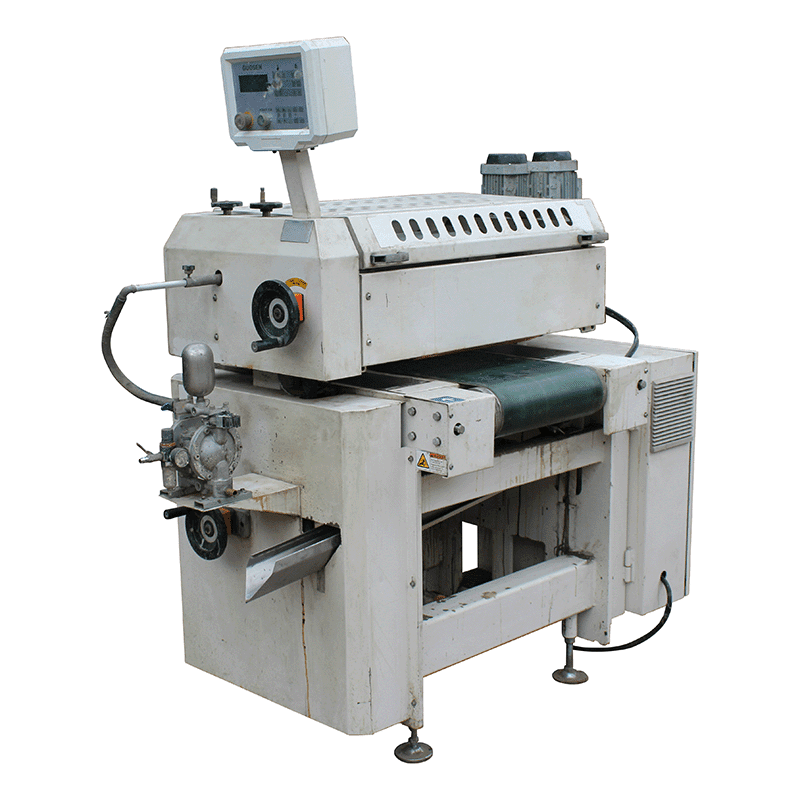

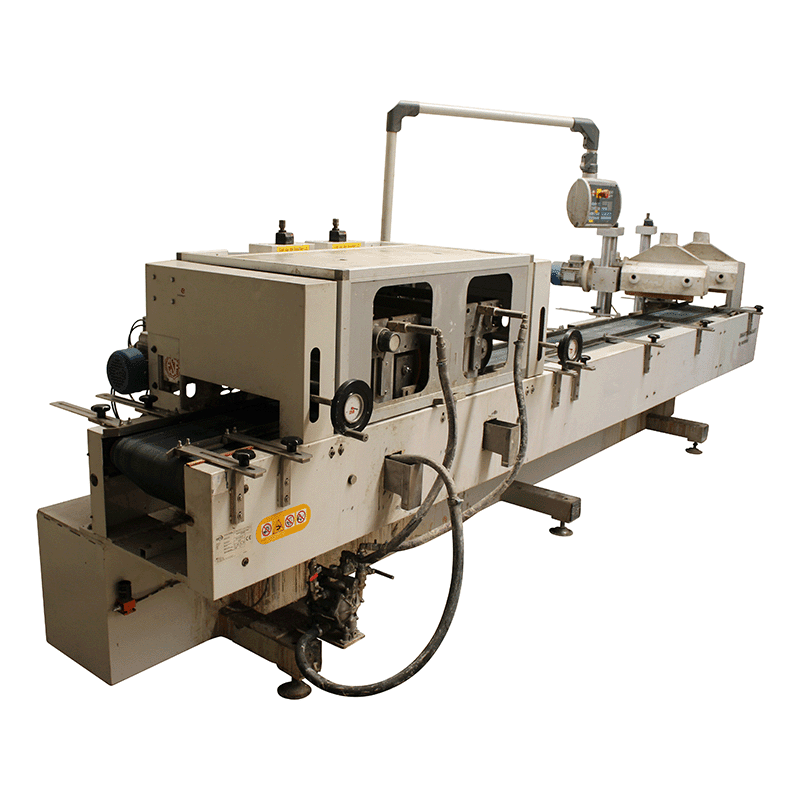

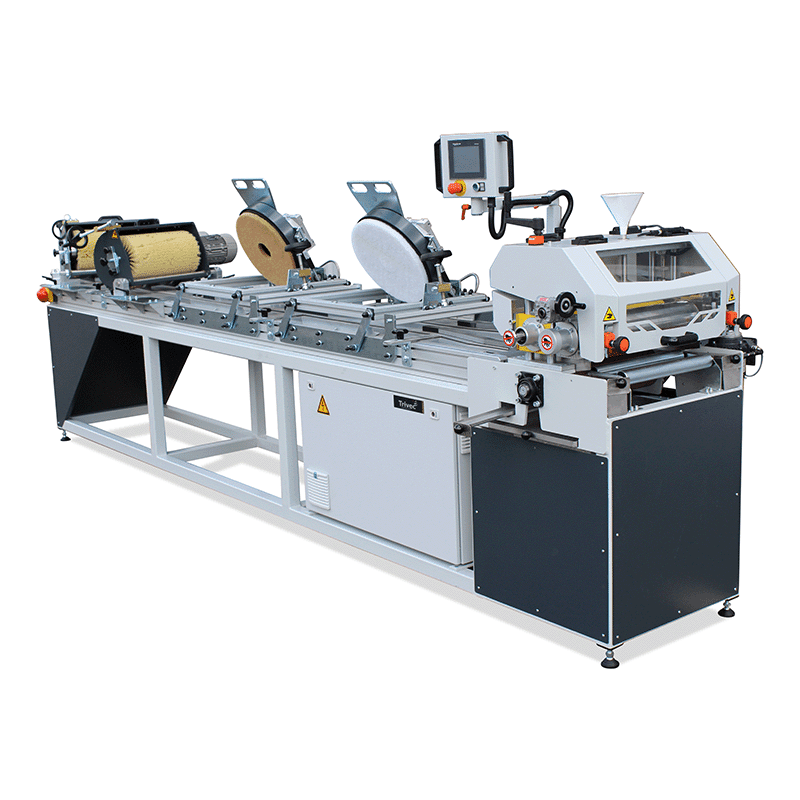

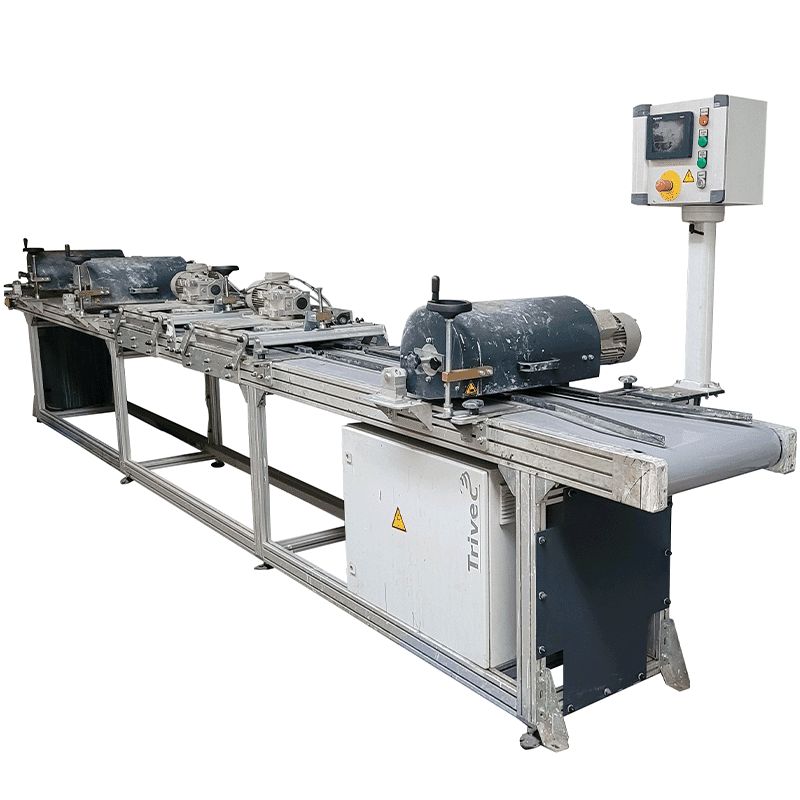

