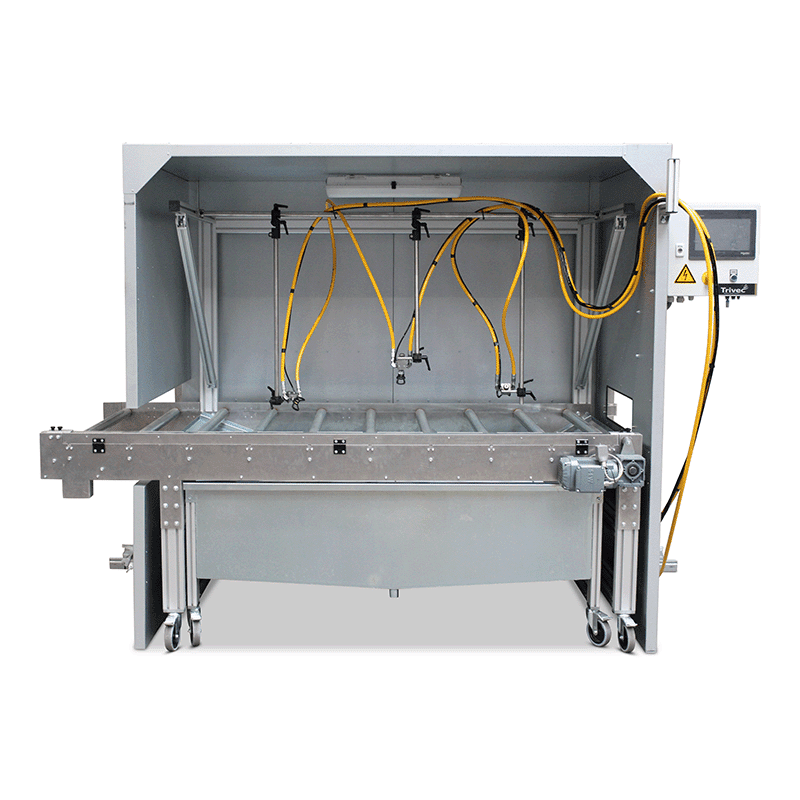

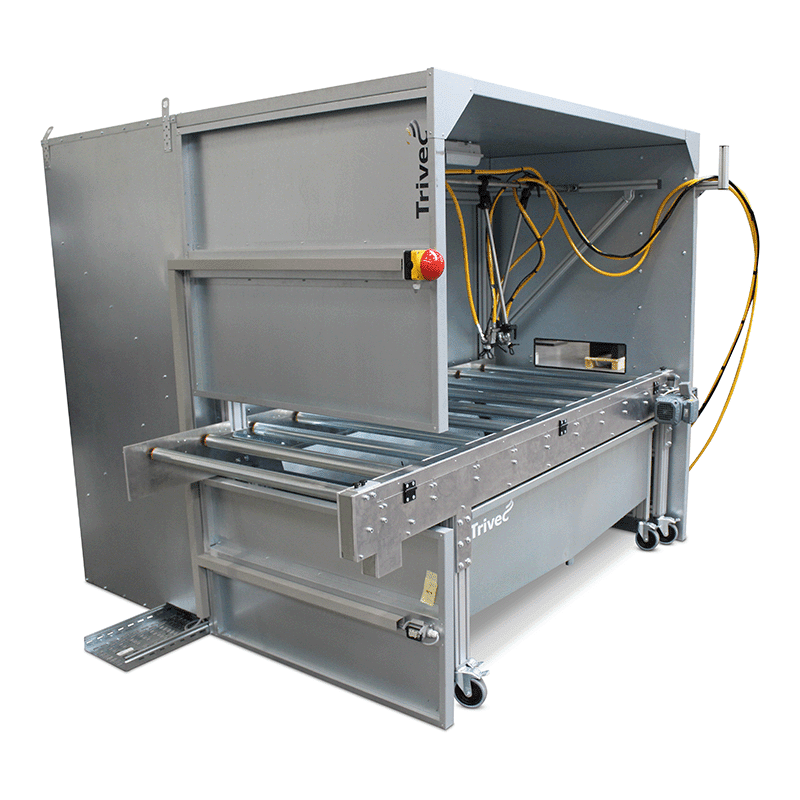

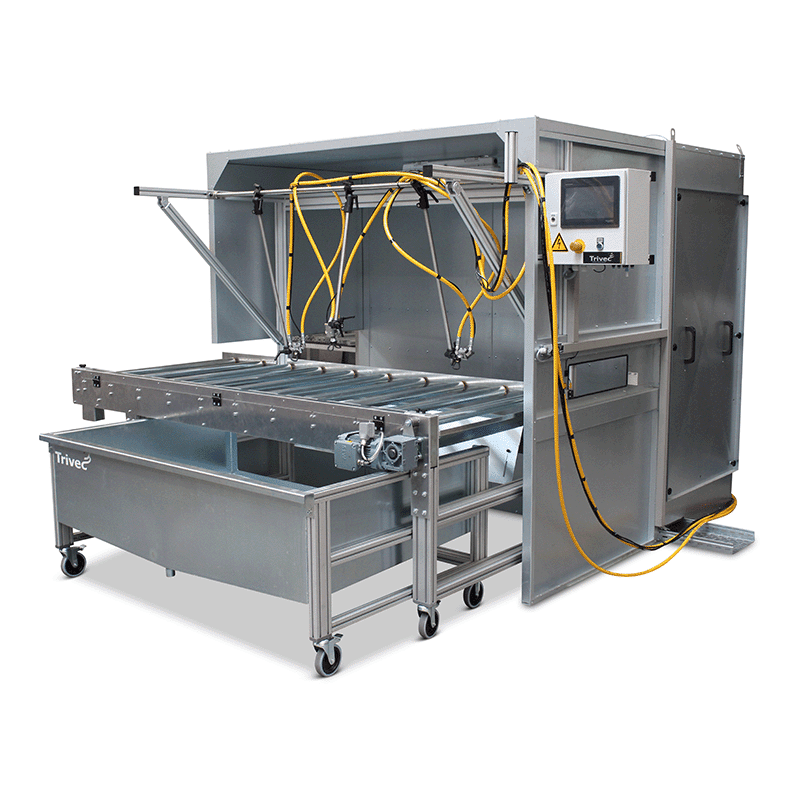

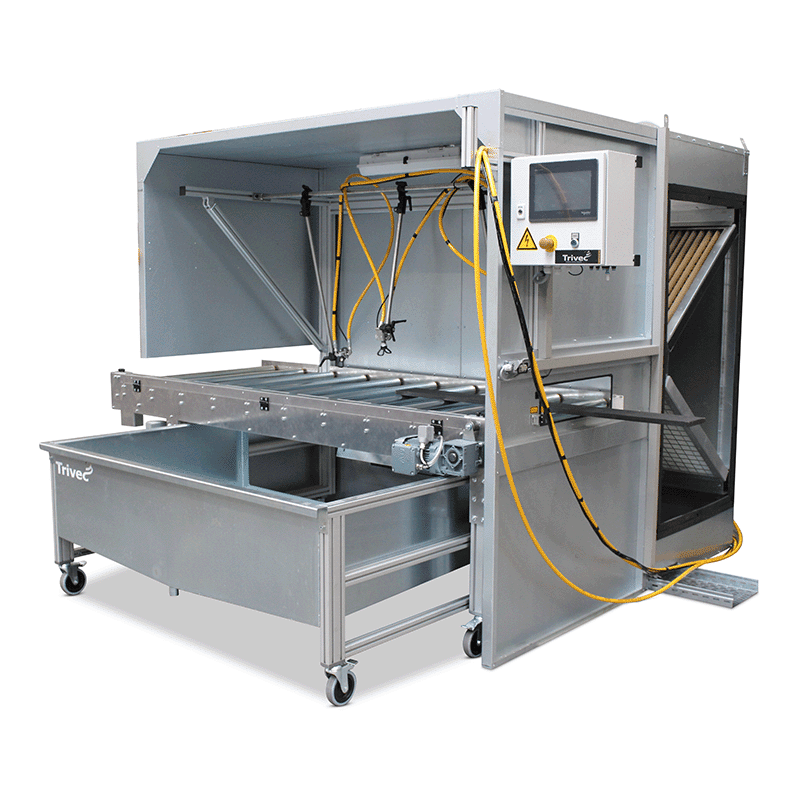

