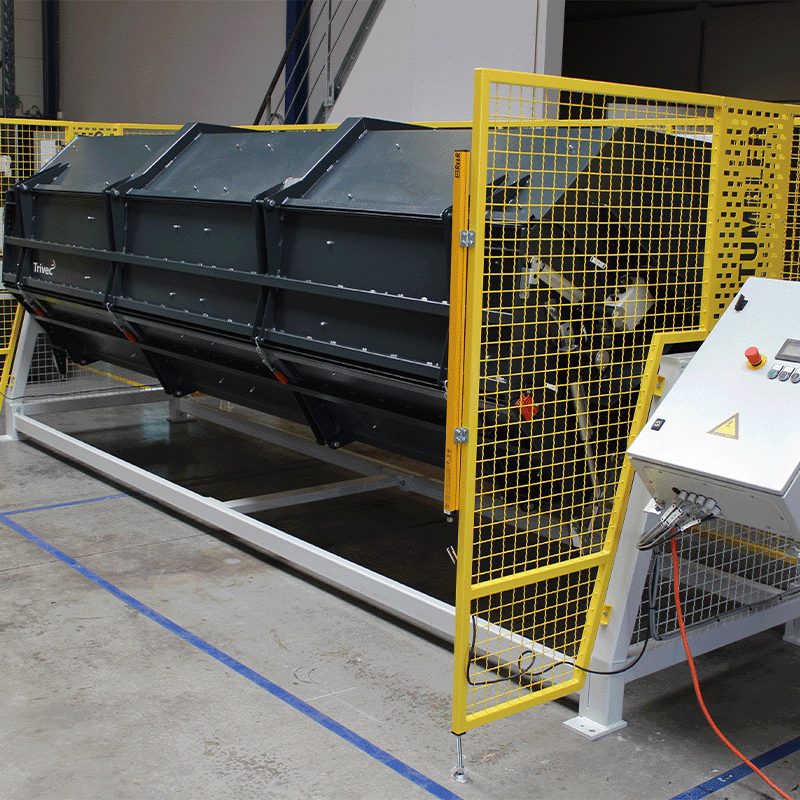

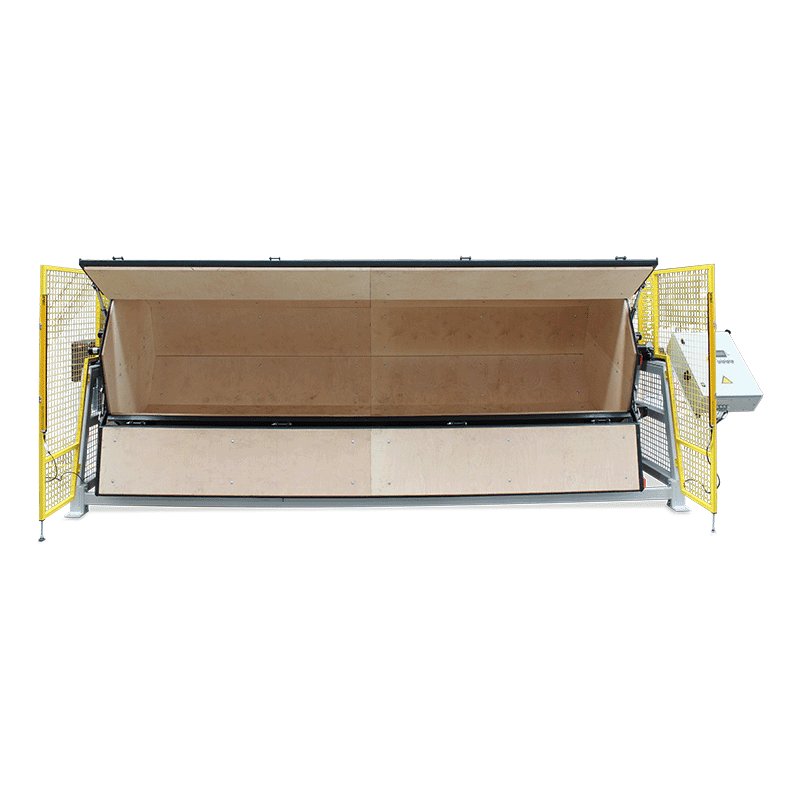

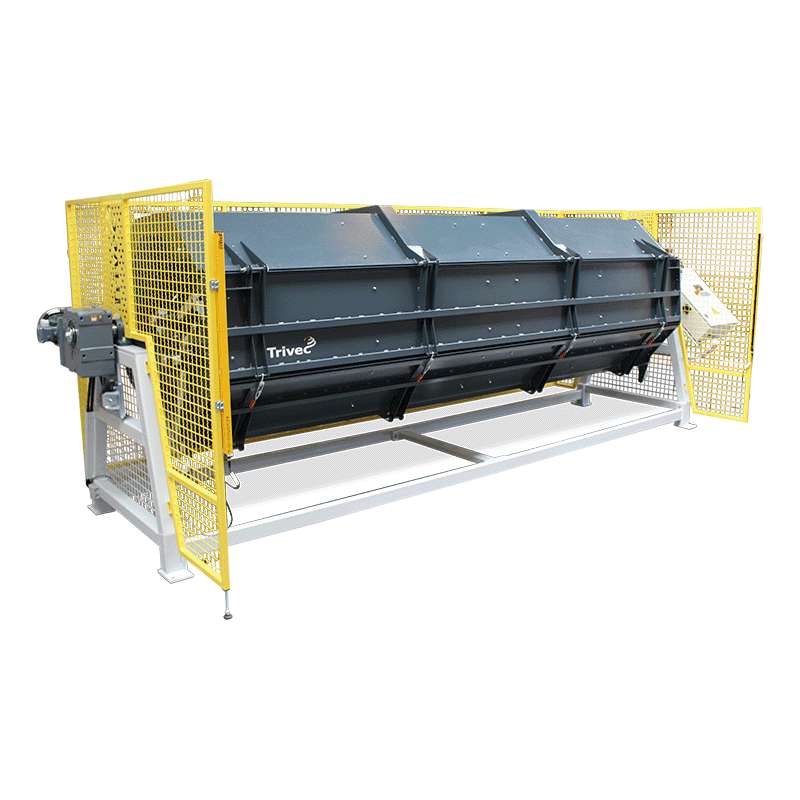

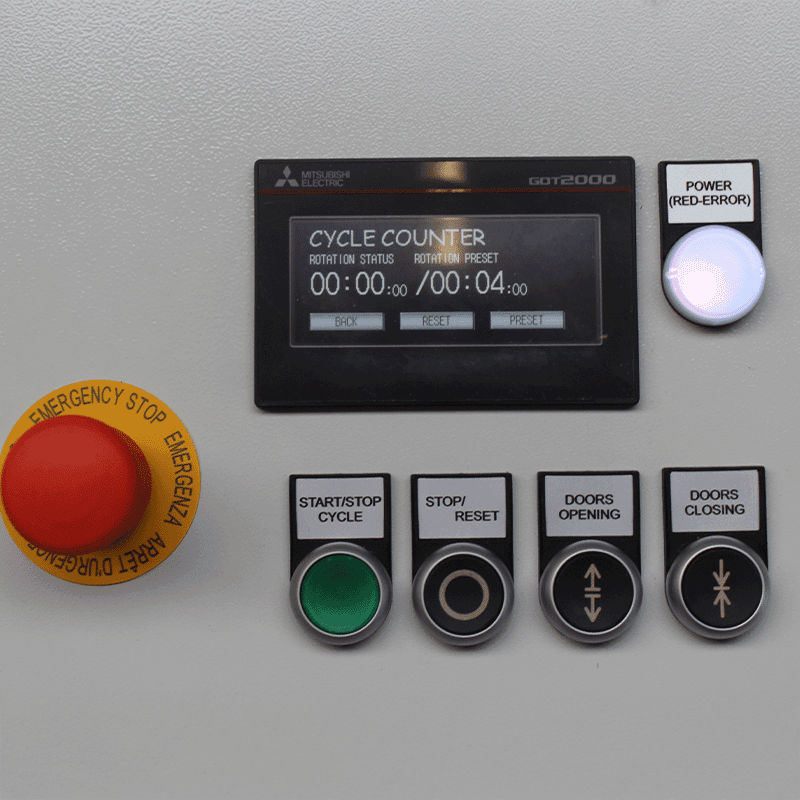