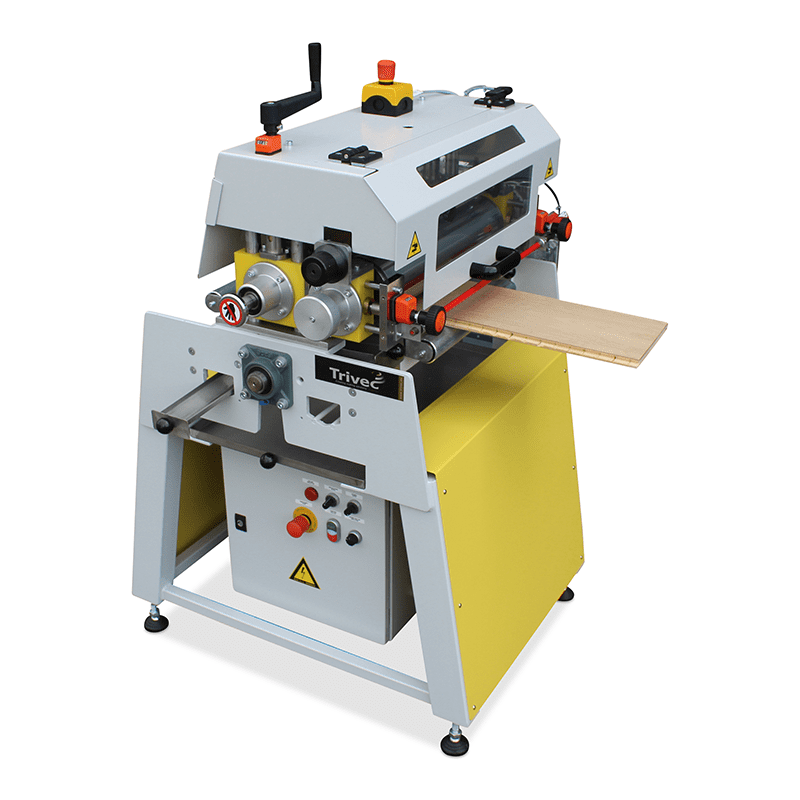

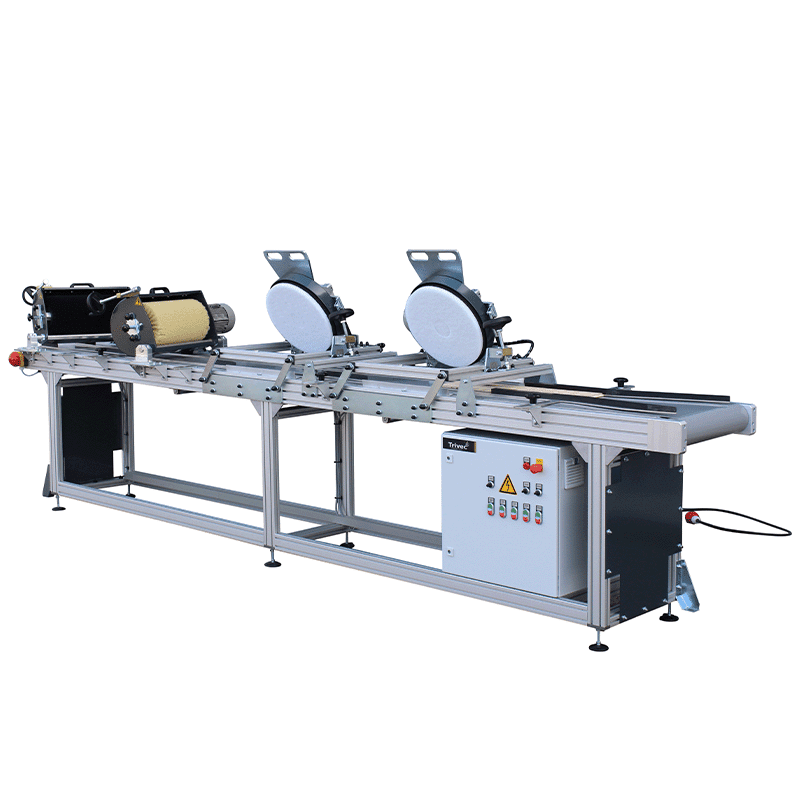

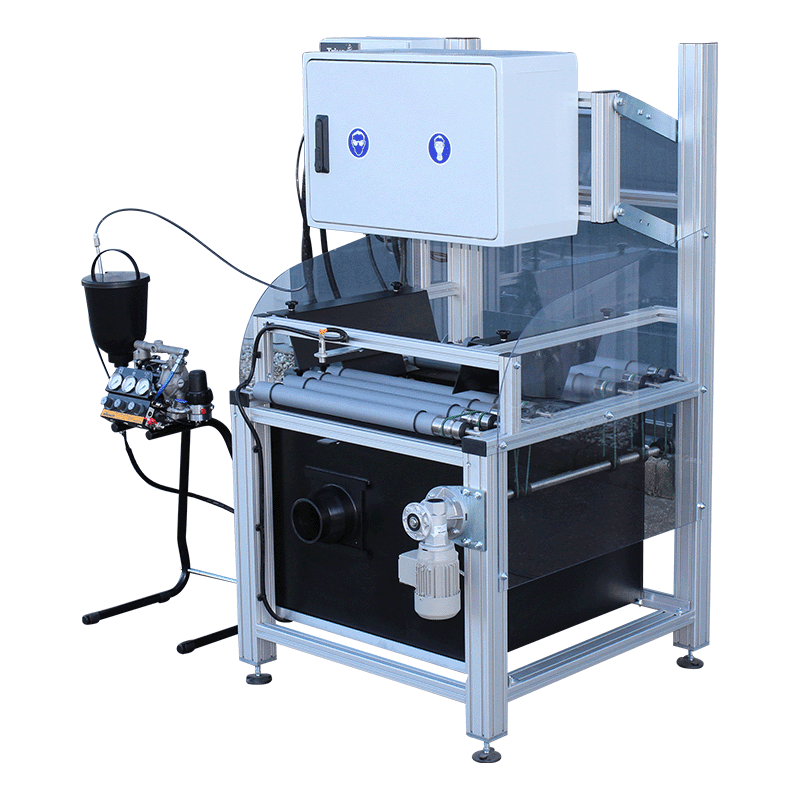