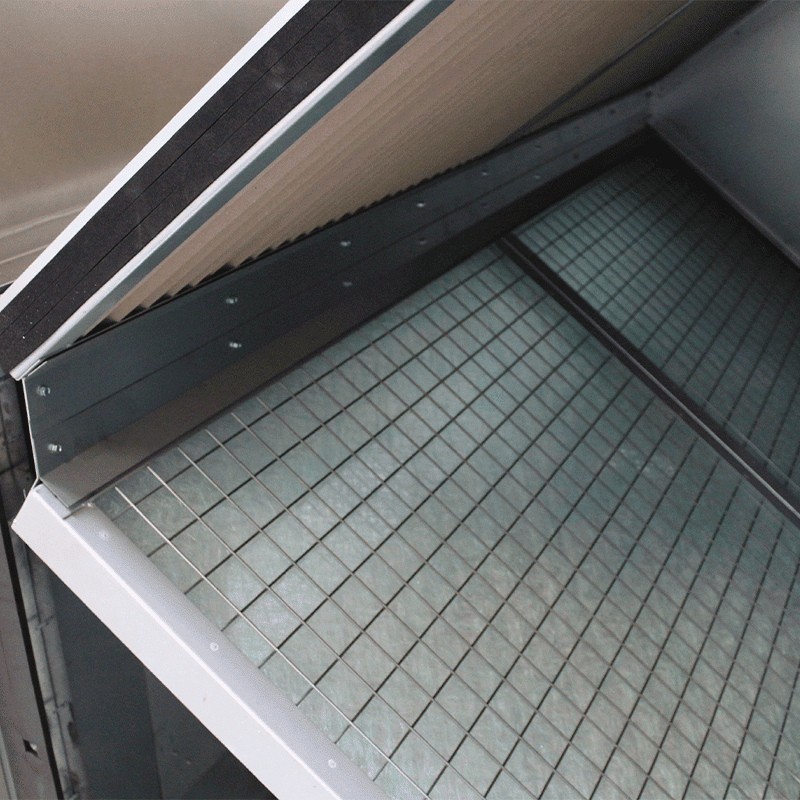

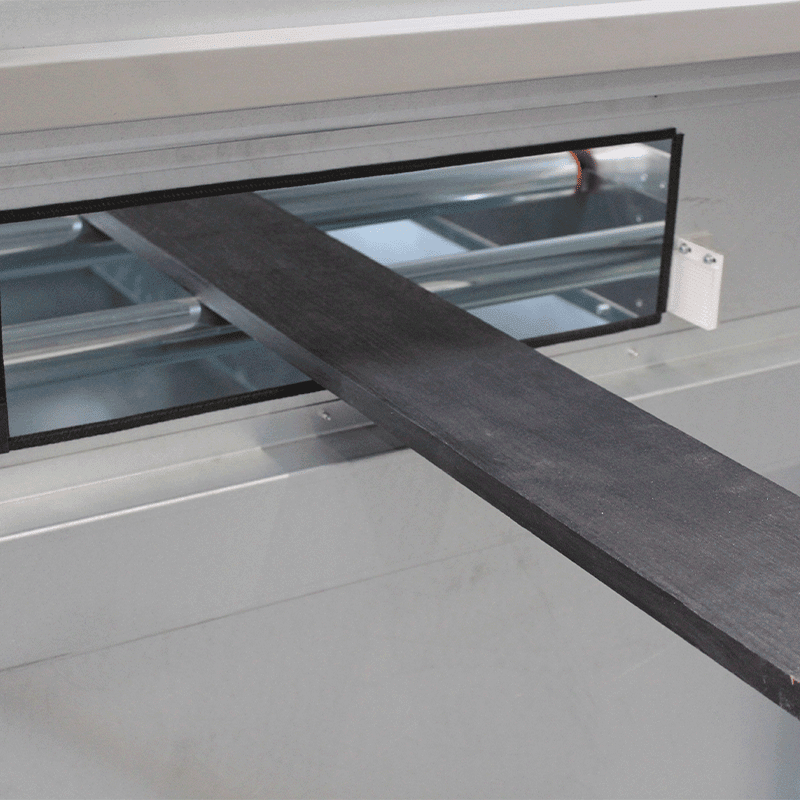

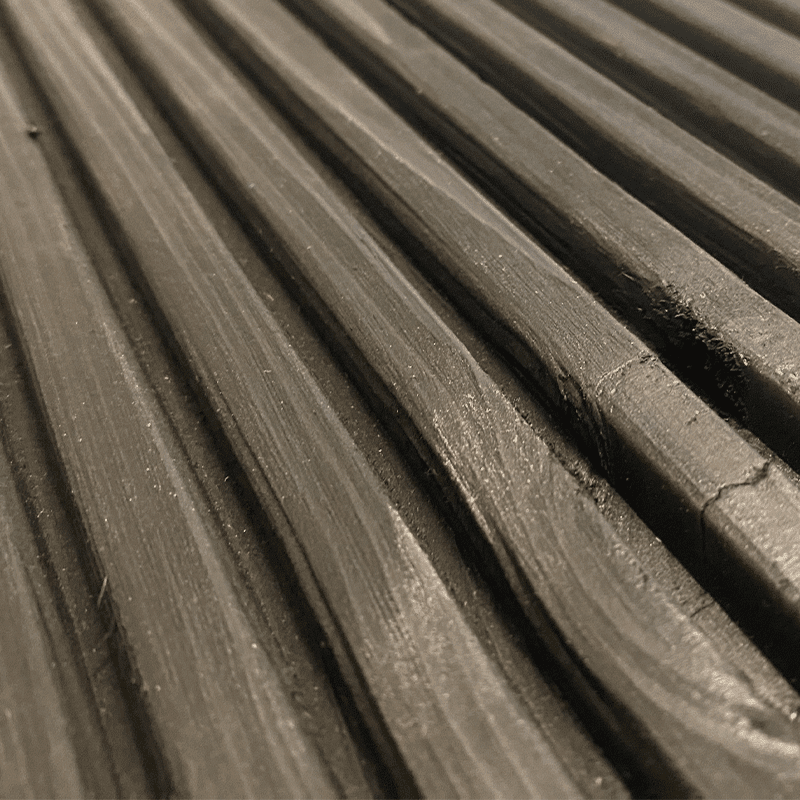

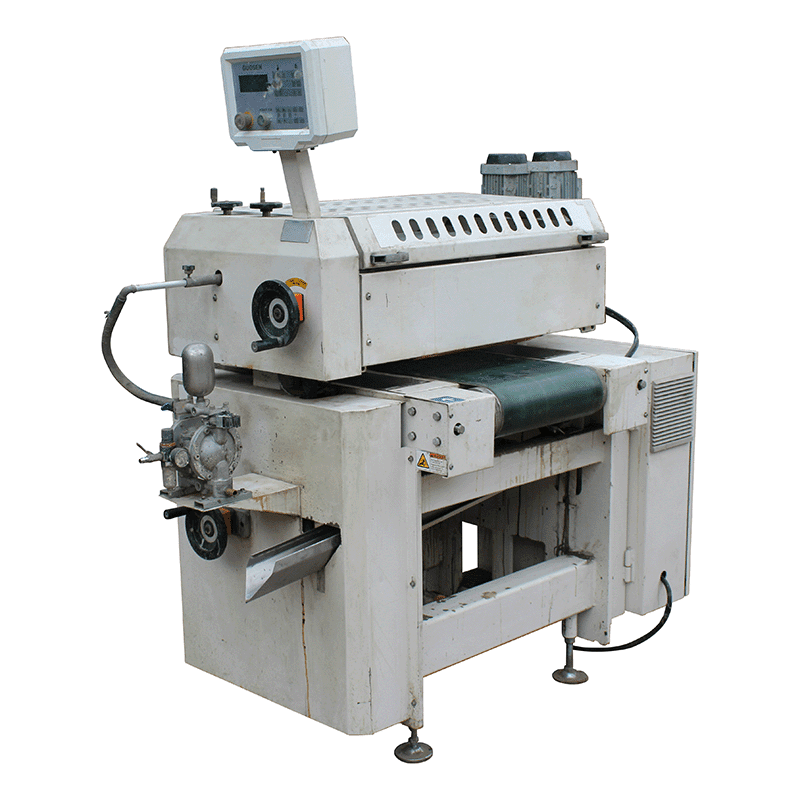

