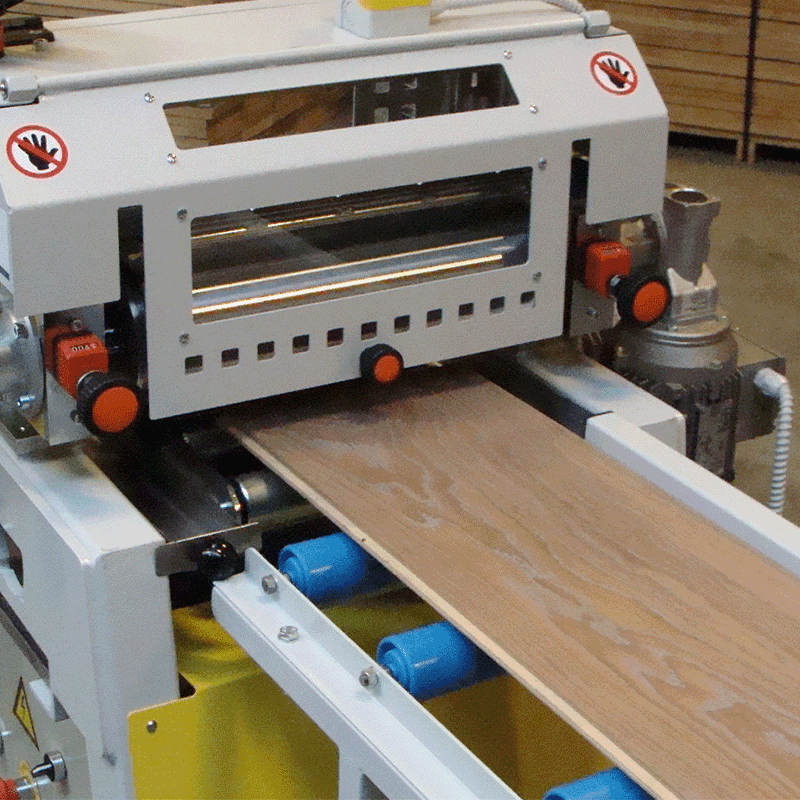

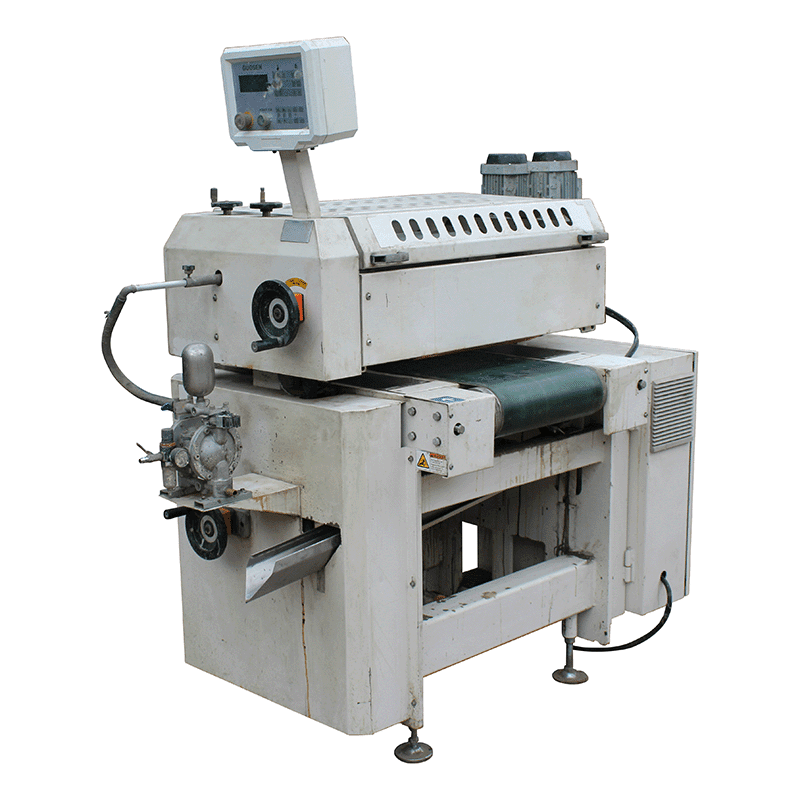

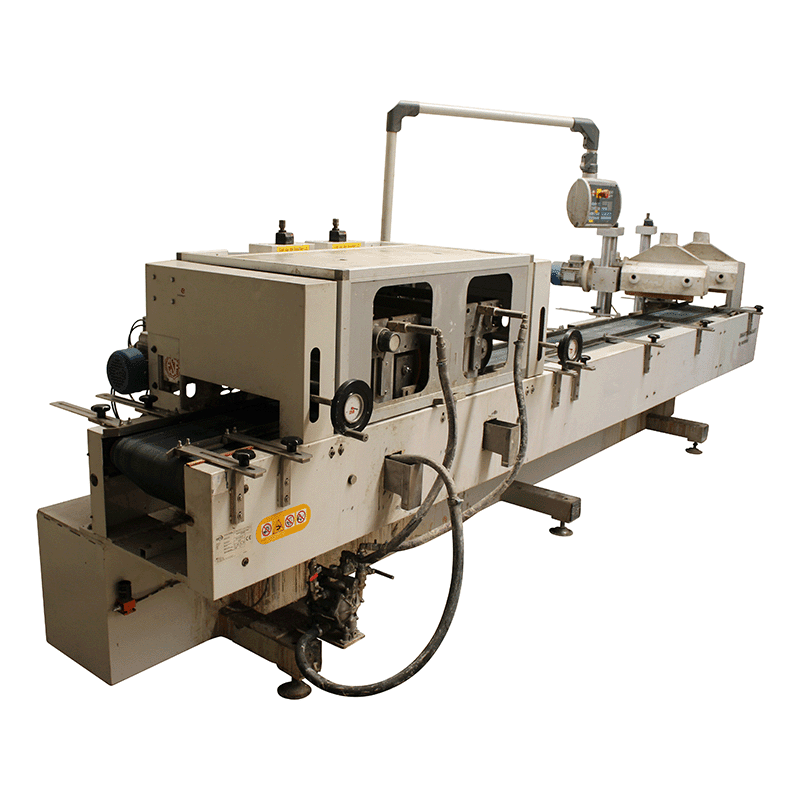

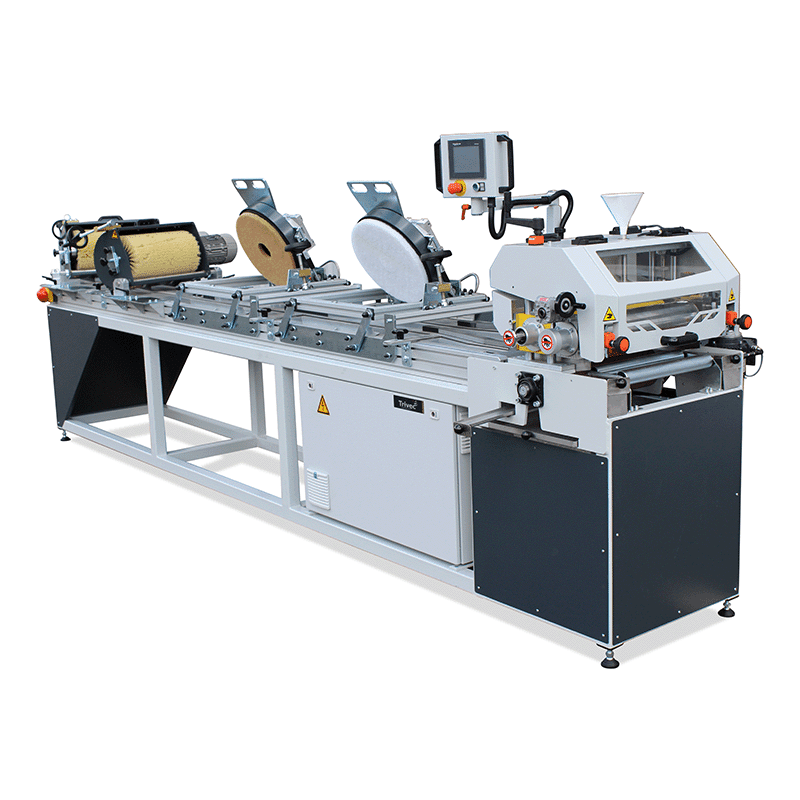

