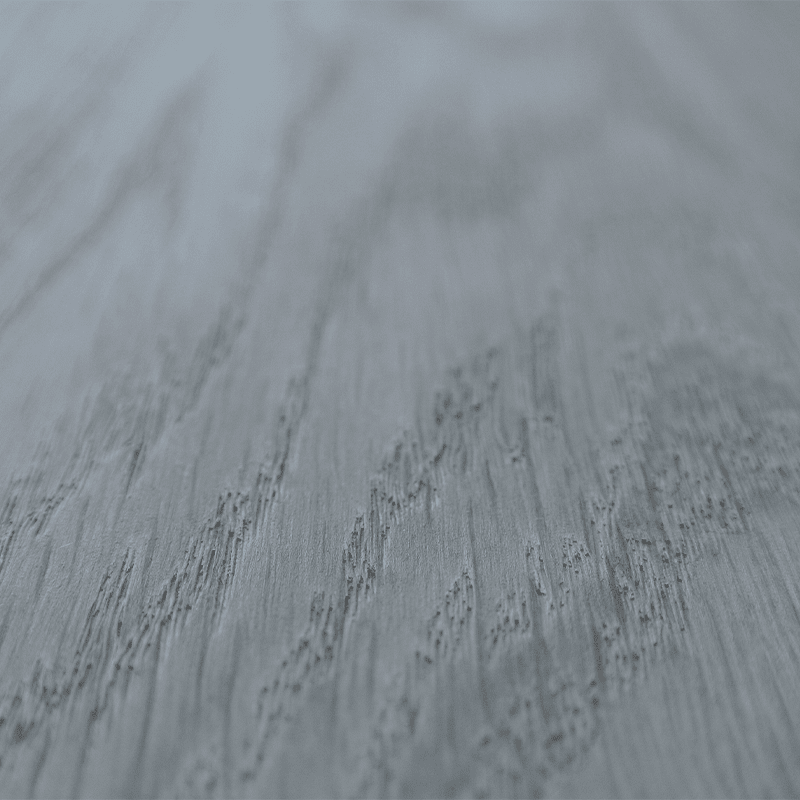

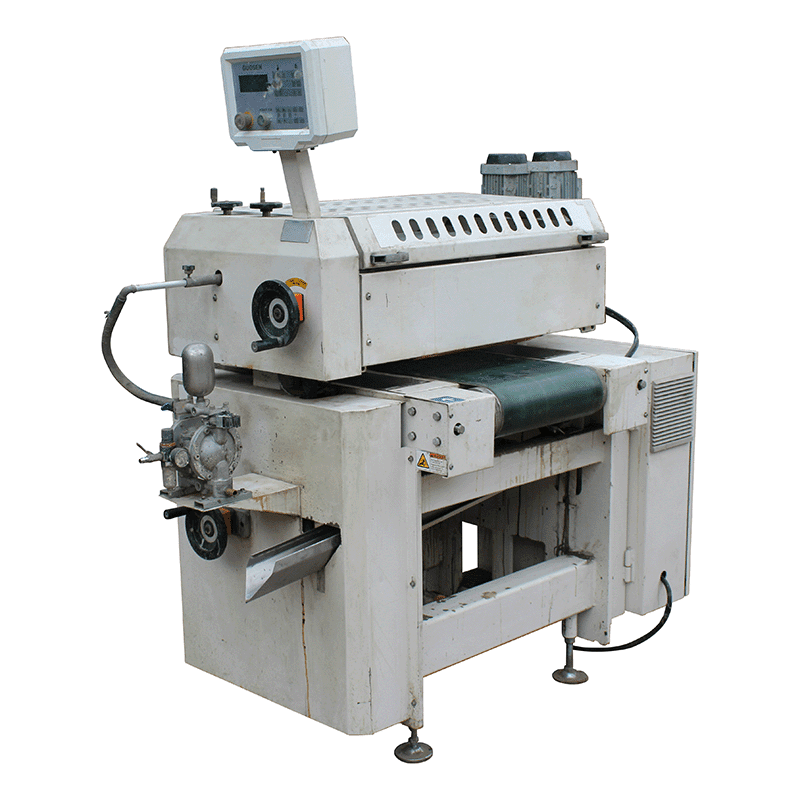

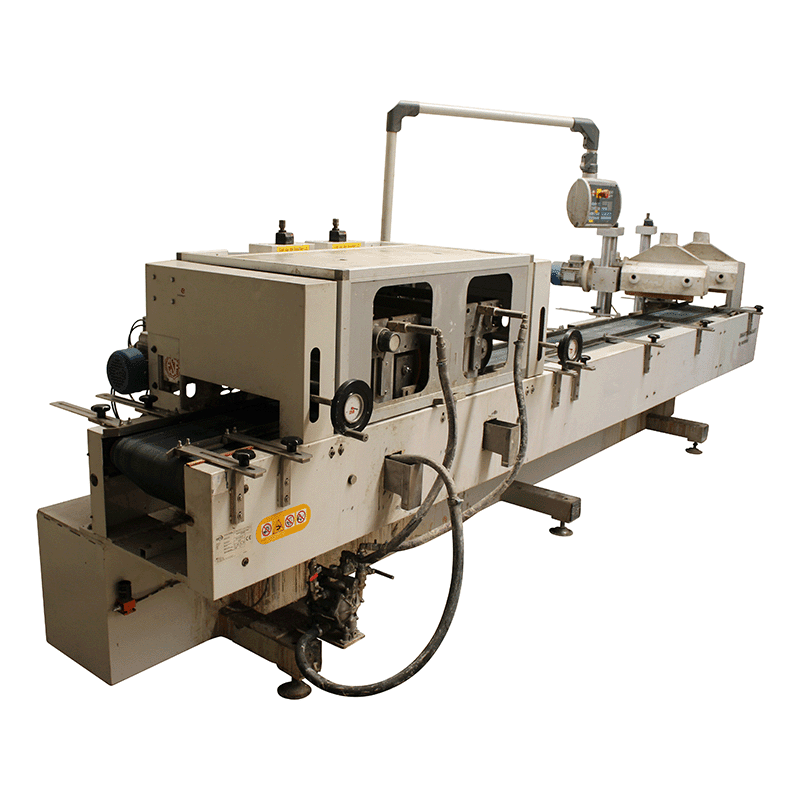

