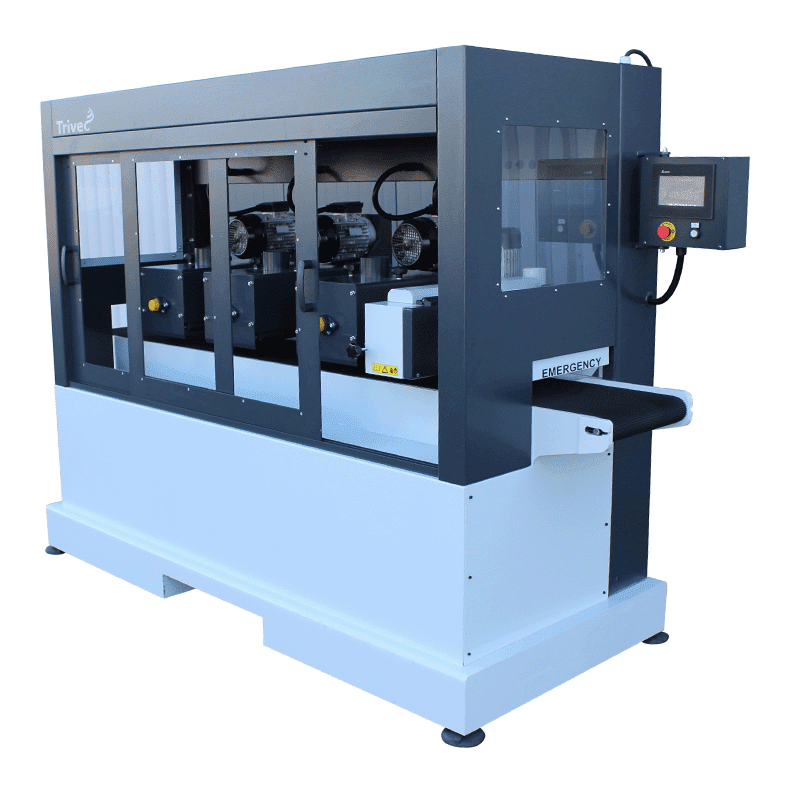

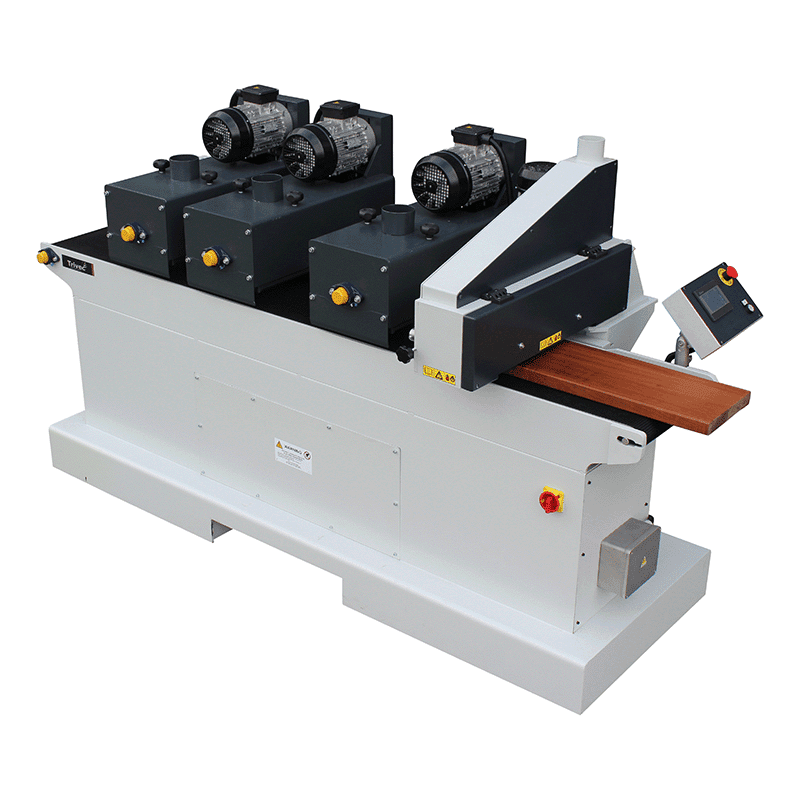

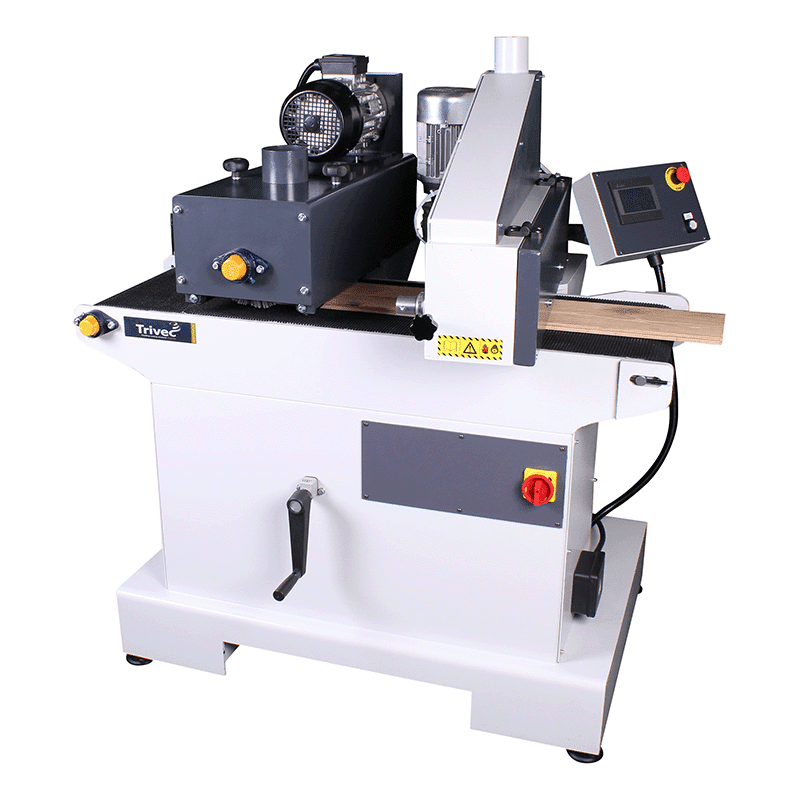

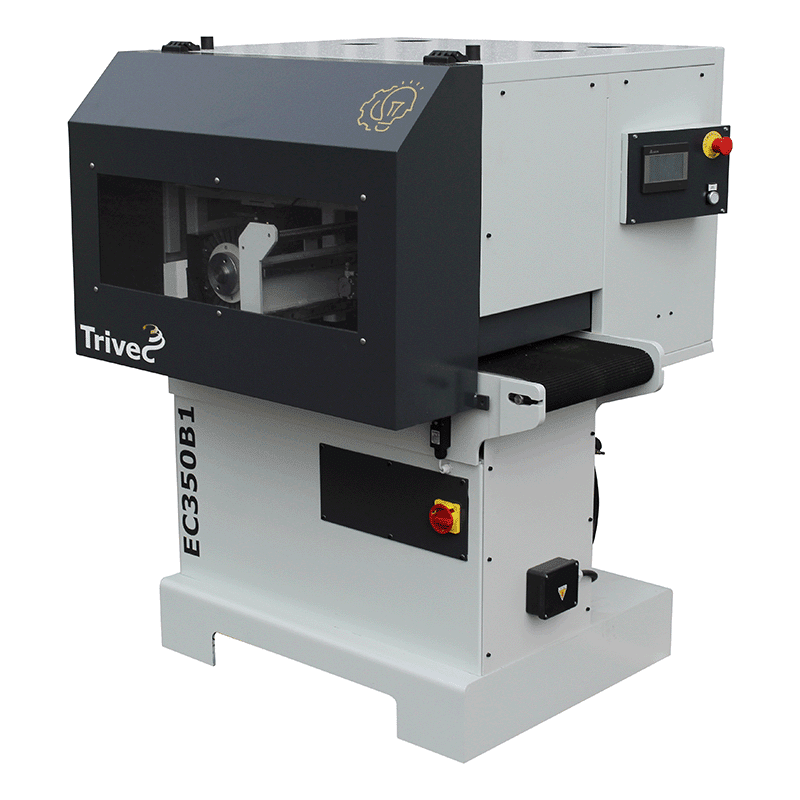

The Rotor Brushing Machine is equipped with six heavy-duty brush units that rotate around a central vertical axis, ensuring thorough brushing, structuring, and sanding of Versailles panels, parquet floors and more. Each brush unit operates in alternating clockwise and counterclockwise directions, achieving a uniform and high-quality finish in all directions.

