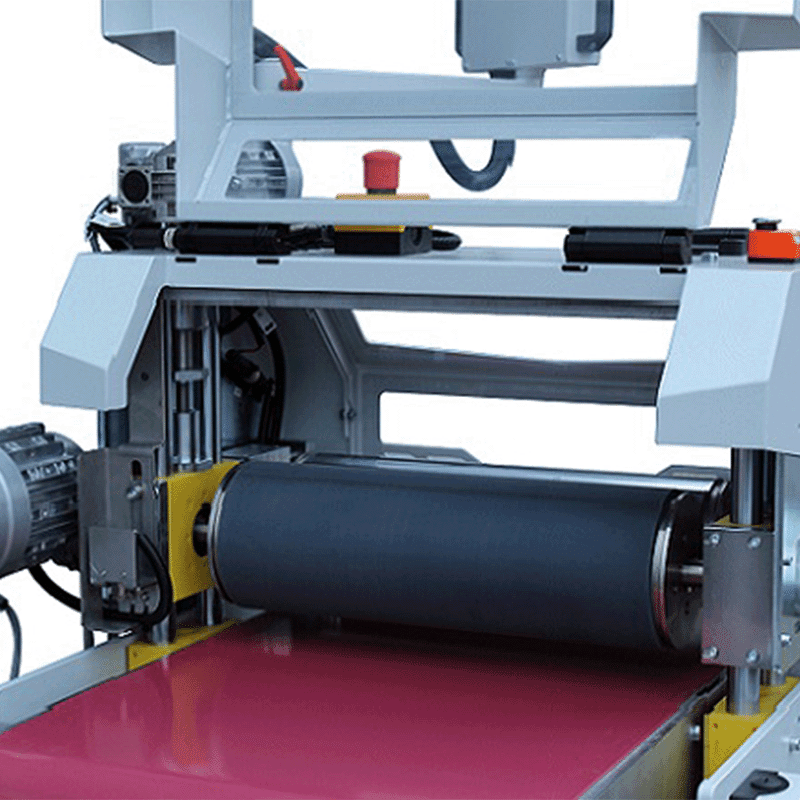

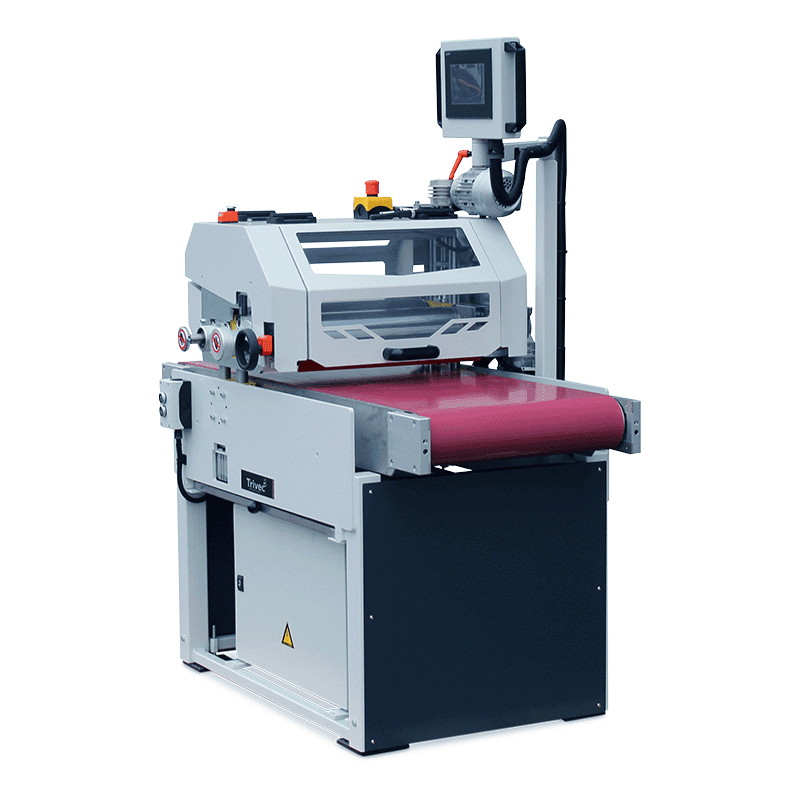

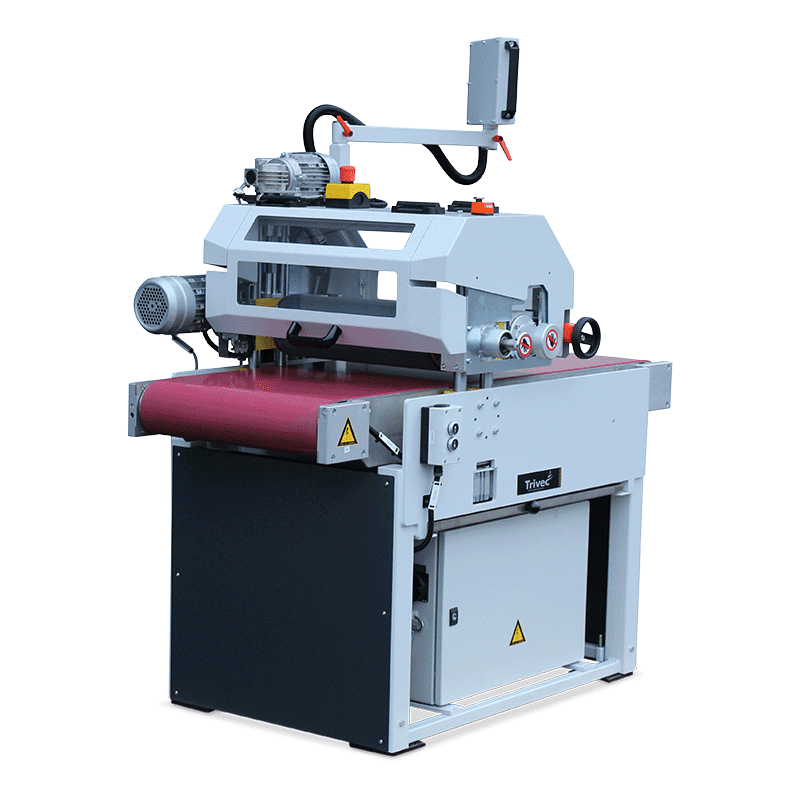

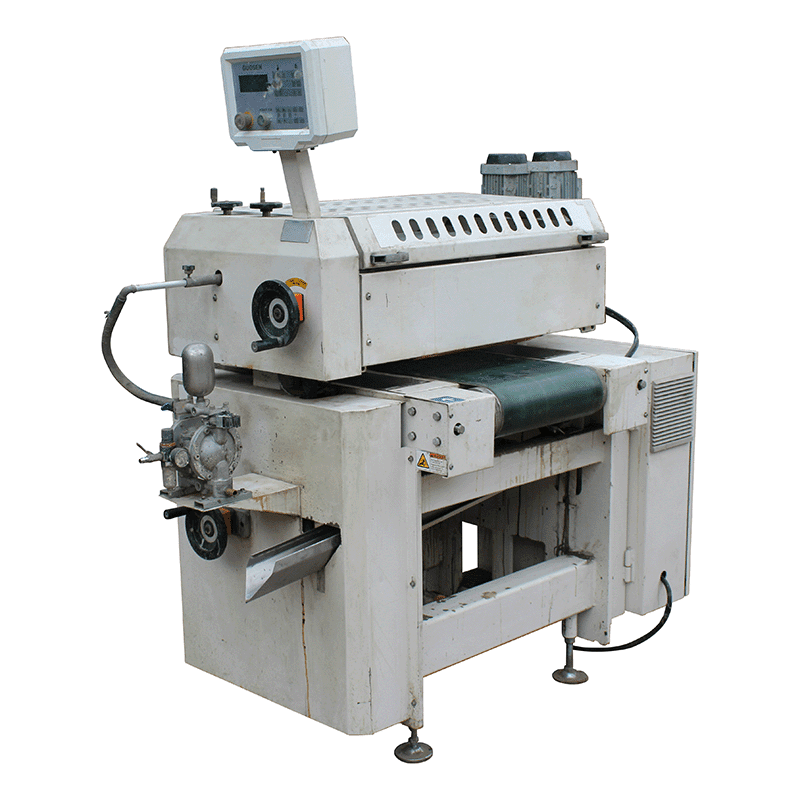

