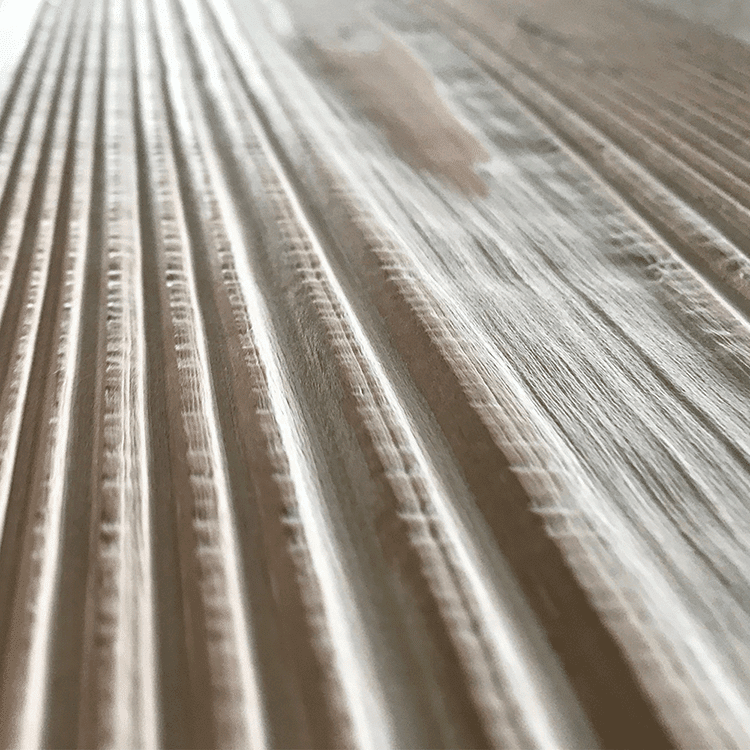

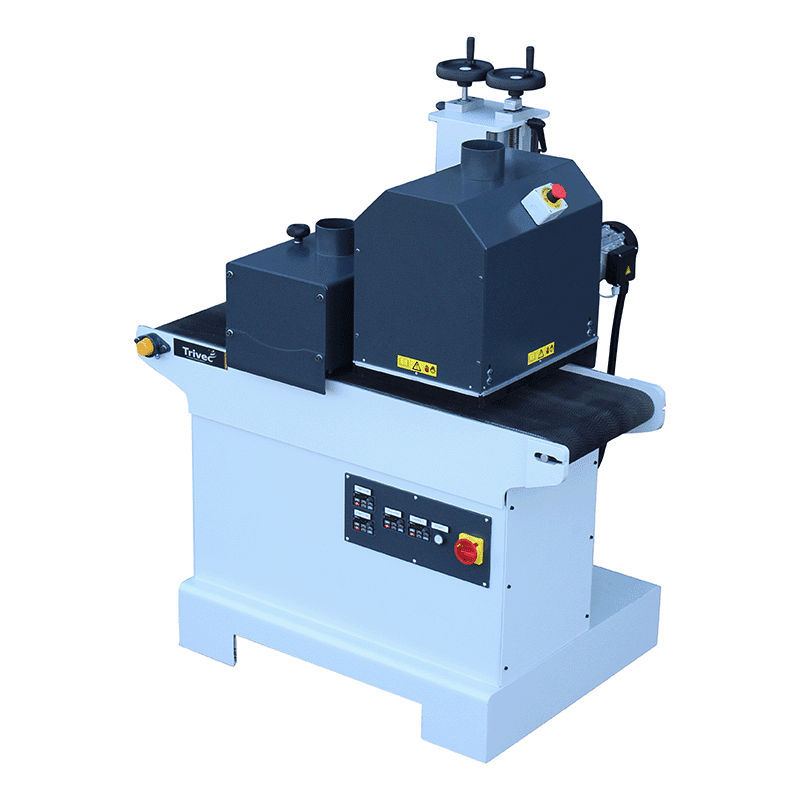

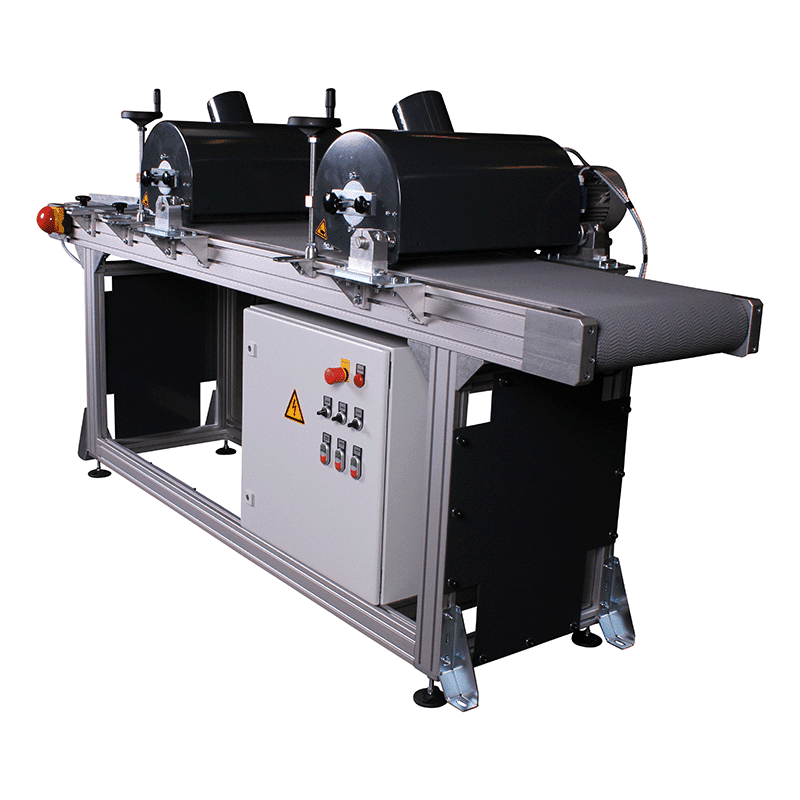

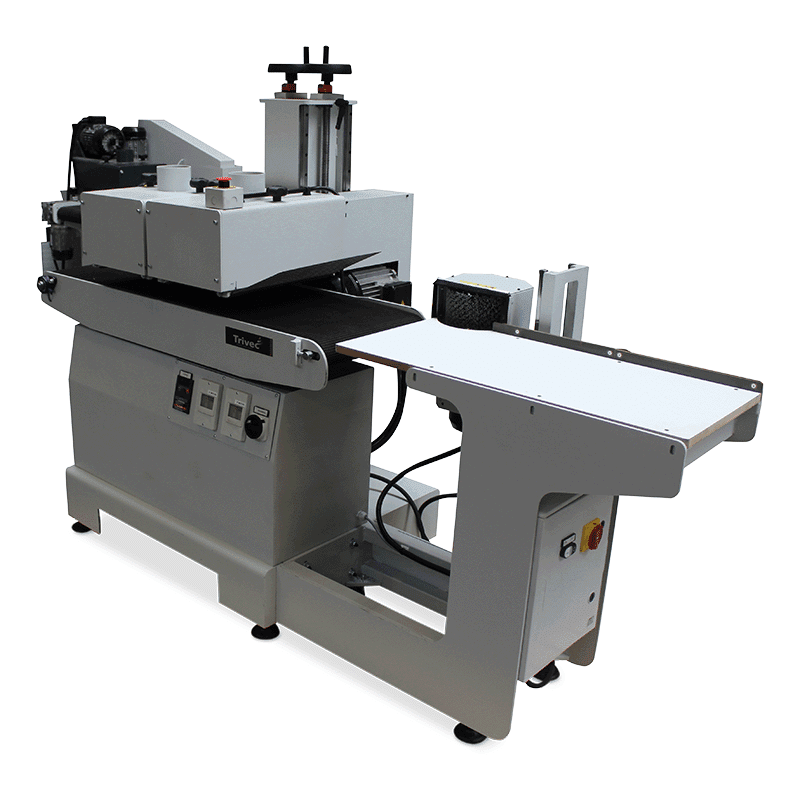

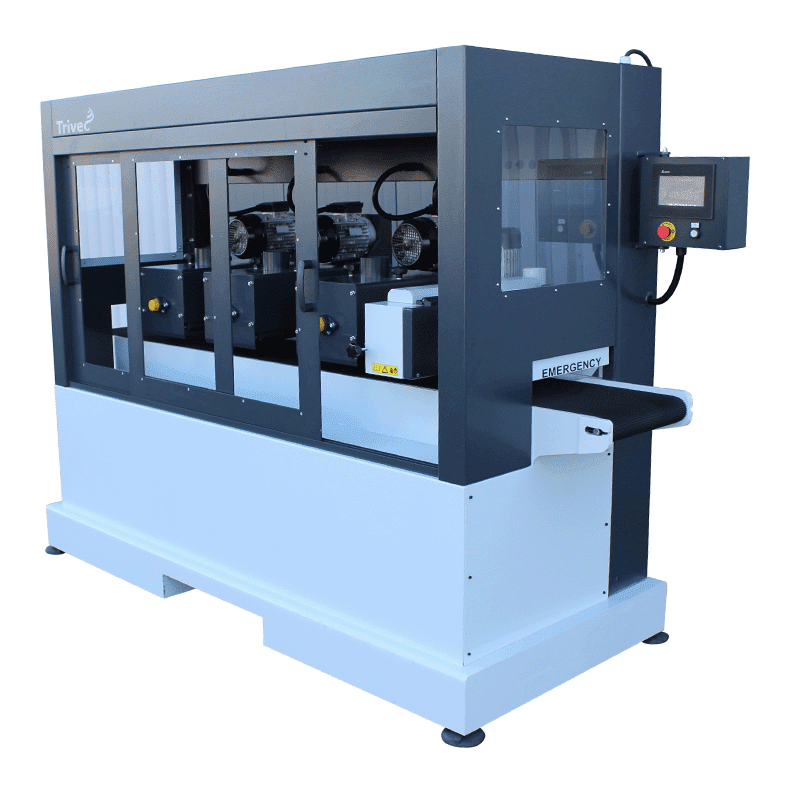

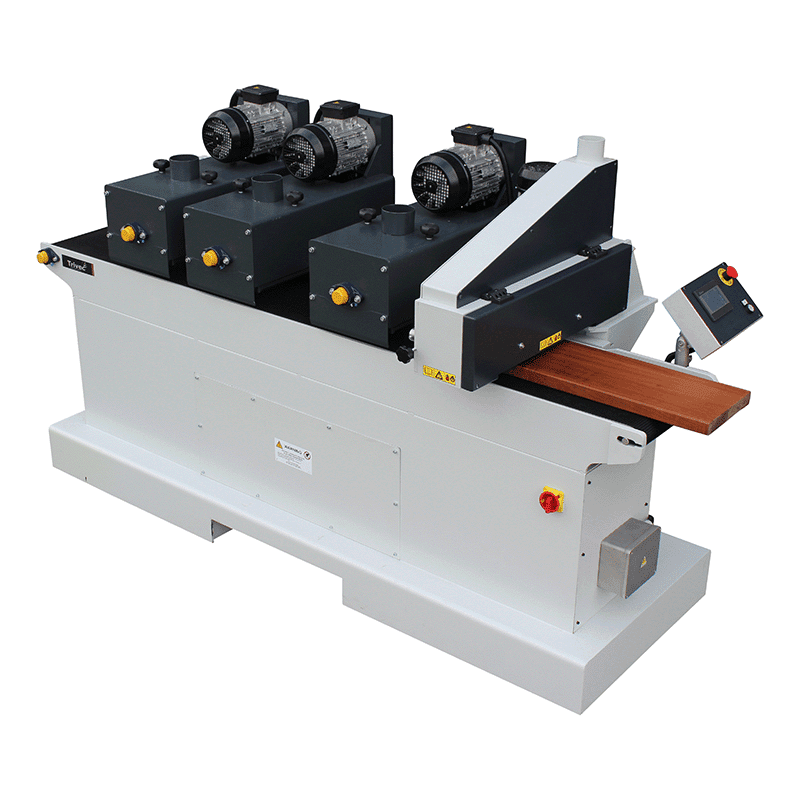

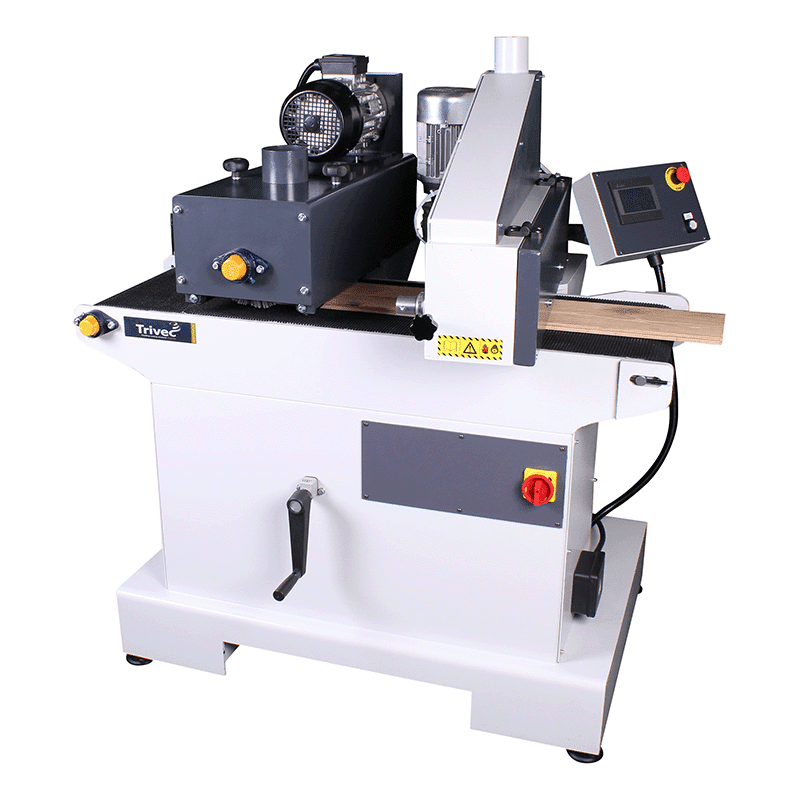

