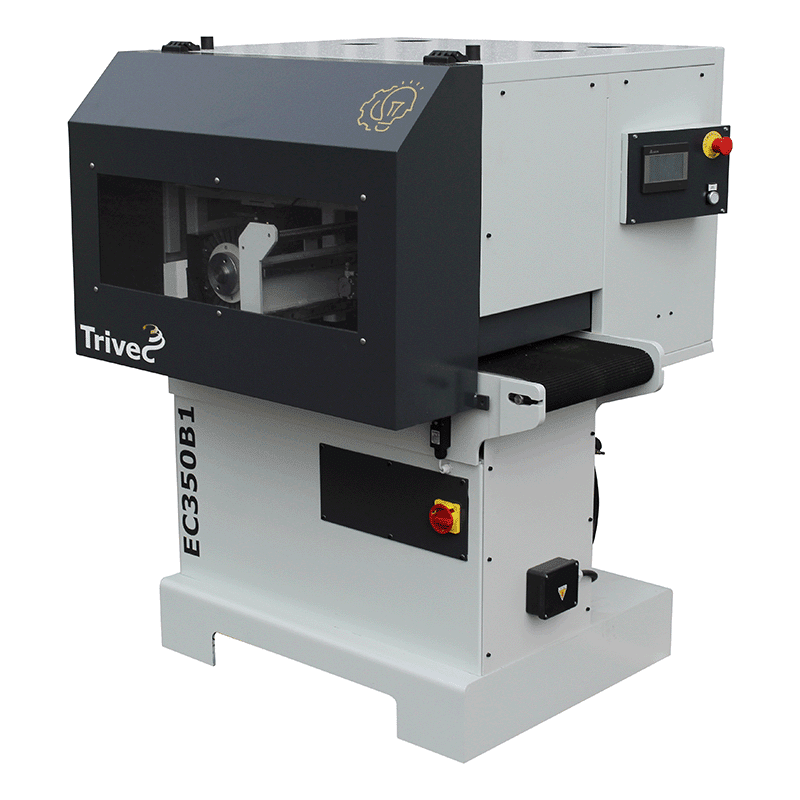

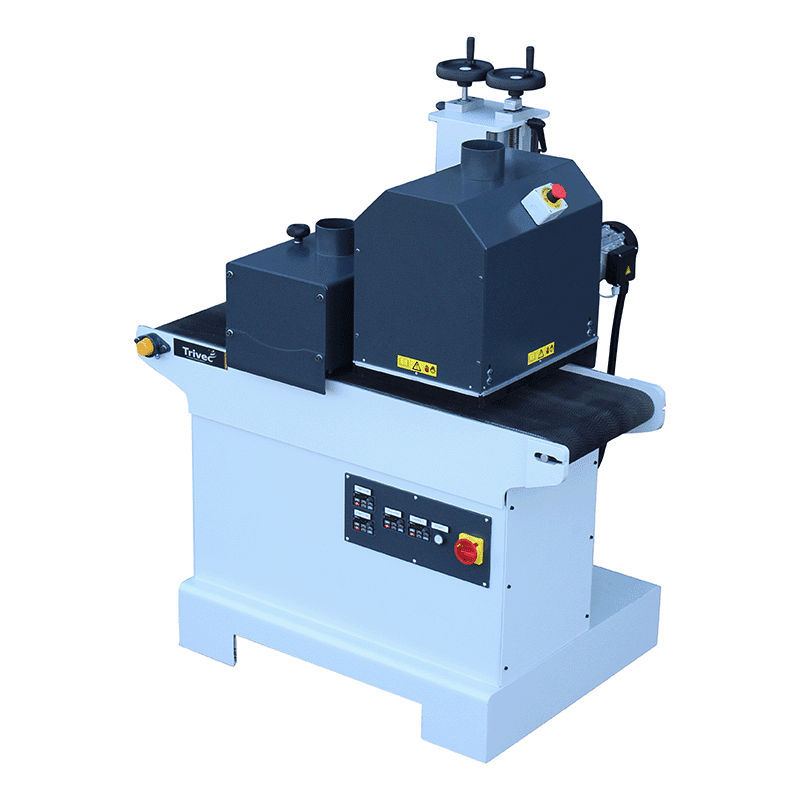

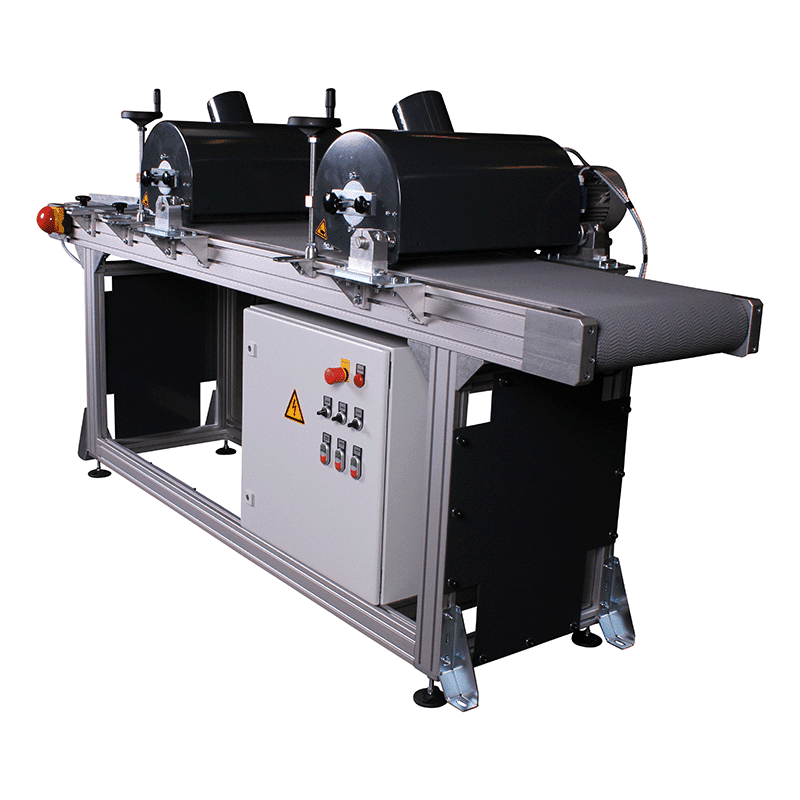