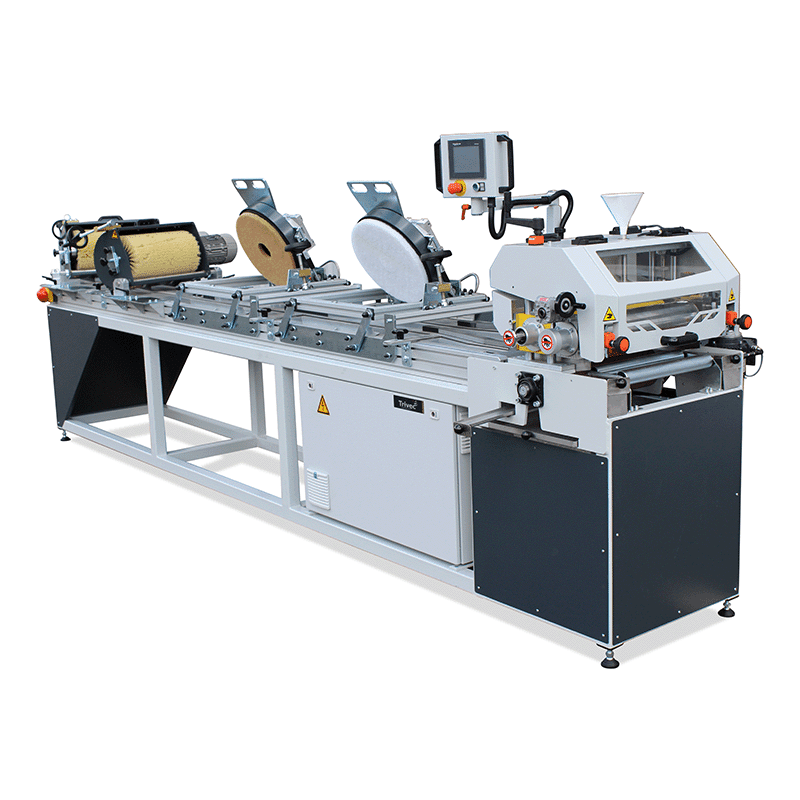

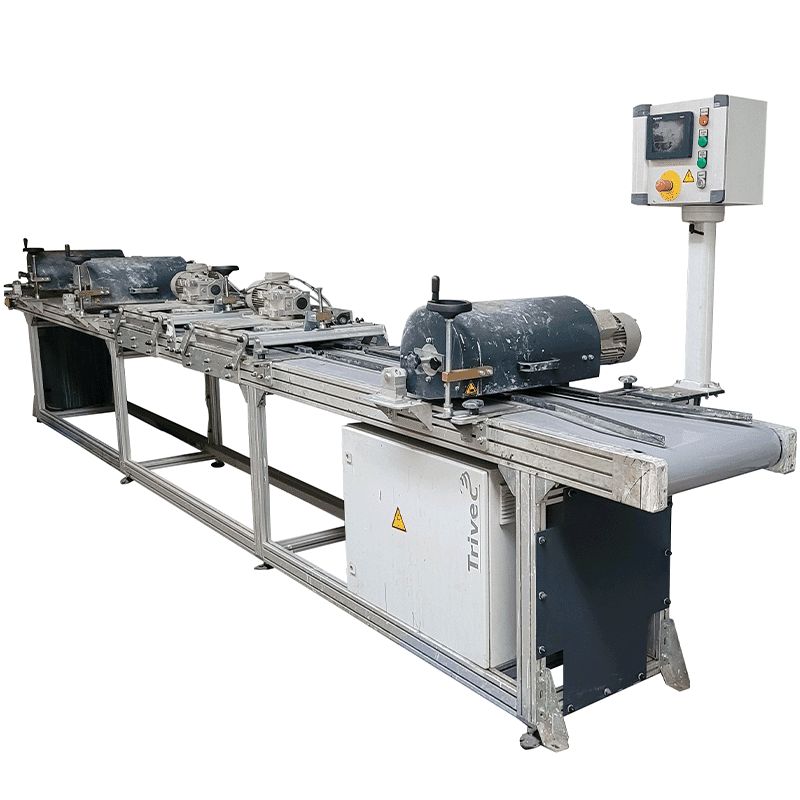

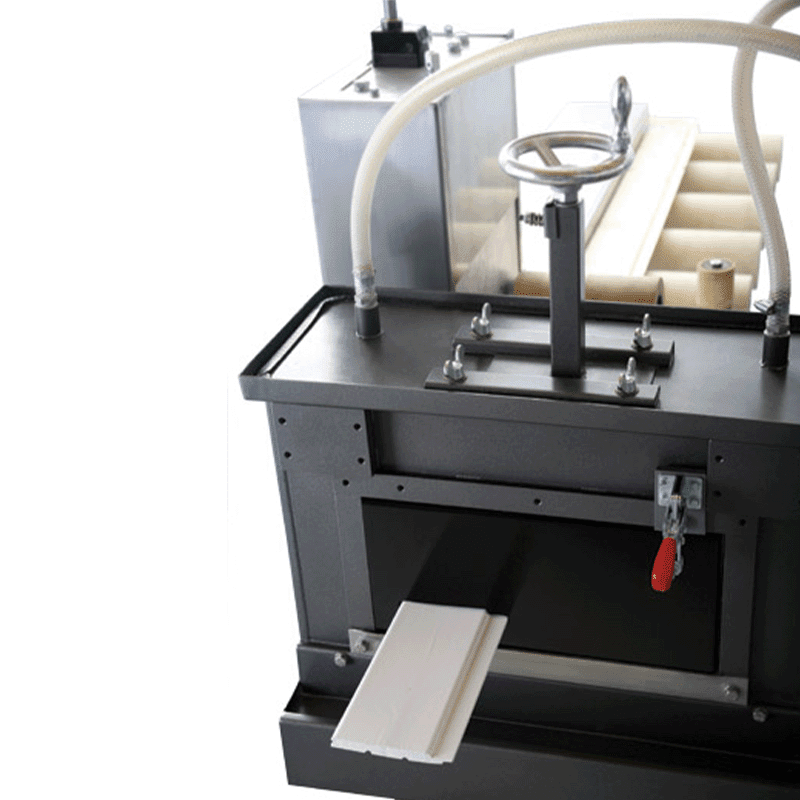

