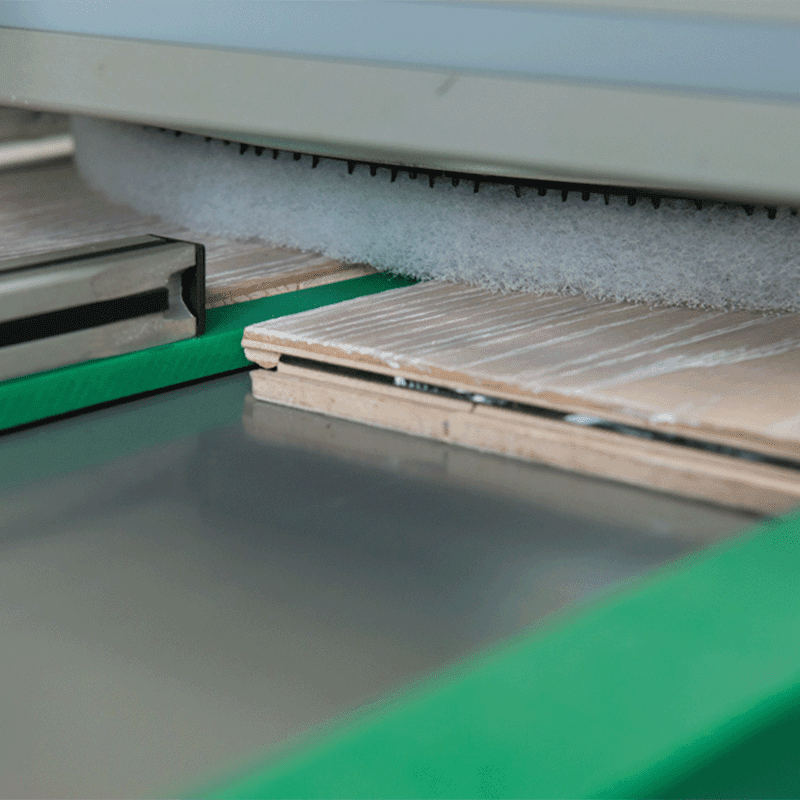

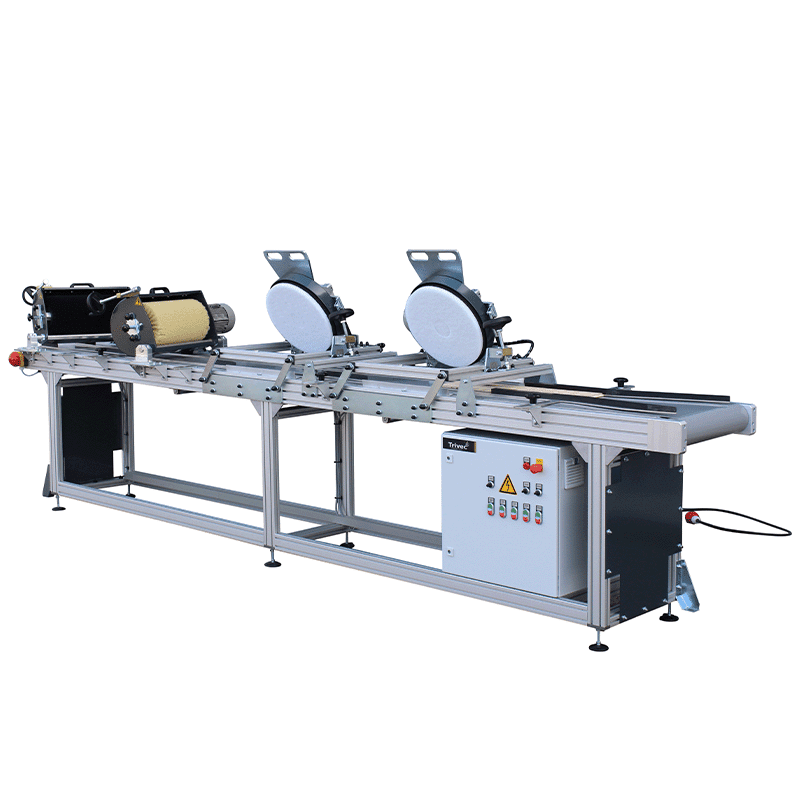

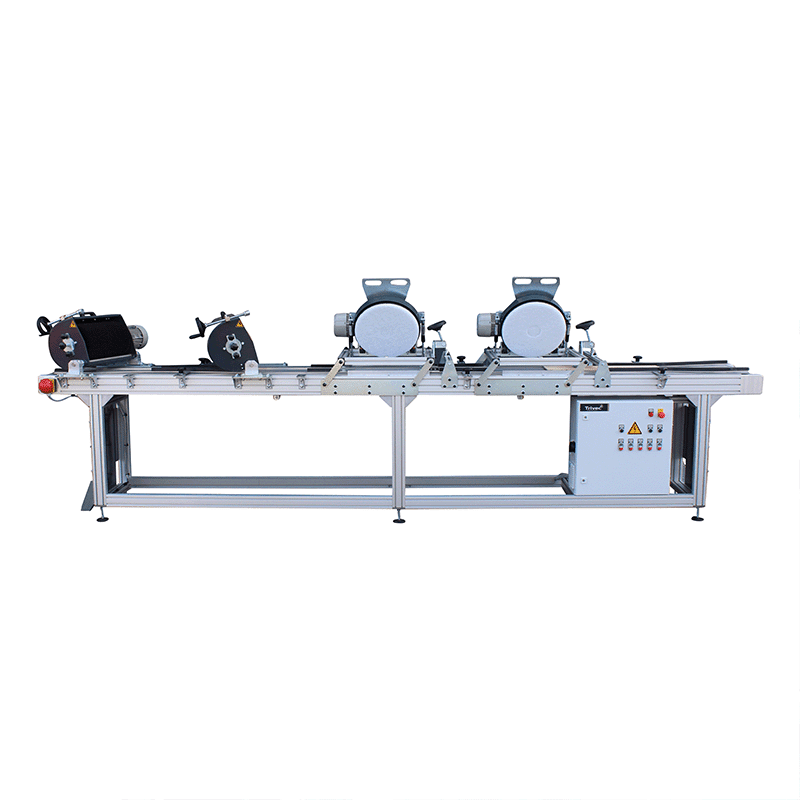

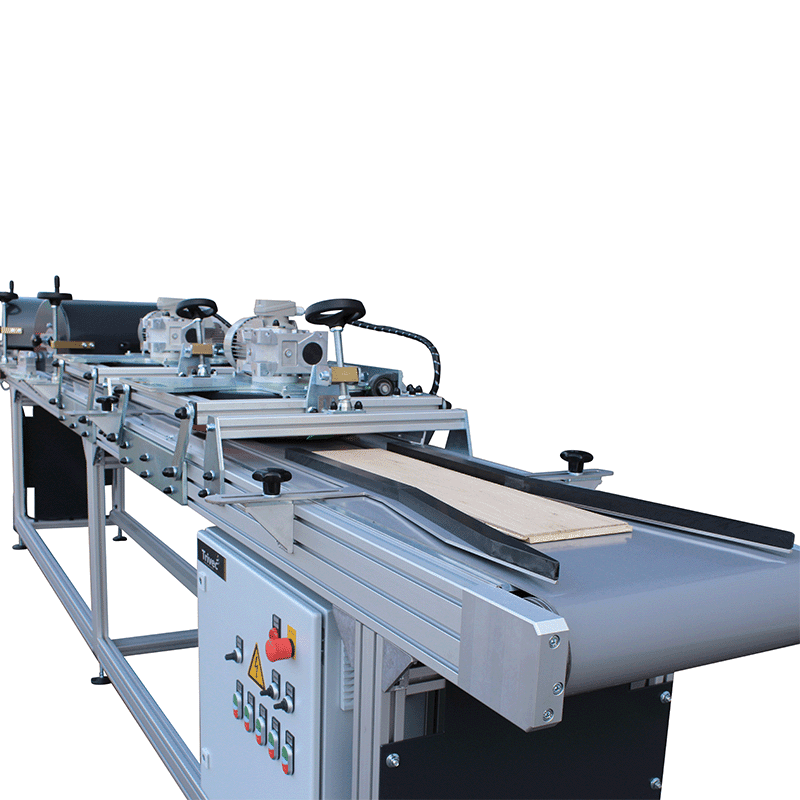

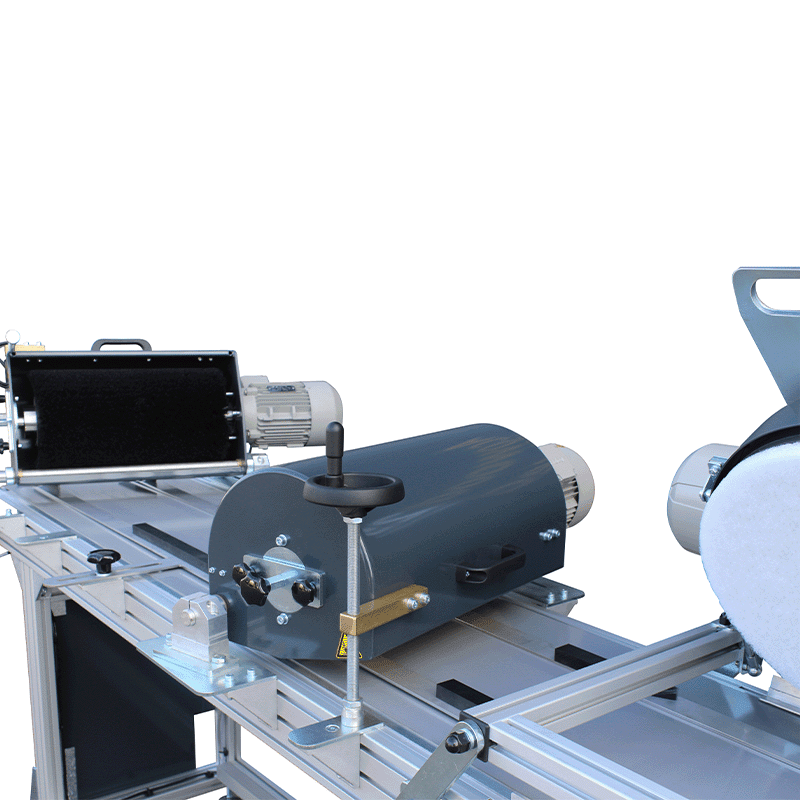

