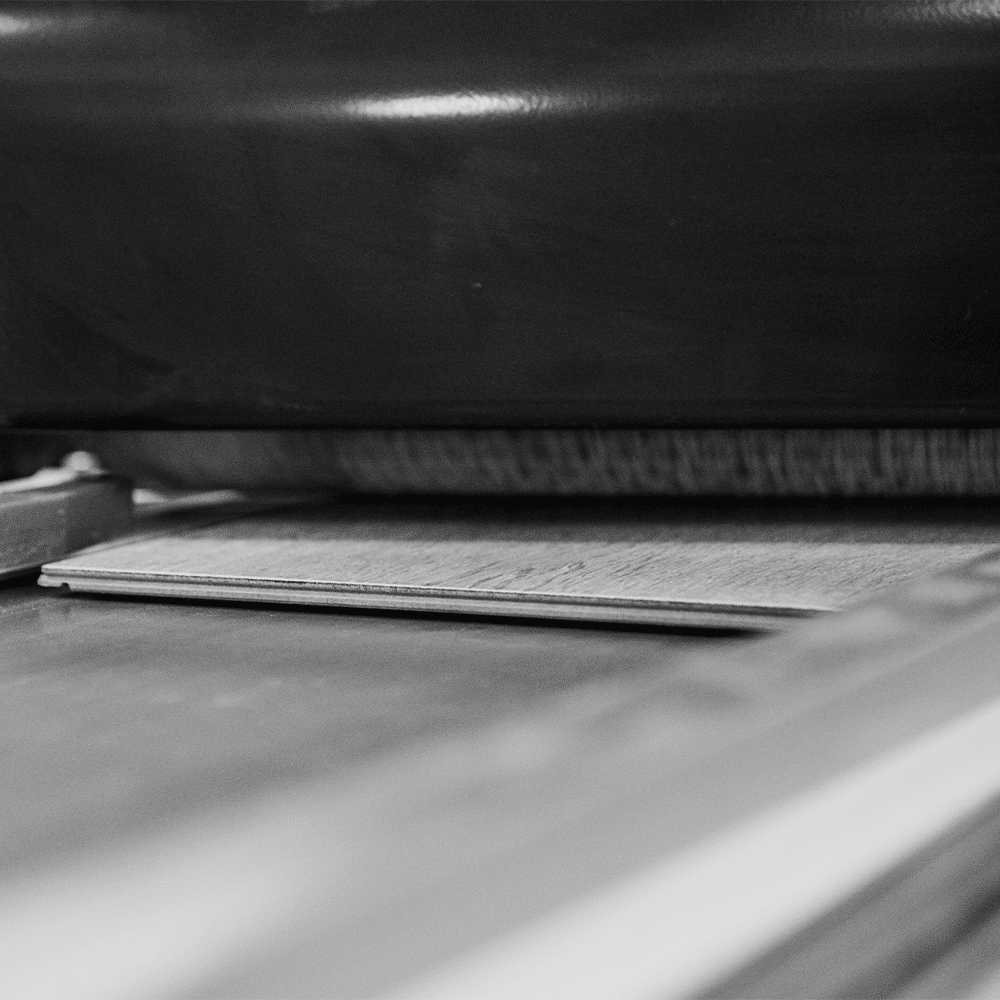

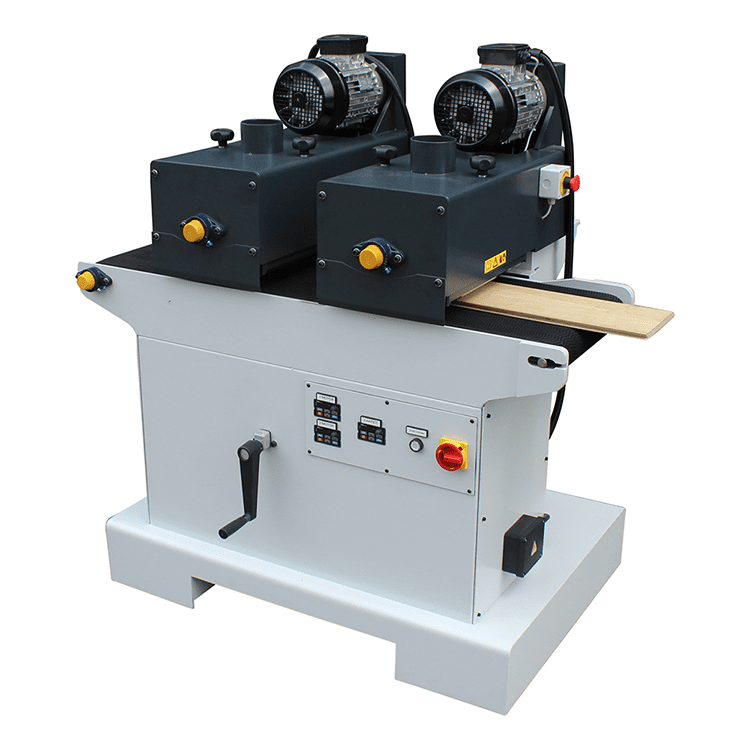

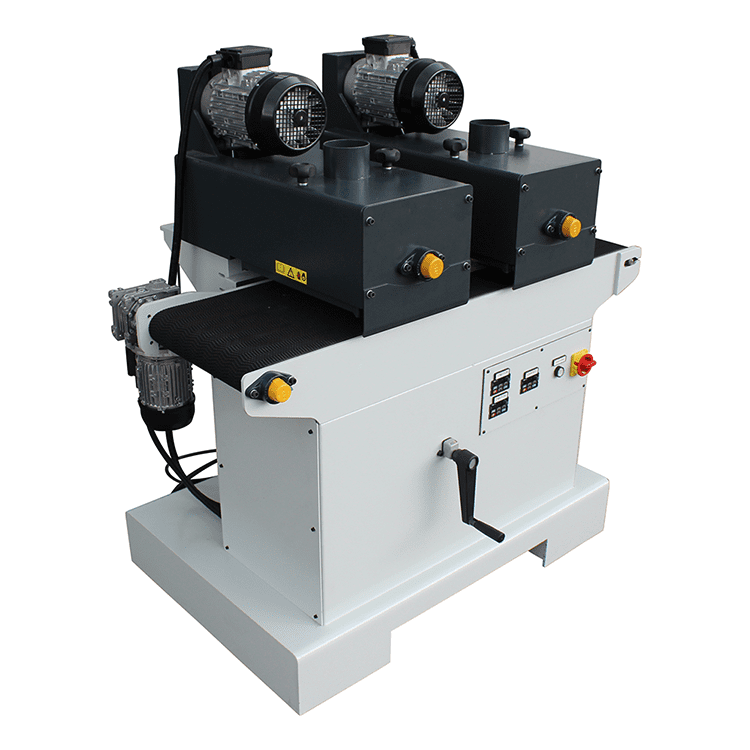

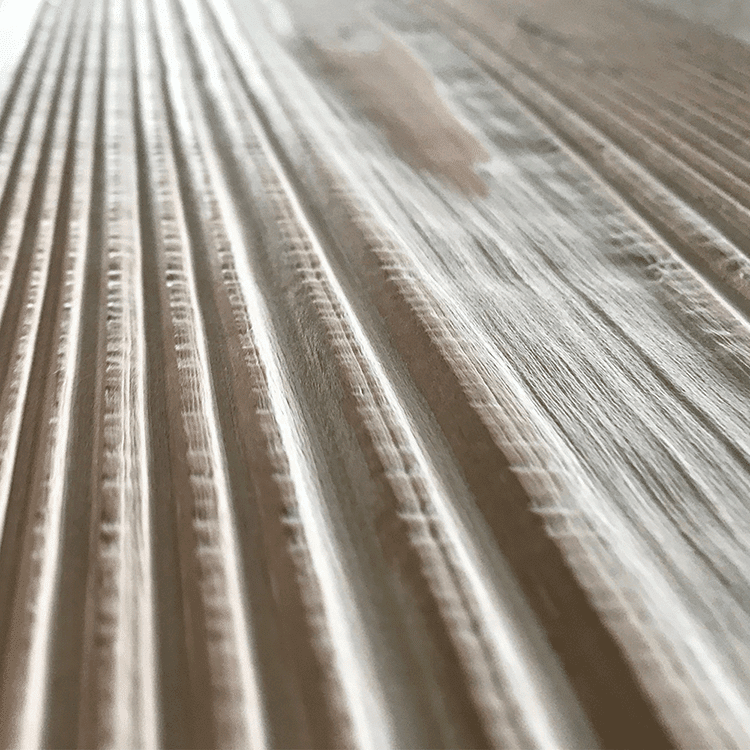

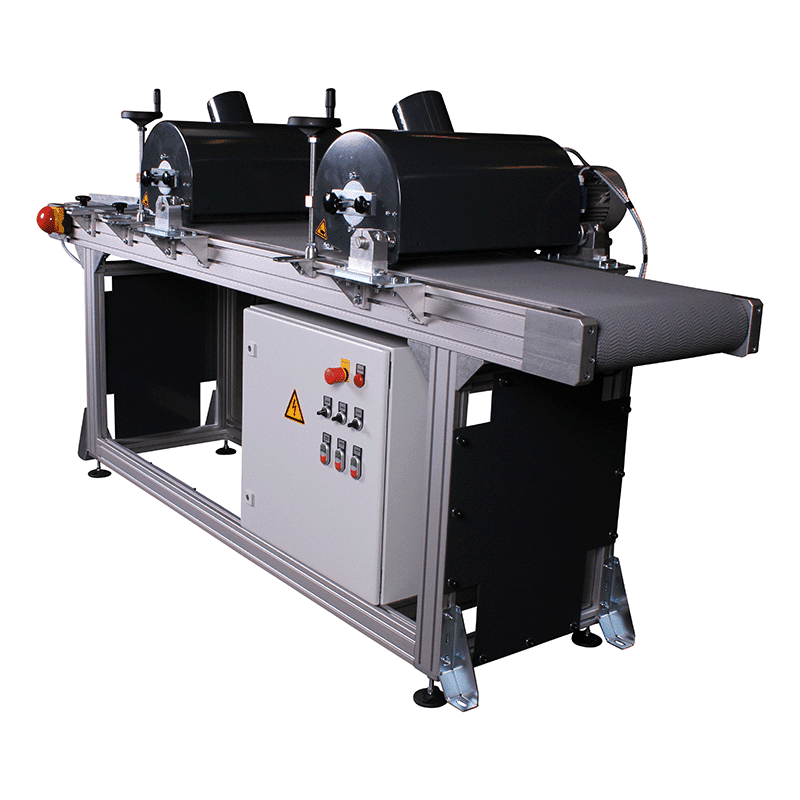

