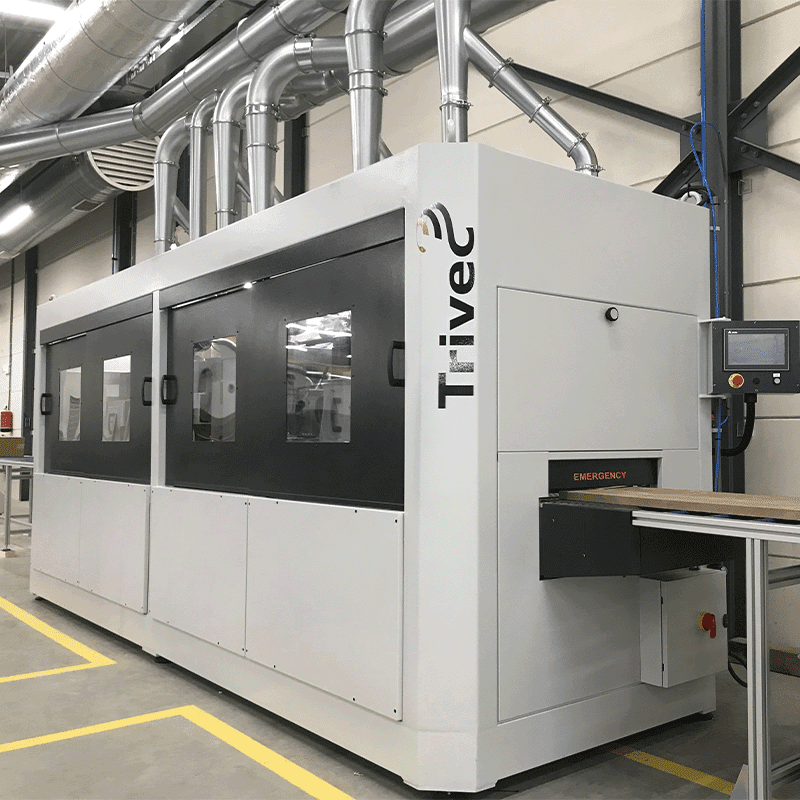

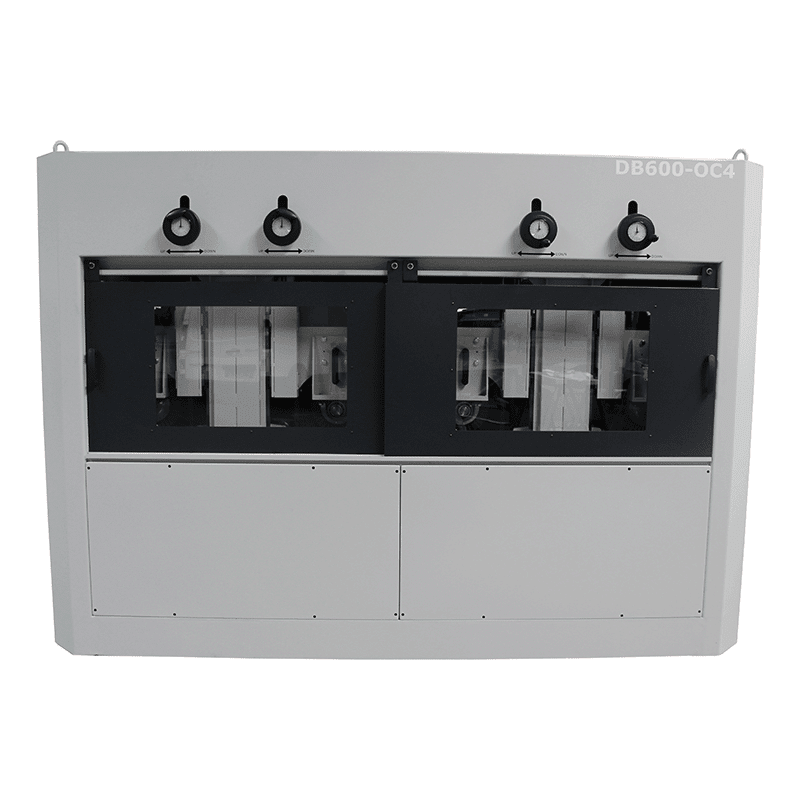

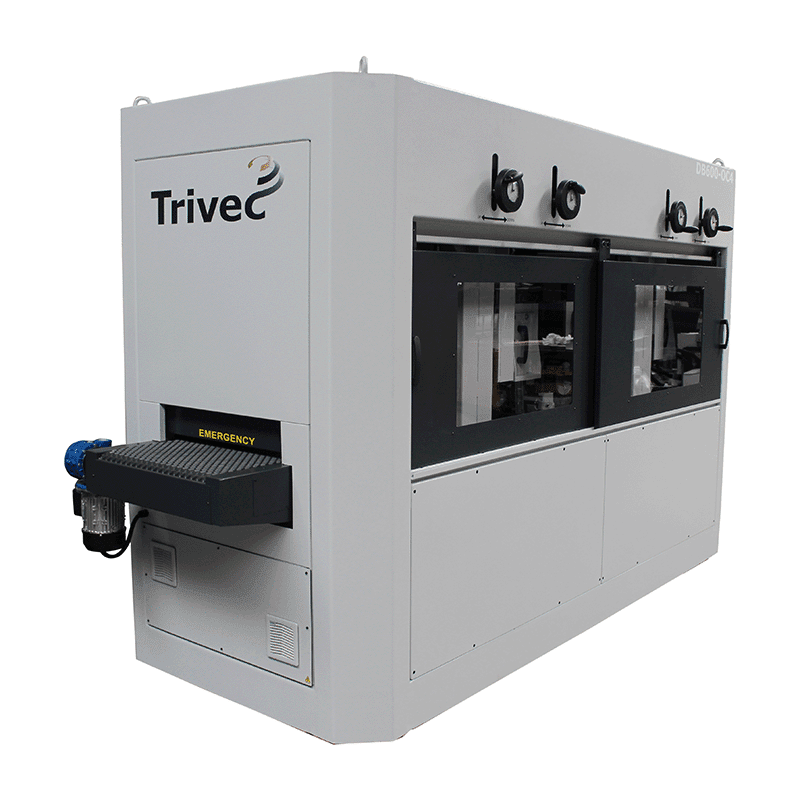

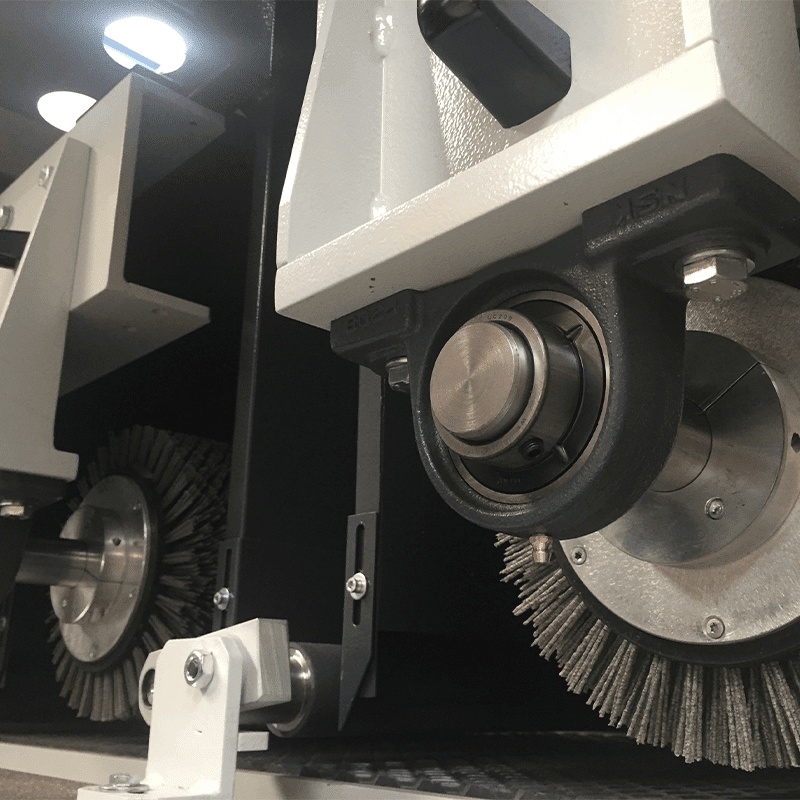