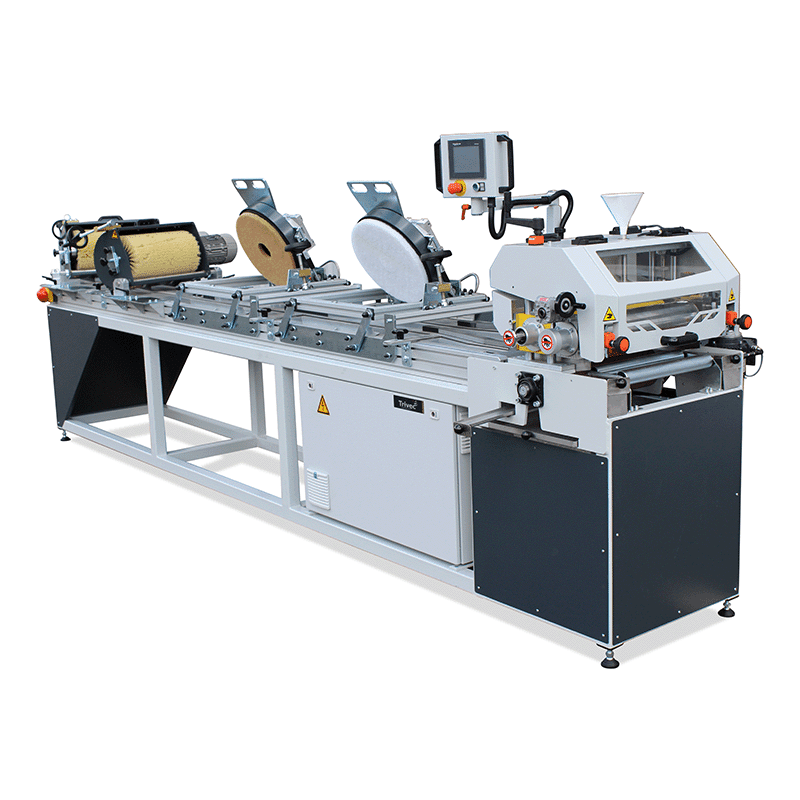

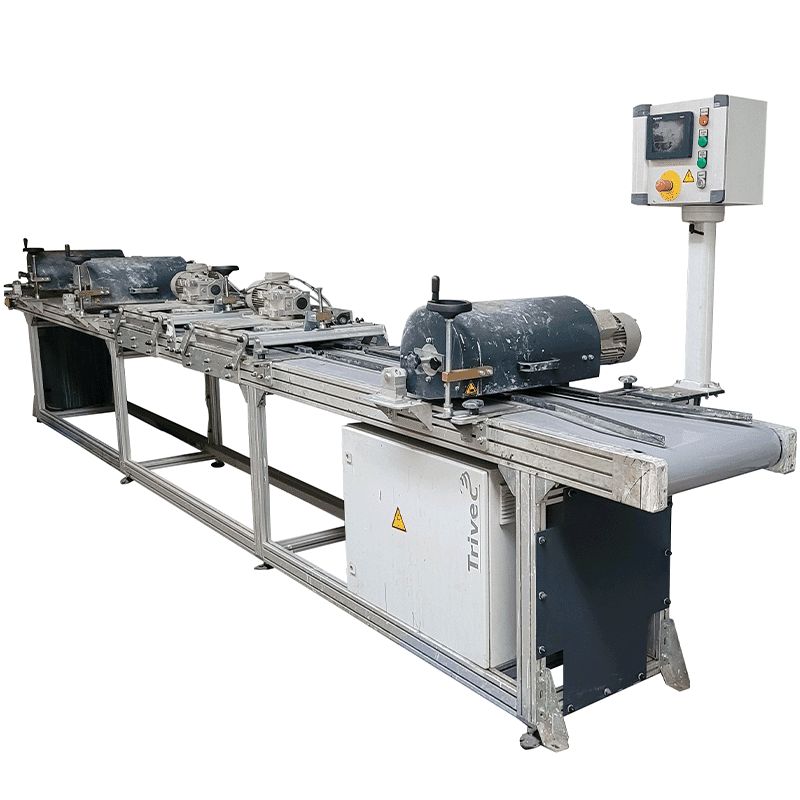

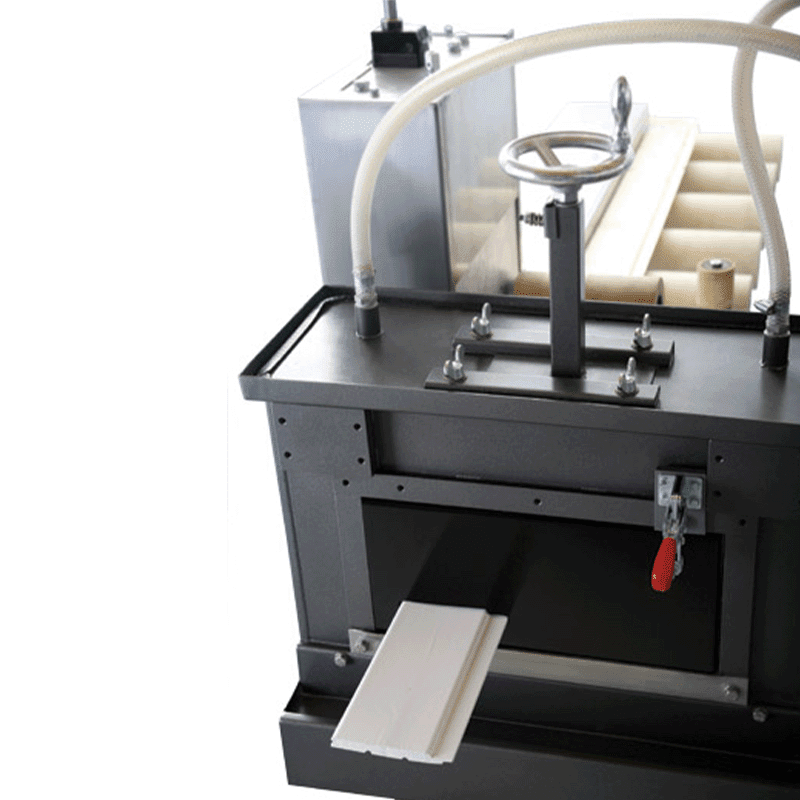

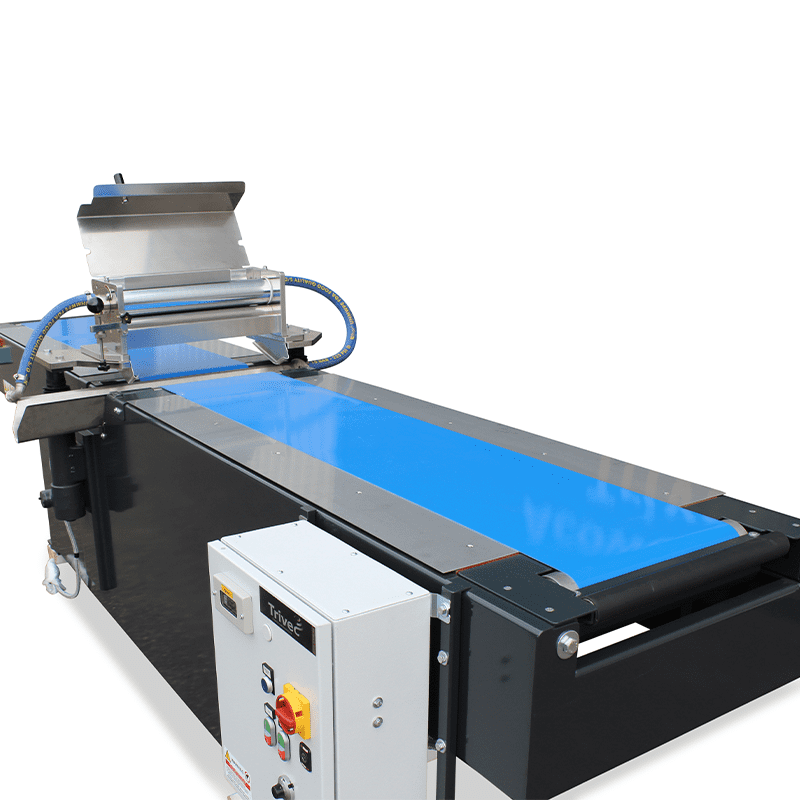