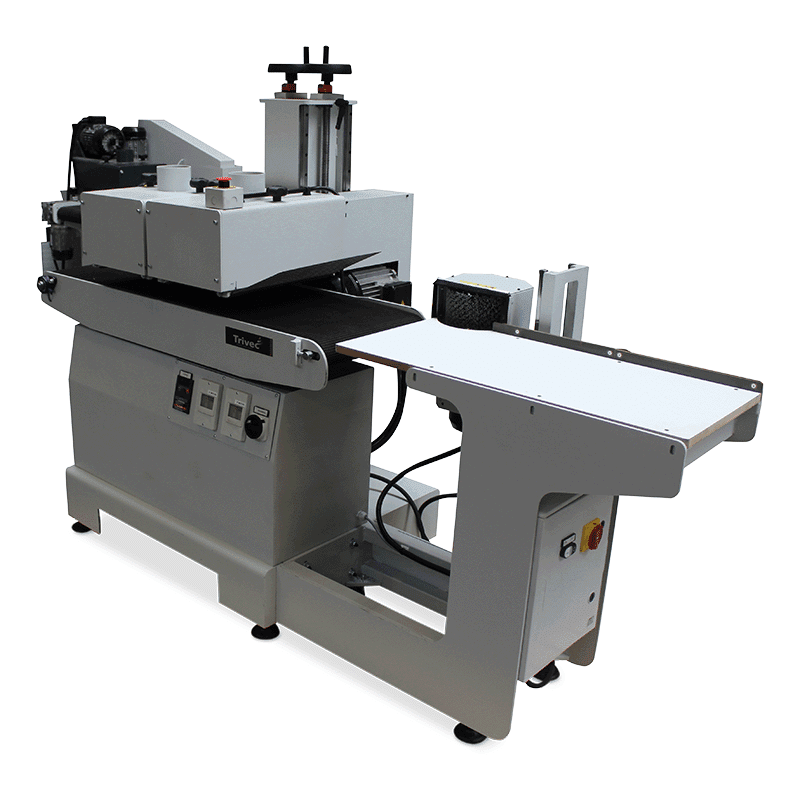

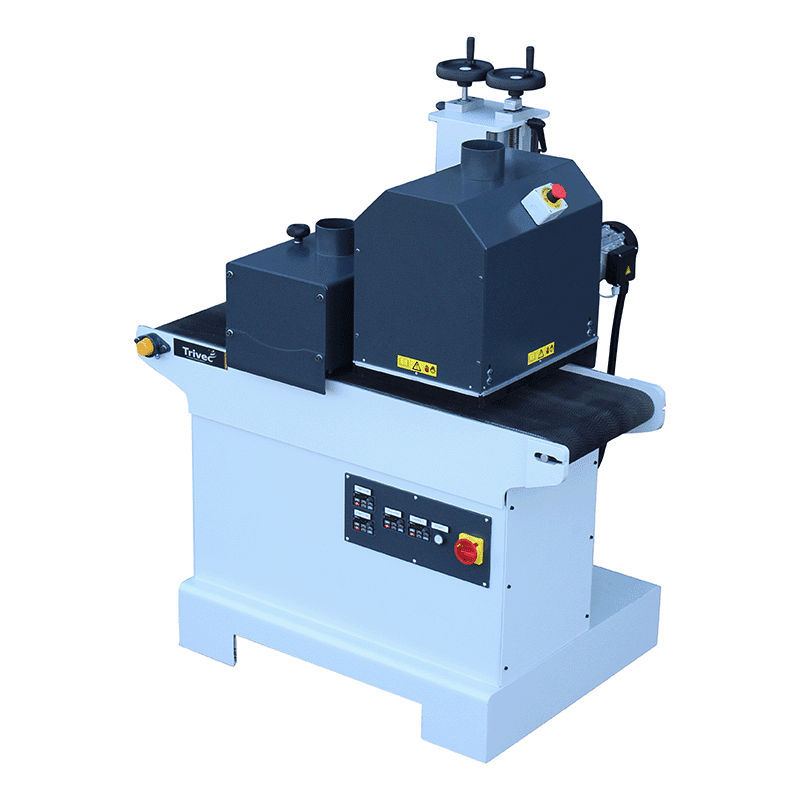

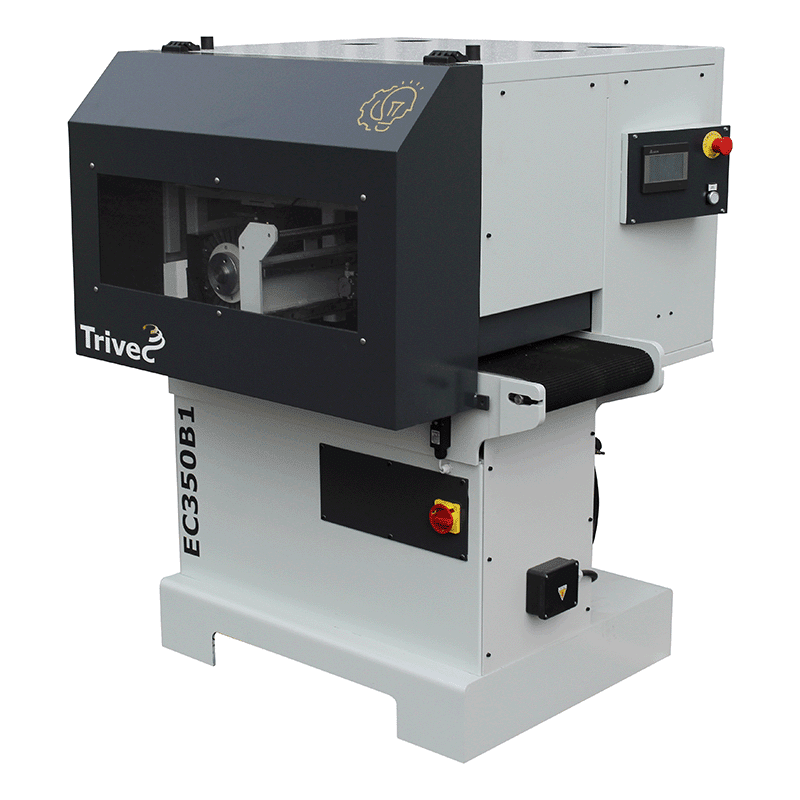

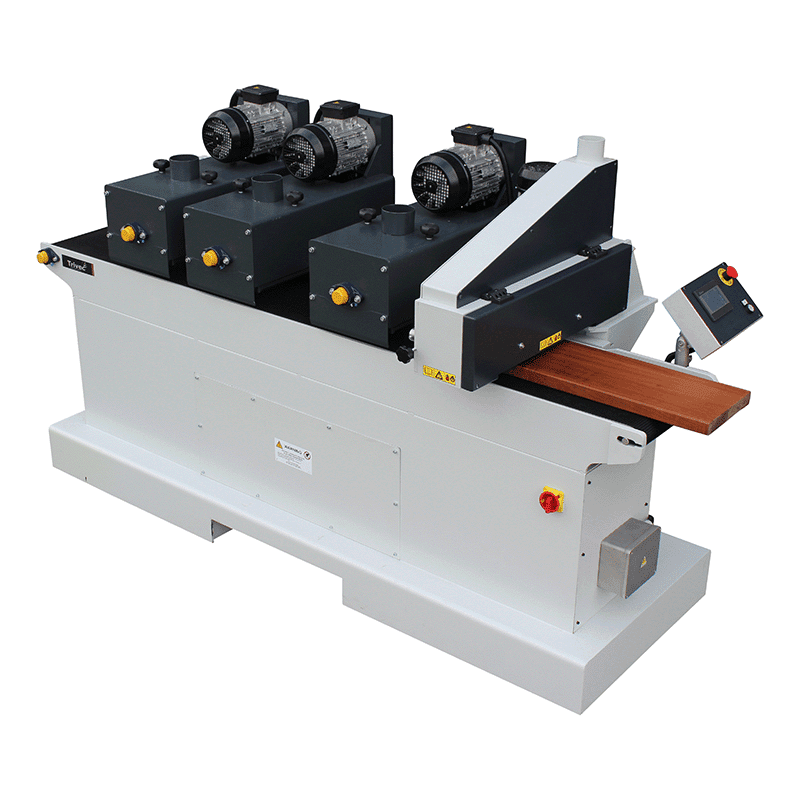

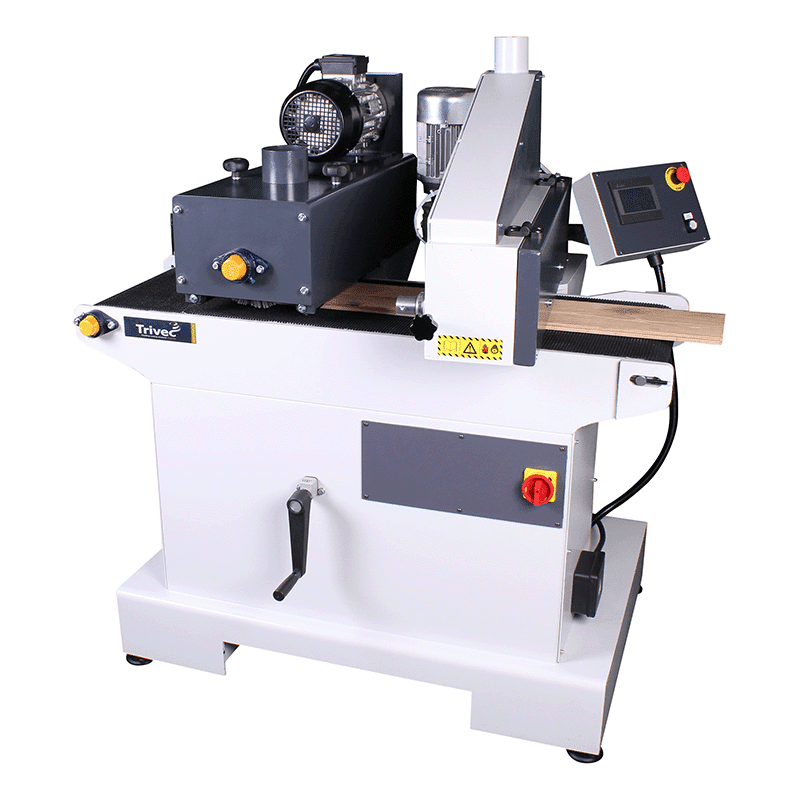