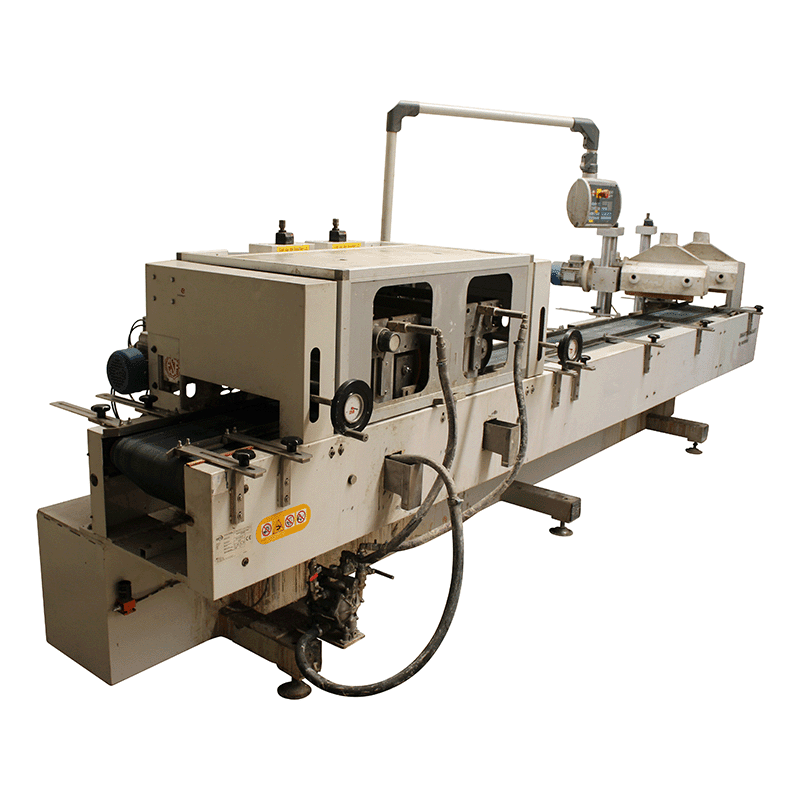

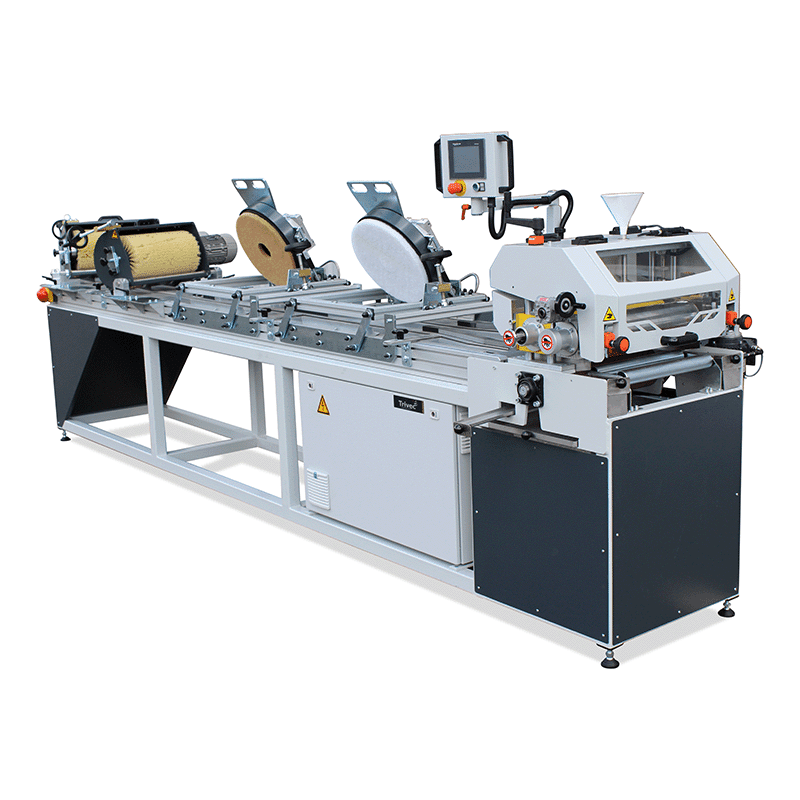

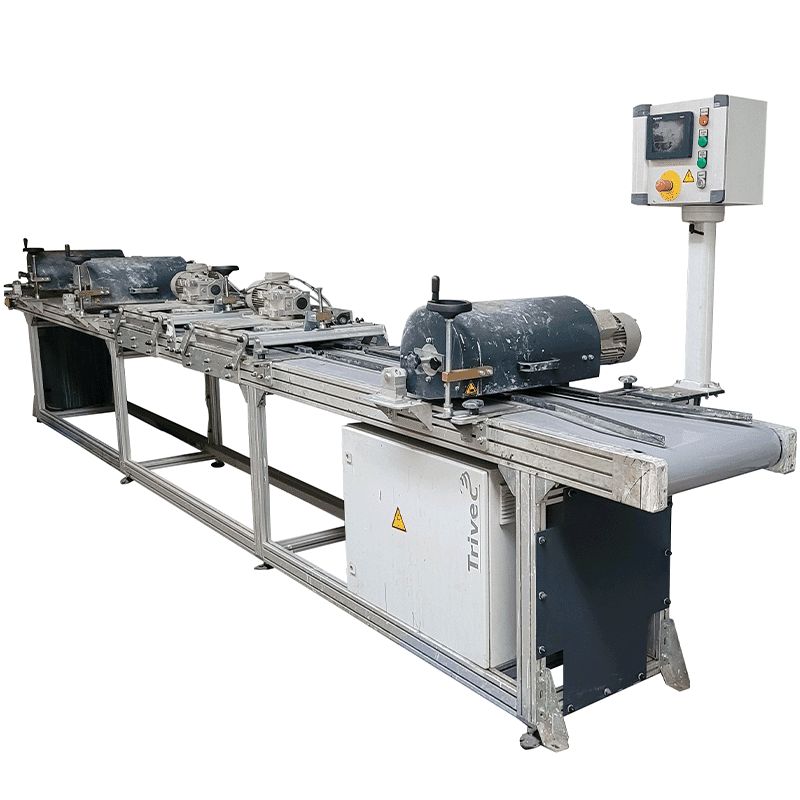

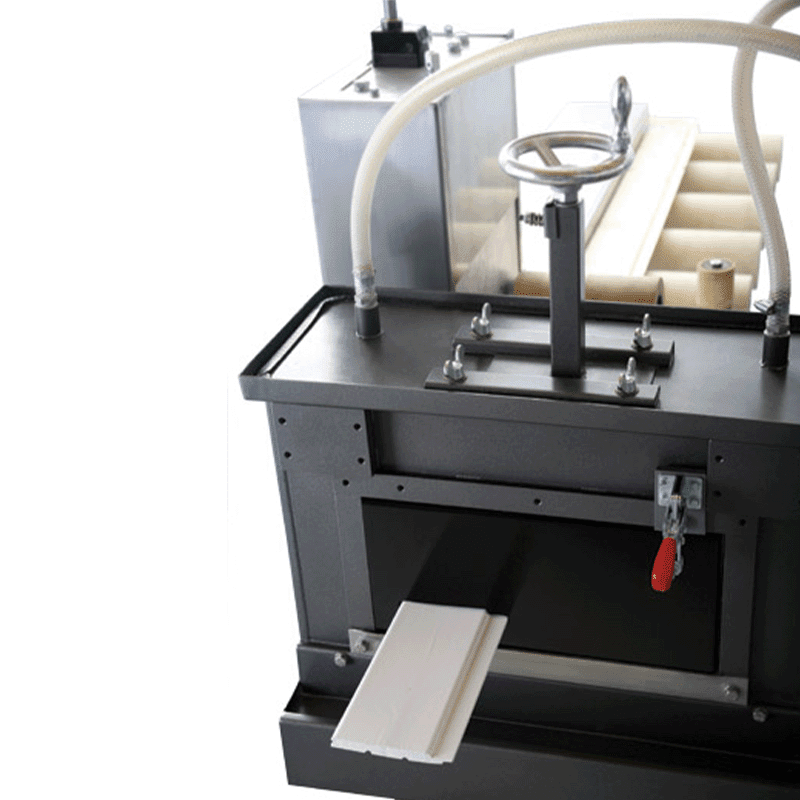