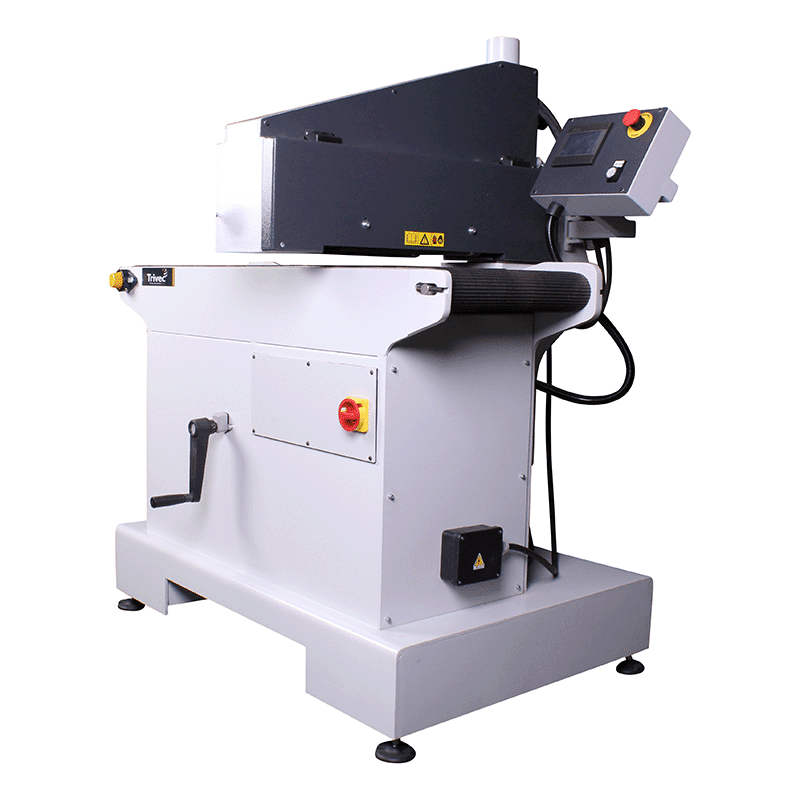

The machine offers adjustable settings for brush pressure, rotational speed, and main axle speed, providing extensive creative control. Workpieces are securely transported on a vacuum-equipped conveyor belt, ensuring stability during the brushing process, even for delicate or lightweight items. The brush units are compatible with a range of brush types. The quick-change brush system ensures fast and efficient replacements, minimizing downtime.