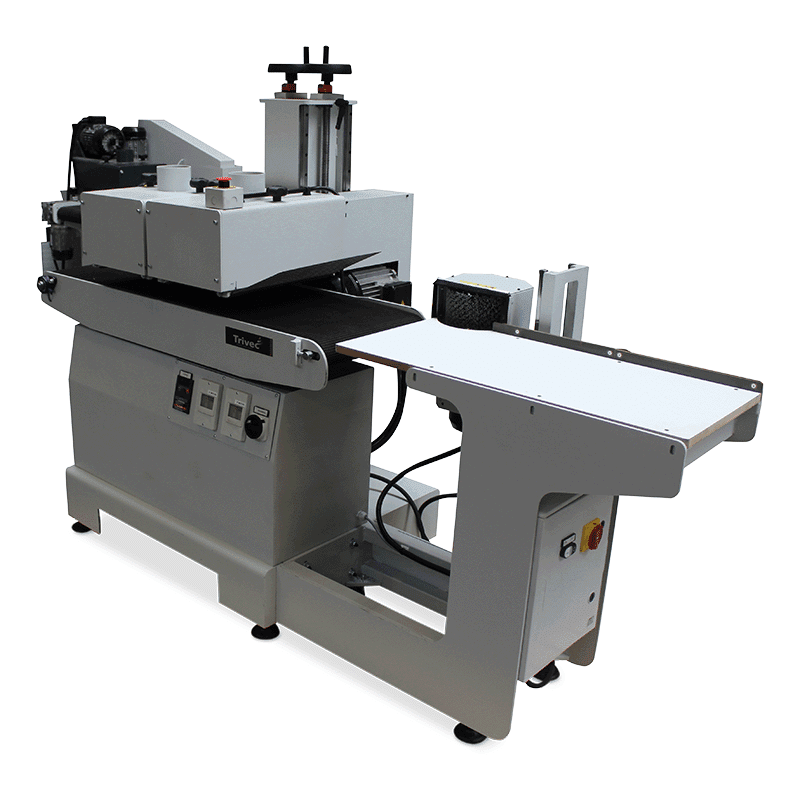

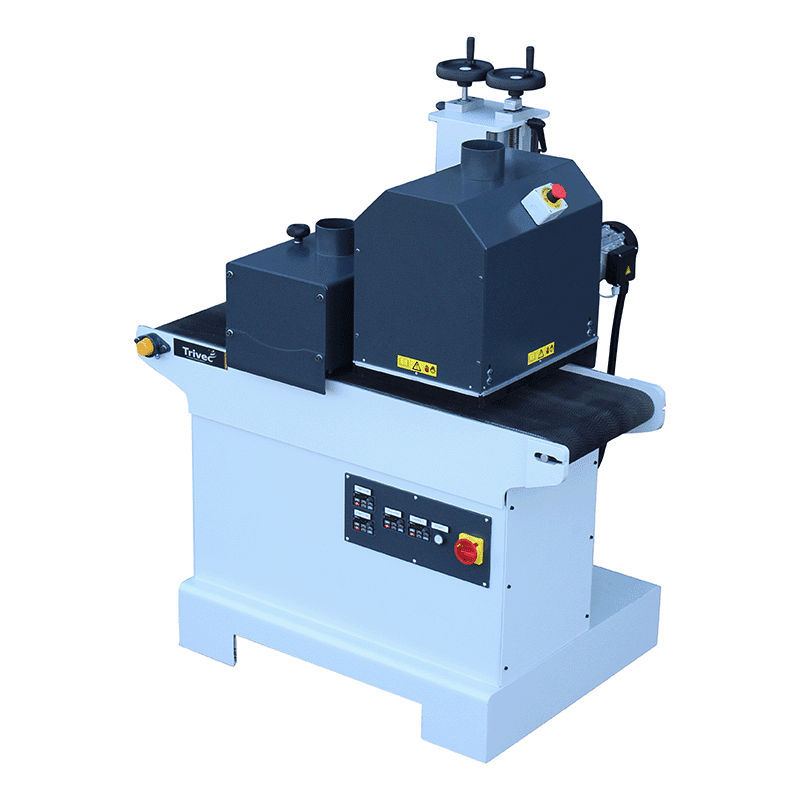

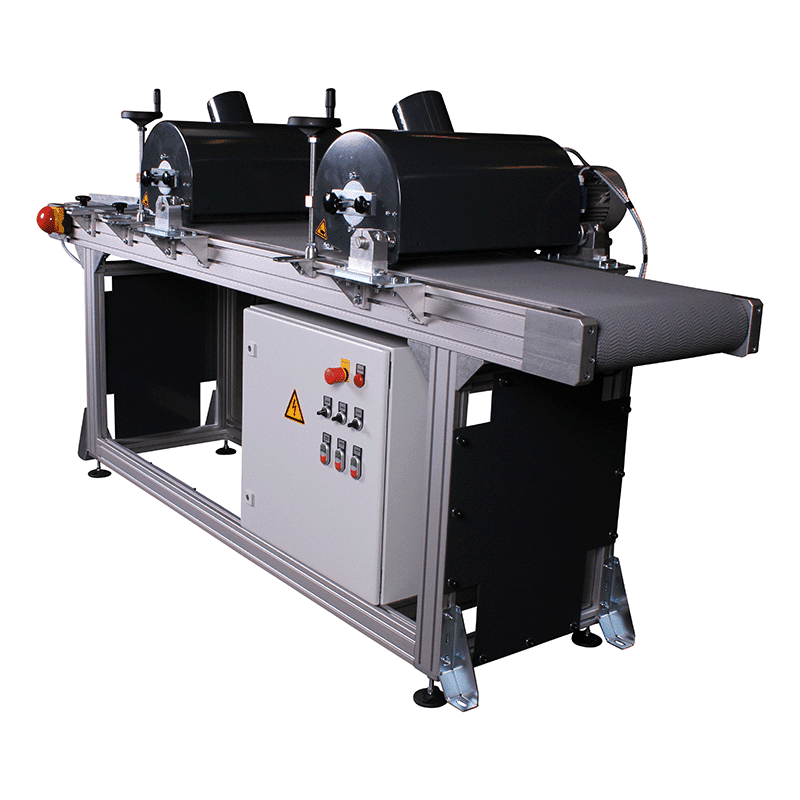

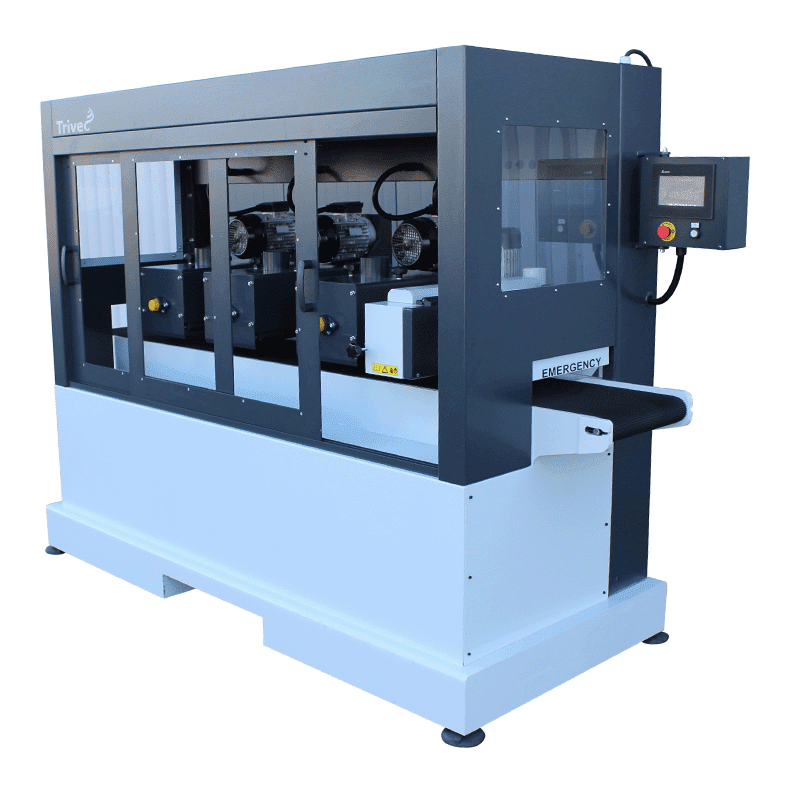

