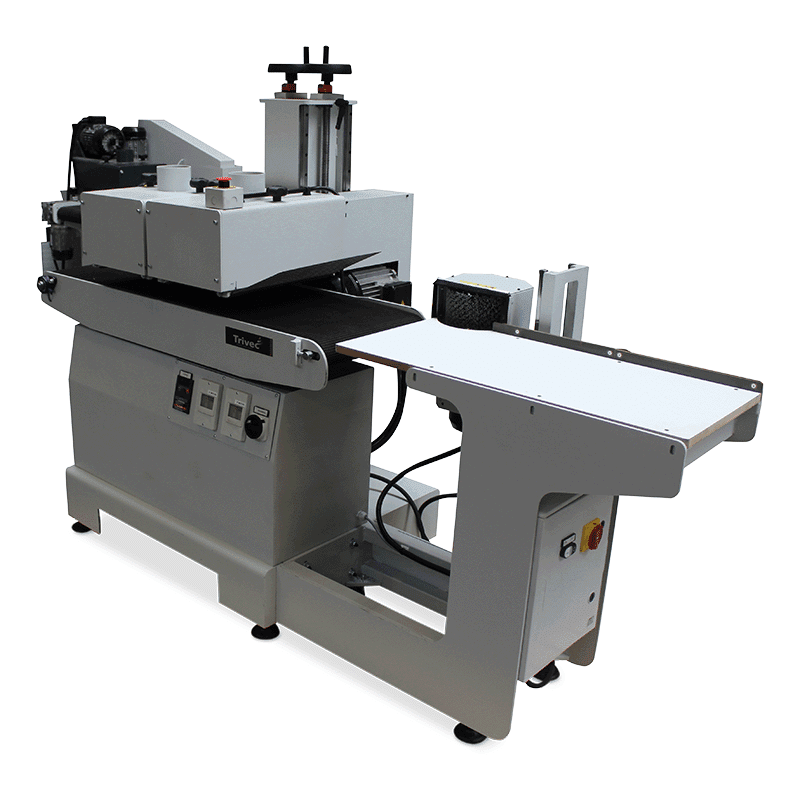

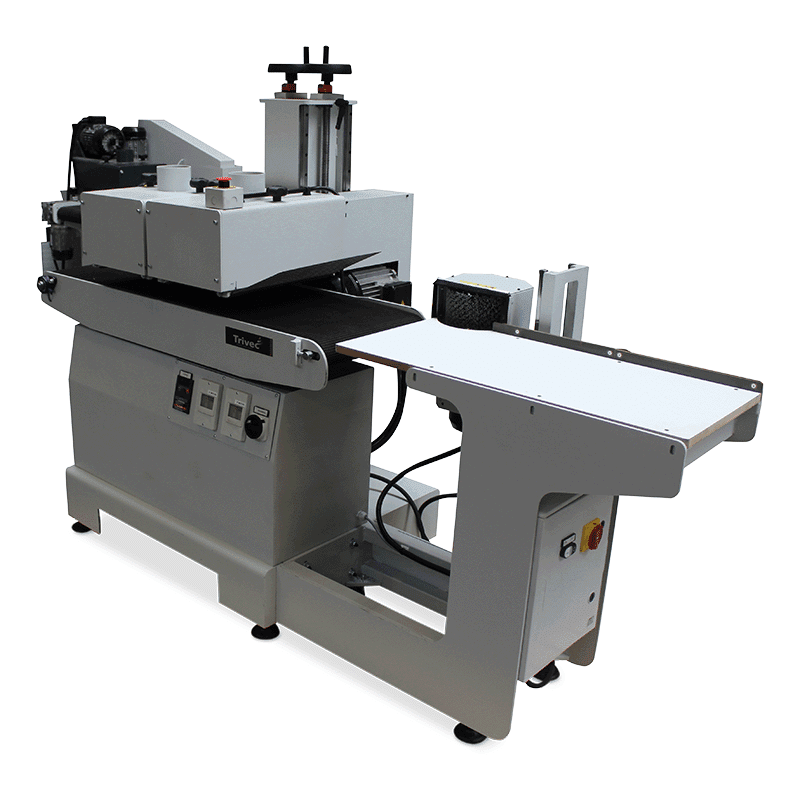

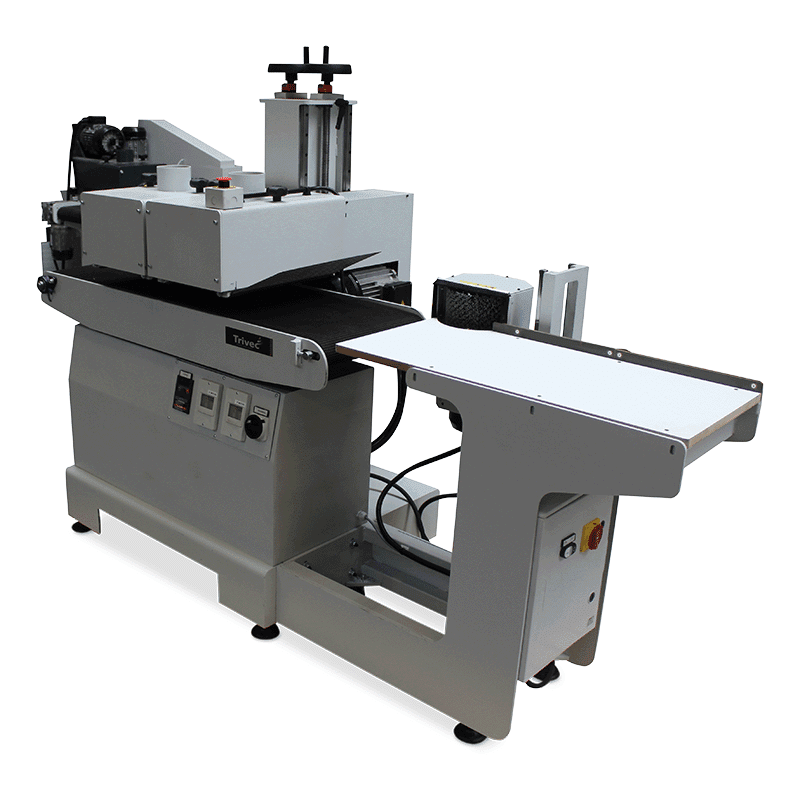

Brushing machine for two-sided structuring, brushing, and polishing of surfaces such as wood.

Exhaust capacity required – 1357 m³/h

Width – 900 mm

Height – 1390 mm

Effective working width – 400 mm

Minimum length workpiece – 250 mm

Work height – 900 mm (+20/-20 mm)

Feed through height min/max – 4 – 180 mm

Feed through speed – 2 – 15 m/min

Brush modules – 2 horizontal units and 1 vertical unit with quick change system and angle adjustment

Power brush engines – 2 x 4.0 kW

Electrical connection – 400V / 50Hz (3Ph + 0 + ground)

Exhaust connections – 2 x 100 mm

Control systems – from switches on the operating side (touch screen optional)

Brush speed – adjustable with potentiometer on all brush units

Height adjustment – central height adjustment, fine adjustment on unit 2

Conveyor belt – high-grip conveyor

Marking – CE

The Brushing Machine with side brush is designed for compatibility with Trivec machines and other manufacturers’ machinery, including coating stations, dryers, and polishing lines. Its flexible design allows for smooth integration into production lines and scalable setups without modifications. Equally effective as a stand-alone machine, it adapts easily to various production environments, offering reliability and efficiency for evolving operational needs.

The Brushing Machine with side brush features a control cabinet with connections for emergency stops and error notifications. These safety measures ensure secure and efficient integration into production lines of varying complexity, supporting uninterrupted and safe operation across the entire production process.

The Brushing Machine with side brush is designed to adapt to a wide range of production environments and applications. Its flexibility lies in its ability to achieve diverse brushing effects through compatibility with various brush types, such as Tynex, brass bundle, brass spiral, Scotch Brite, and sanding brushes. This makes it suitable for handling different materials and meeting the specific needs of various industries.

Curious about solutions with external production systems? We’re happy to assist you!

Explore other machines that could be the perfect fit for your needs.