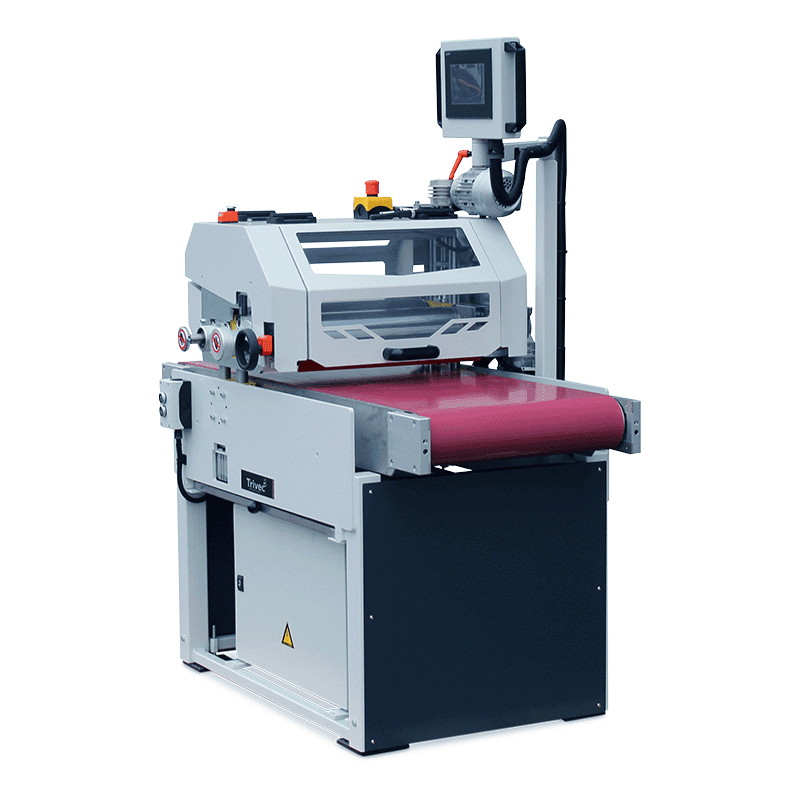

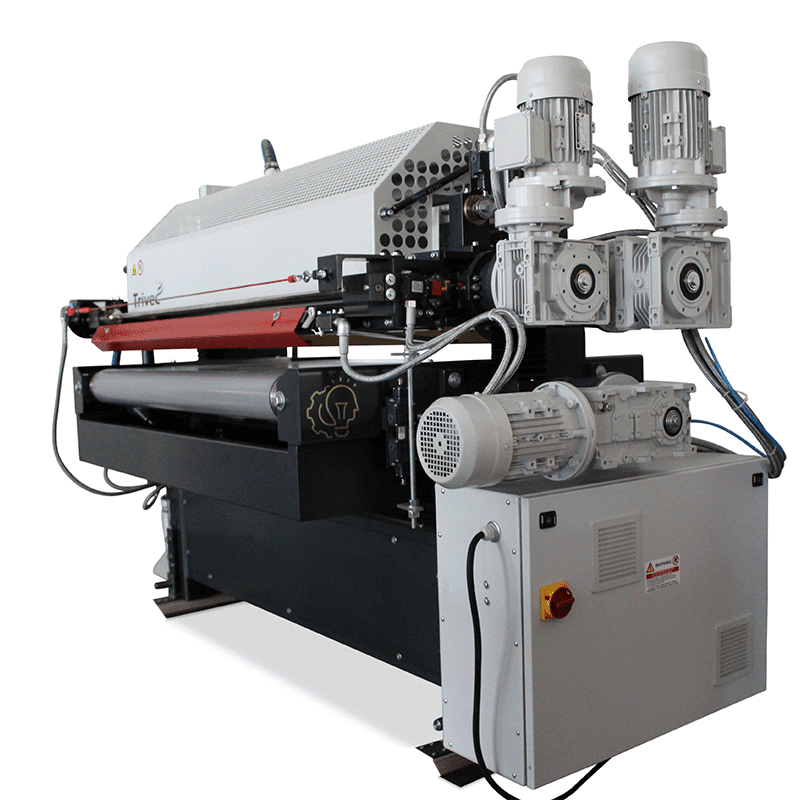

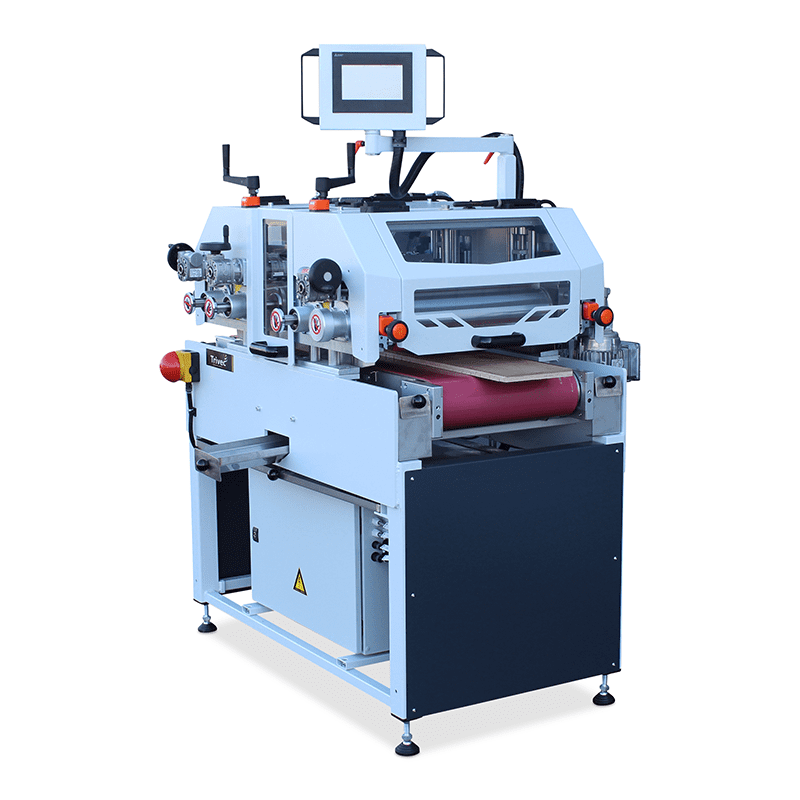

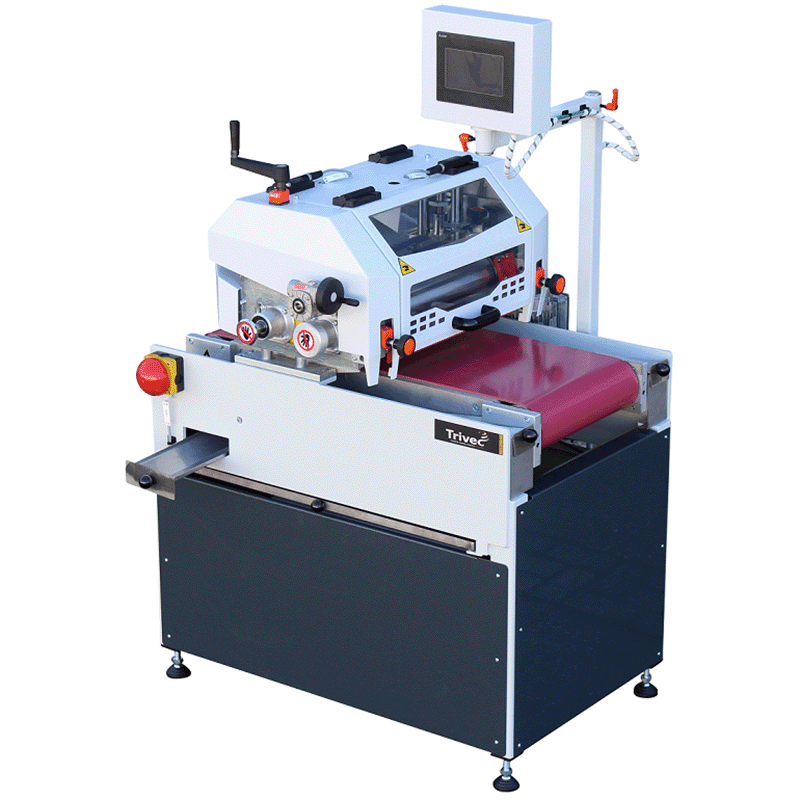