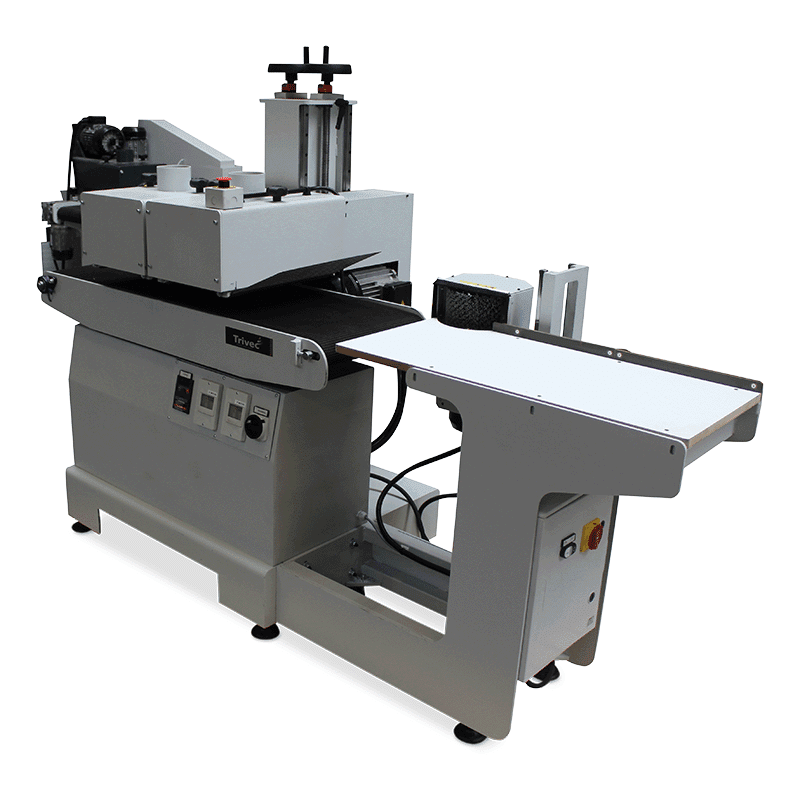

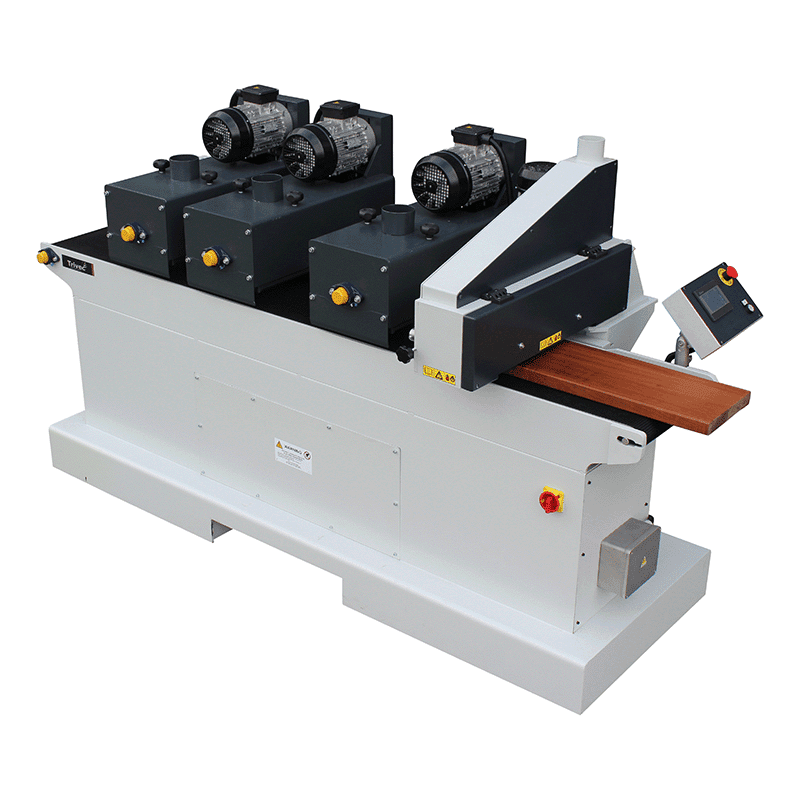

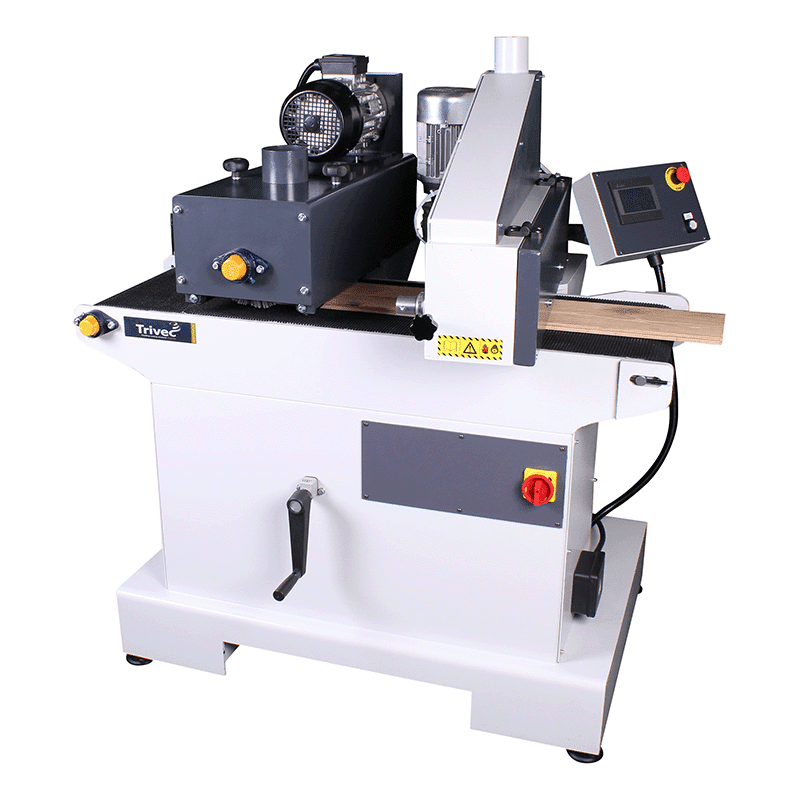

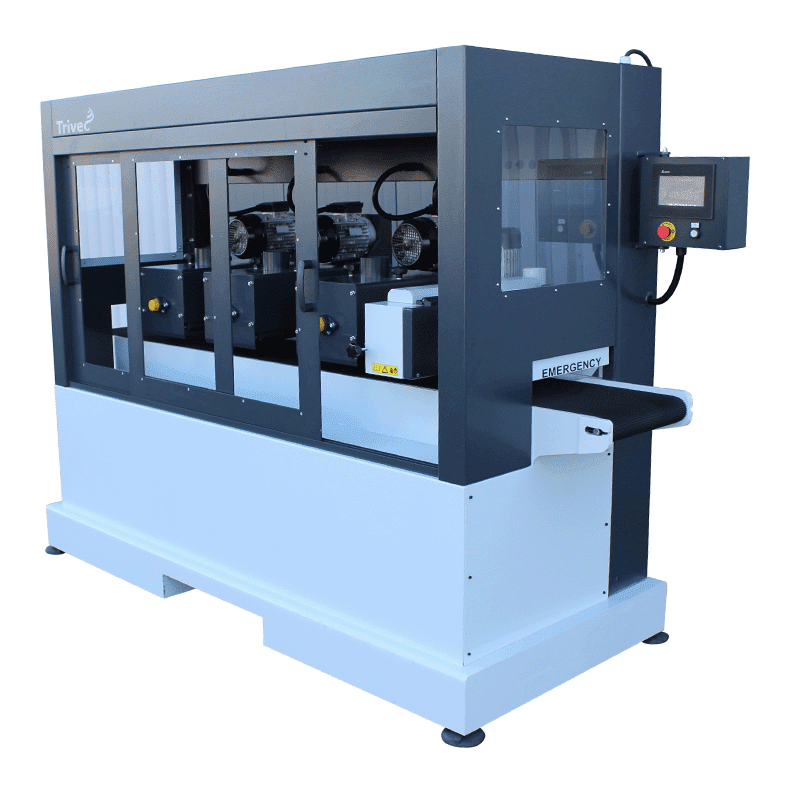