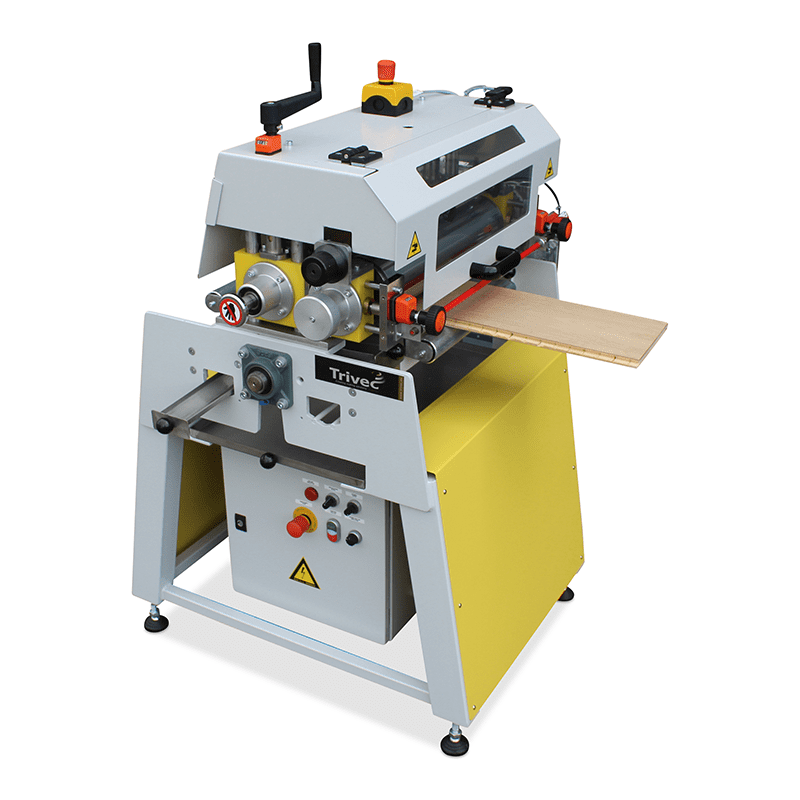

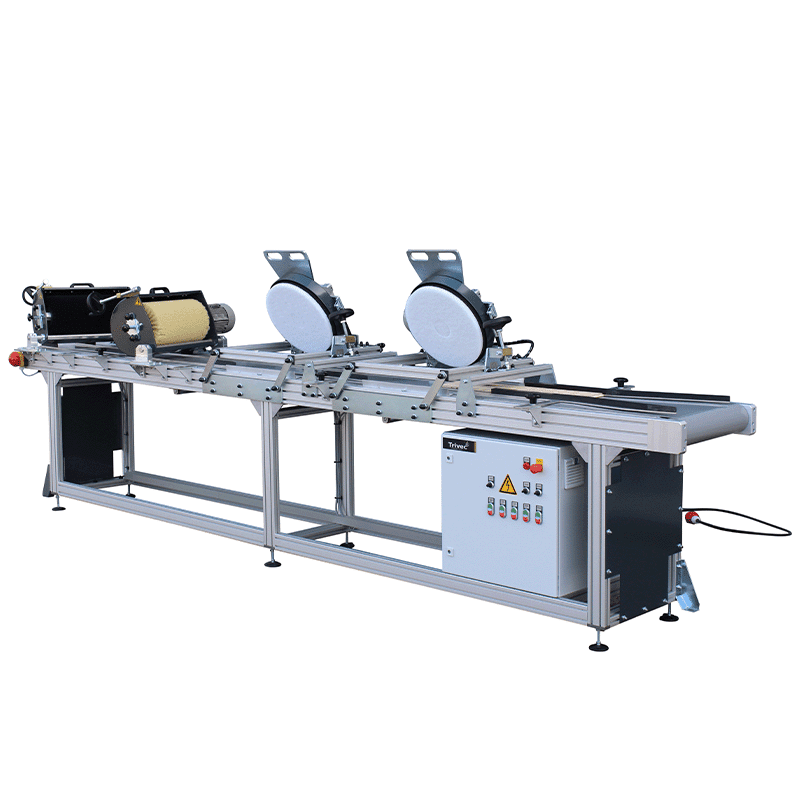

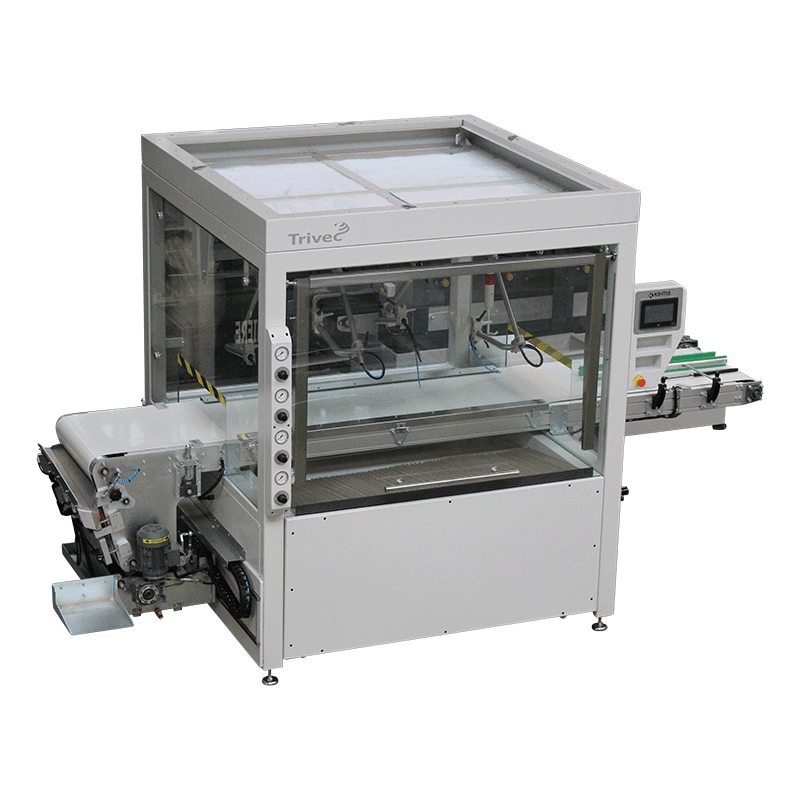

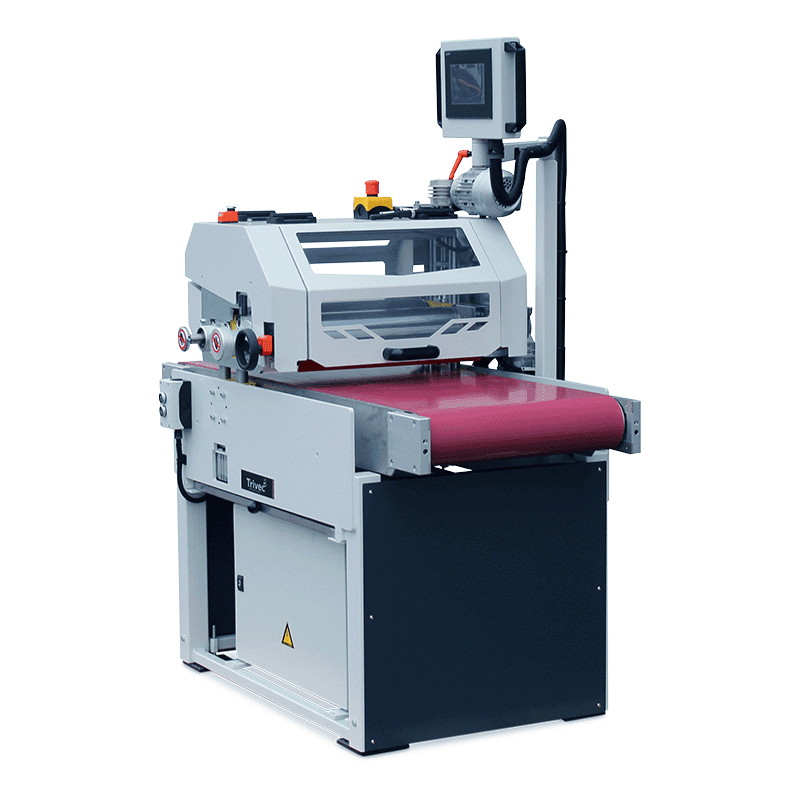

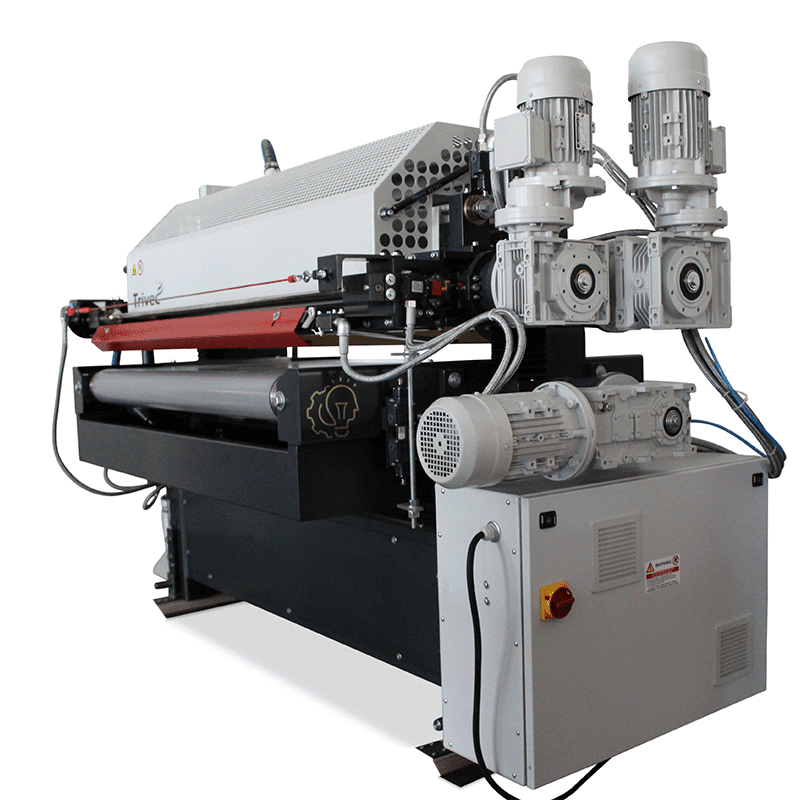

