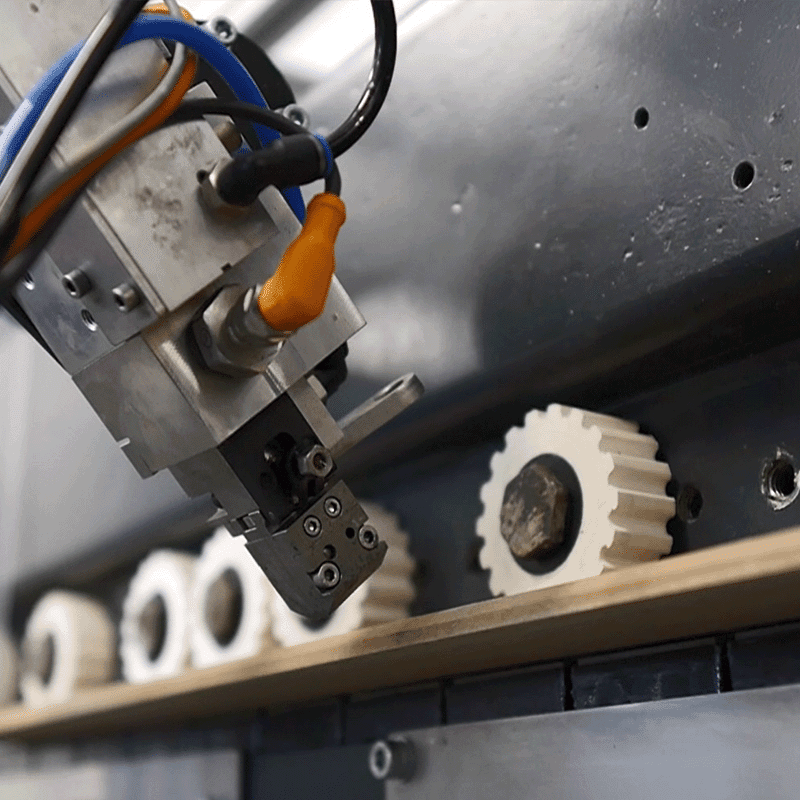

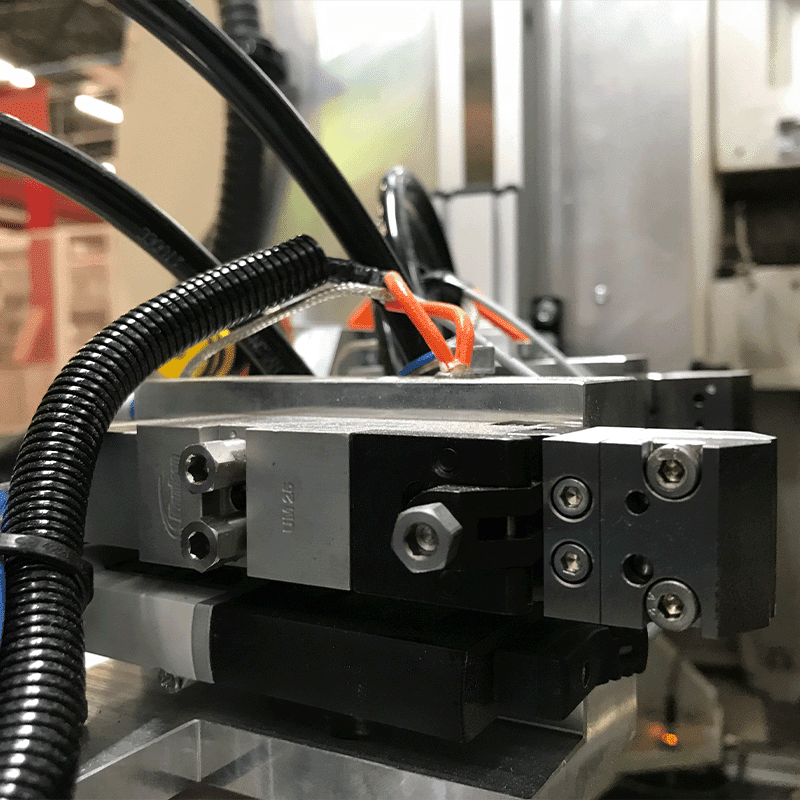

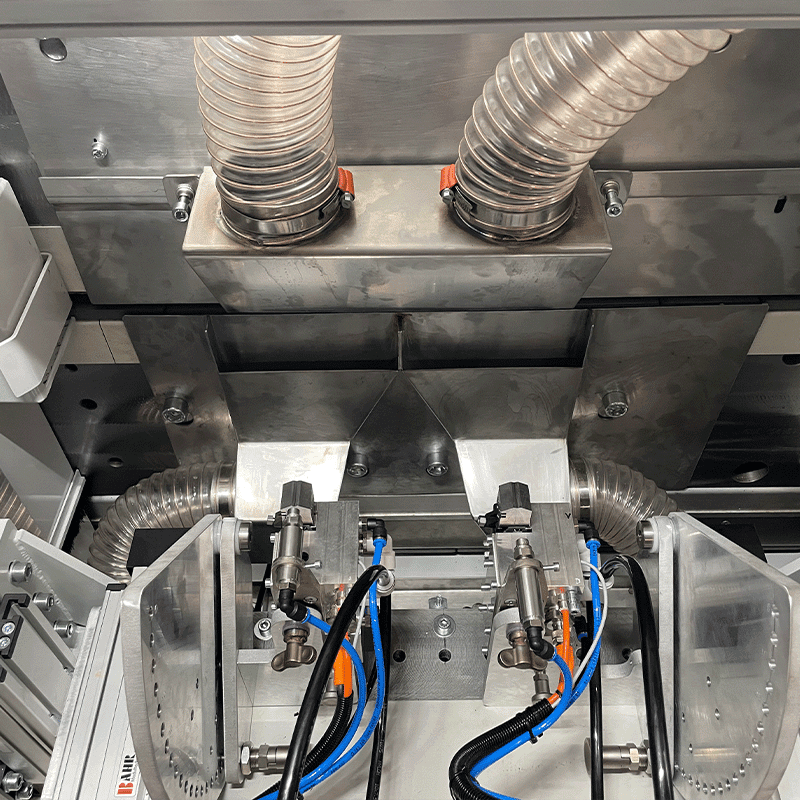

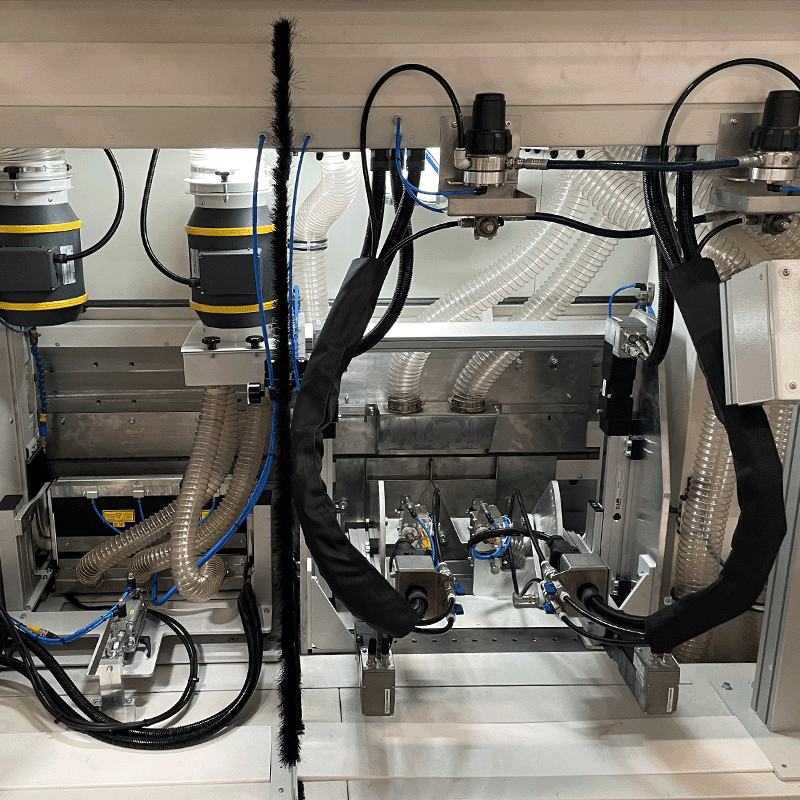

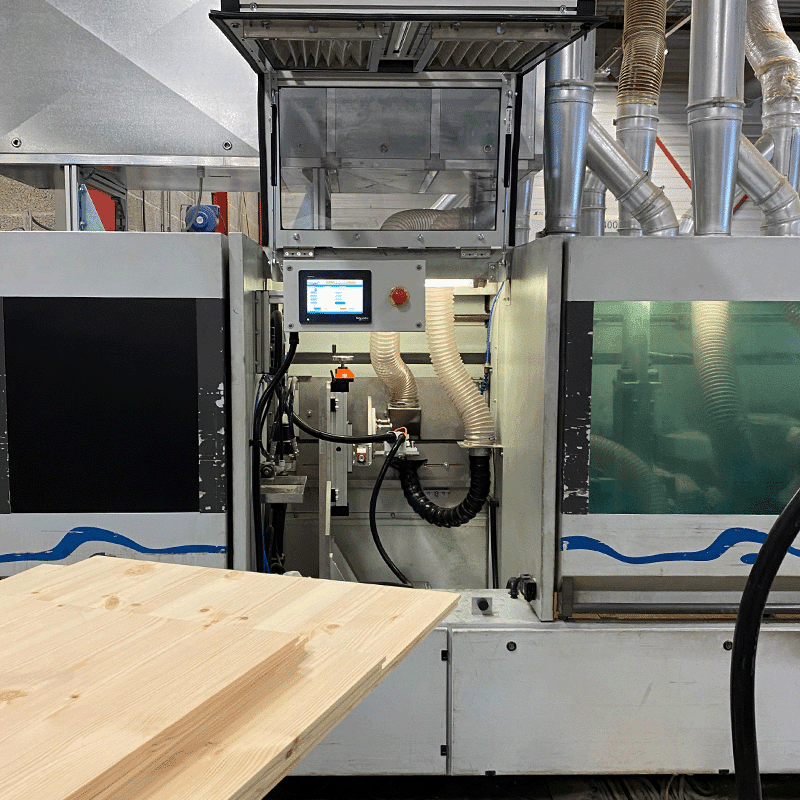

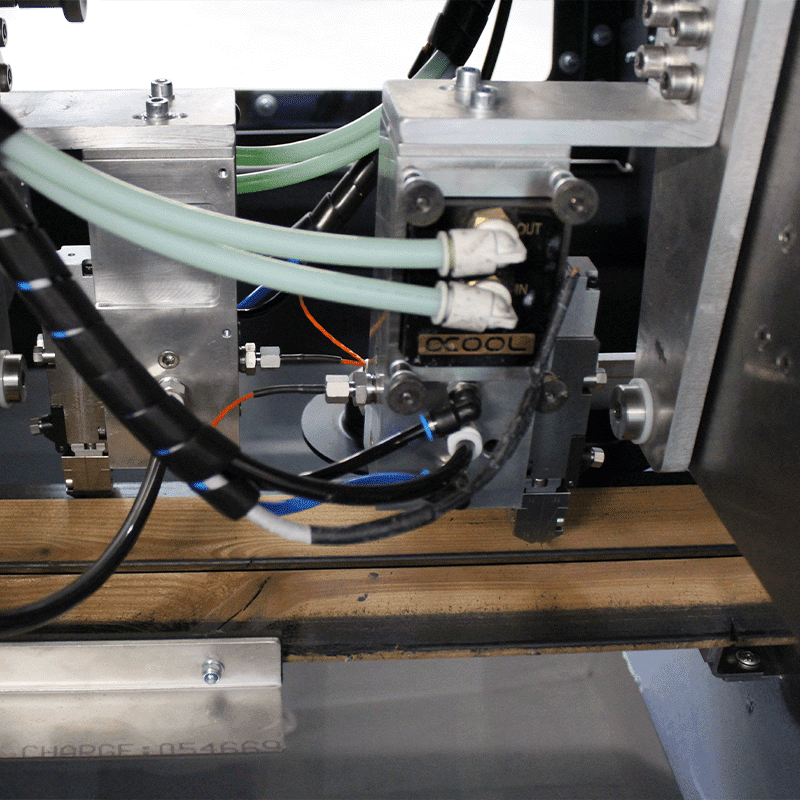