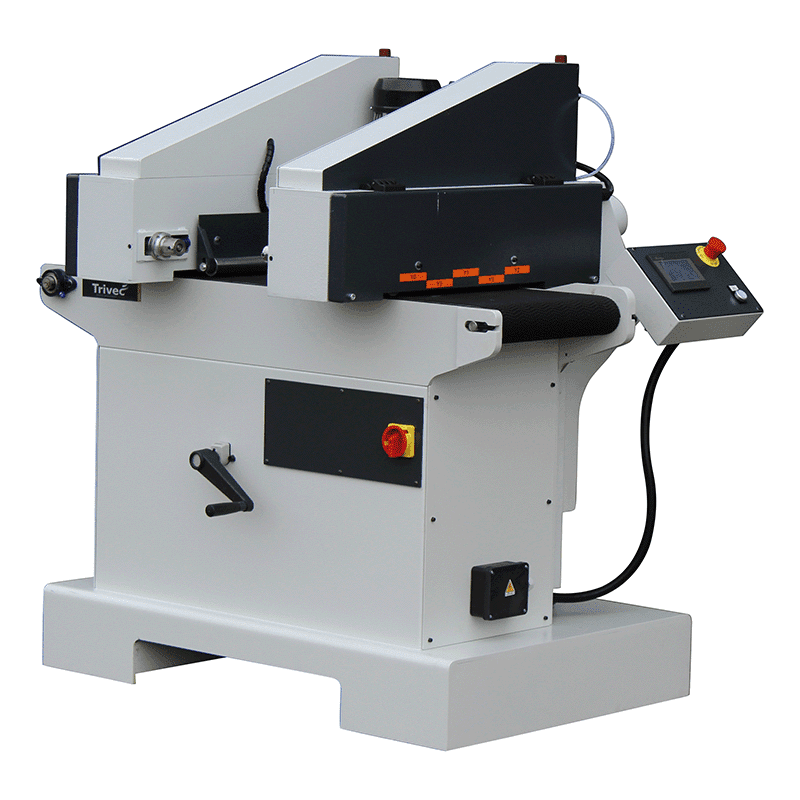

The Trivec Edge Cutter is used for the random aging of outer edges of parquet floorboards. The ECB-system (Edge Cutting Blade) in combination with an extensive PLC, workpieces can be hit at random or continuously depending on preferences.