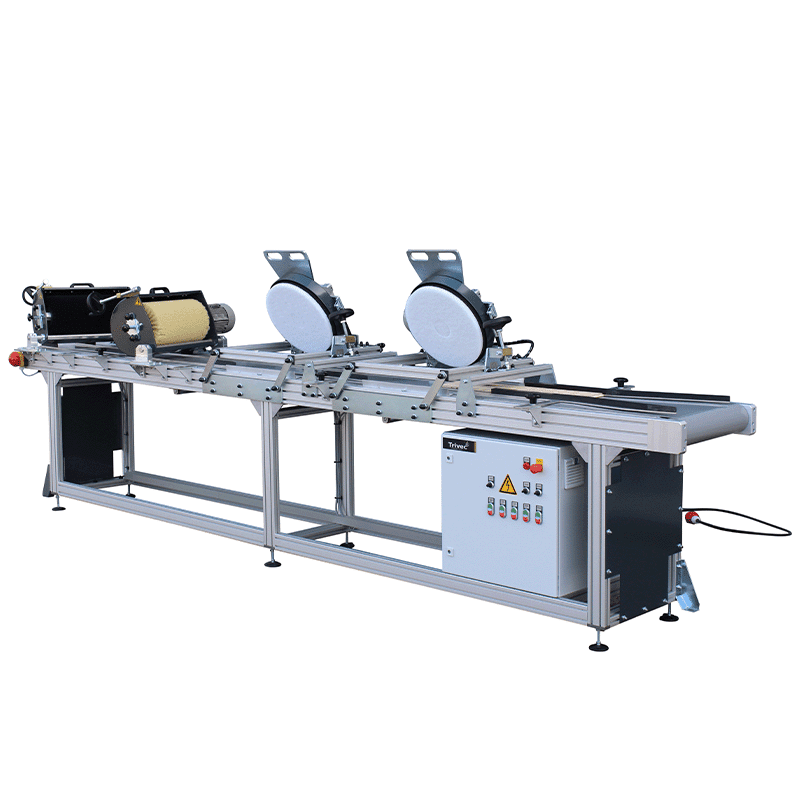

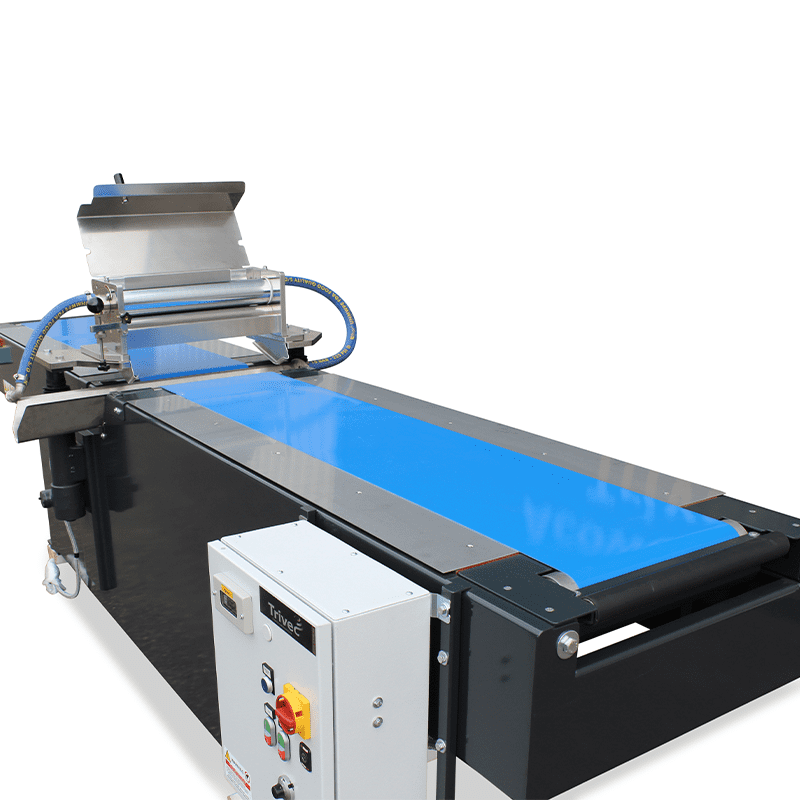

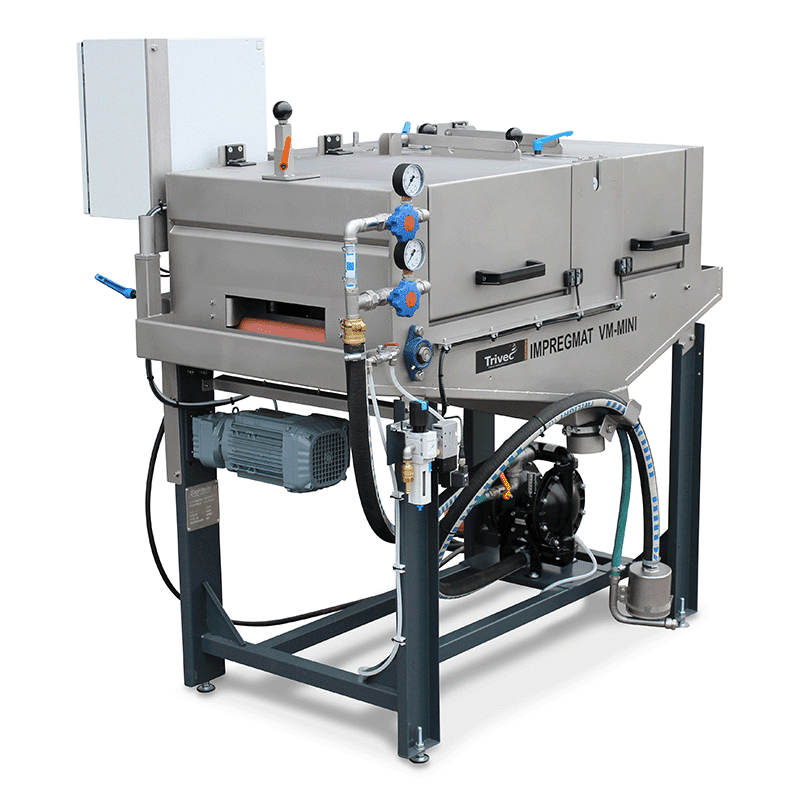

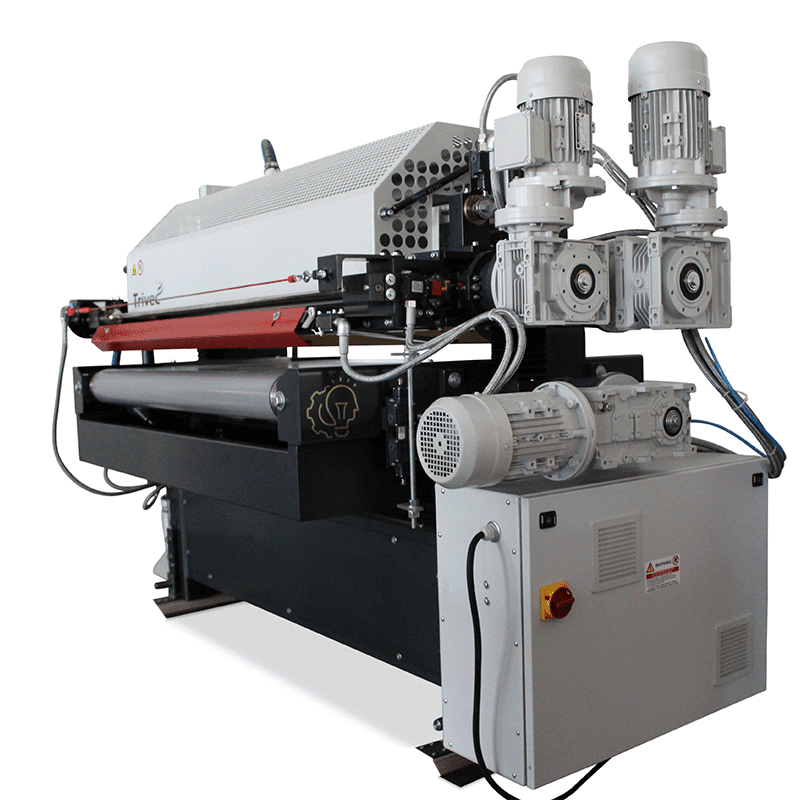