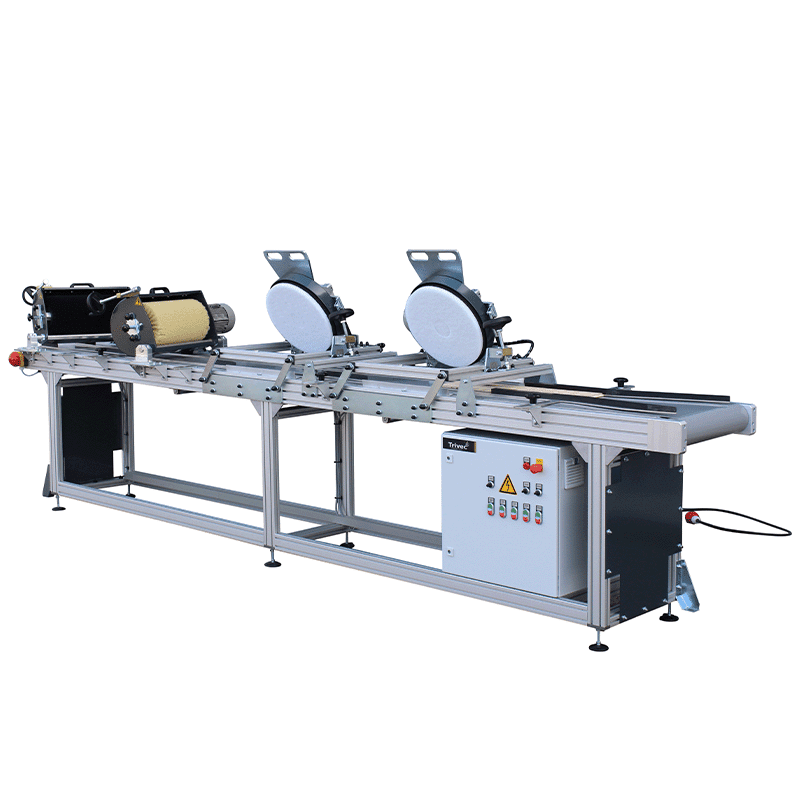

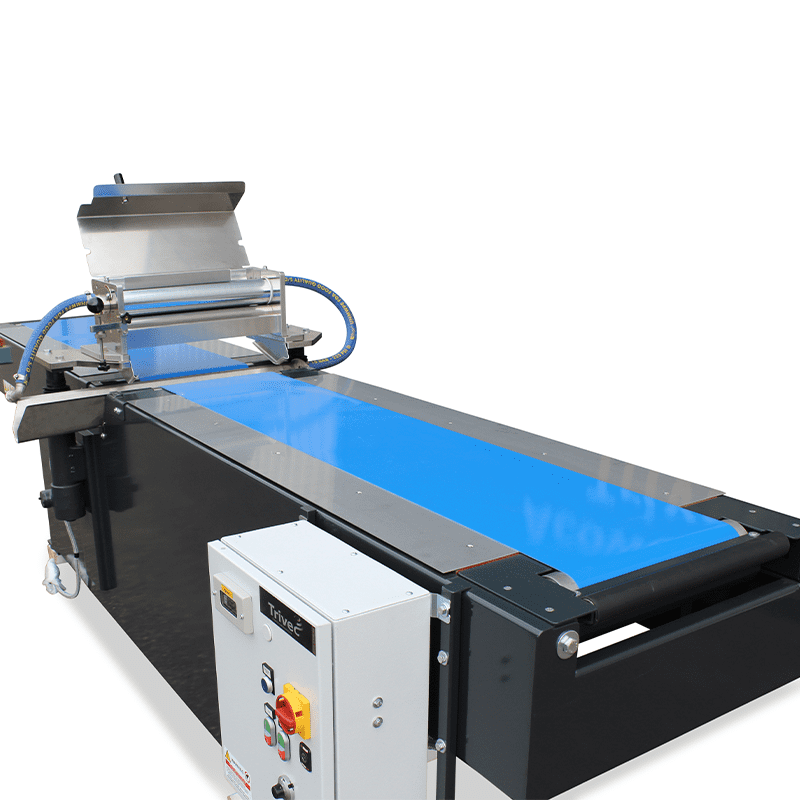

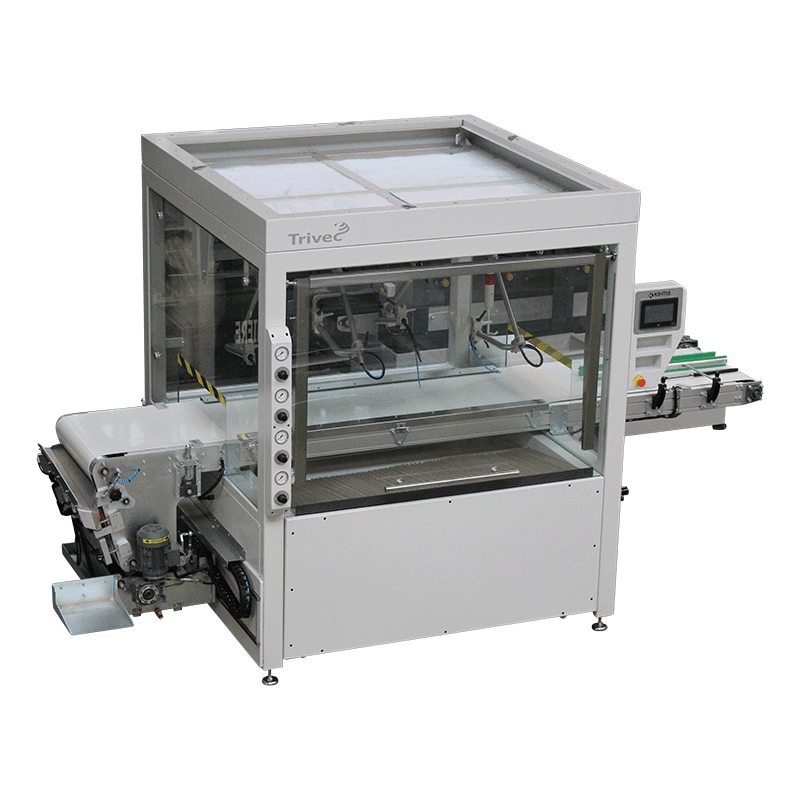