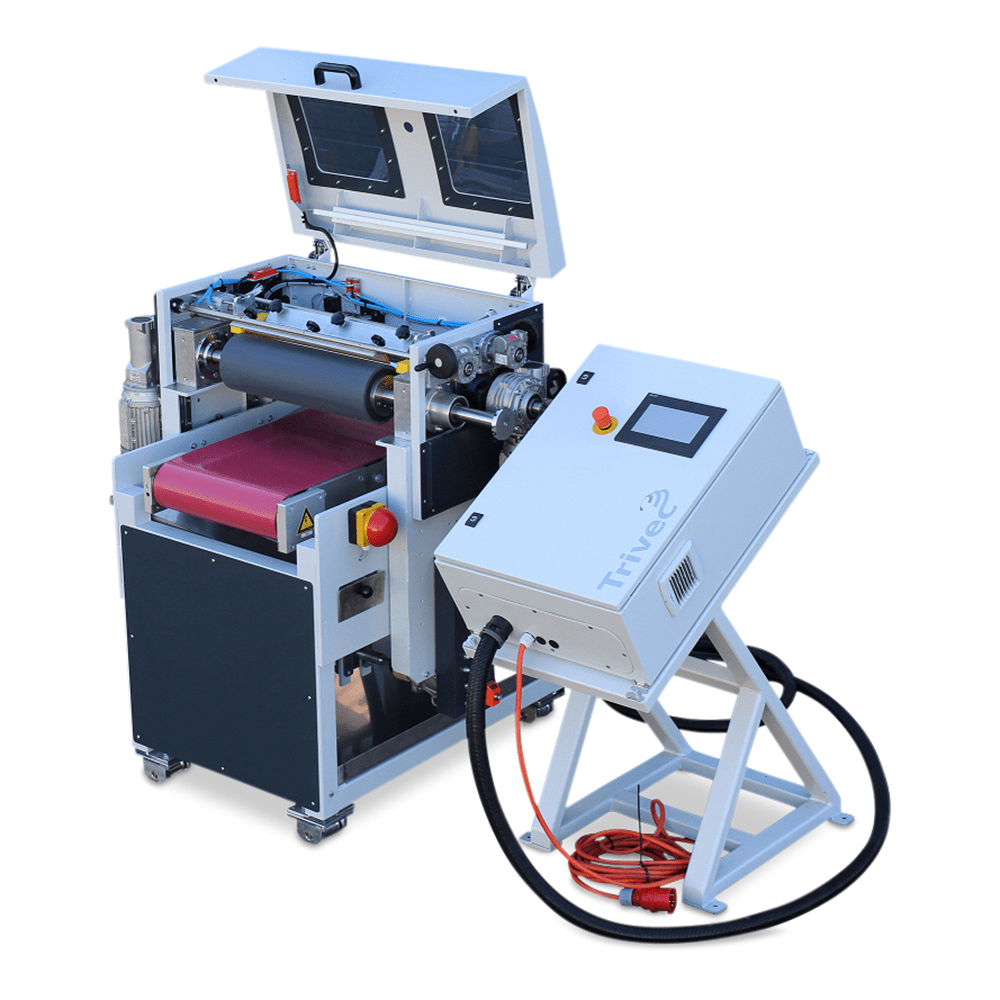

Trivec Vacuum Coating Machine

Efficient, precise, and built for high-throughput four-sided coating.