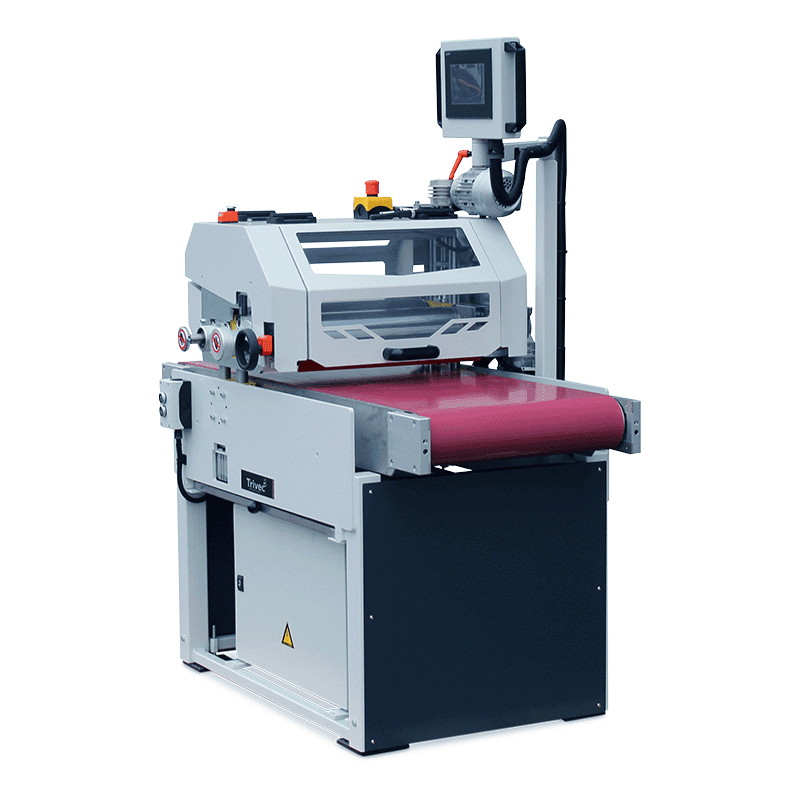

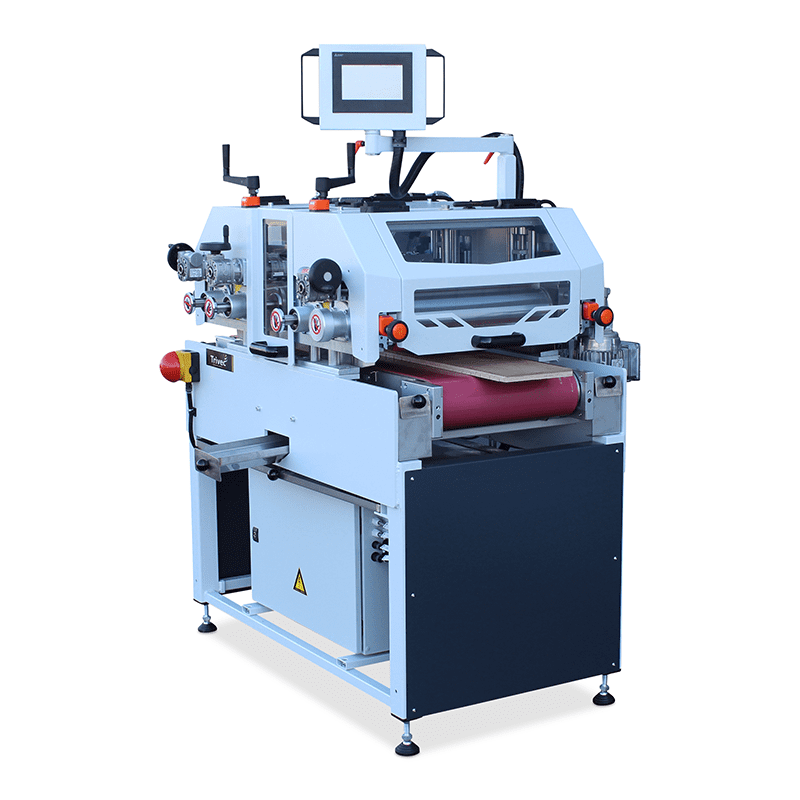

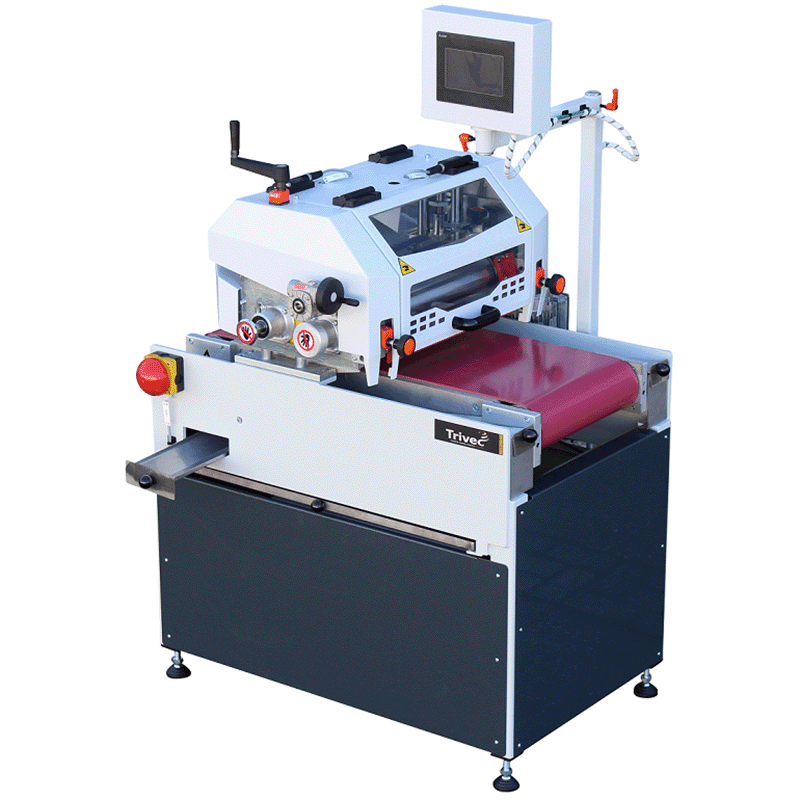

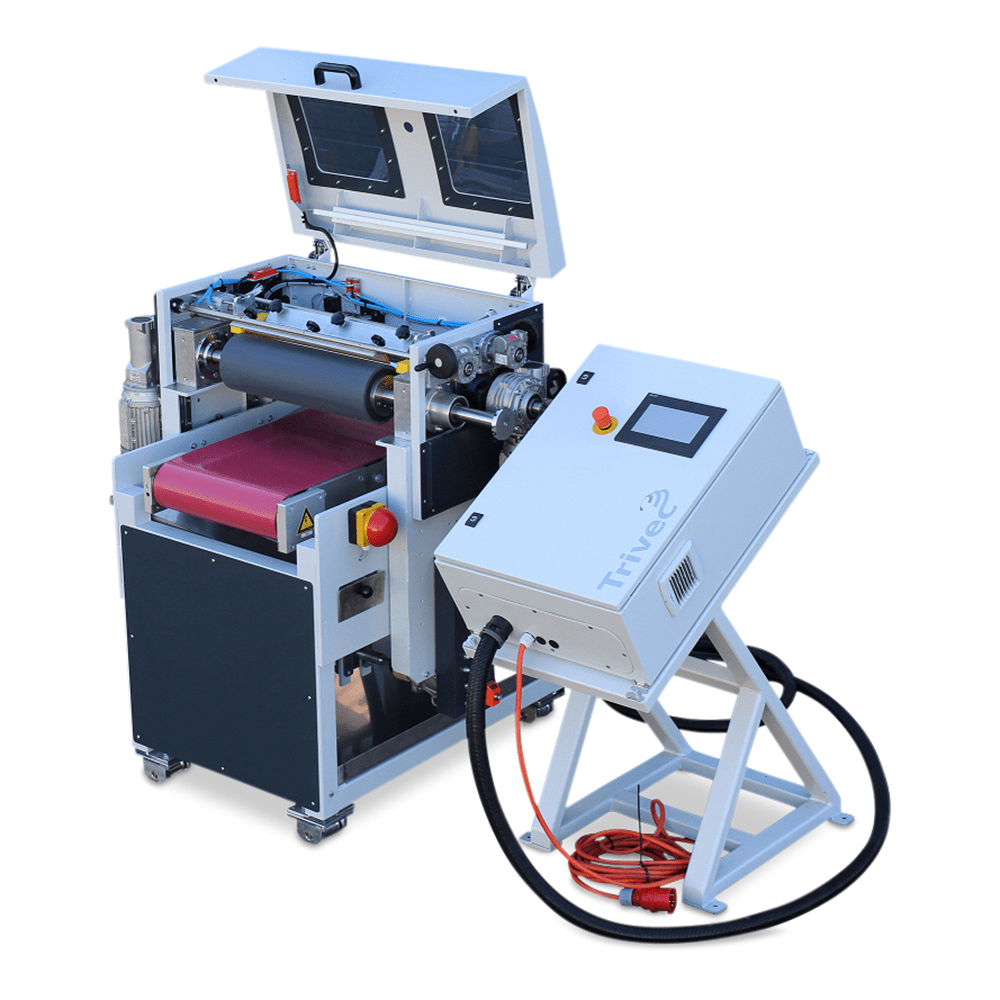