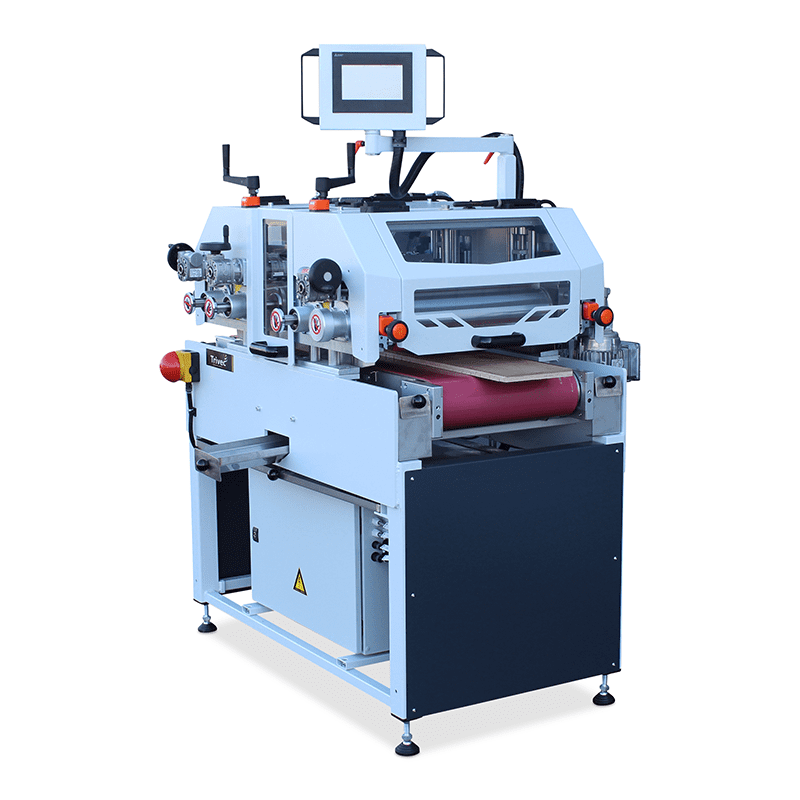

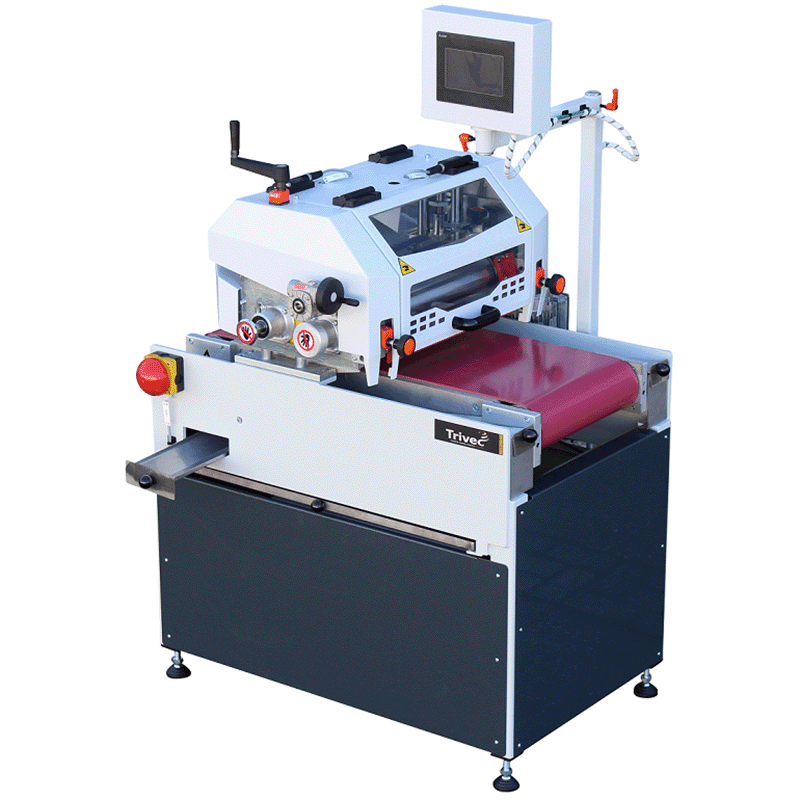

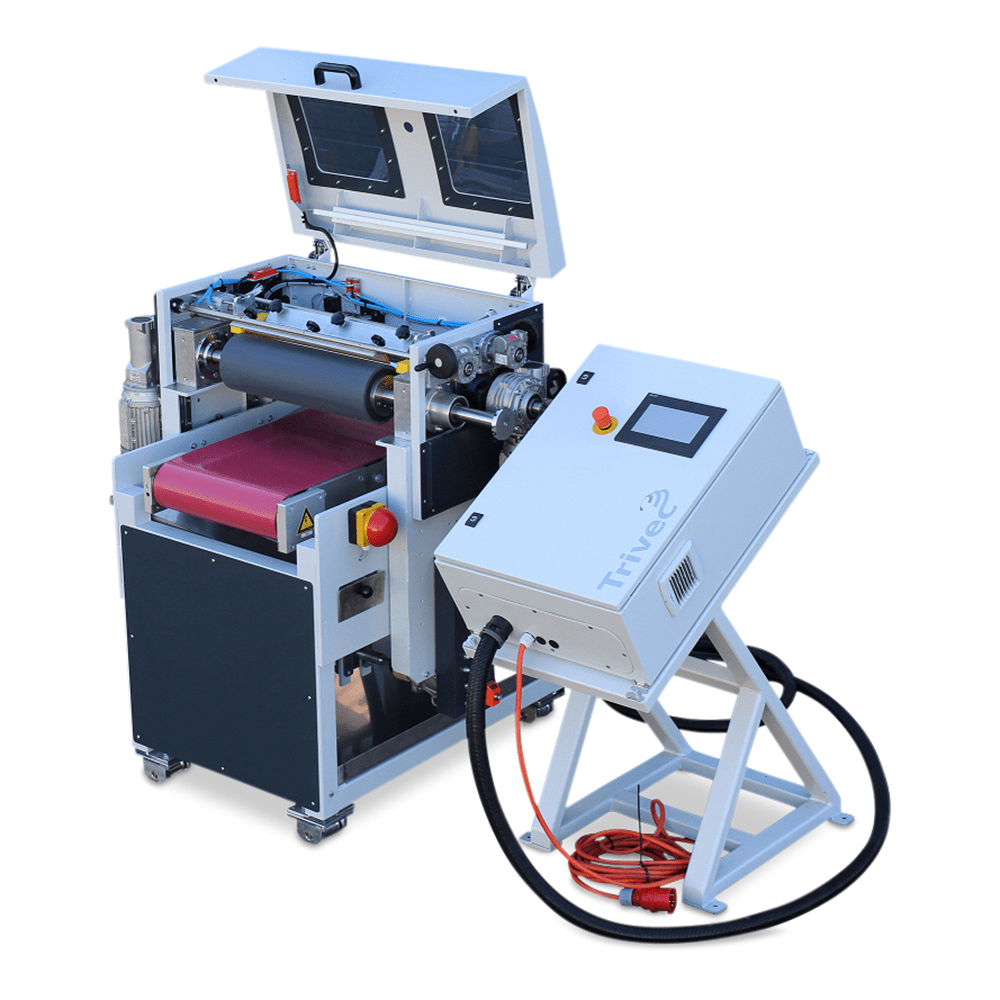

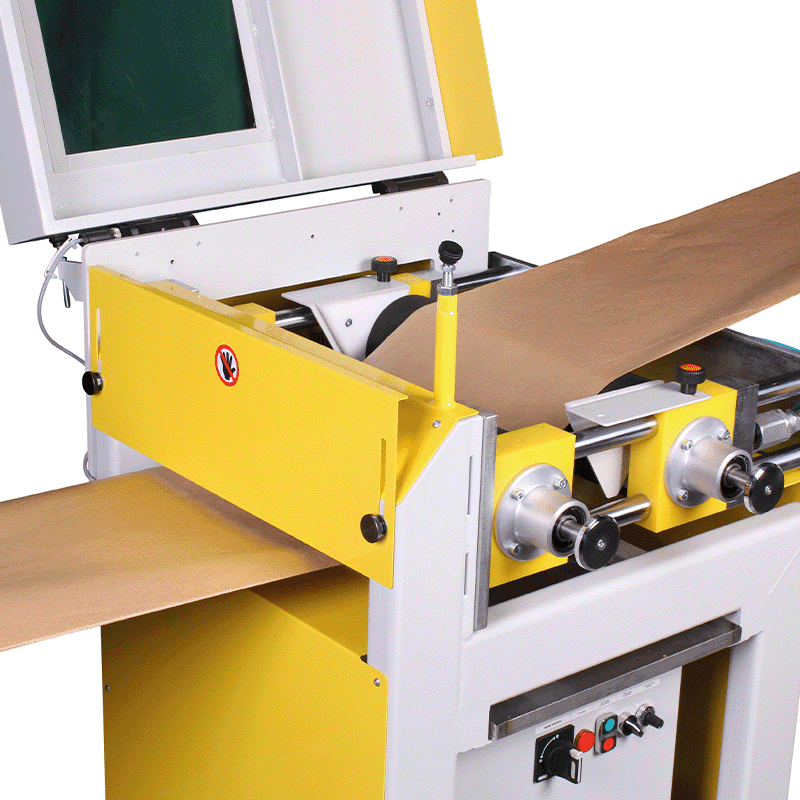