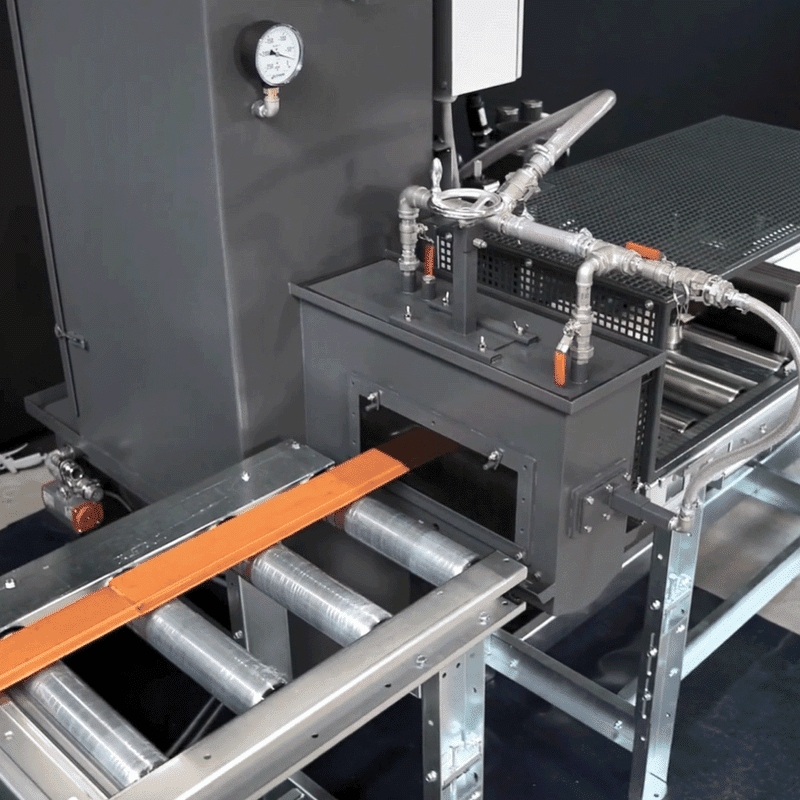

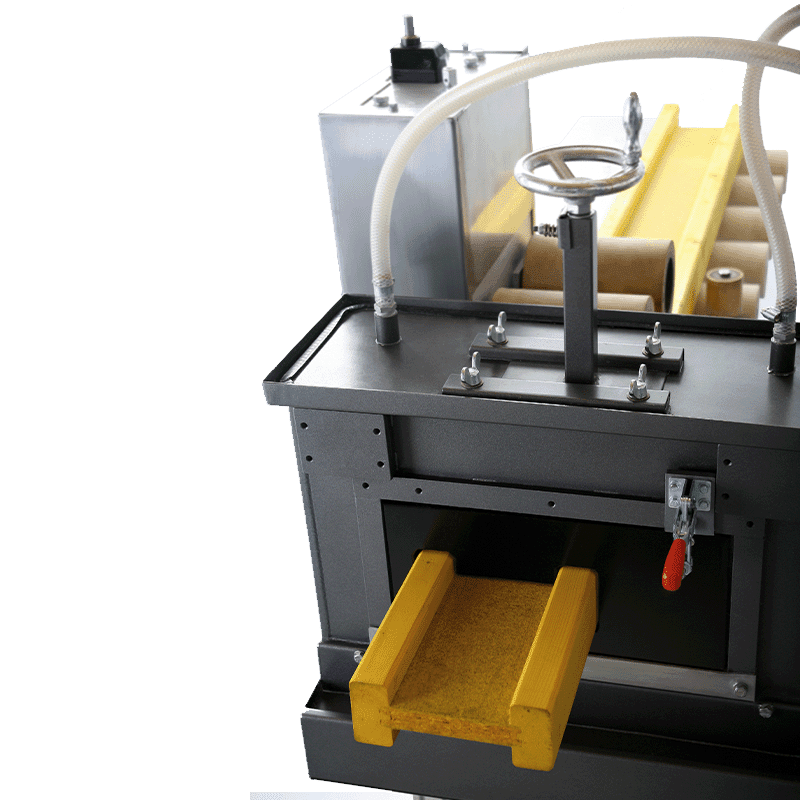

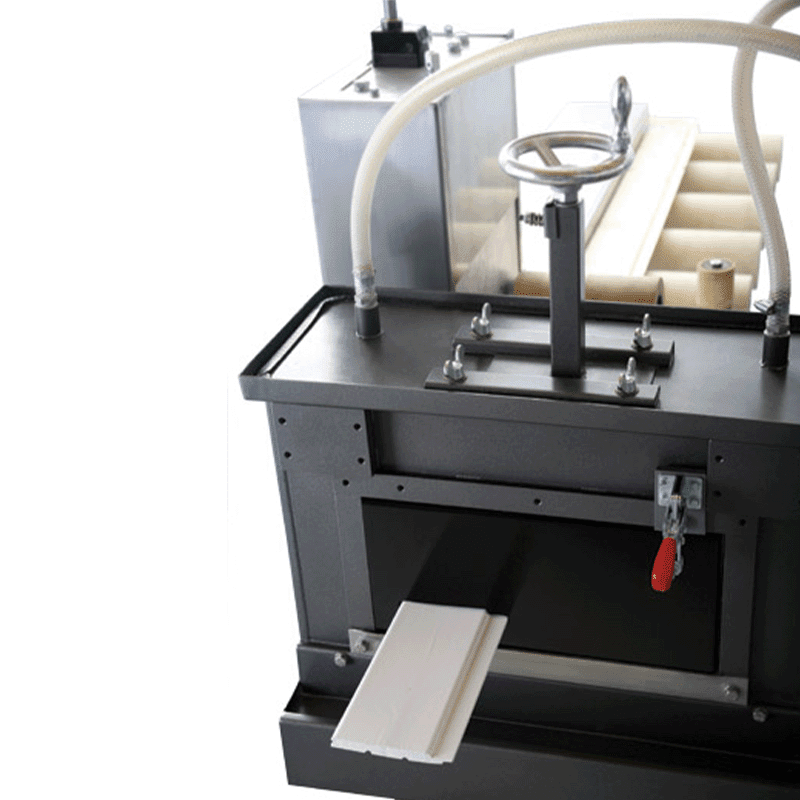

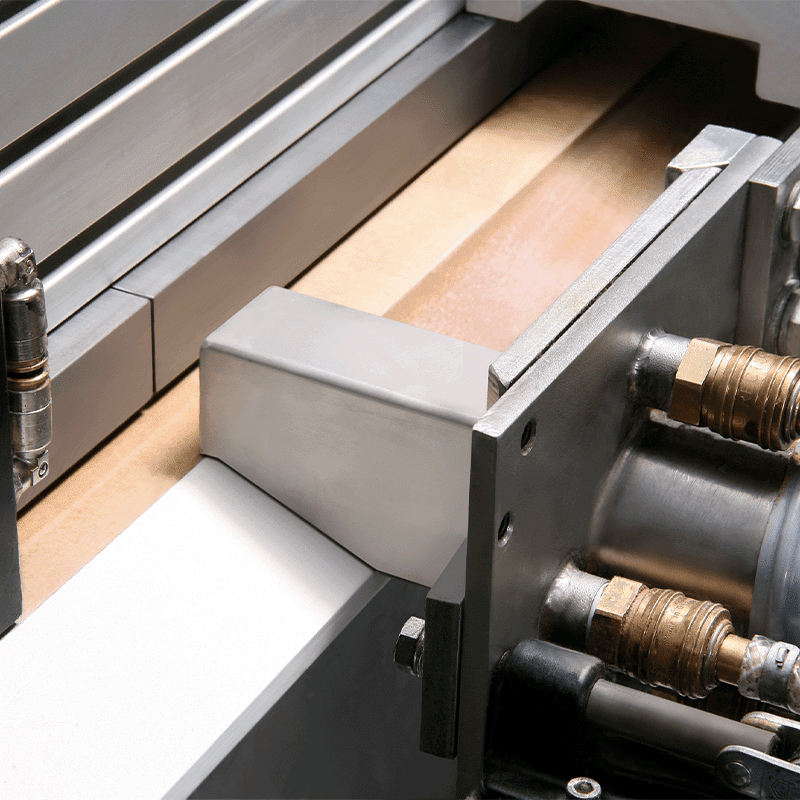

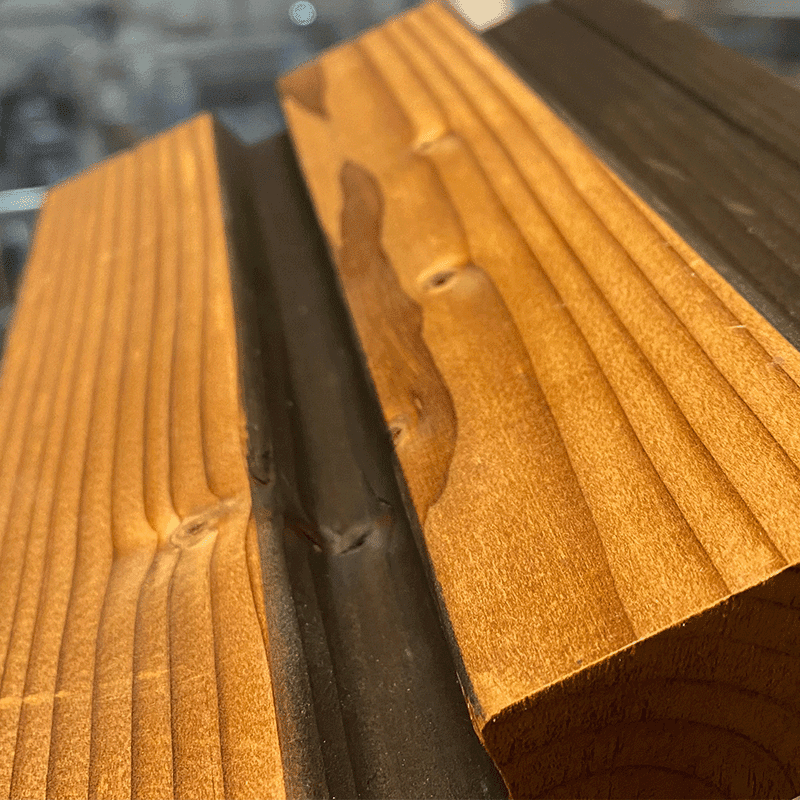

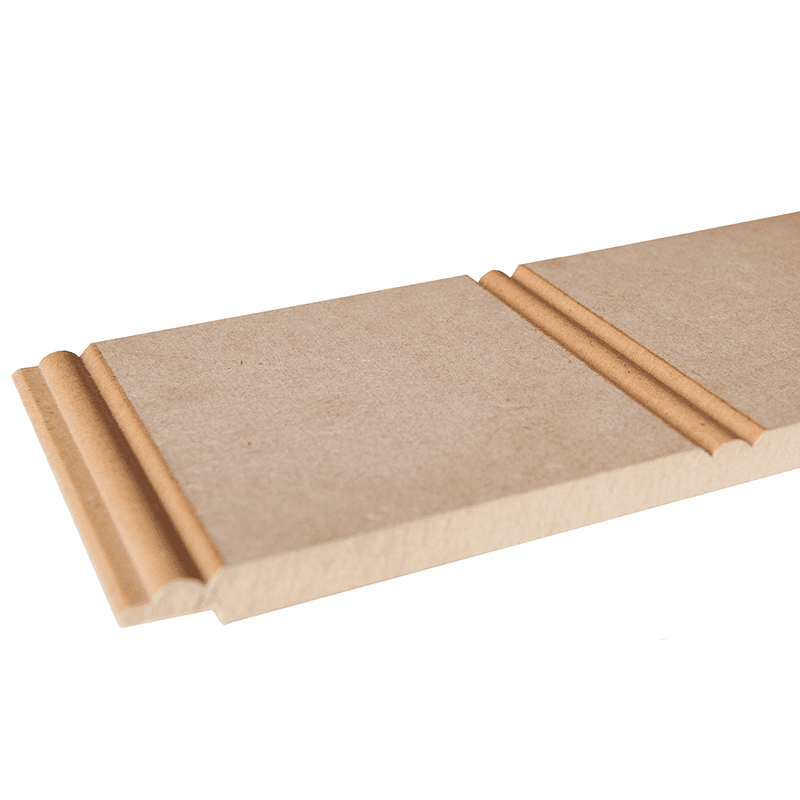

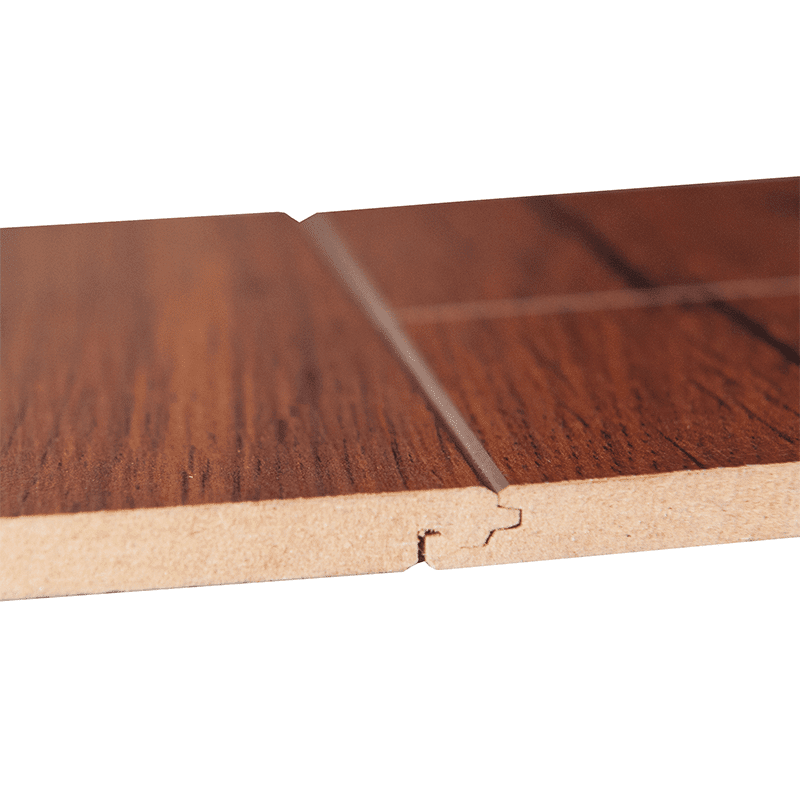

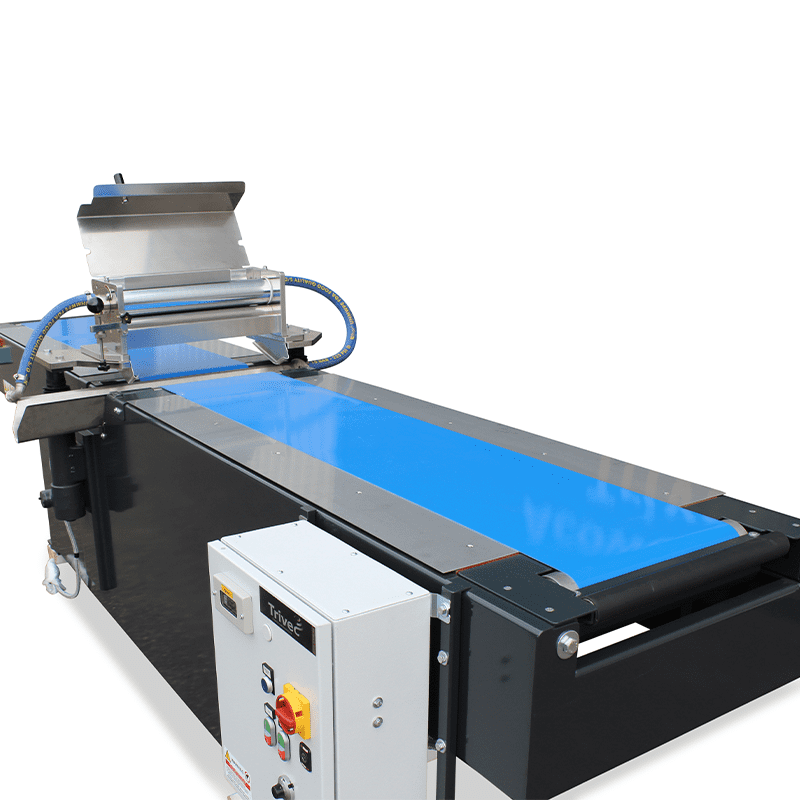