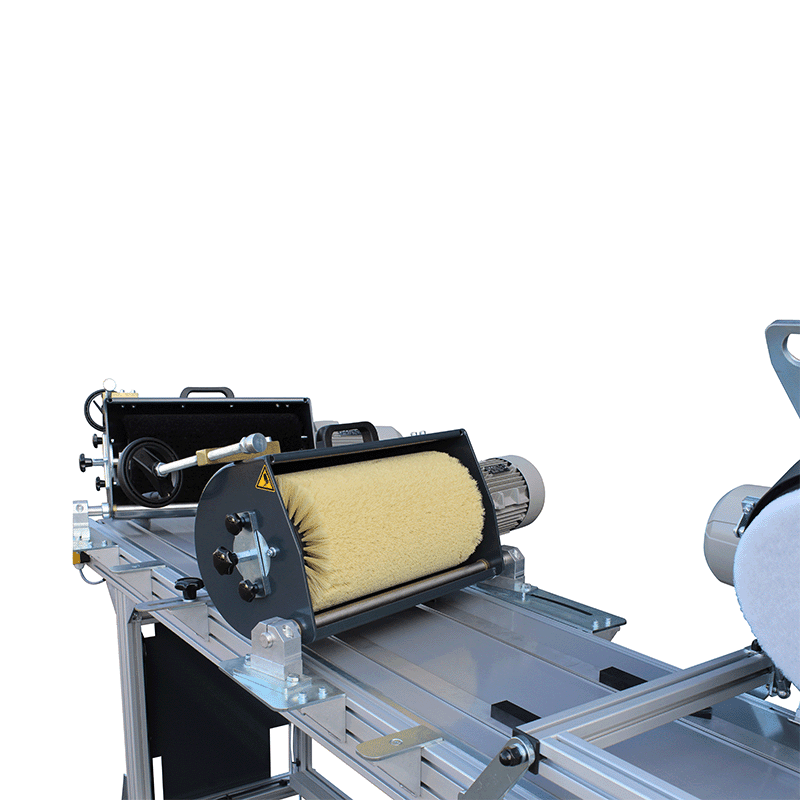

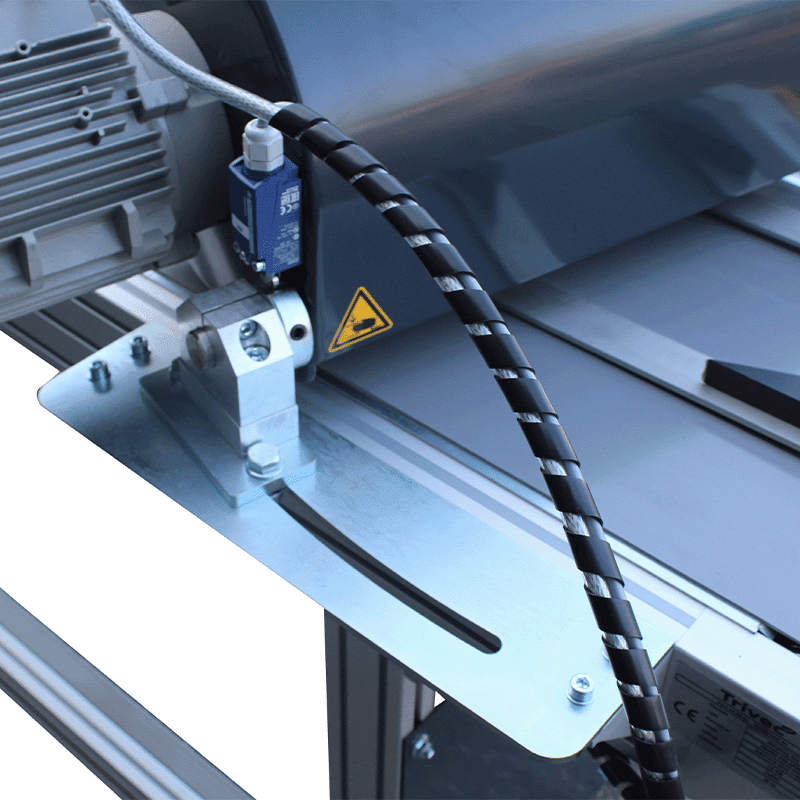

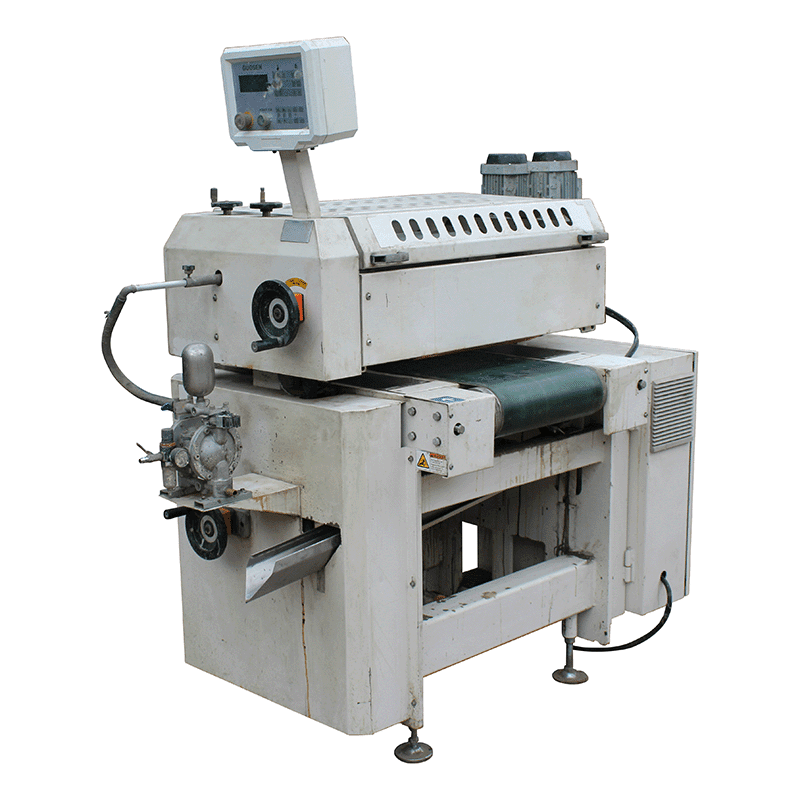

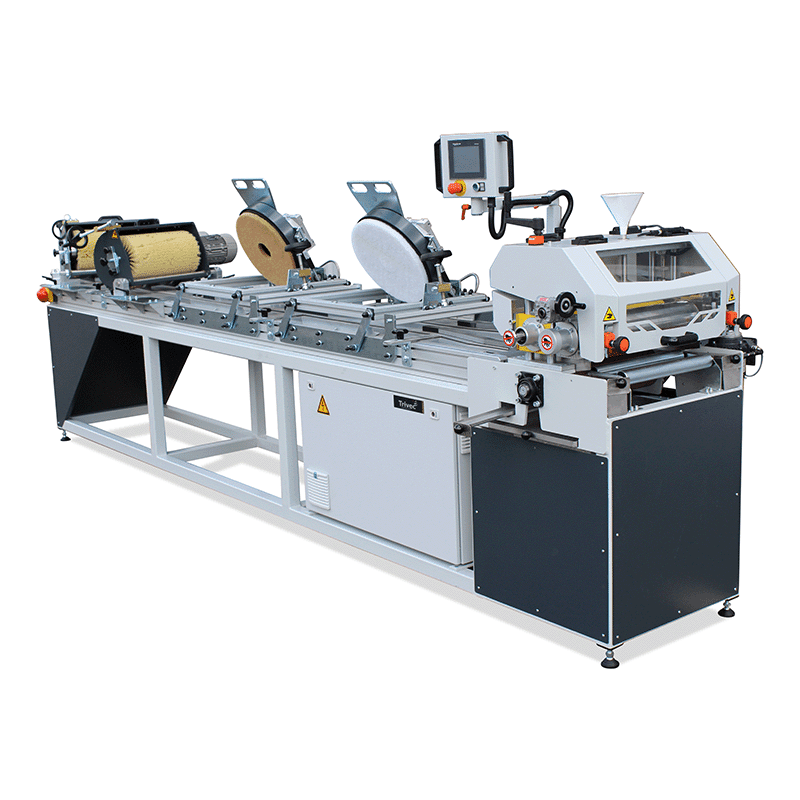