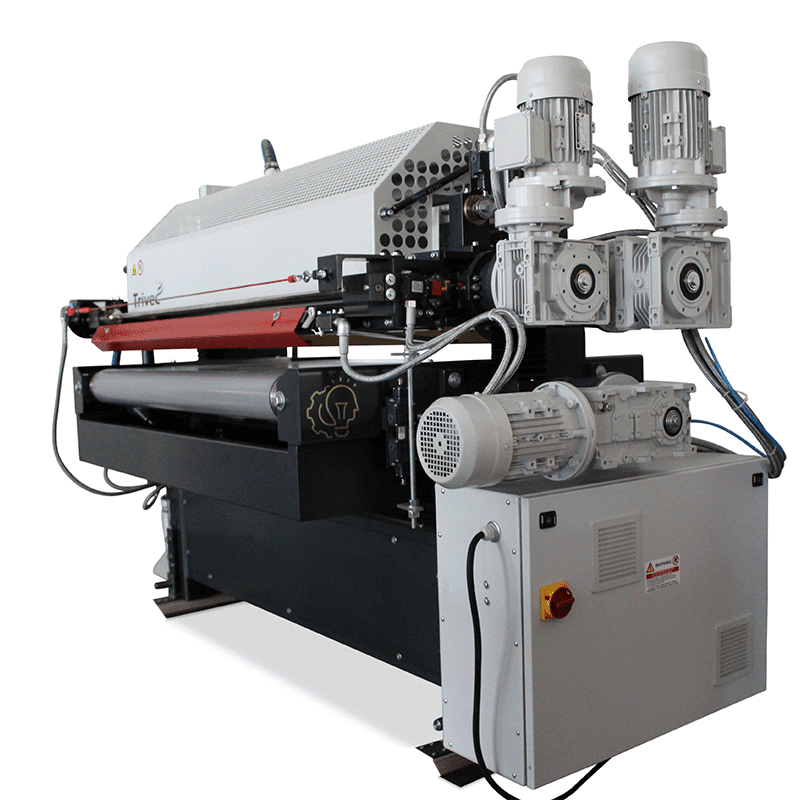

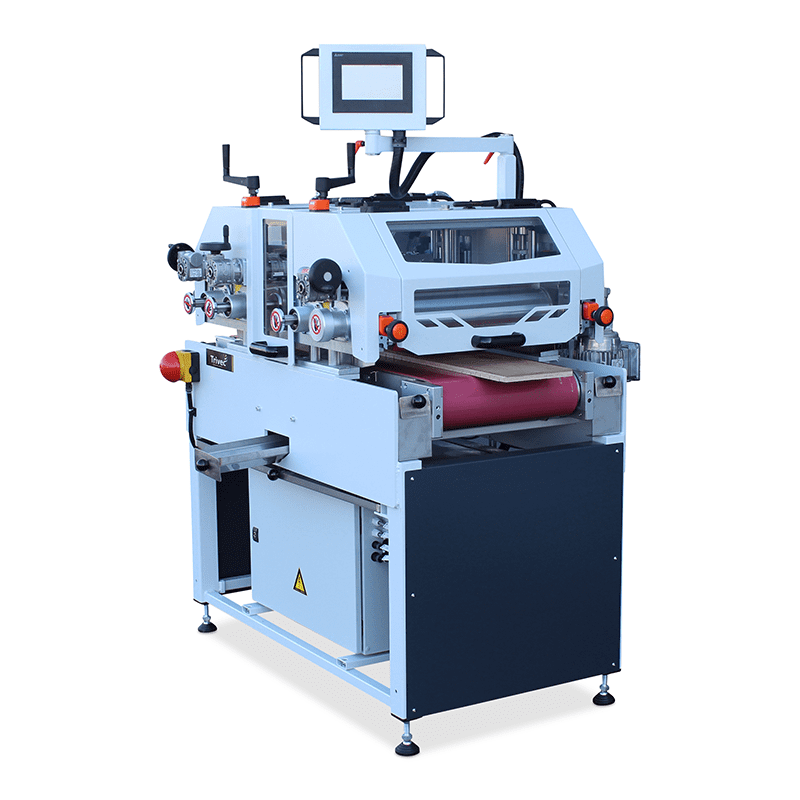

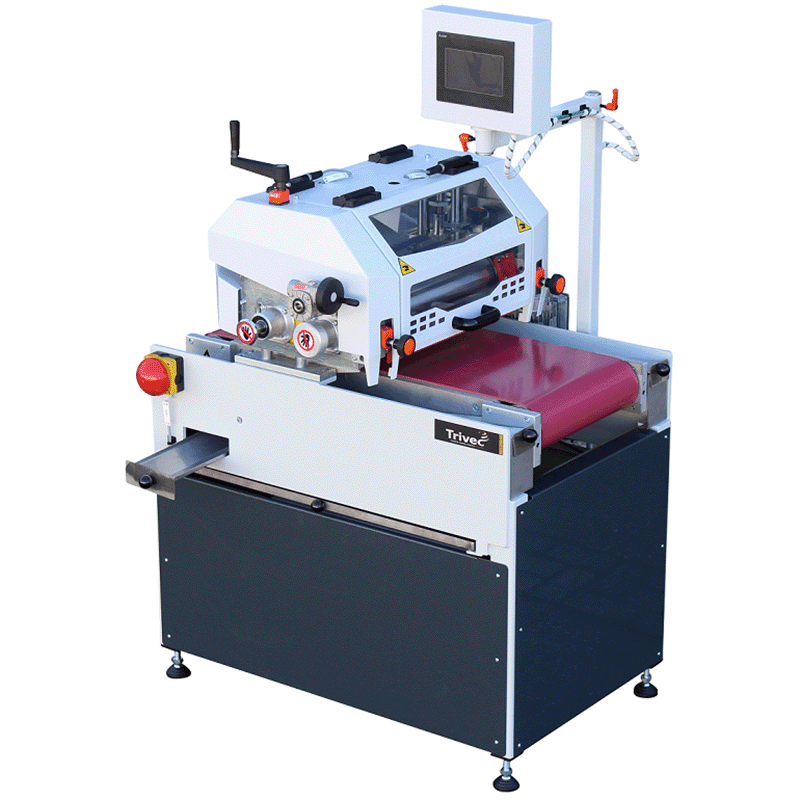