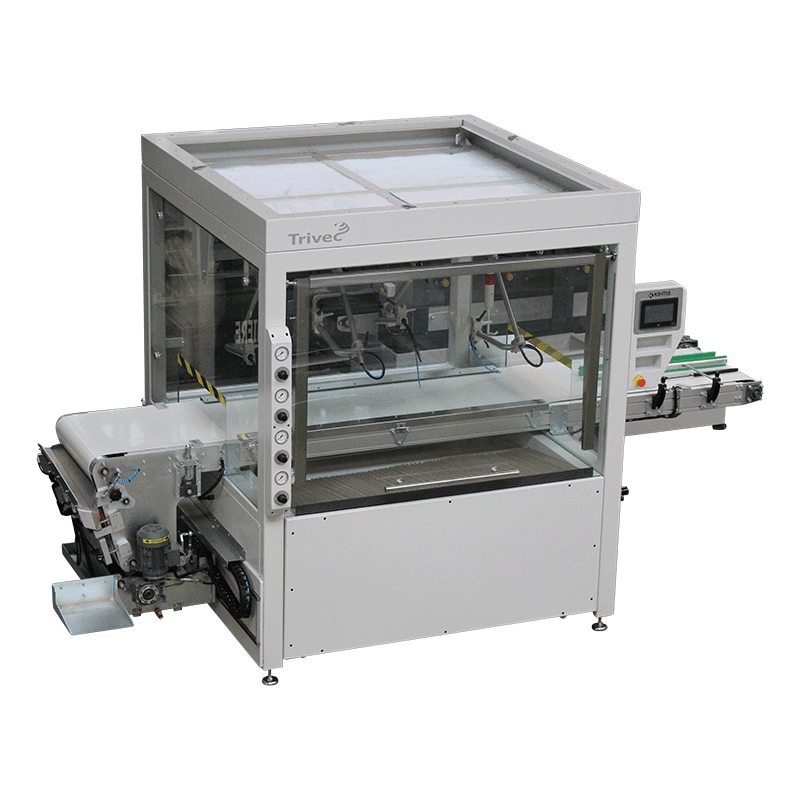

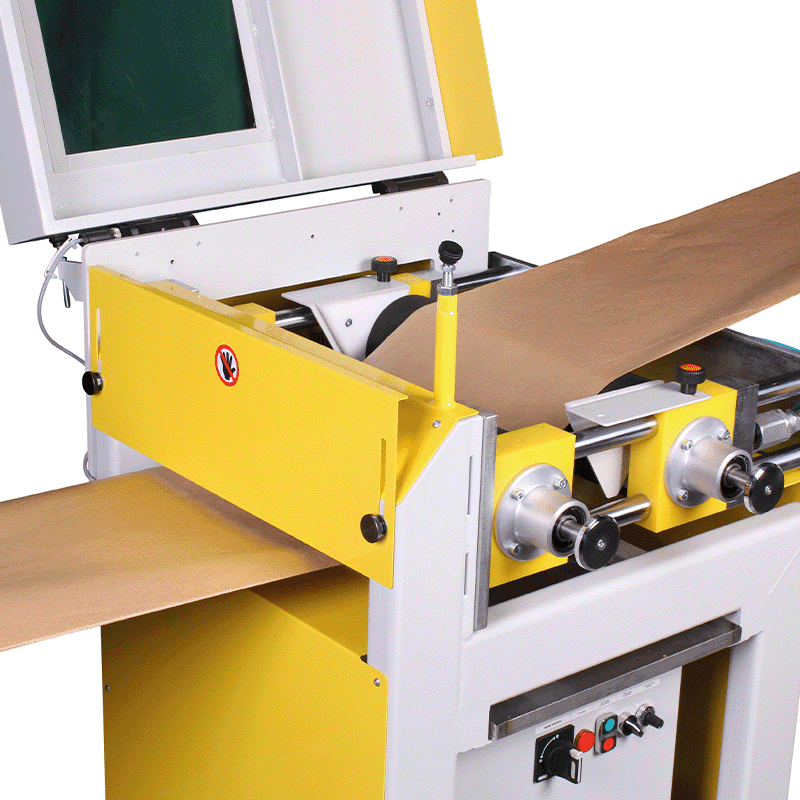

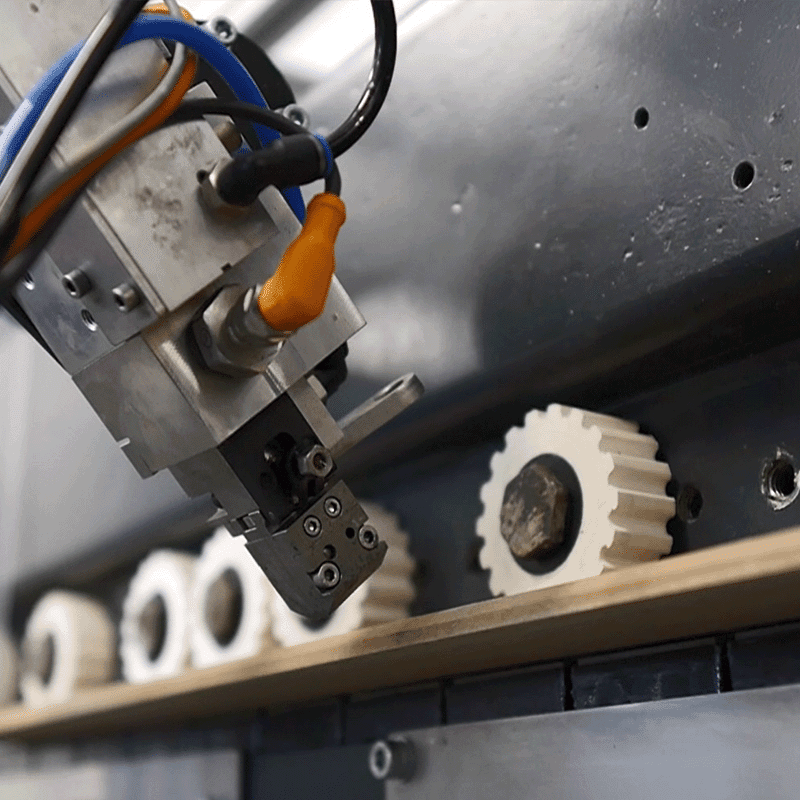

The Trivec Vacuum Coating Machine applies coatings on all four sides of the workpiece in a single pass. An integrated conveyor system ensures consistent feeding and uniform coverage, even on rough, smooth, or detailed profiles.