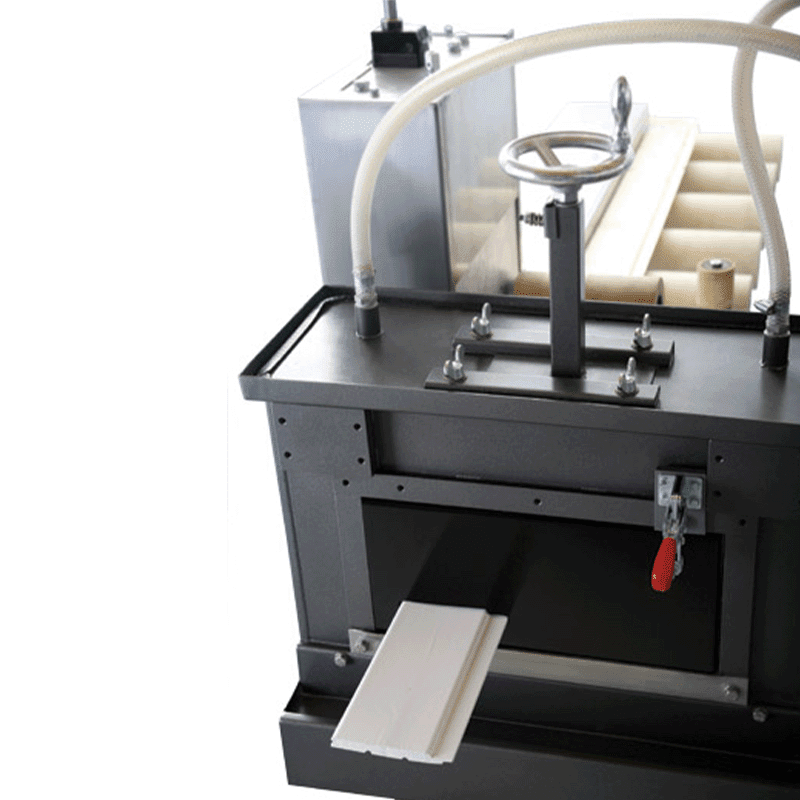

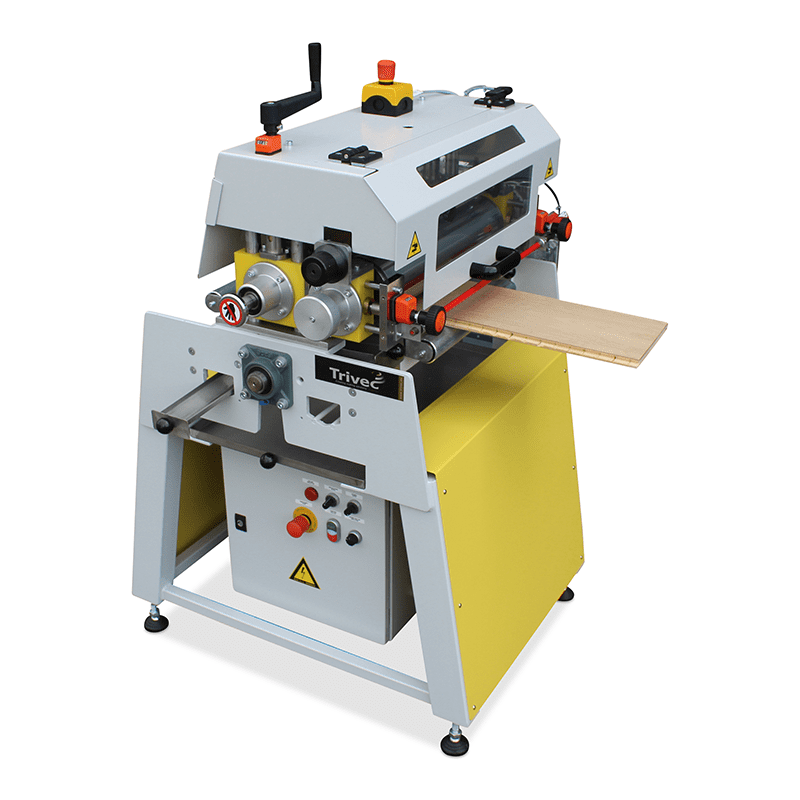

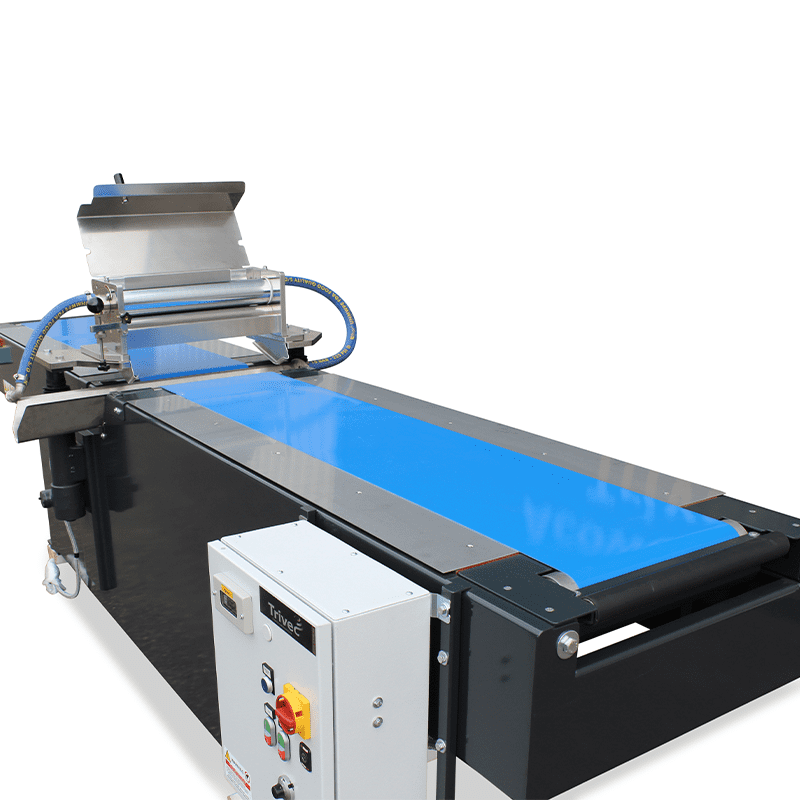

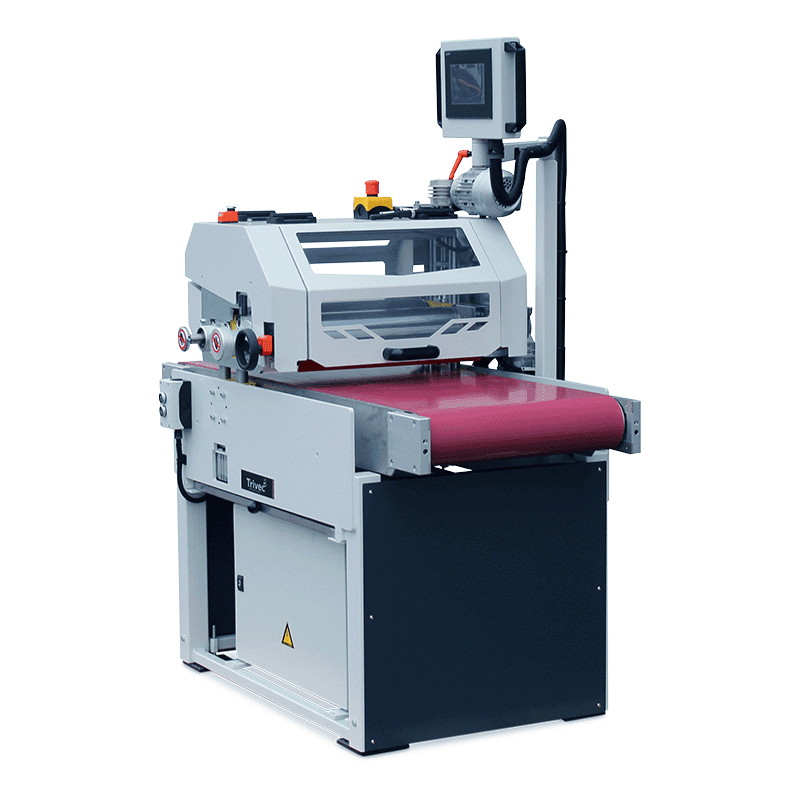

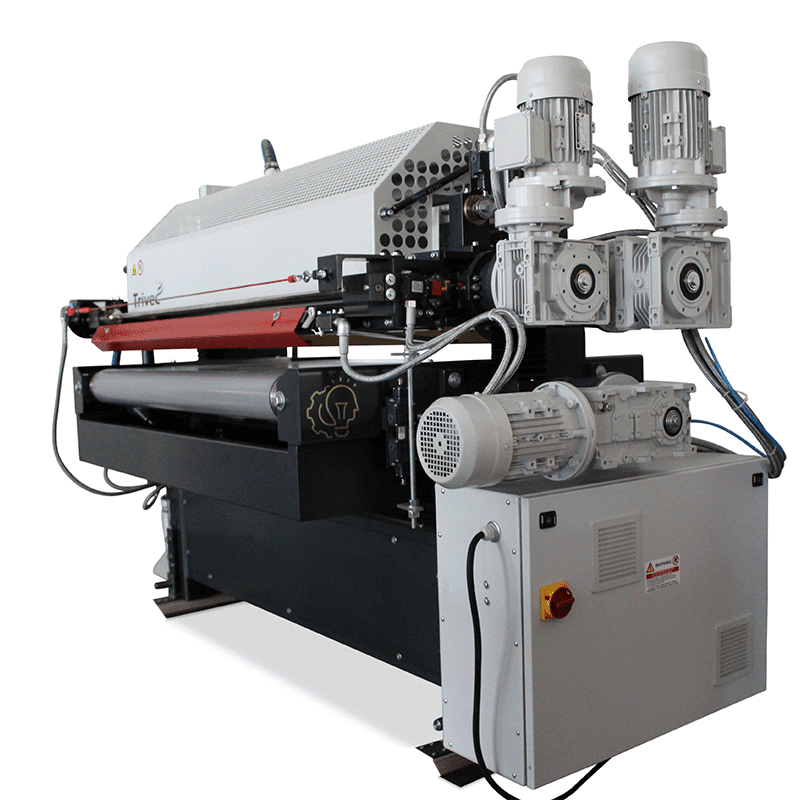