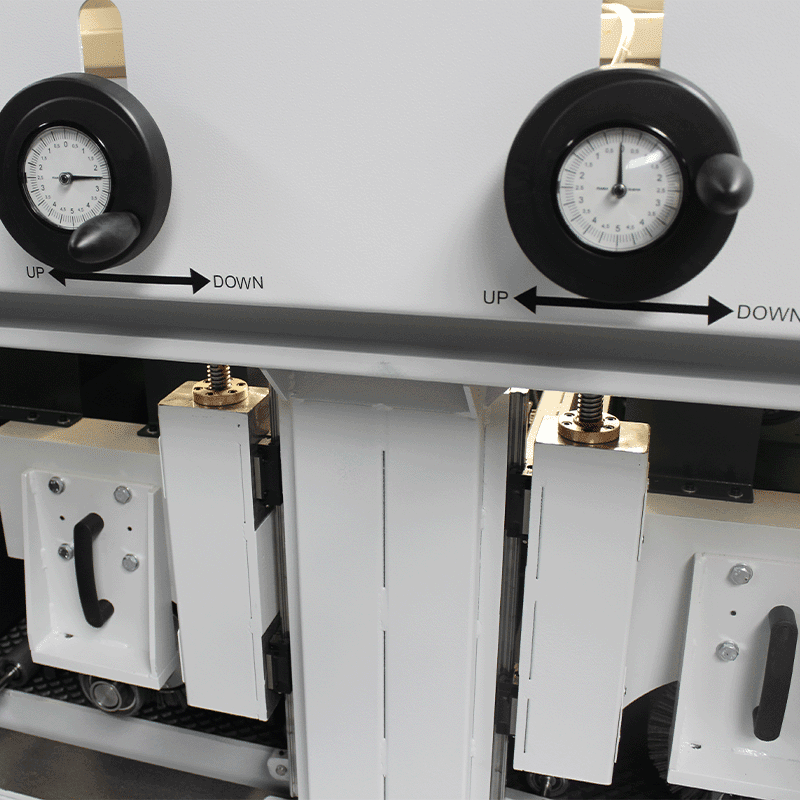

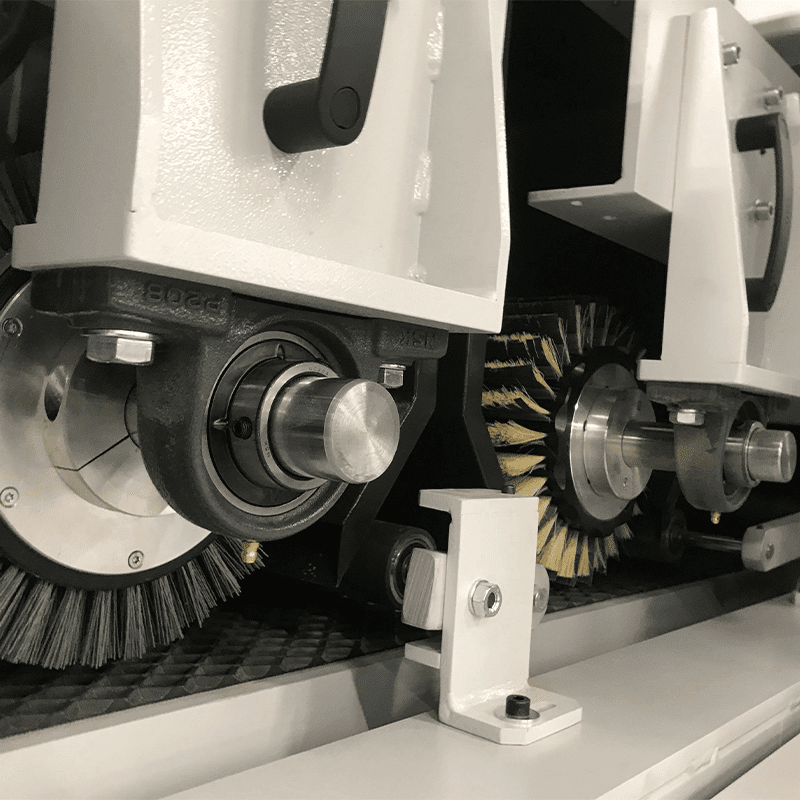

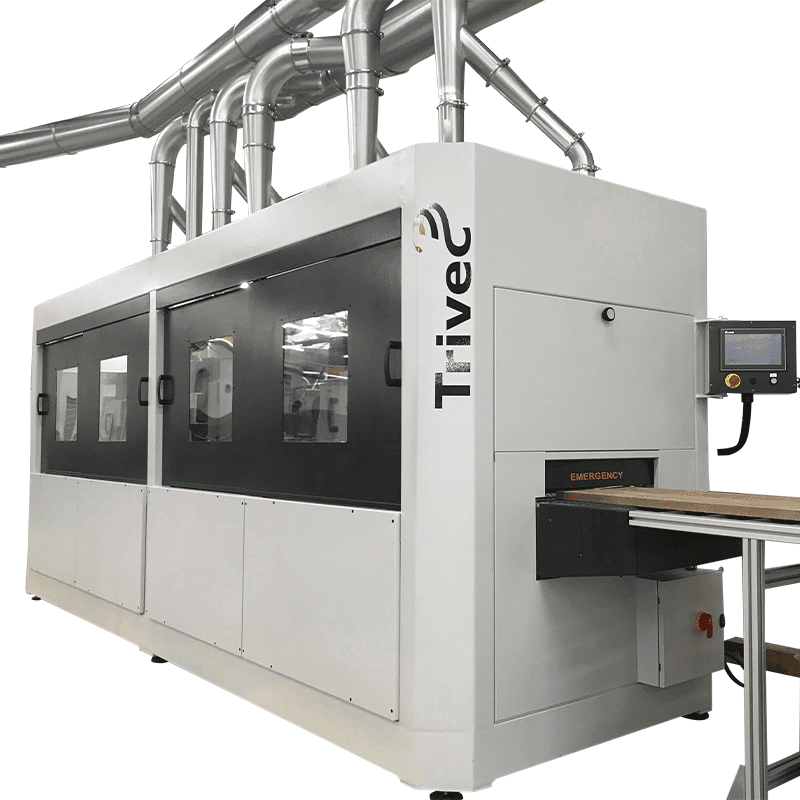

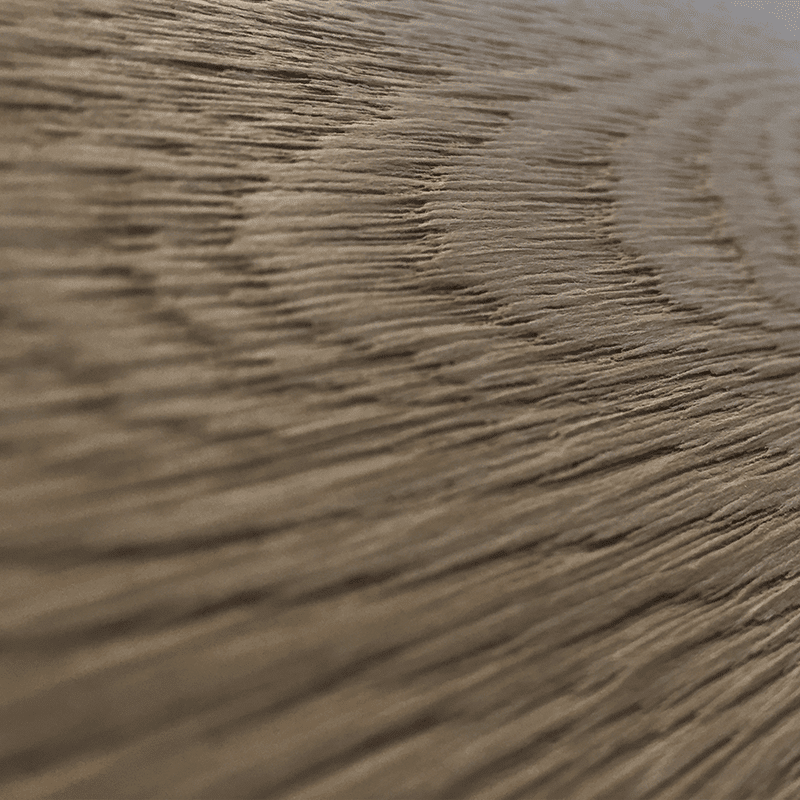