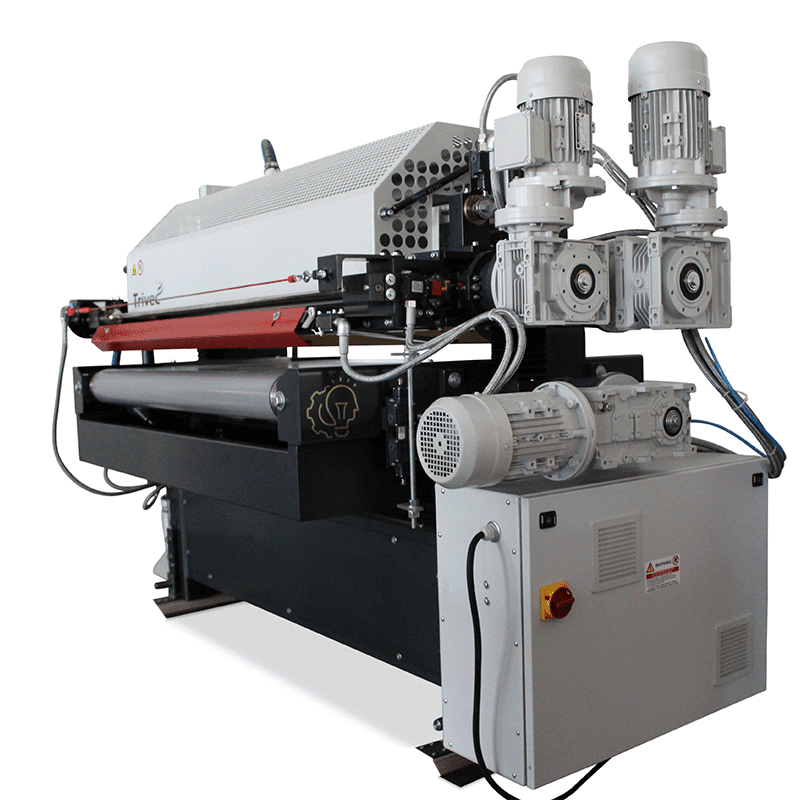

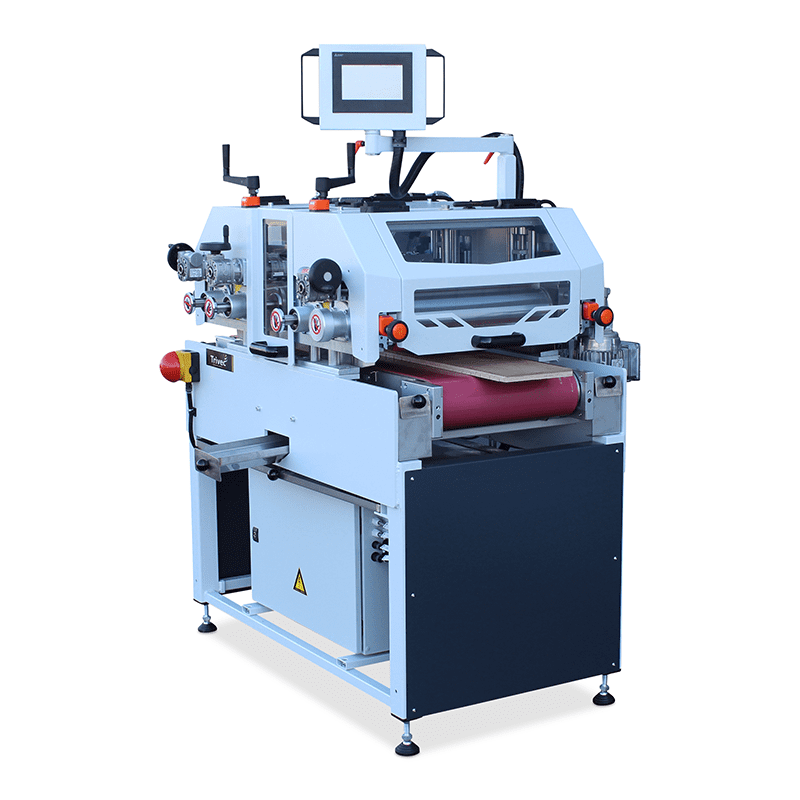

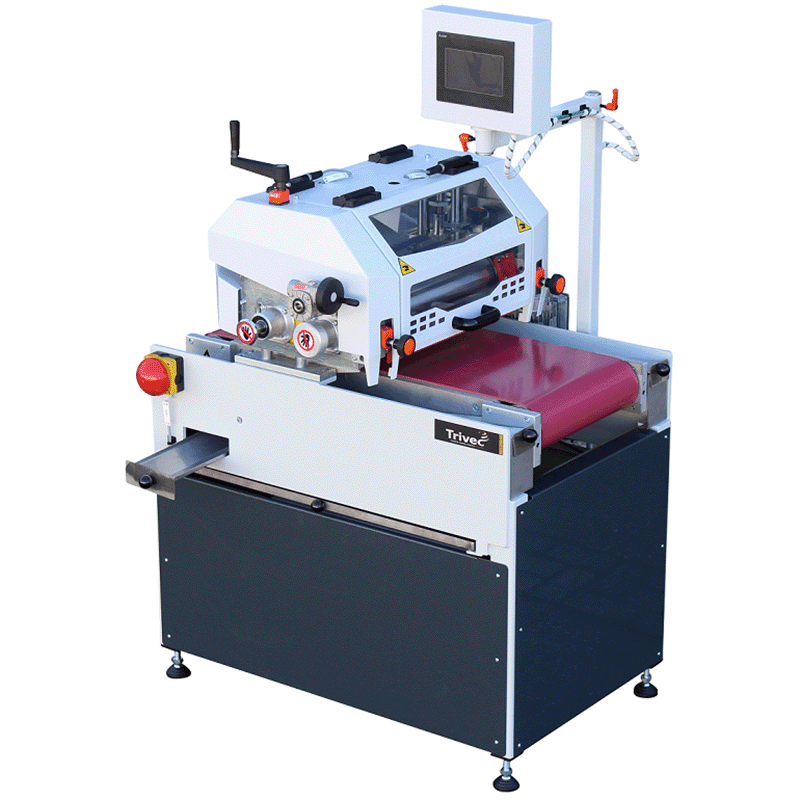

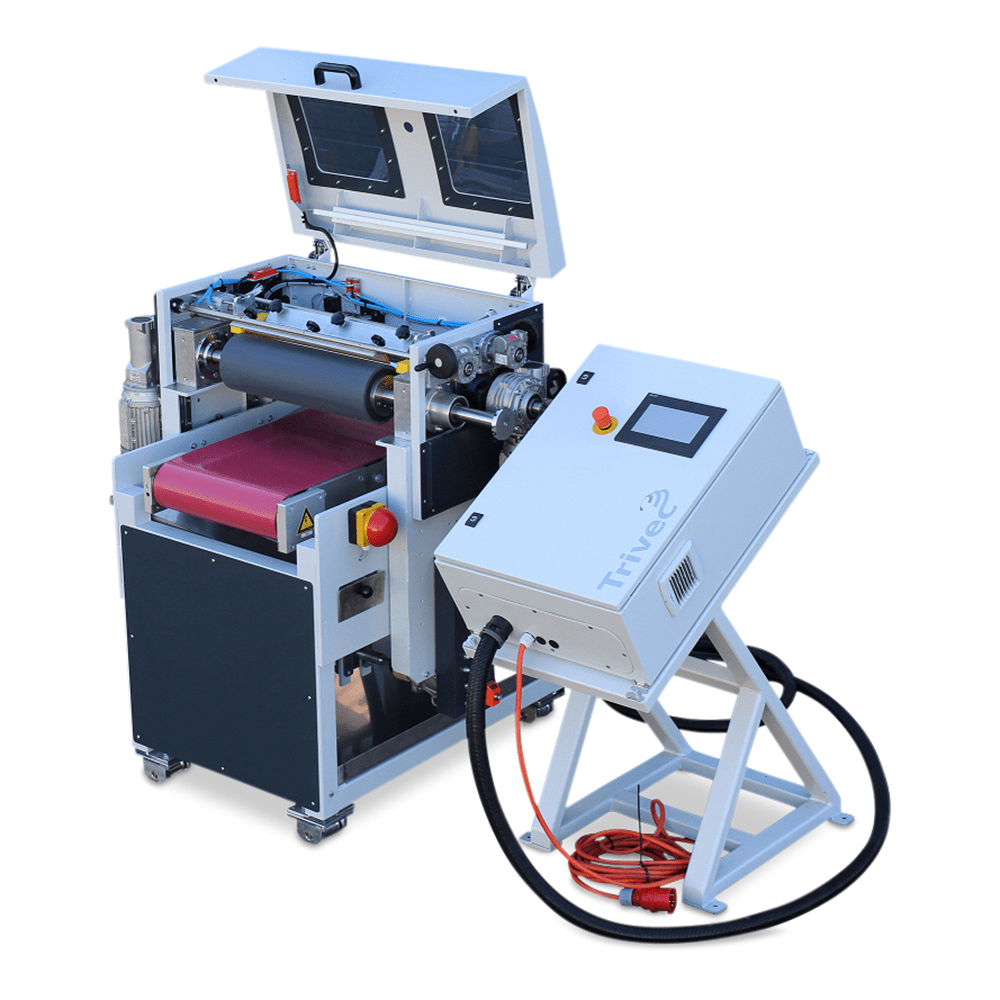