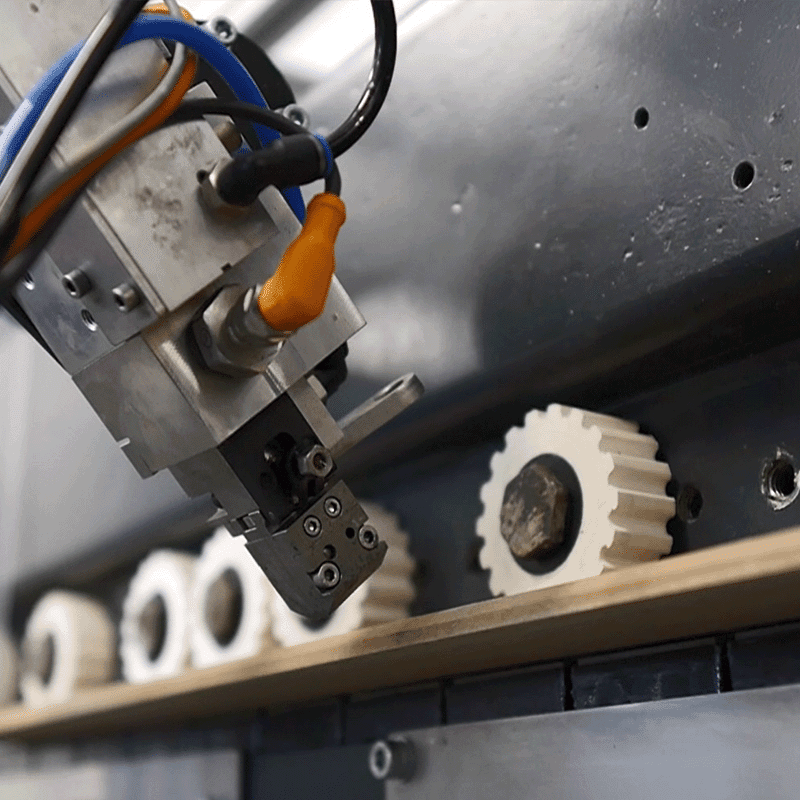

The Spraying Machine BOX provides an efficient solution for 1, 2, or 3-sided treatment of façade wood, beams, and other longitudinal wood with water-based paints and stains. Its design ensures precise application while minimizing waste, with overspray collected, filtered, and managed efficiently.