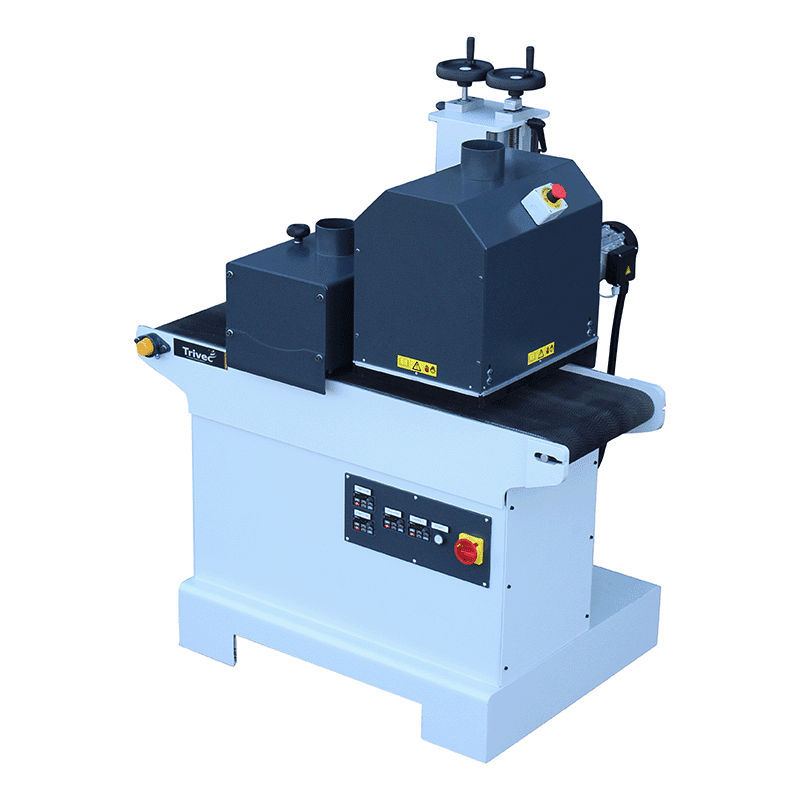

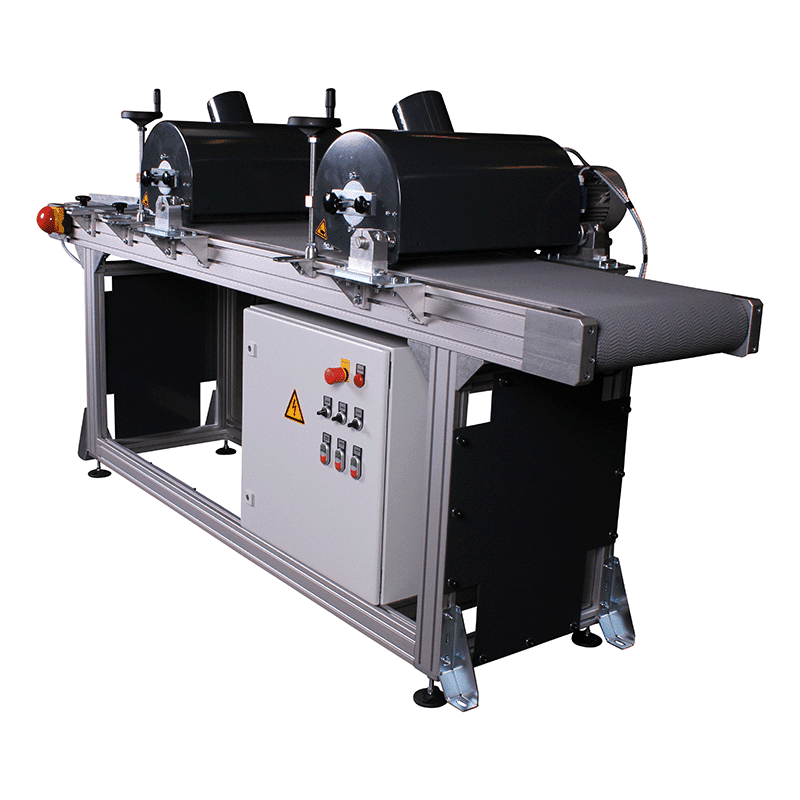

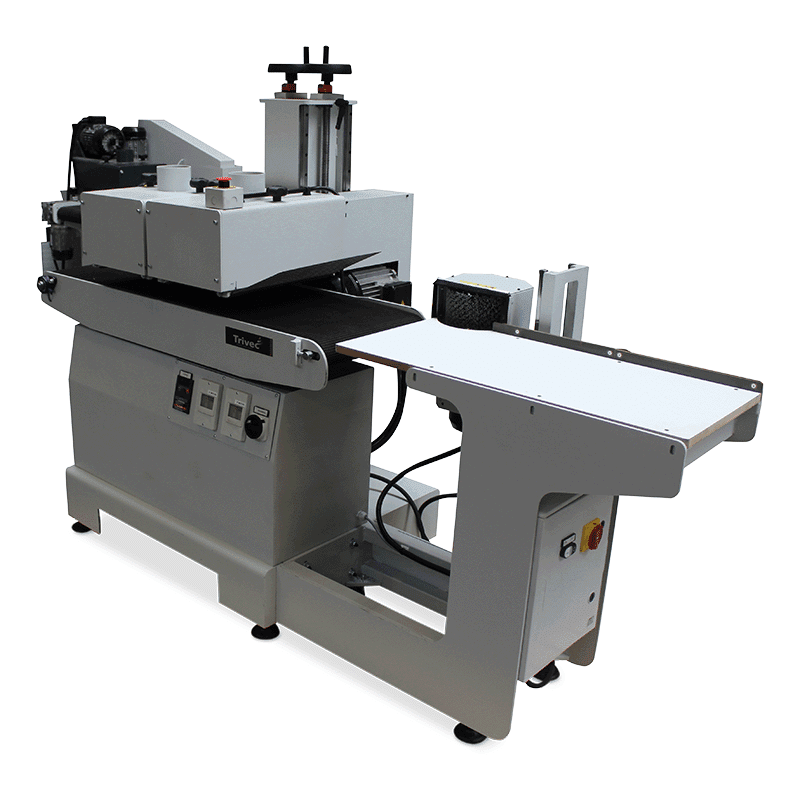

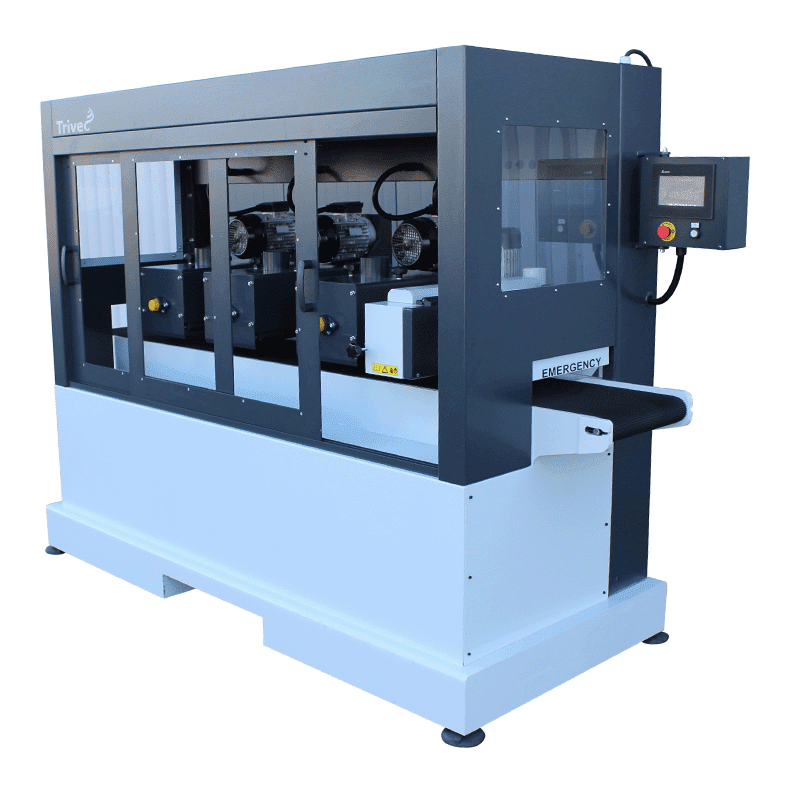

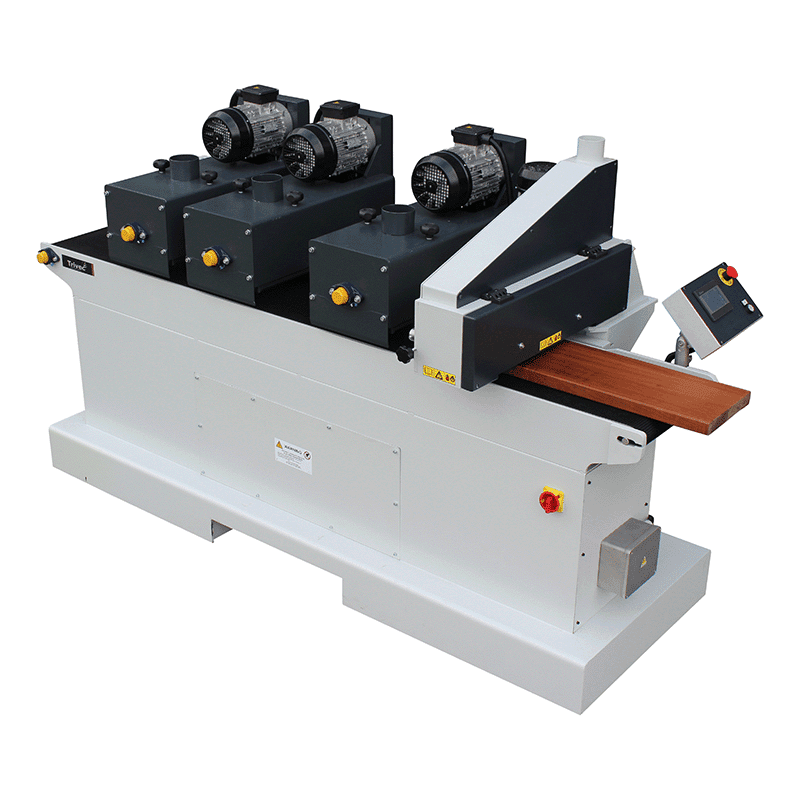