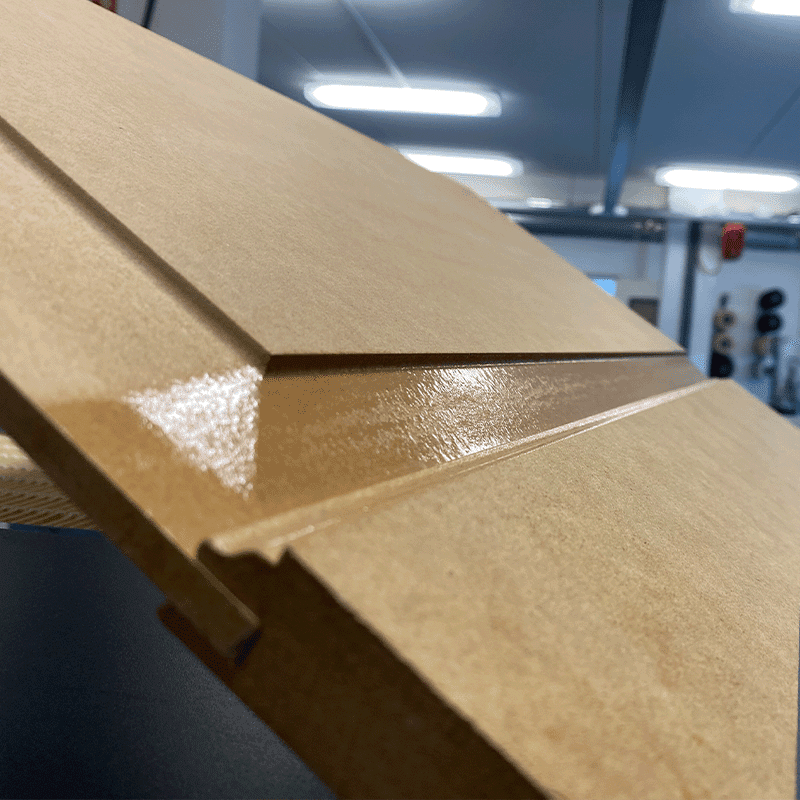

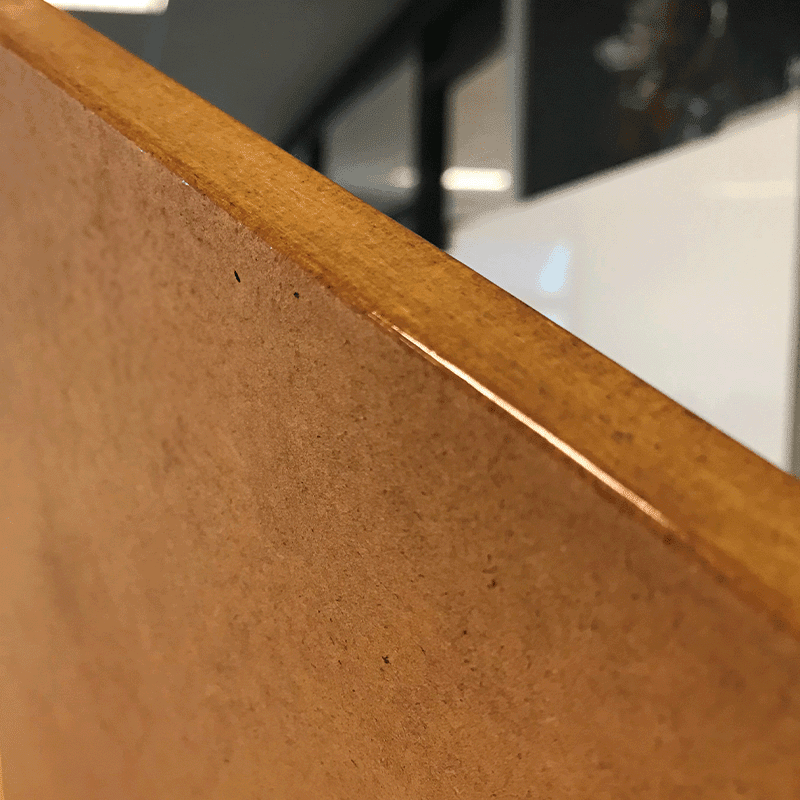

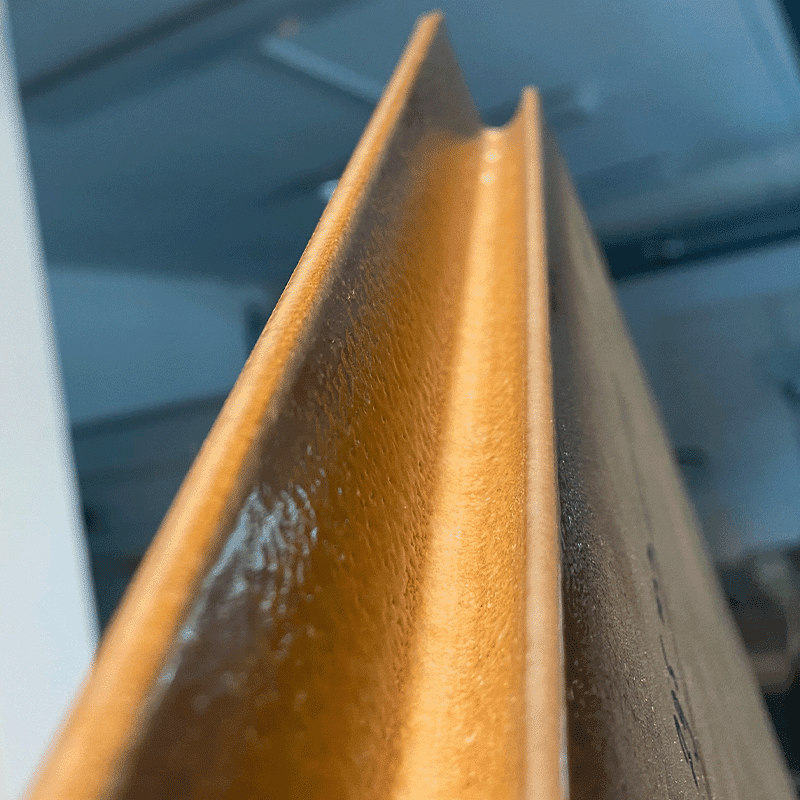

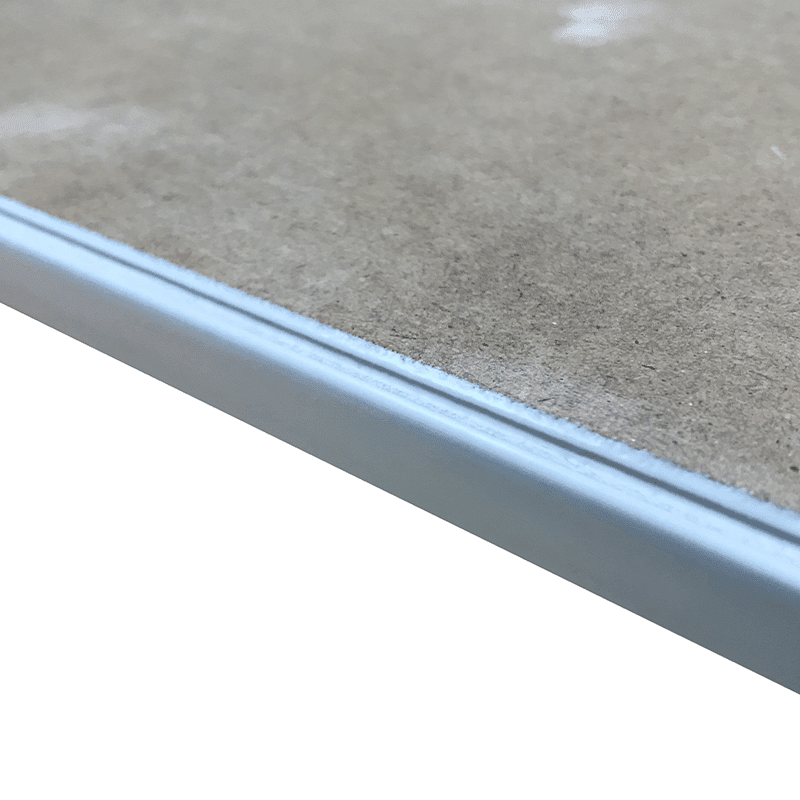

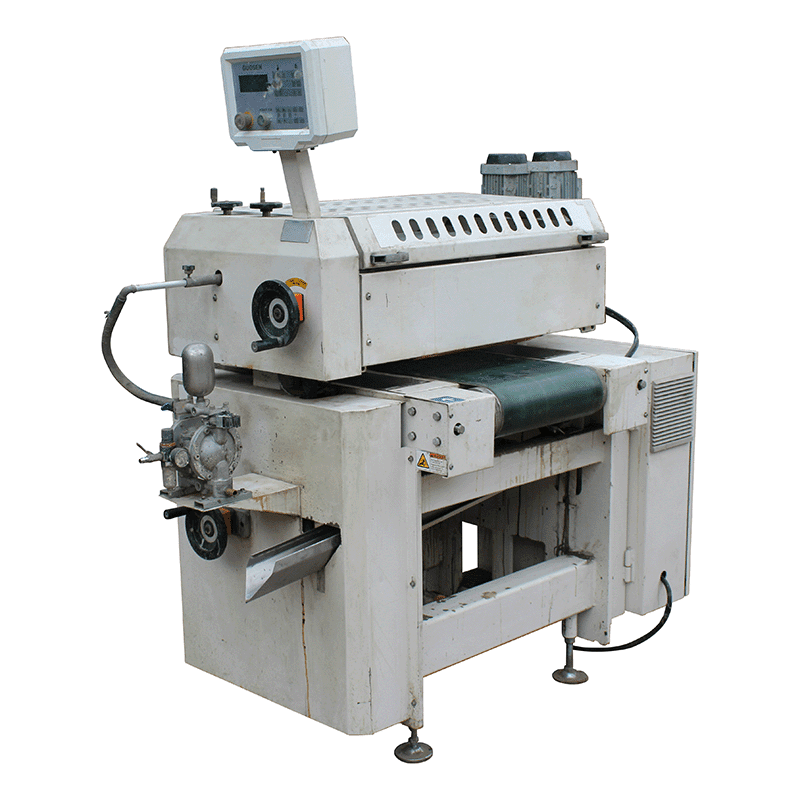

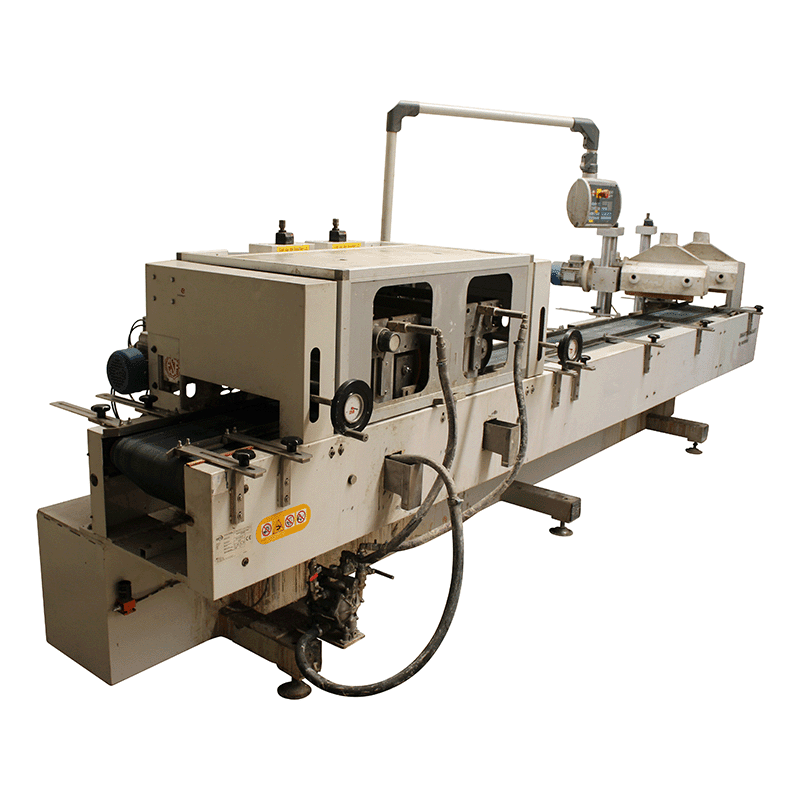