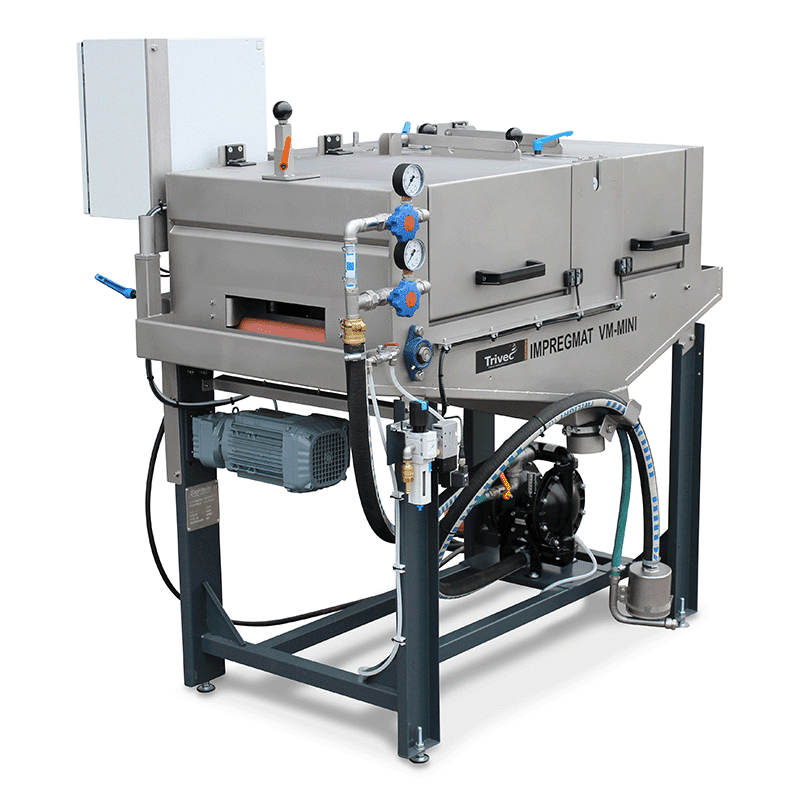

Adjustable parameters—including coating speed, flow rate, and vacuum pressure—allow for precision control and reduce material waste. The machine supports high production speeds of 8–60 m/min or 15–110 m/min (depending on configuration).

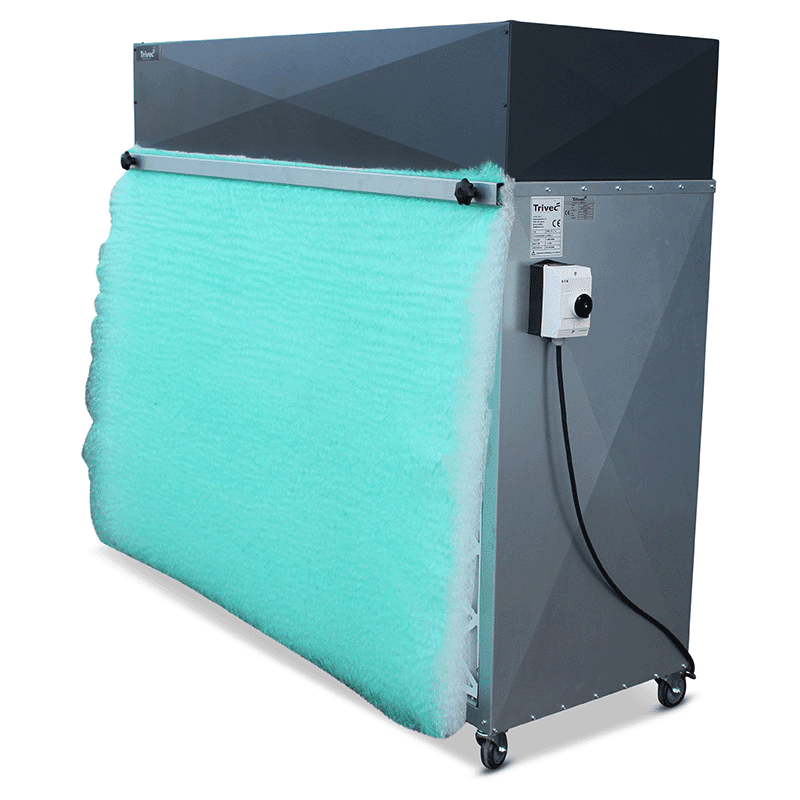

Tool-free maintenance makes cleaning and color changes fast and easy. Optional features include touchscreen control, adjustable feeding systems, and a wet-on-wet configuration for complex finishing requirements.

Designed for industrial use, this machine operates at noise levels below 80 dB(A) and is fully compliant with European CE safety standards.