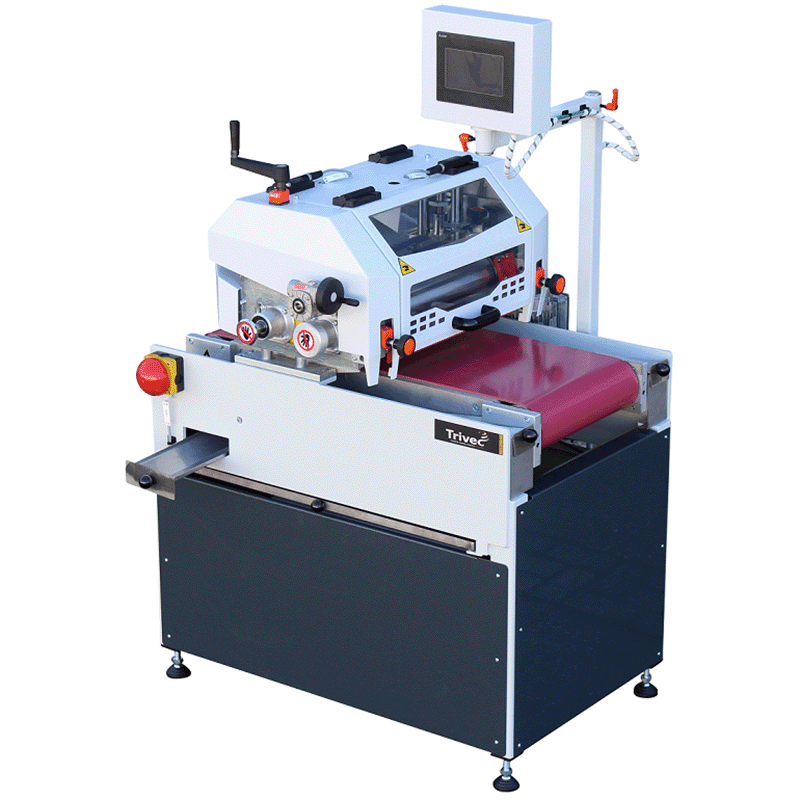

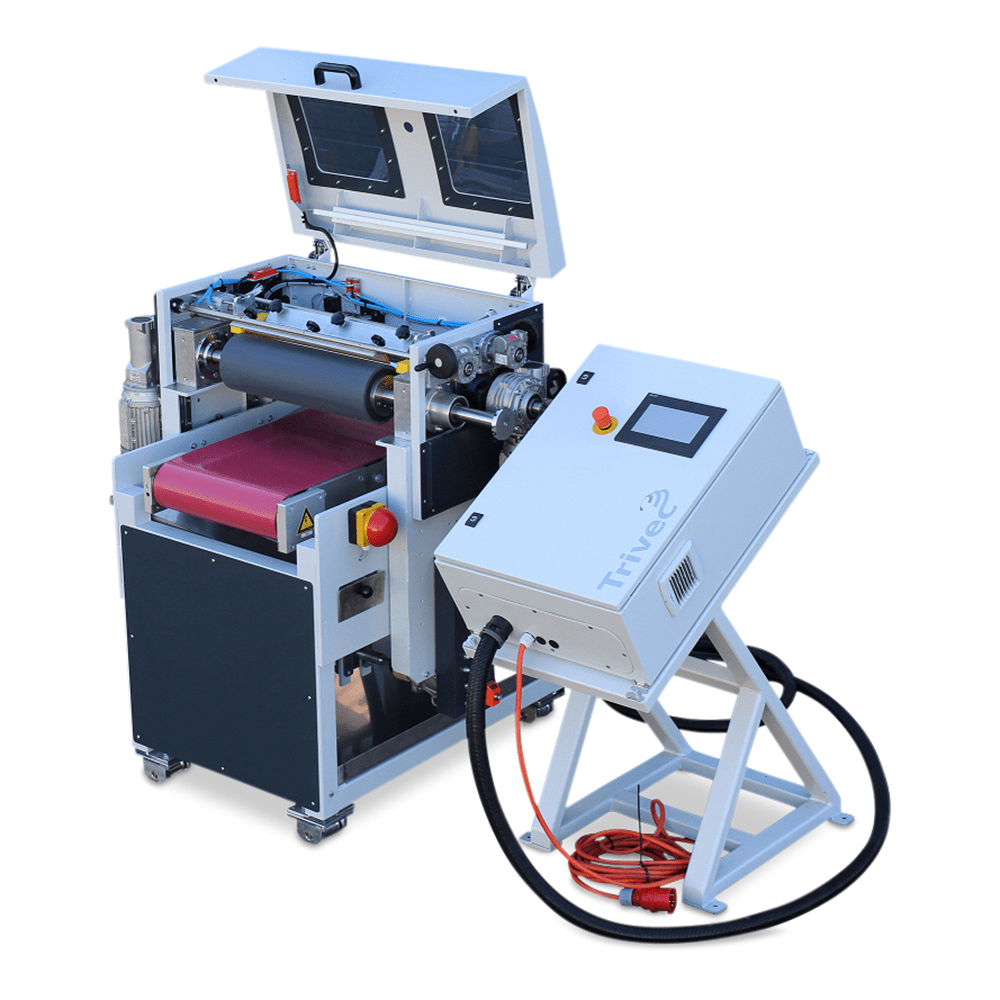

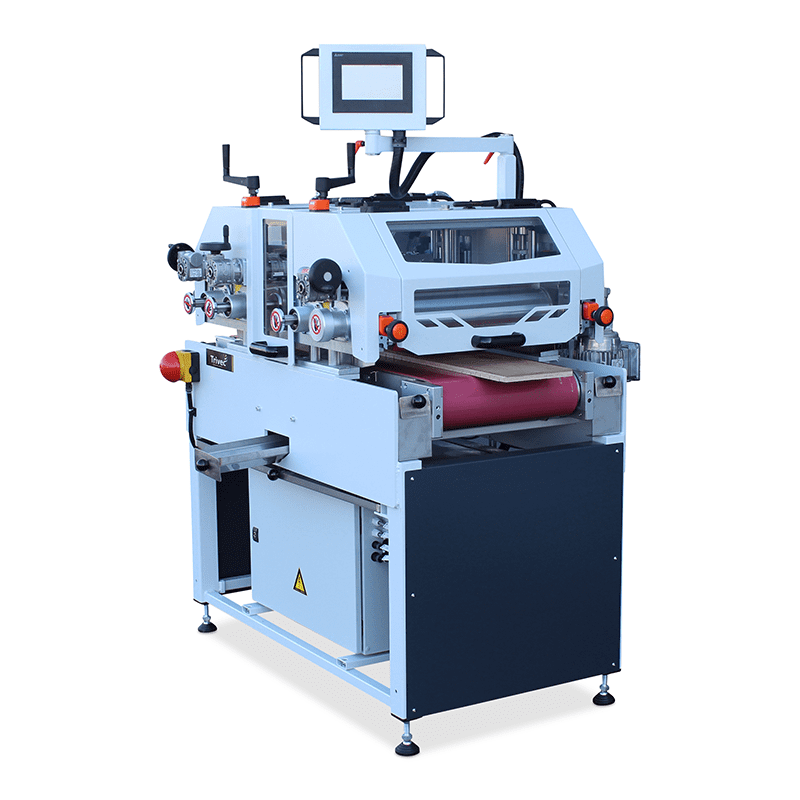

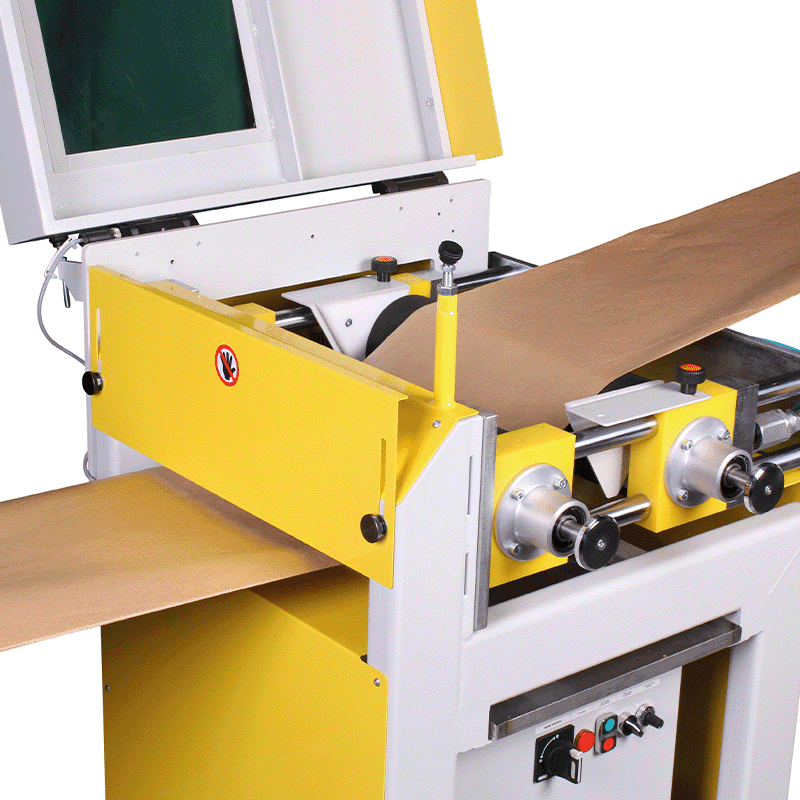