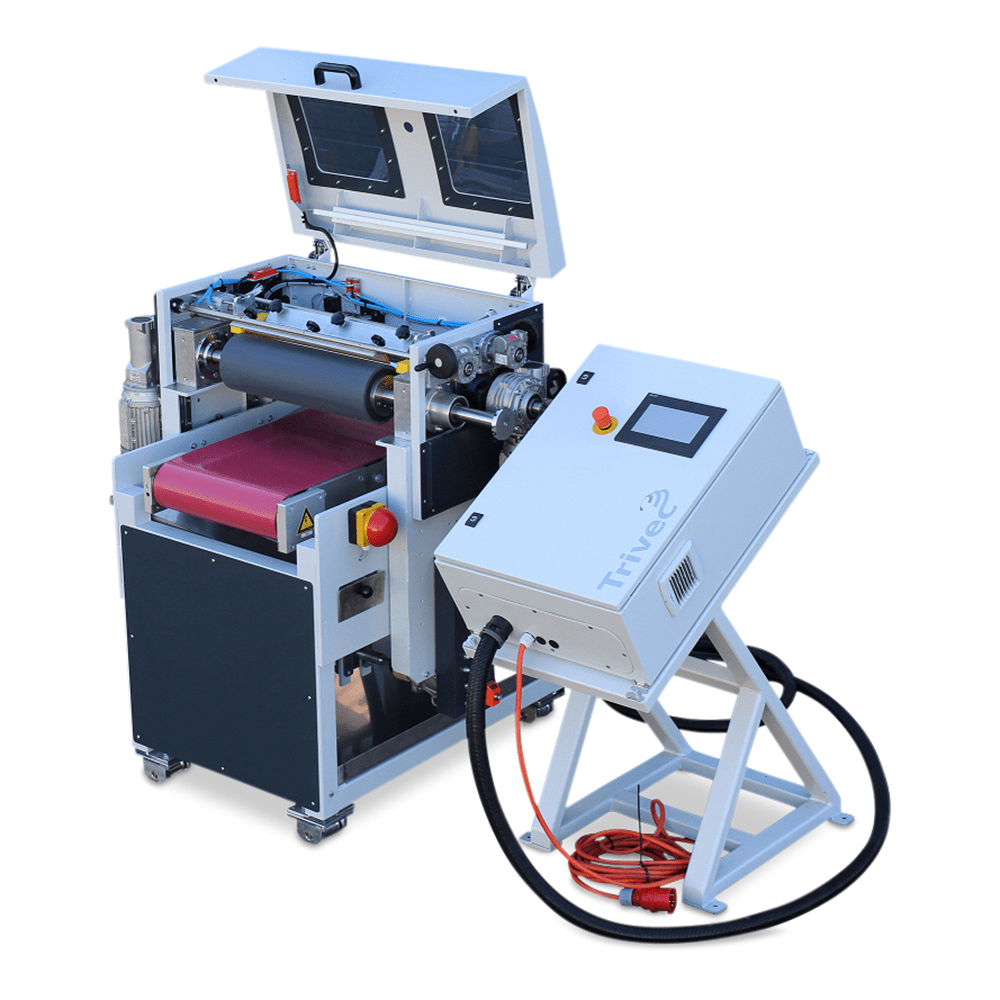

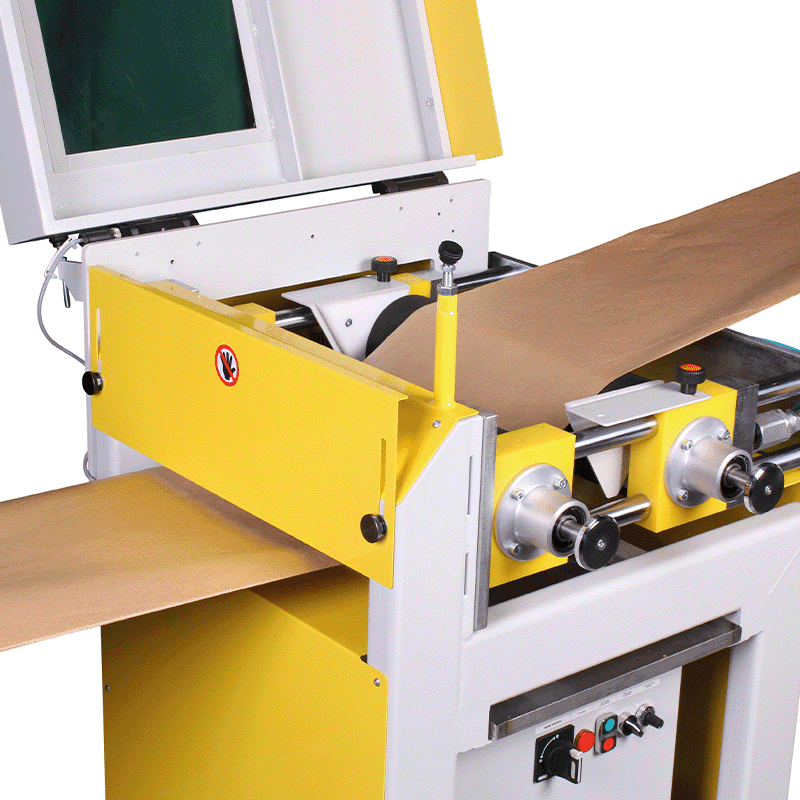

The Premium Reactive Stain Sprayer is a modular spraying system designed for the precise application of water-based stains, reactive stains, ammonia, and bleach. Workpieces are processed efficiently with the help of an integrated conveyor system, ensuring consistent and accurate results.