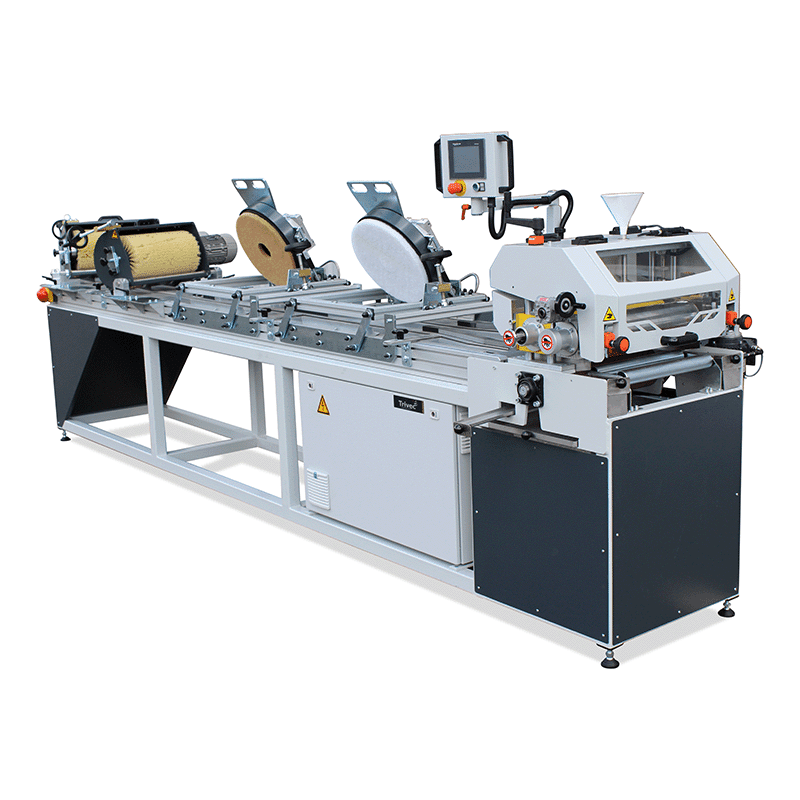

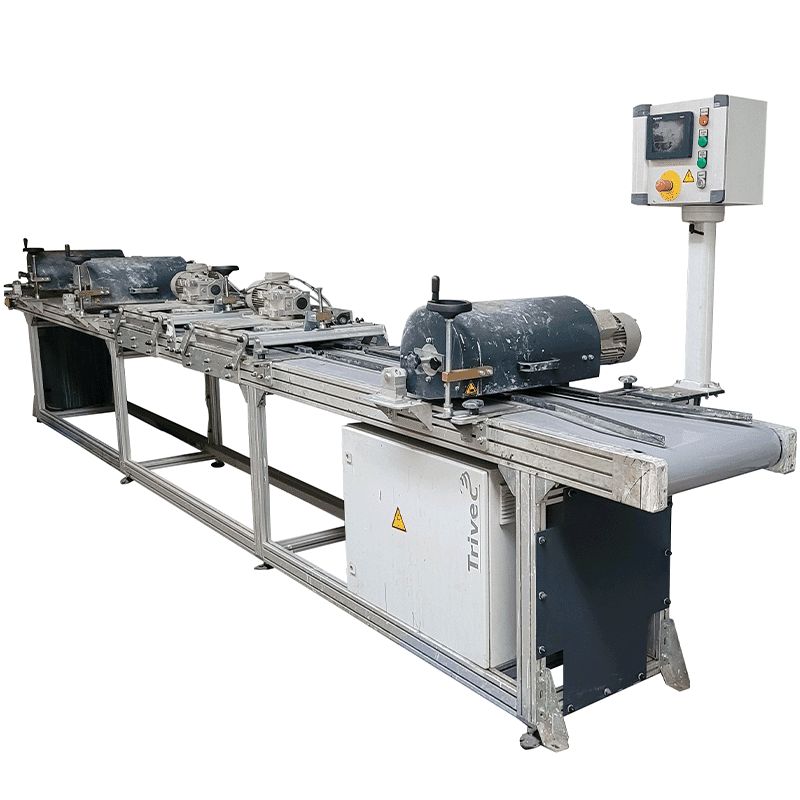

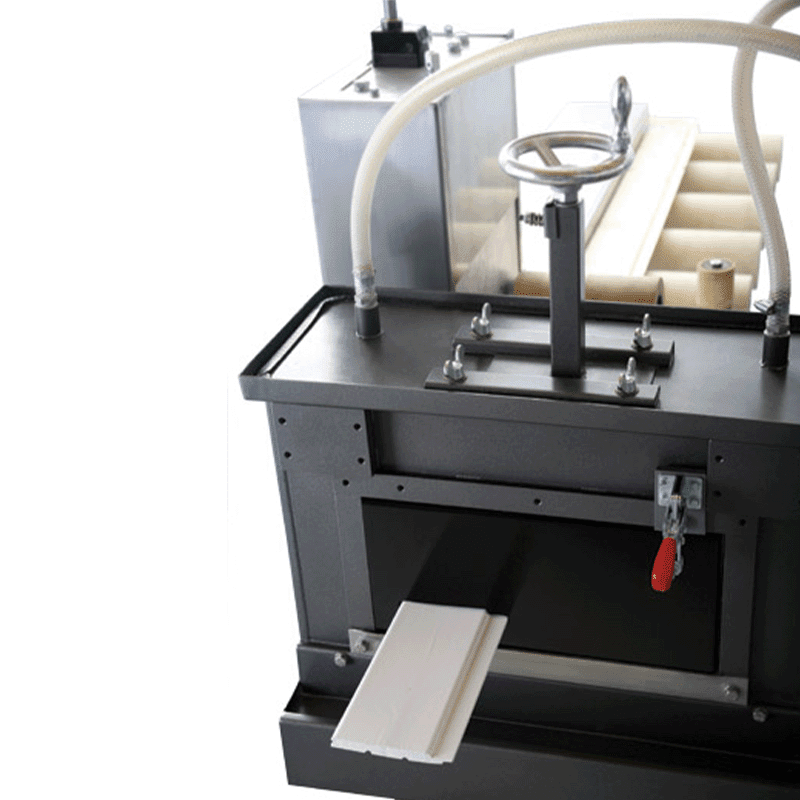

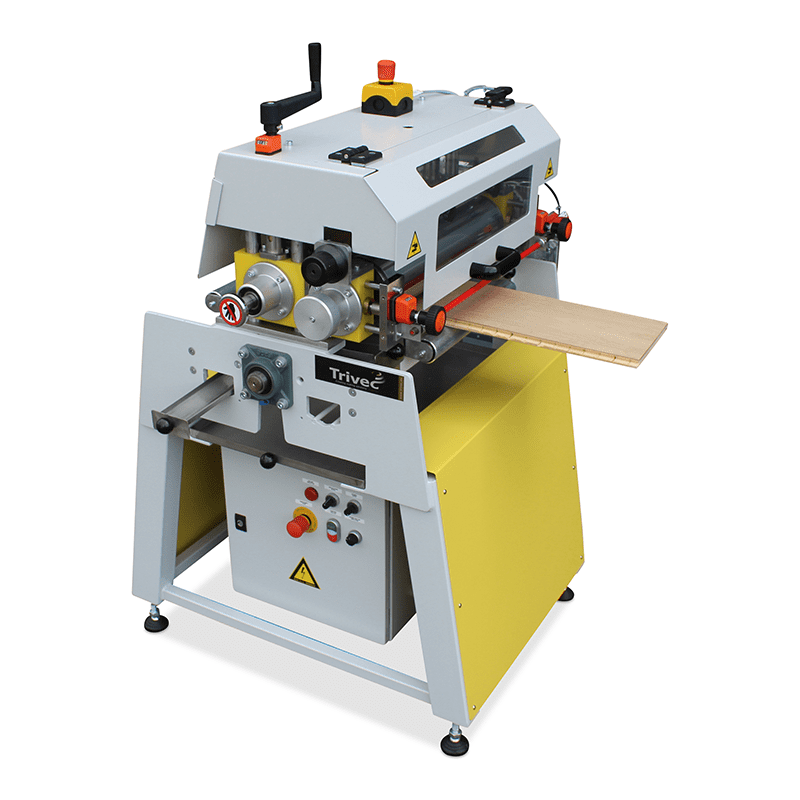

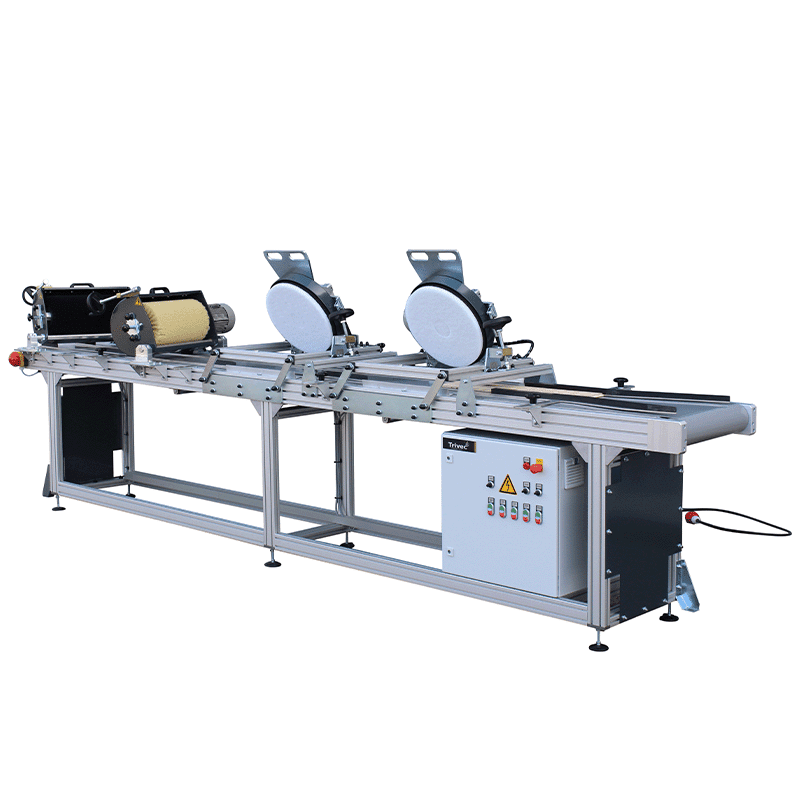

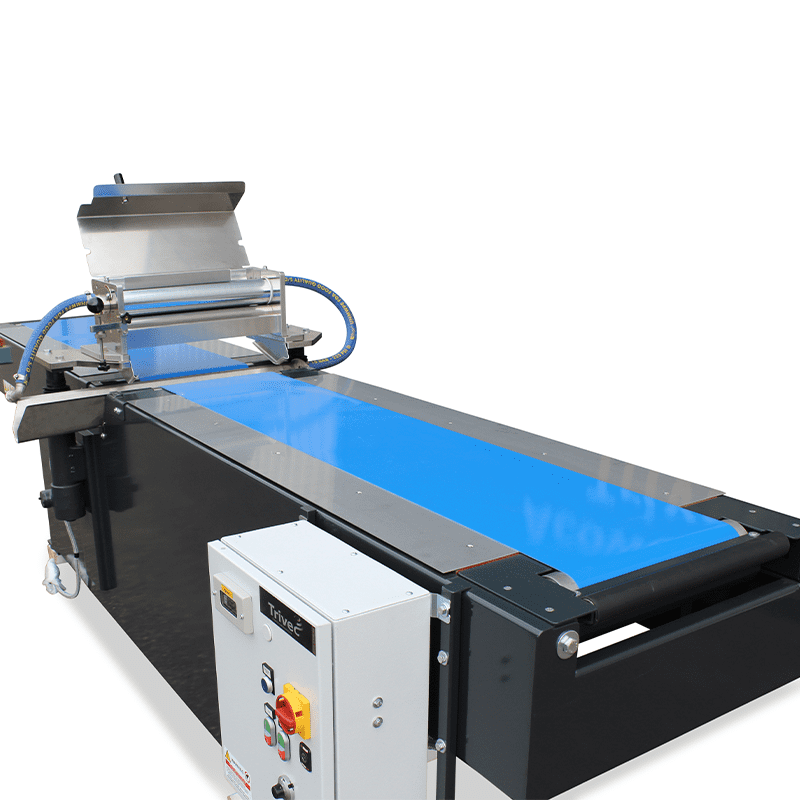

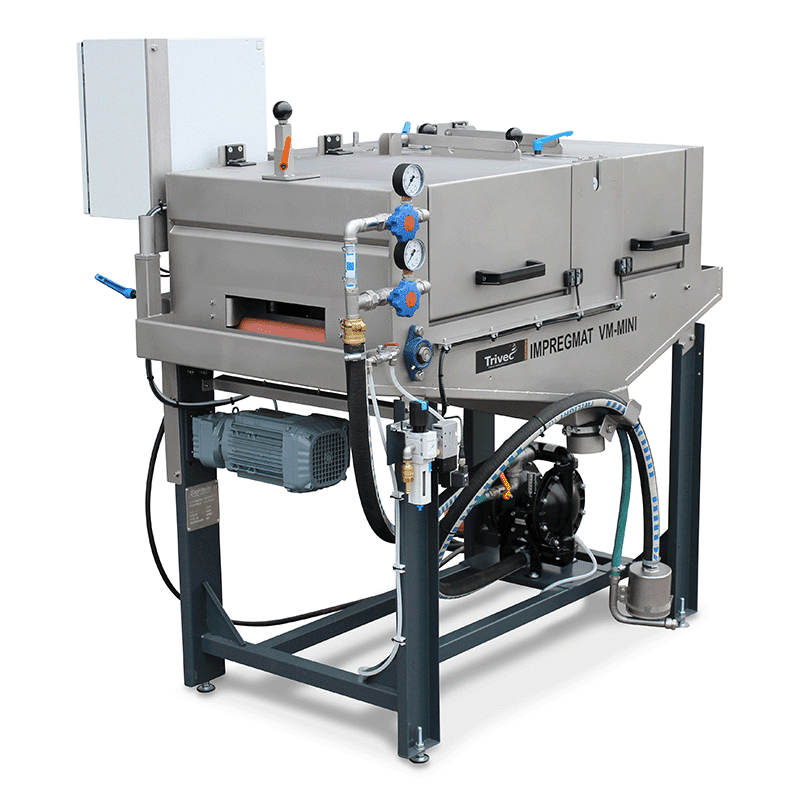