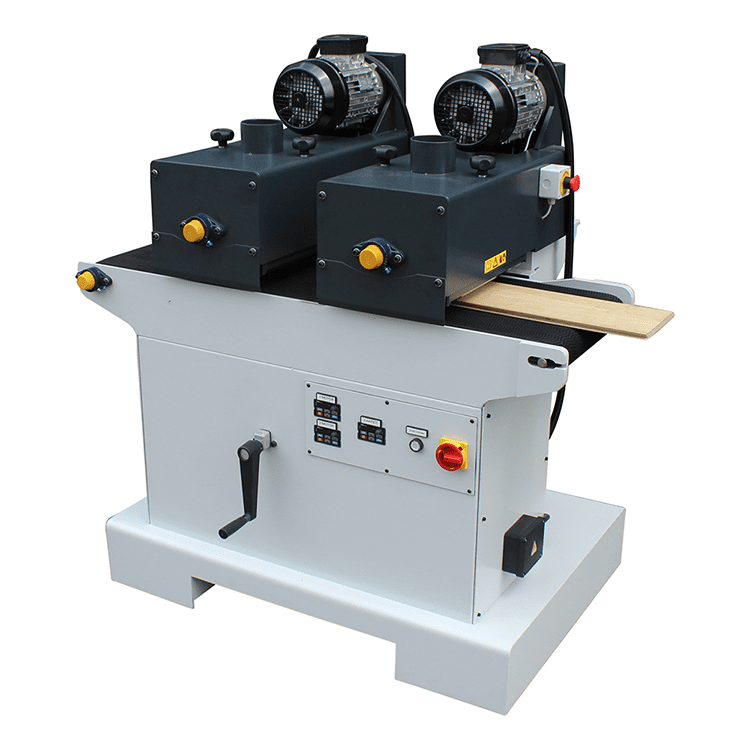

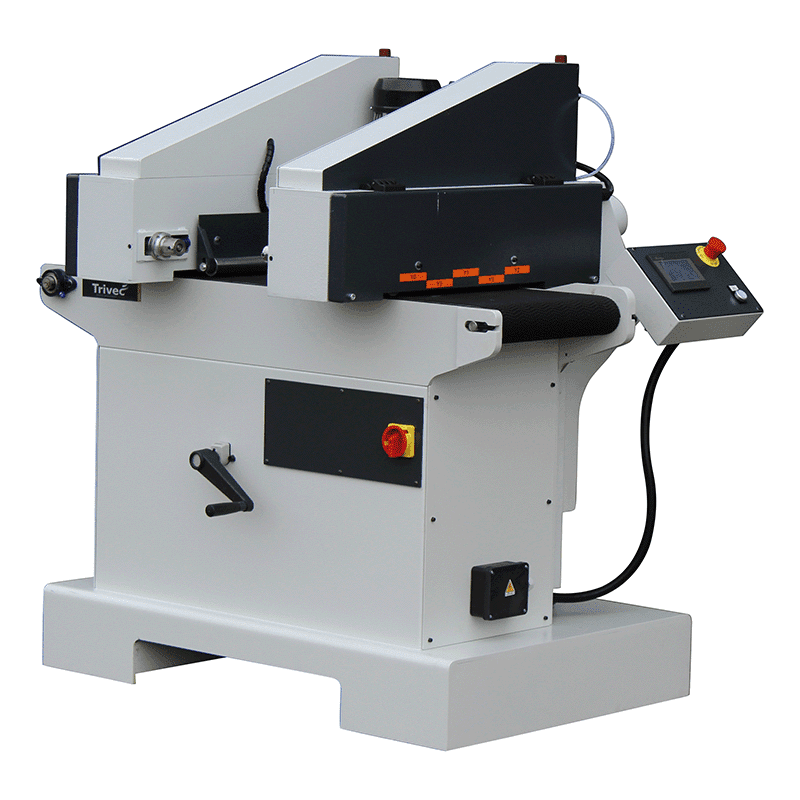

The DB600-PREMIUM is a heavy duty brushing machine with extra powerful brush motors, oscillating units, and brushes with a larger diameter. This machine comes with 4 brushing units and can be configured up to 7 units. The combination of power, variable oscillating speeds, rotational direction of brushes, brush pressure, brush speed, and type of brush give an extensive measure of flexibility to create effects. Equipped with ease-of-use touchscreen with built-in memory to store several configurations, enabling the recreation of previously created effects on the fly. The grip conveyor and integrated pressure rollers ensure that workpieces do not shift during production. Brushes can be detached quickly and easily. The way brushes can be changed is unique from other machines.