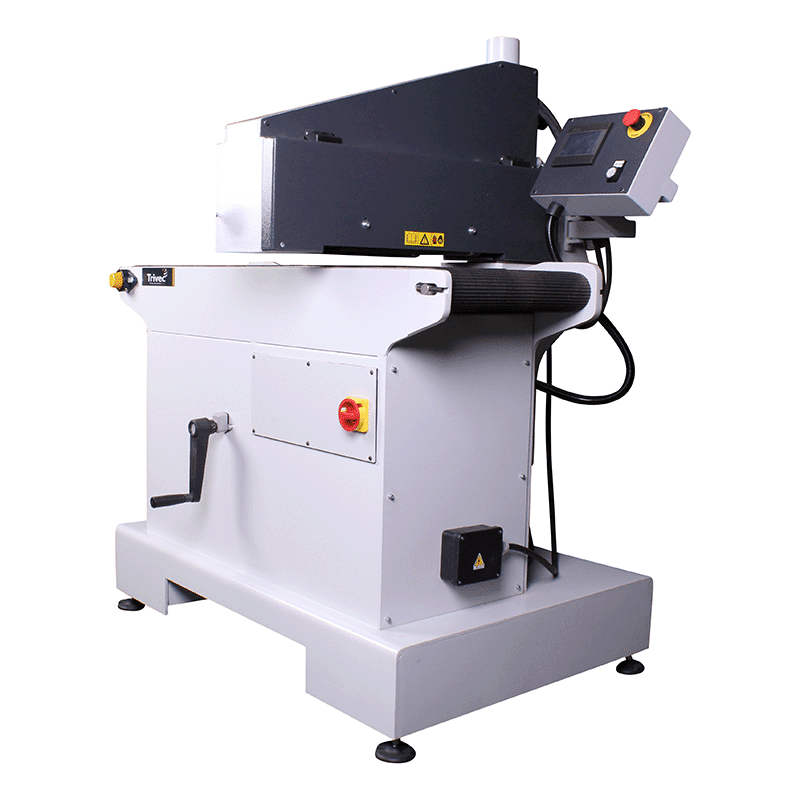

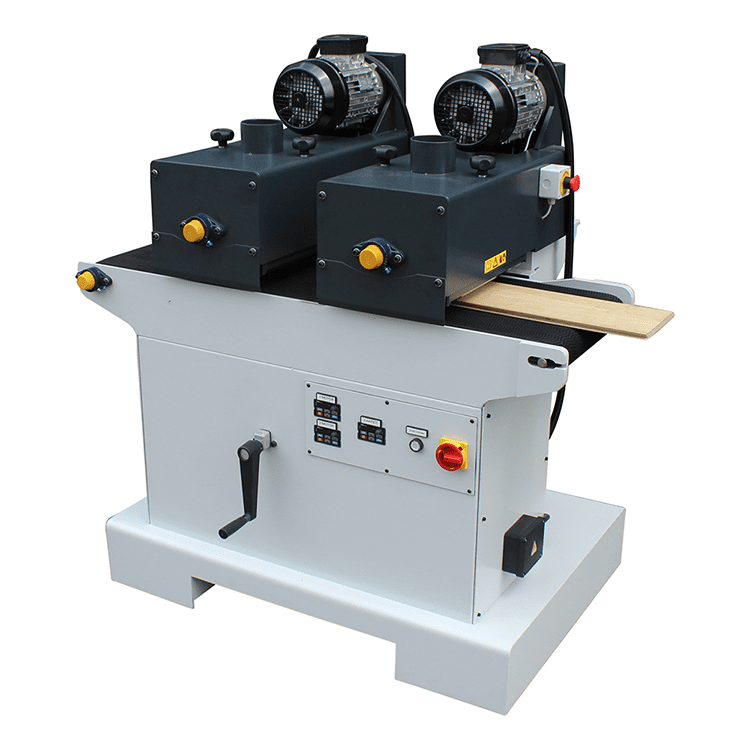

The system can be setup via the touchscreen, programs can then be stored in the memory of the system and can be called upon at any moment. The machine is equipped with a brush module on the second position to enable sanding or light structuring of the panelling after aging. Aspects such as throughput speed, edge cutting speed, type of blade, brush speed, brush pressure, brush type, and blade pressure, many effects are possible. The Edge Cutter can be used as a standalone machine, or in combination with other machines from the Trivec machine program.