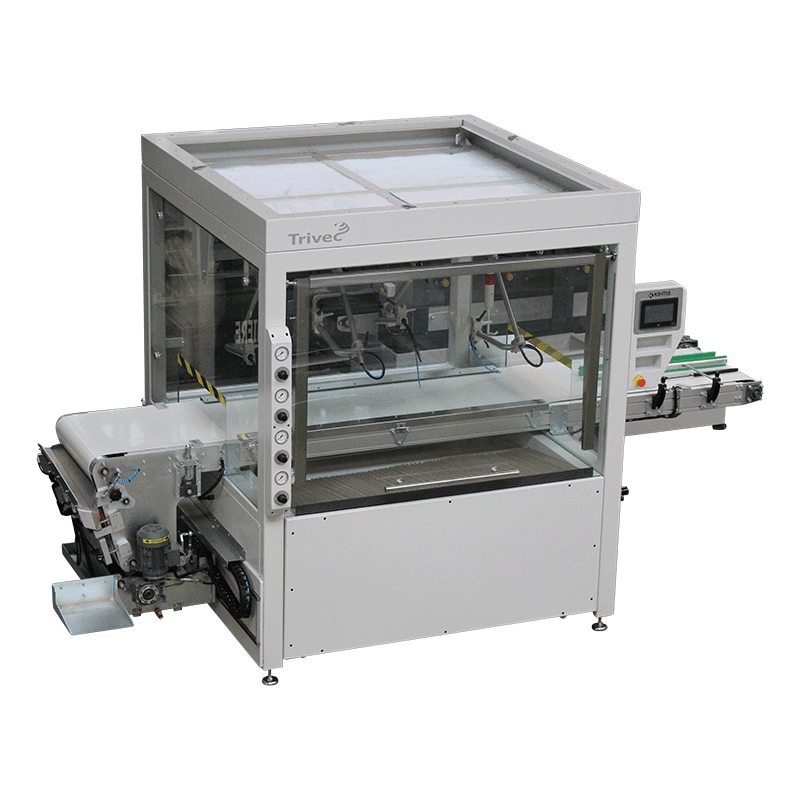

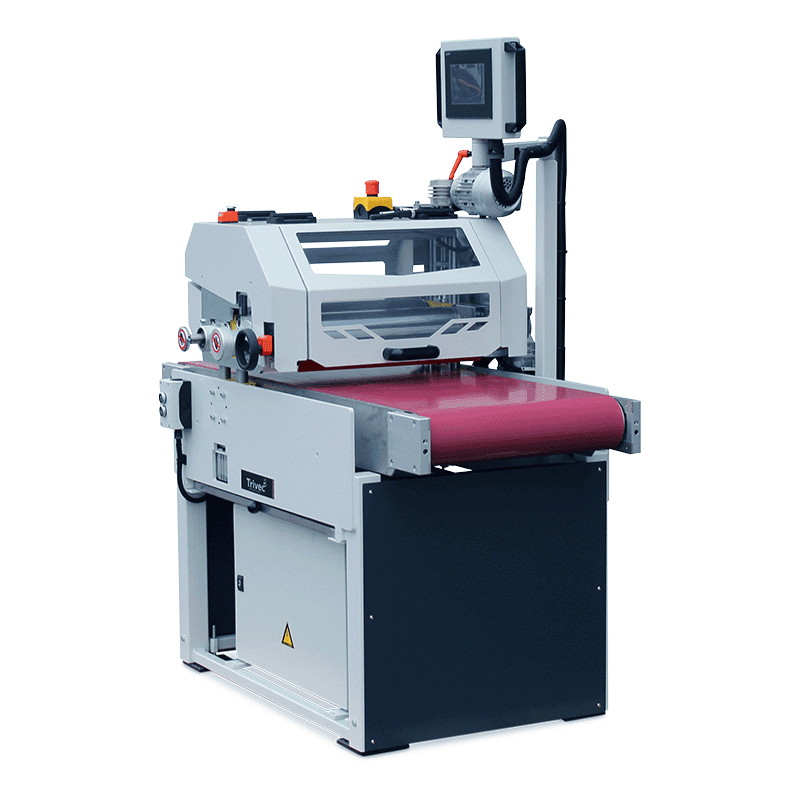

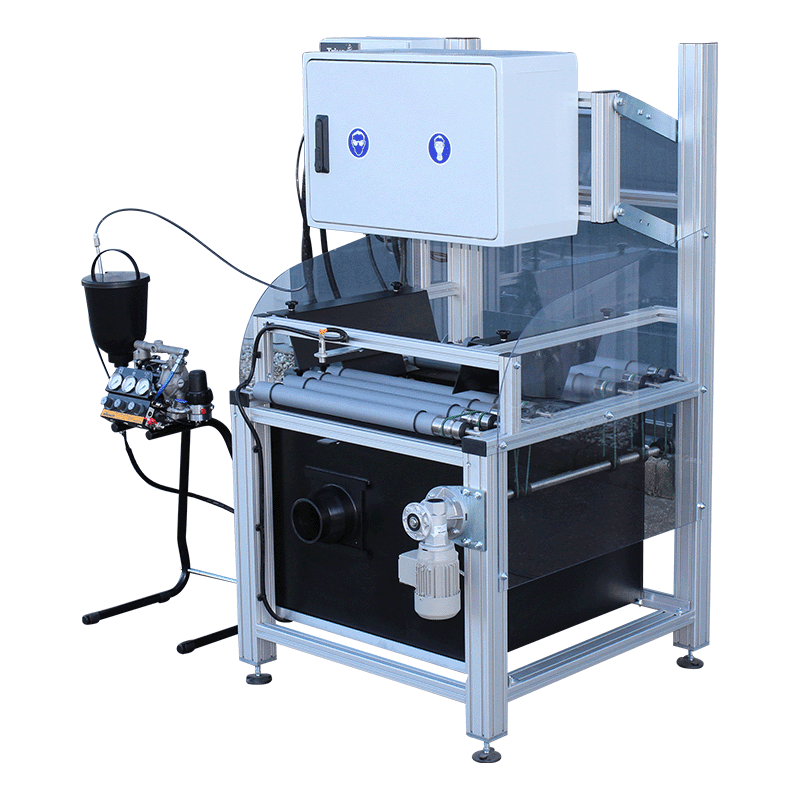

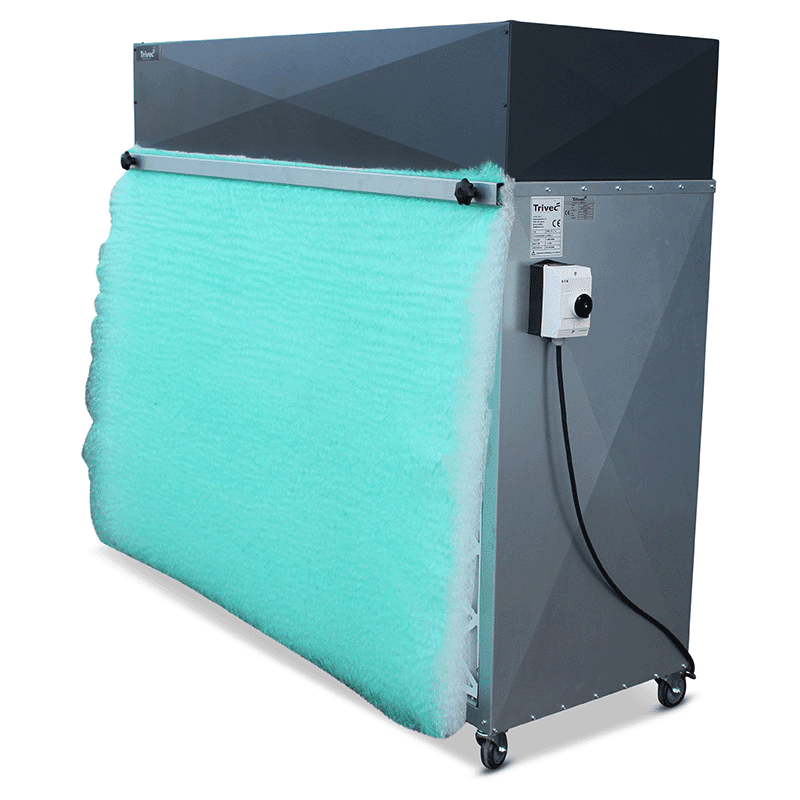

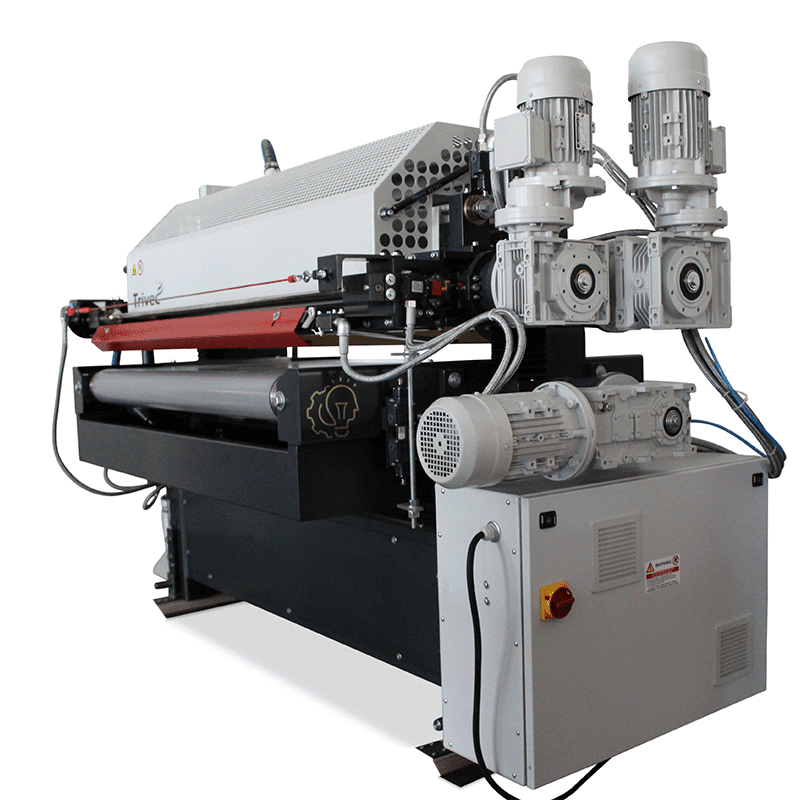

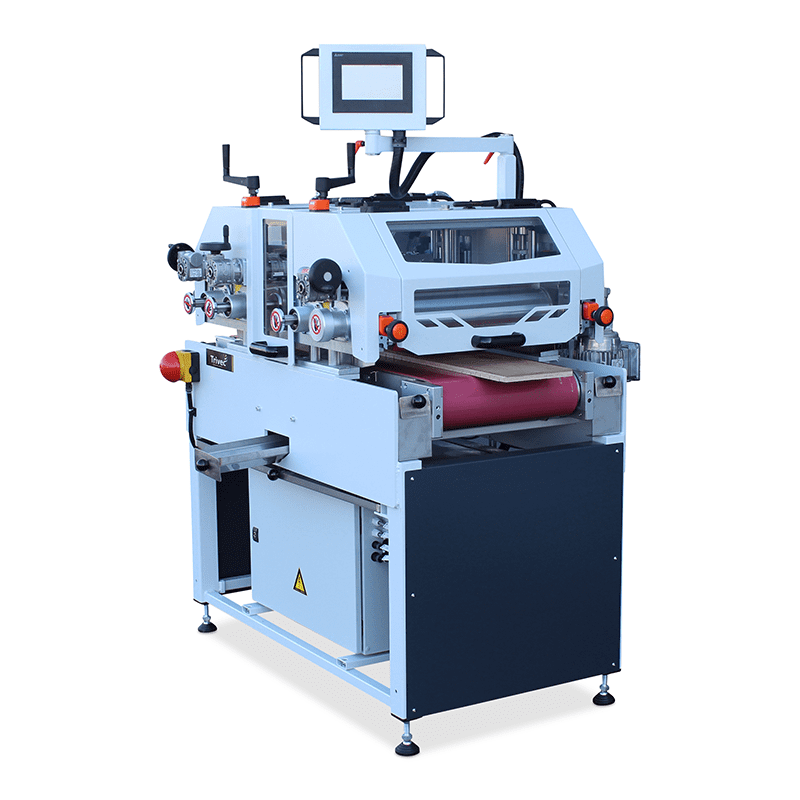