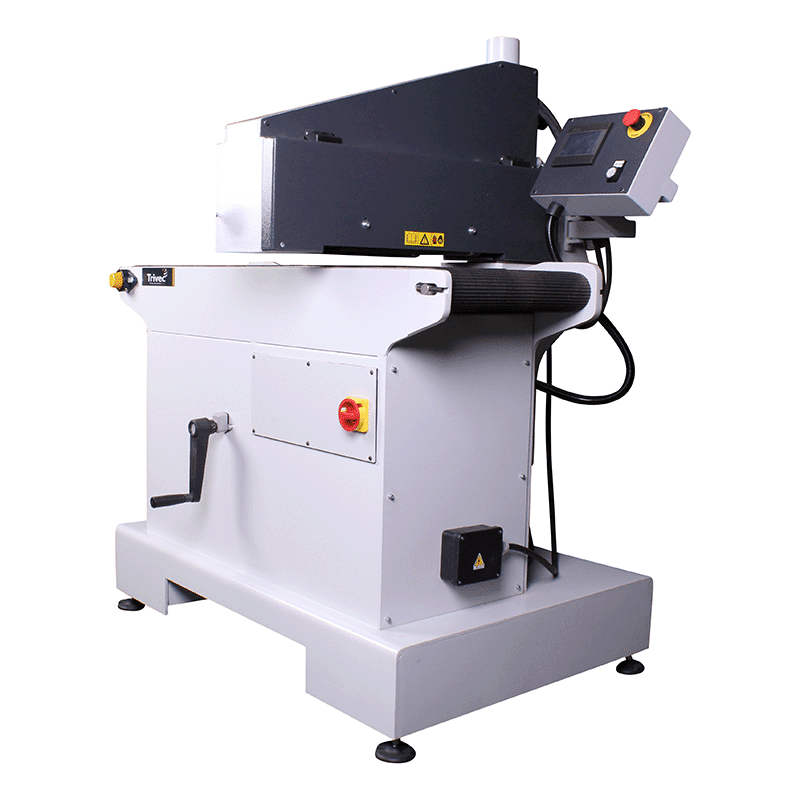

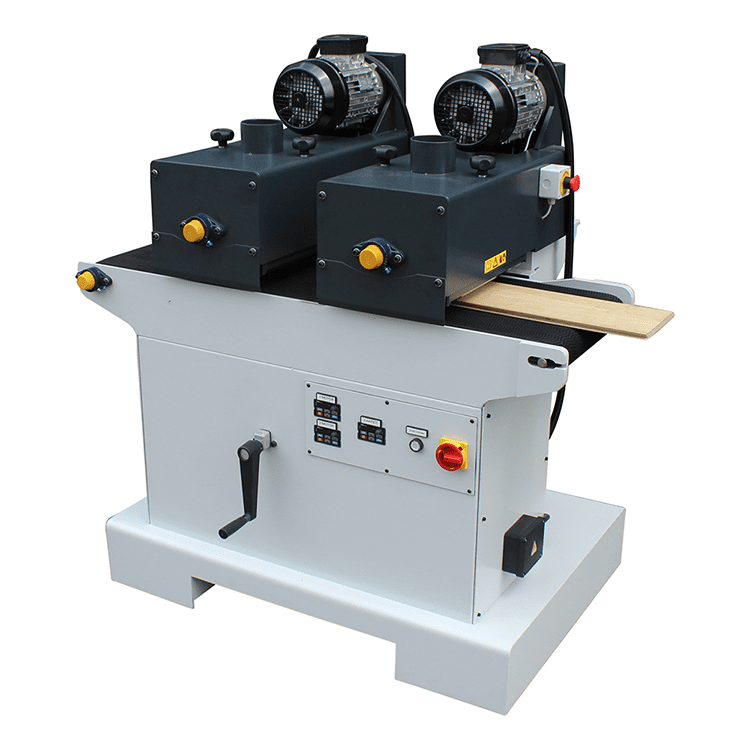

The Brushing Machine features four adjustable brush units, each capable of being angled to optimize sanding and grain-effect results on wooden surfaces. The brushes offer both central height adjustment and fine-tuning for individual units, ensuring precision in every application. Workpieces are transported smoothly via the integrated high-grip conveyor, while pressure rollers on each unit keep the pieces stable, allowing for the efficient handling of smaller items.

Each of the four heavy-duty brush motors can be independently controlled in terms of speed and rotational direction, providing extensive creative flexibility. Additional control options include adjustable pressure, brush type, angle settings, and conveyor speed.