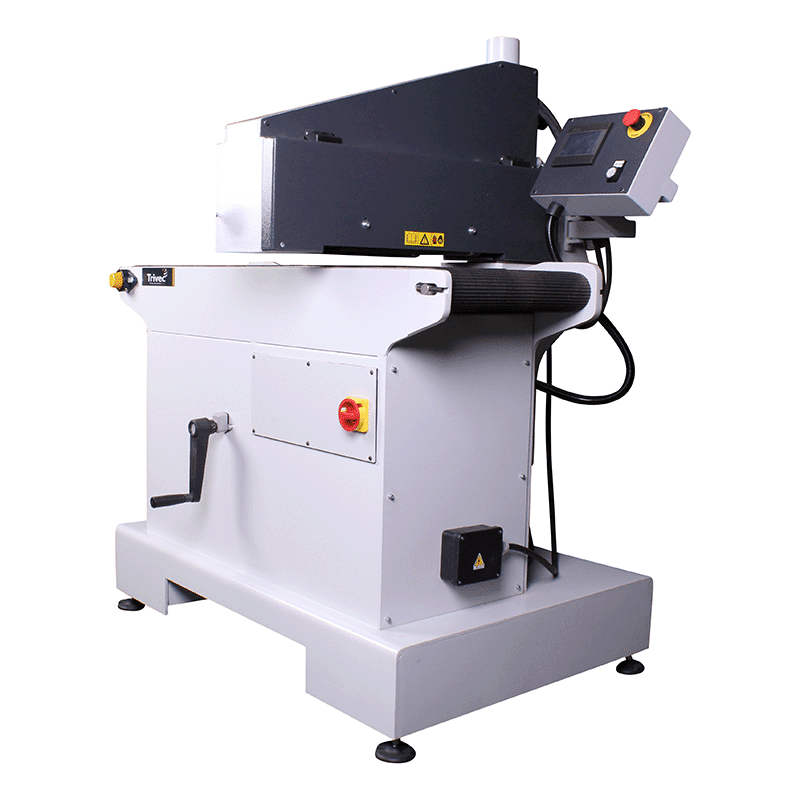

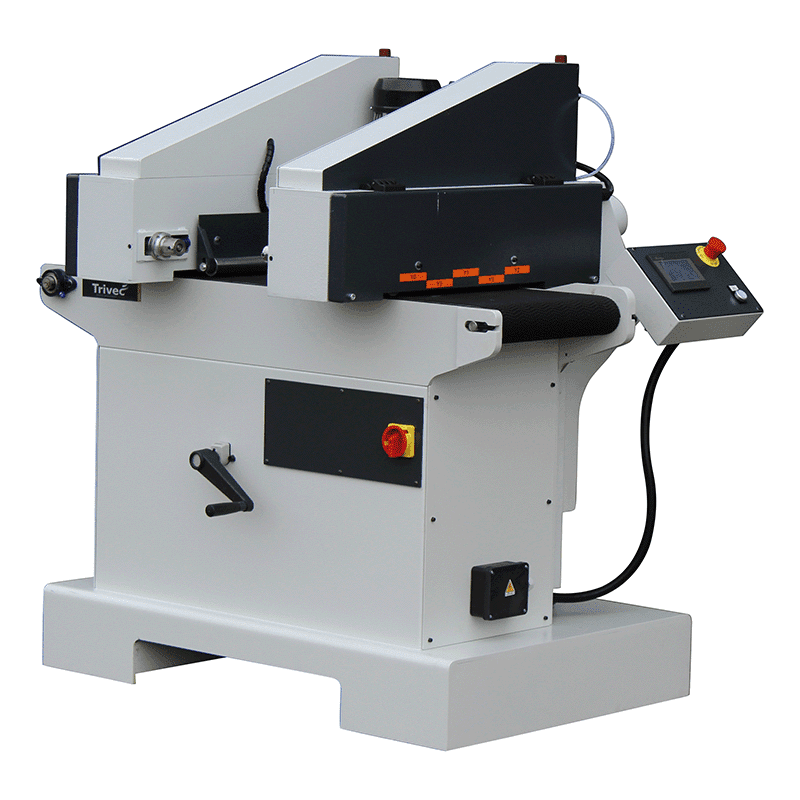

The brushing machine is equipped with two brush units. Each unit can be adjusted in angle to maximize sanding and grain-effect results on wooden surfaces. With a central height adjustment as well as a fine adjustment on all following unit(s). Workpieces are transported over the integrated high-grip conveyor. Each brush unit is further equipped with pressure rollers to keep the workpieces stable and enables the processing of smaller workpieces.

The heavy duty brush motors can each be separately regulated in speed, as well as rotational direction for creative control. Furthermore, pressure, brush type, angle adjustment and conveyor speed further increase this creative control. Can be equipped with Tynex, messing bundle, messing spiral, Scotch Brite, or sanding brushes.