Trivec’s team is exceptional. Wiebe’s expertise and problem-solving skills keep our production running at peak performance, while Branko’s innovative approach ensures we stay ahead with new design concepts. Their commitment to quality and customer satisfaction makes them more than a supplier—they’re a true strategic partner. We highly recommend Trivec to any company looking to optimize its production.

We faced serious bottlenecks in our coating line, slowing down production and efficiency. Trivec Engineering provided the perfect solution with a custom-designed Coating Line that completely eliminated these issues. Our output has increased, and their proactive maintenance service prevents costly downtime. Trivec’s expertise, reliability, and commitment to customer satisfaction make them a trusted partner. We highly recommend them to any company looking to optimize production.

Initially, we had doubts about choosing Trivec, particularly regarding the price and the robustness of the machines. However, we have purchased multiple machines from them and have always experienced a professional and pleasant collaboration. The support was prompt and helpful, and the service was solution-oriented. We appreciate Trivec as a reliable and customer-focused partner. That is why we would certainly recommend them to others.

We have been using Trivec machines on our production line for some time now, and we couldn’t be more satisfied. The build quality is outstanding—robust, reliable, and clearly designed with long-term use in mind. The machines are also incredibly user-friendly, which has helped streamline our workflow and reduce training time.

Equally impressive is Trivec’s customer support. Their team is consistently responsive, knowledgeable, and genuinely helpful whenever we’ve needed assistance, and we are especially grateful to Wiebe for all his support. It’s clear they stand behind their products and are committed to their customers’ success.

We would highly recommend Trivec to any company looking for high-quality, dependable finishing equipment backed by excellent service.

Still have questions? Find the answers you’re looking for below.

Feel free to reach out, we’re here to help!

Together, we turn aspirations into reality. Do you have ideas and want to explore how we can support your innovation?

Fill in your details and receive the whitepaper.

Or call us via +31 (0)512 510035

Fill in your details and receive a quote within a few days.

Or call us via +31 (0)512 510035

Ask your questions about this product.

Or call us via +31 (0)512 510035.

Questions or comments about our services? Post them here!

Or call: +31 (0)512 510035