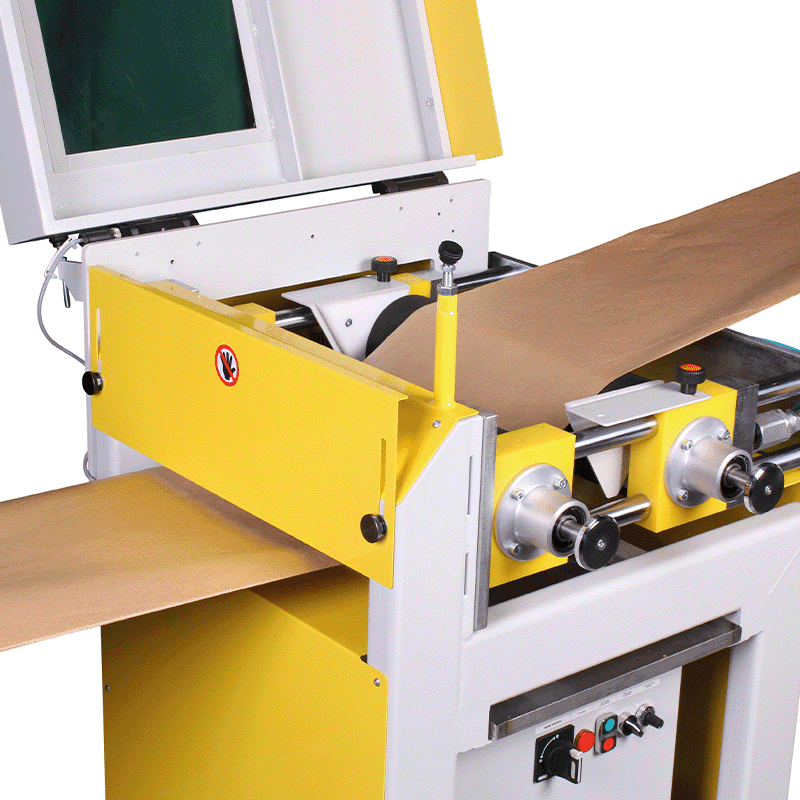

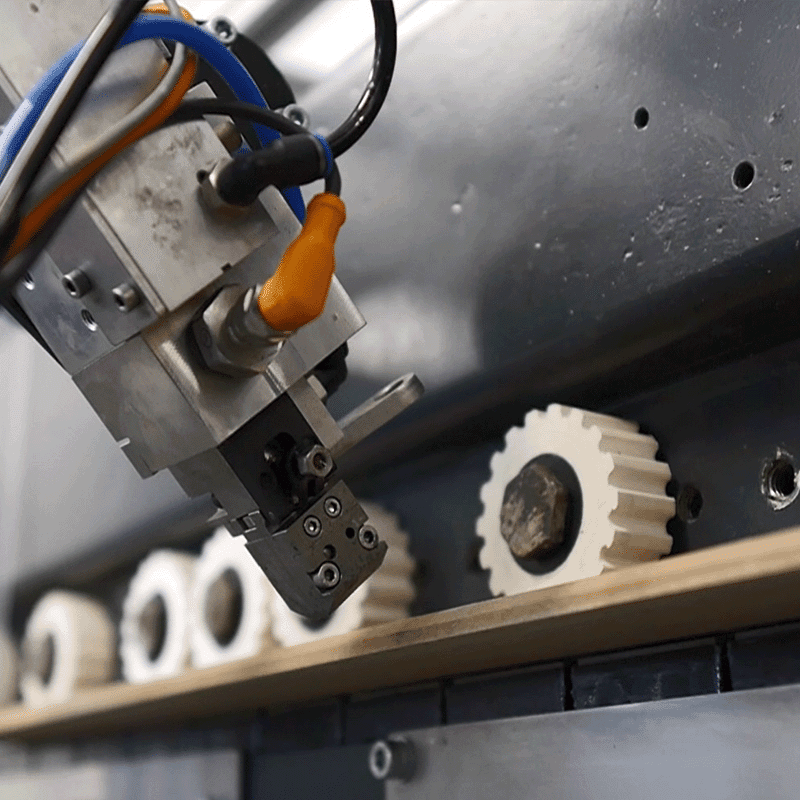

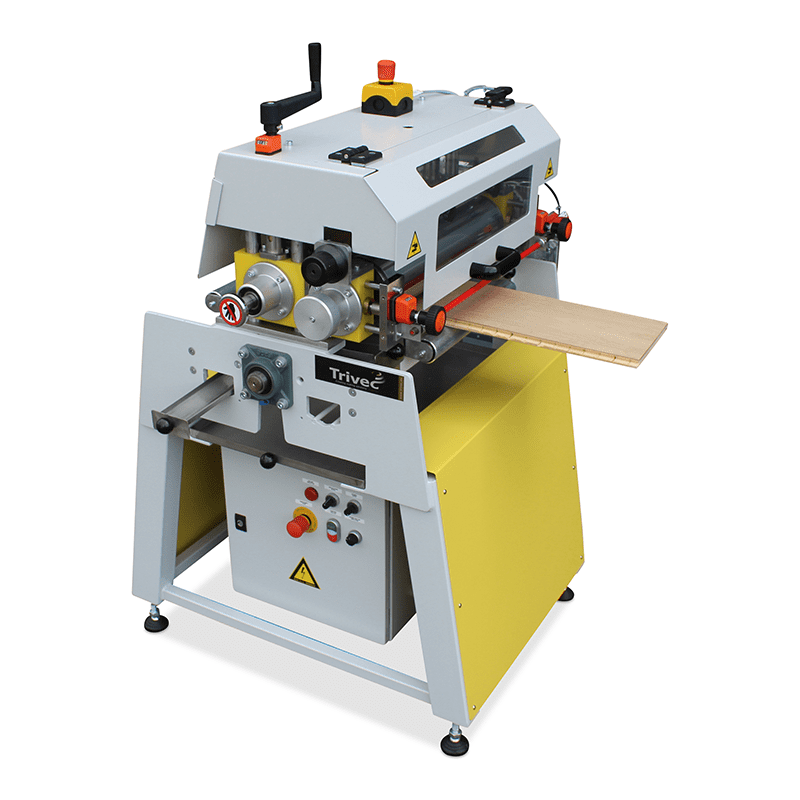

The Trivec Single Roller Coater is a coating