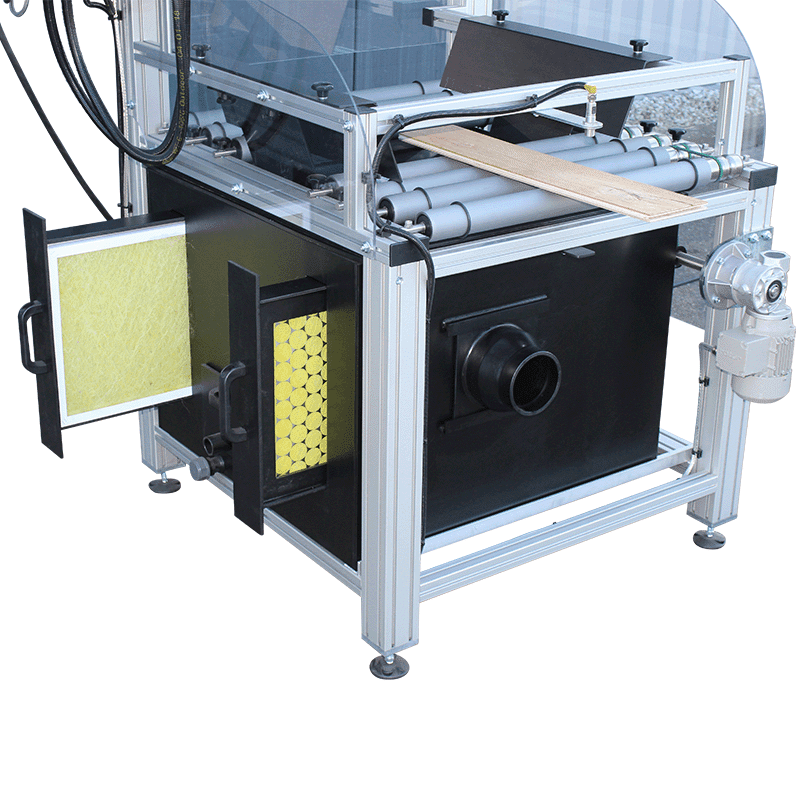

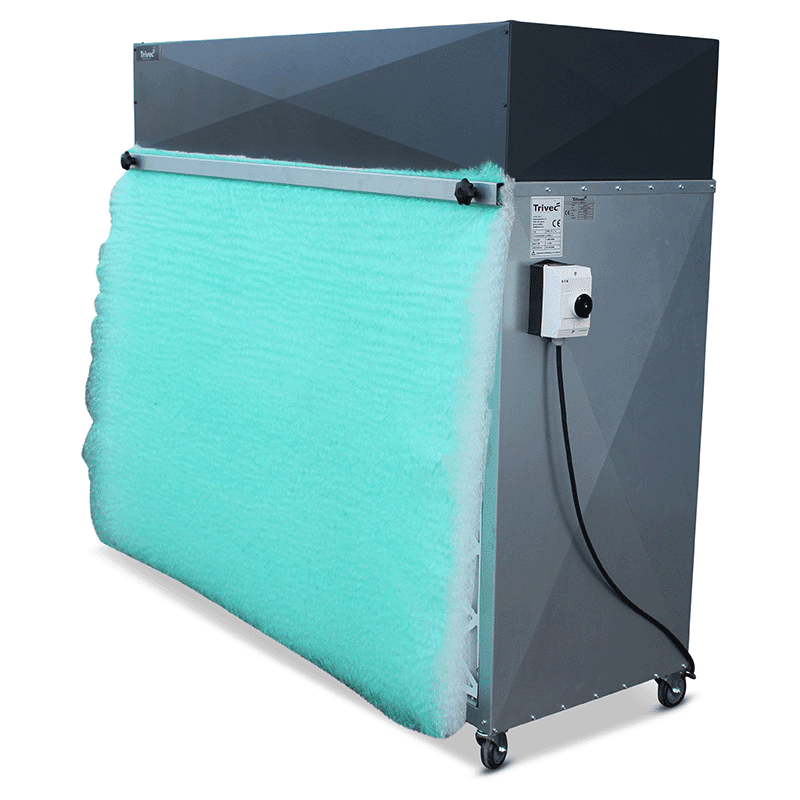

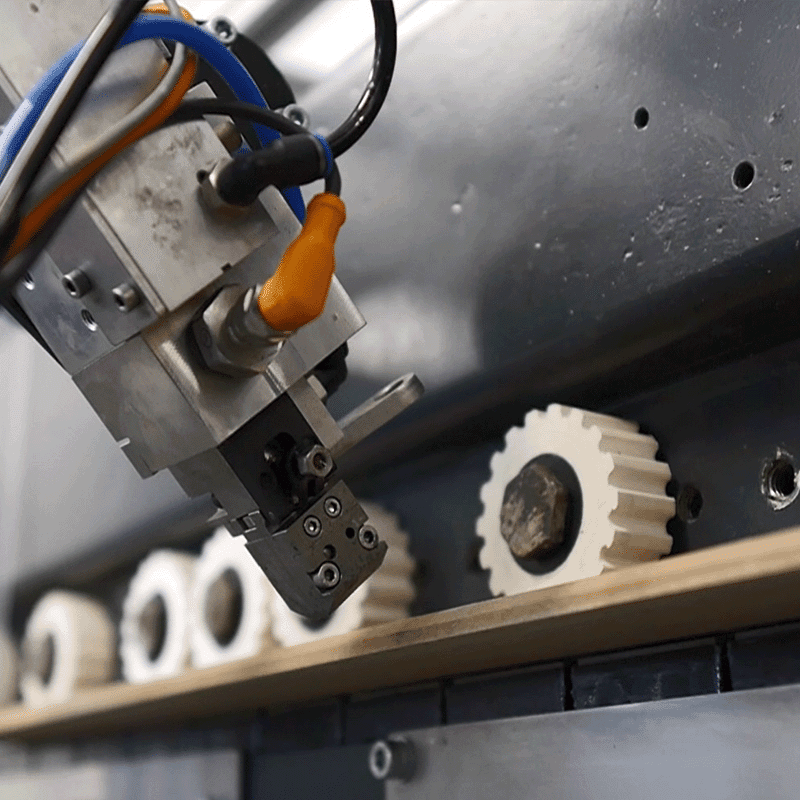

The system is equipped with a workpiece detection sensor and advanced spray nozzles to prevent overspray and reduce material waste. Excess material is collected in a double-walled overspray reservoir, connected to a supplied exhaust unit for clean and efficient operation. The spray nozzles can be operated individually and are designed for quick adjustments or cleaning without tools, allowing for seamless color changes and maintenance.