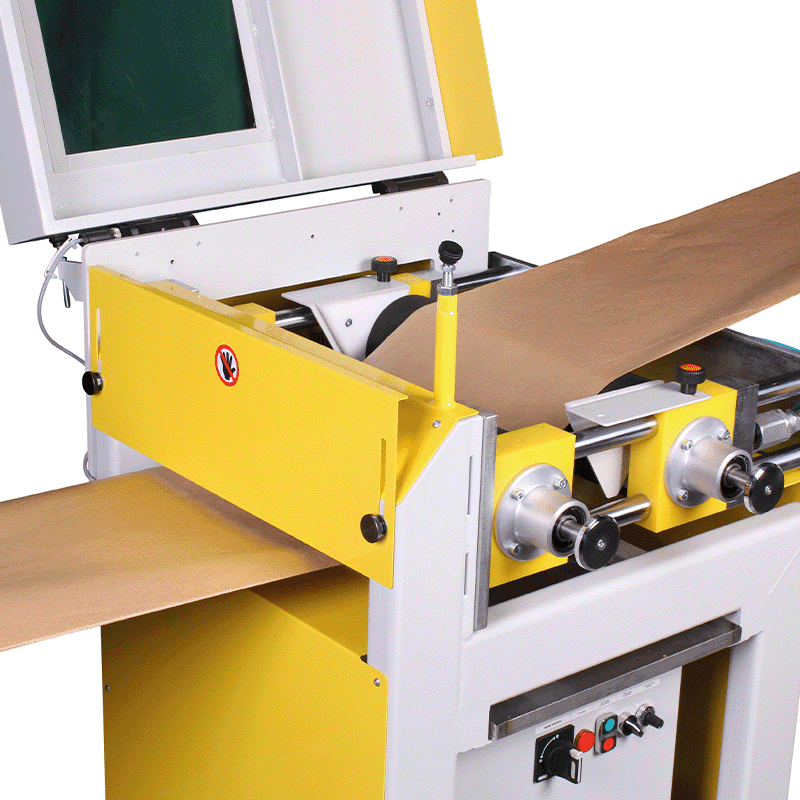

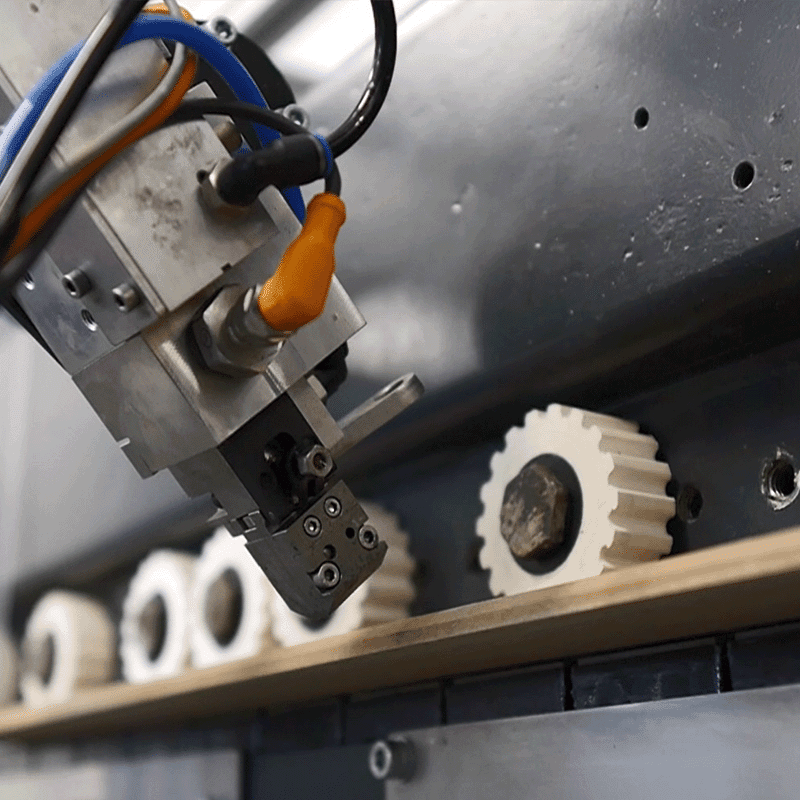

The Roller Coater Single is a highly versatile and precise machine designed specifically for the application of adhesives and thick liquid coatings to paper, cardboard, and other flexible materials. With its ability to apply coatings in controlled strips, it excels in projects where precision and efficiency are key. The machine is engineered for use in a wide variety of industrial applications, providing consistent and reliable performance for tasks that require the exact application of glues, adhesives, and coatings. Its design allows for the application of viscous liquids with high accuracy, making it ideal for manufacturers in industries such as packaging, printing, and textile production.