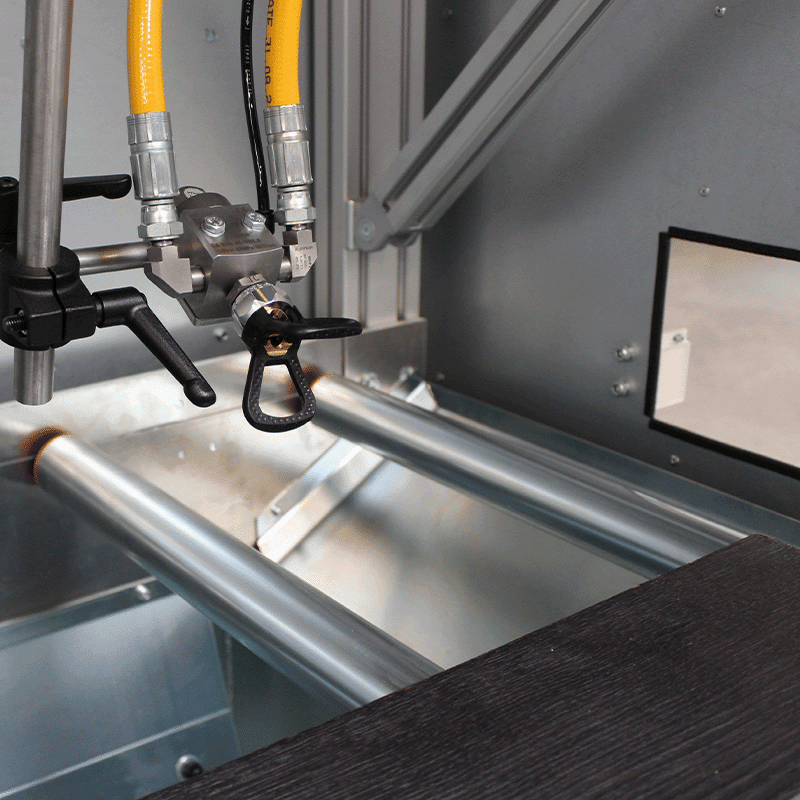

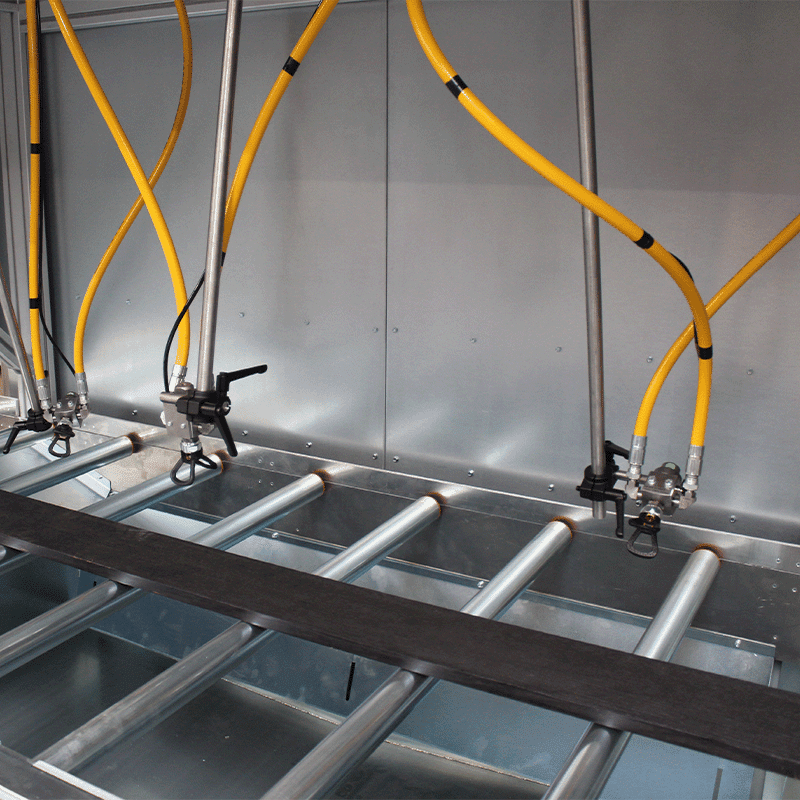

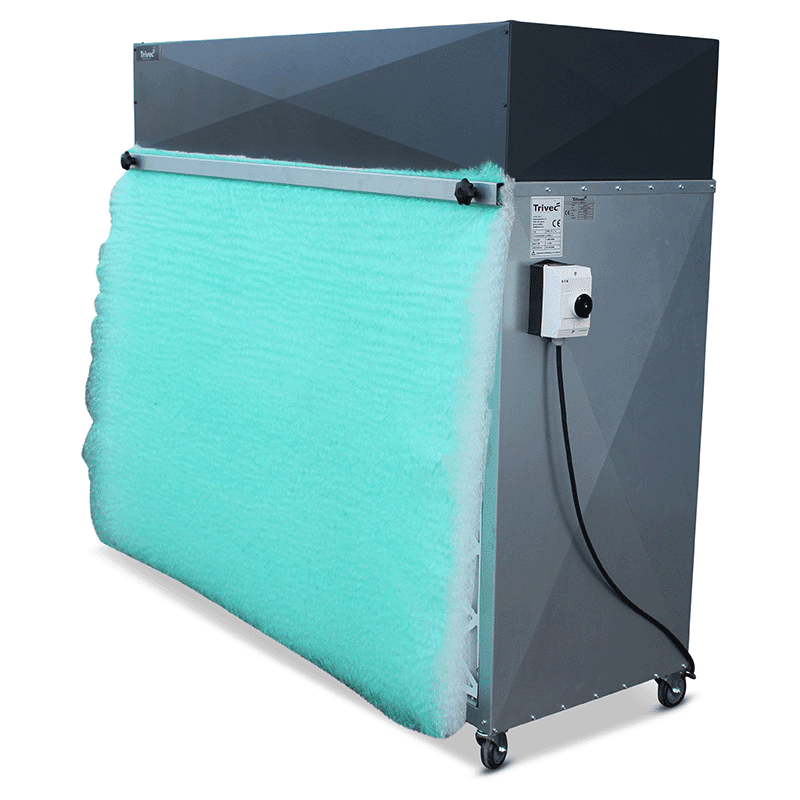

The modular system allows for easy removal of the overspray unit and transport system for quick cleaning and maintenance. An indirect air extraction system recovers up to 80% of the air, reducing heating costs. The cabin can be equipped with tailored guns and pump circuits, based on the paint product’s specifications. Optional modules enable seamless integration into automated production lines.