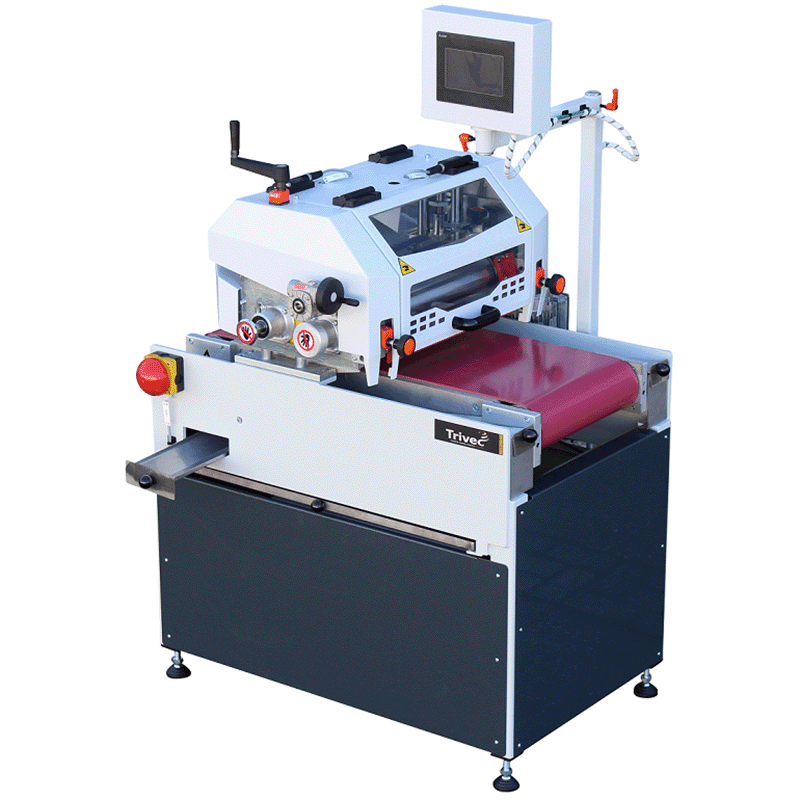

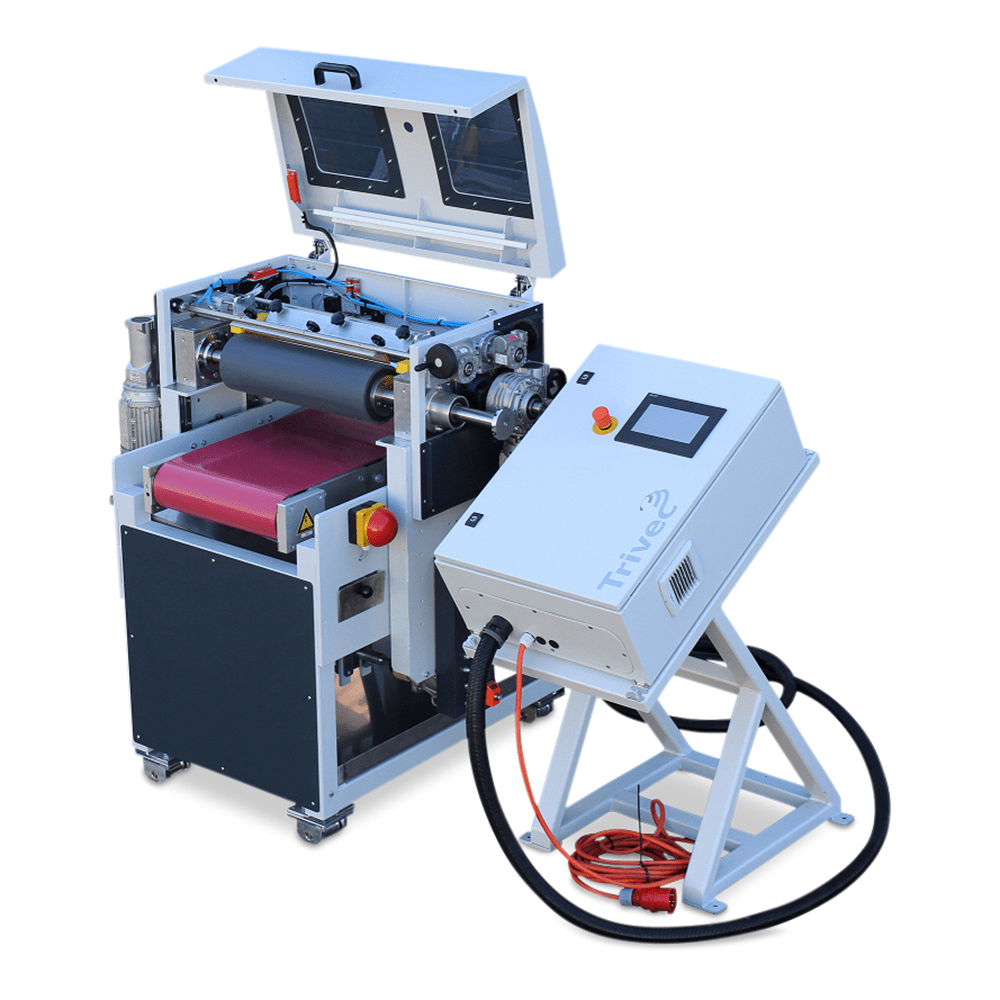

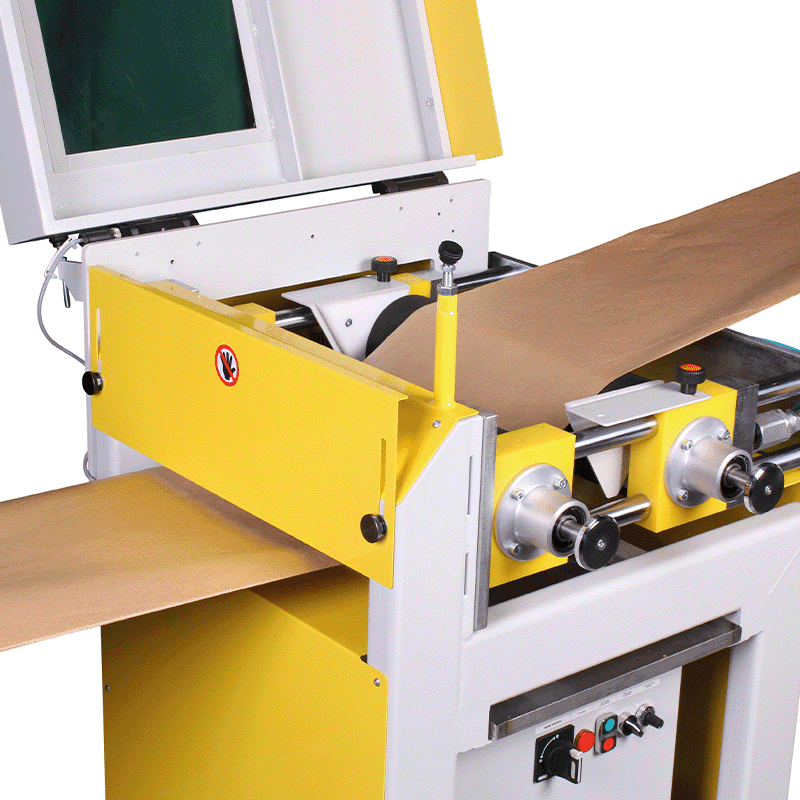

The TTEPS Edge Coater is a high-precision solution for sealing flat or profiled edges of MDF, chipboard, and similar workpieces. Using advanced UV or UV-LED lacquer application, this system ensures consistent results while eliminating overspray, reducing waste, and optimizing production efficiency. Designed for integration, the TTEPS can be seamlessly added to sanding or profiling machines, enabling profiling, sealing, drying, and sanding in a single, efficient passthrough. It is also available as a standalone edge coating and drying unit, providing flexibility for various production setups.

Key features include precise spray technology for targeted edge treatment, fast-drying UV systems, and tool-free maintenance for quick adjustments and color changes. Whether for furniture manufacturing or other industries demanding precise edge sealing, the TTEPS Edge Coater delivers accuracy, efficiency, and reliability.