machine that is used for applying oxidative oils, UV oils, lacquer, stains, and hard wax on, amongst others, parquet, plinths, stairs, and furniture. The Basic Roller Coater uses a combination of dosing and application rollers to enable users to apply the coating evenly and precisely by adjusting the individual roller speeds and the rotational direction of the dosing roller.

Due to this setup the machine can also be used for coating concrete tiles, metal, glass, foam, cork, and plastic sheeting can be achieved.

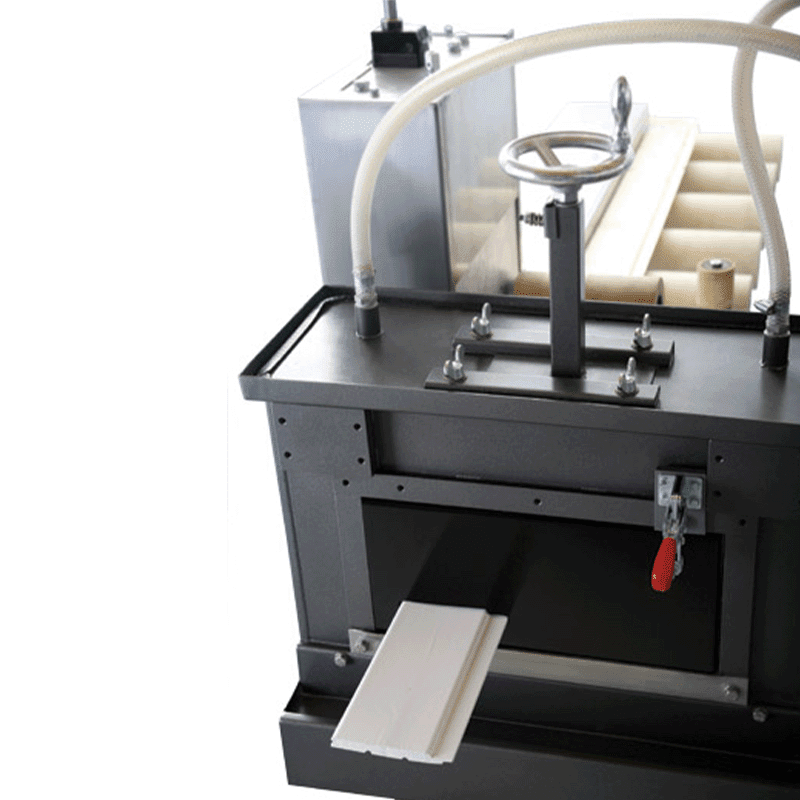

The application roller can be removed without the use of tools from the machine, for quick colour change or cleaning.