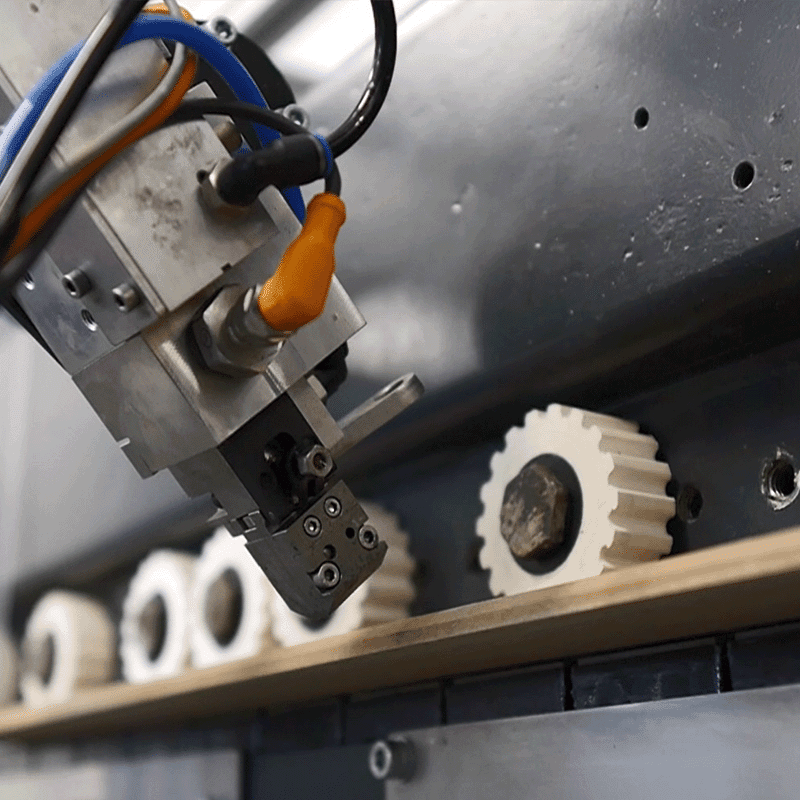

Designed for the efficient and even distribution of oils, stains, and UV/LED coatings on flat surfaces like parquet, flooring, and concrete tiles. Available in working widths of 400 mm or 600 mm, tailored to your specific needs. It features adjustable height for each unit, independent frequency control of pad and brush units, and an adjustable conveyor belt speed for maximum flexibility. The modular design allows for easy addition of extra units, and the pads and brushes can be quickly removed for cleaning or color changes. Compatible with a wide range of products, the Trivec Polishing Machine ensures a consistent, professional finish.

The number of pads and brushes are customizable to meet your specific application requirements.