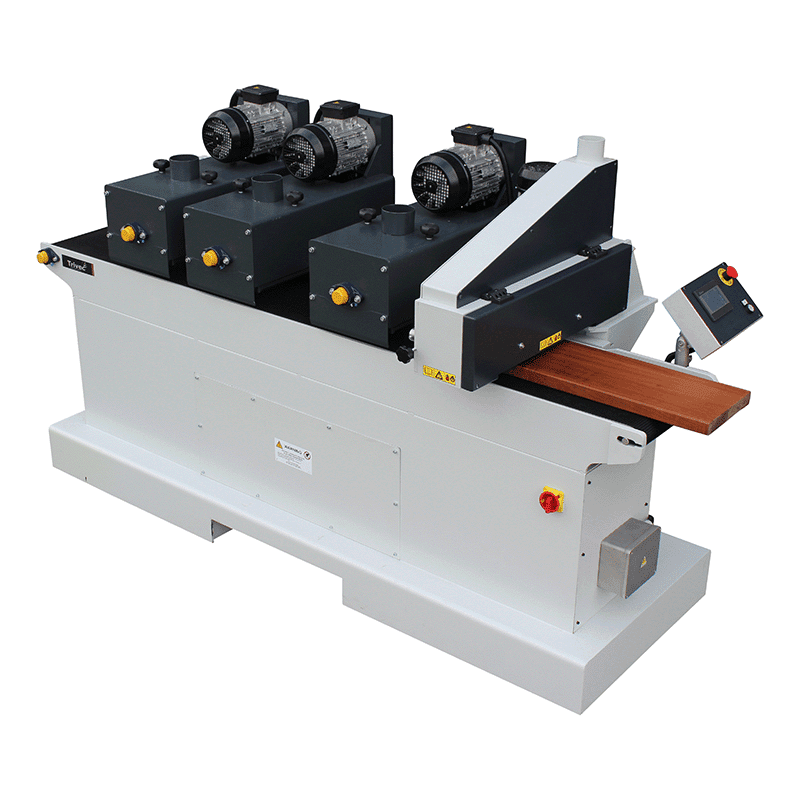

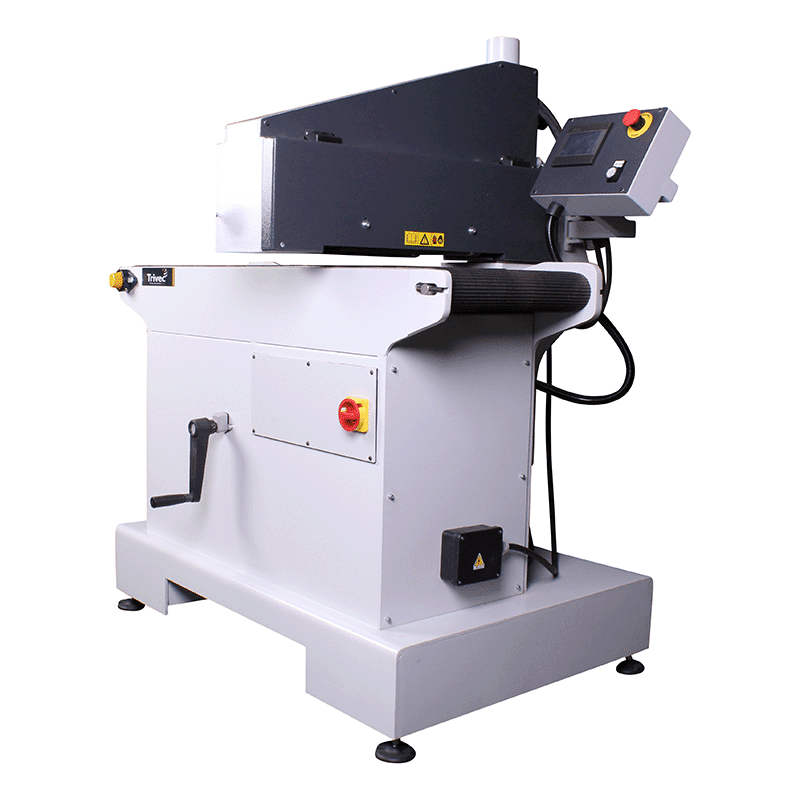

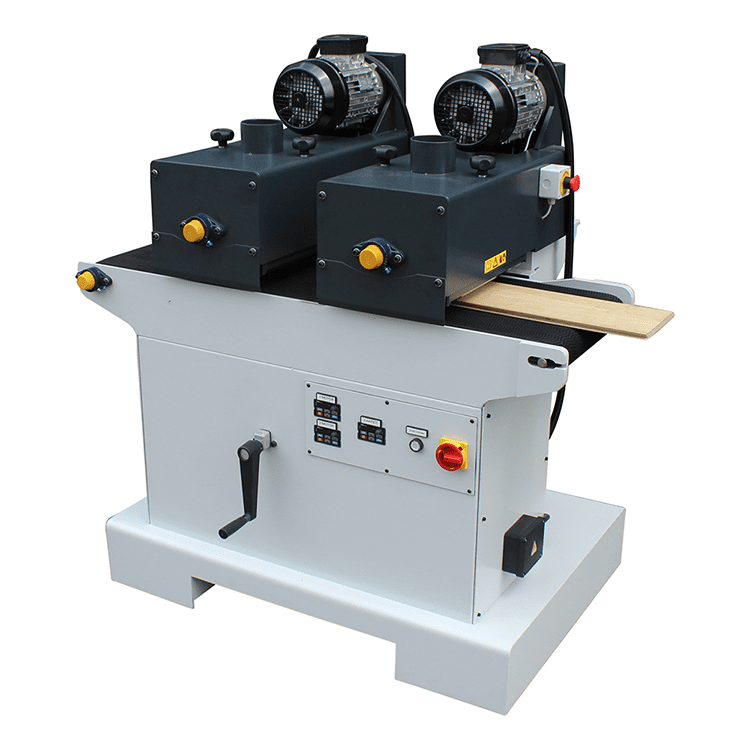

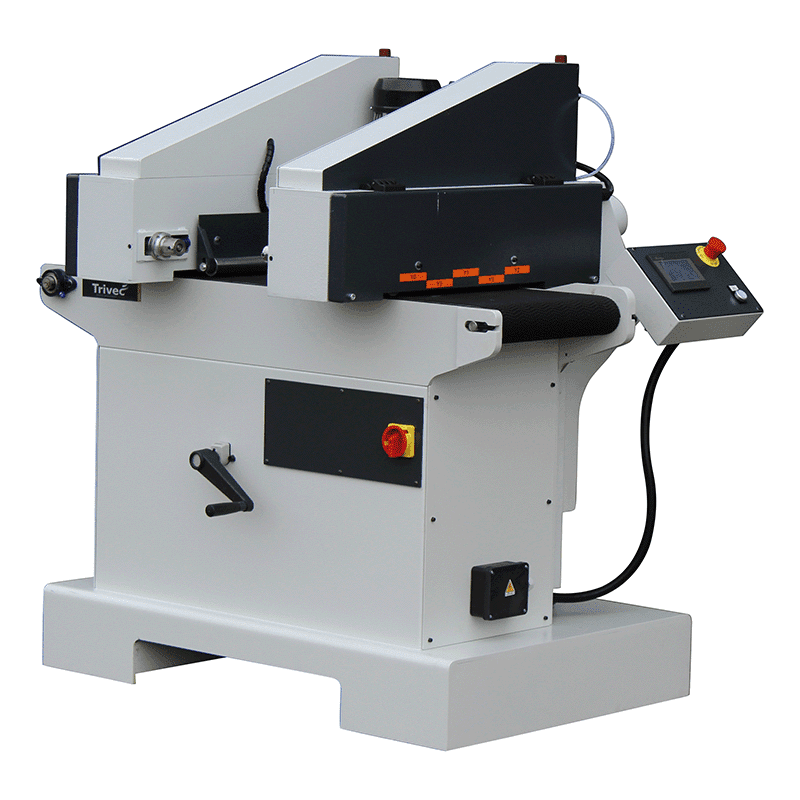

Engineered to give wooden surfaces a beautiful, aged appearance in just minutes. With adjustable tumble speed and time, this machine offers a fast and efficient way to create custom vintage effects on your wood surfaces. The boards can be easily loaded into the tumbler via the wide doors. The doors open and close electrically via the touchscreen on control panel. Equipped with sensor technology that prevents the operation of the machine while an operator is within the safety zone.

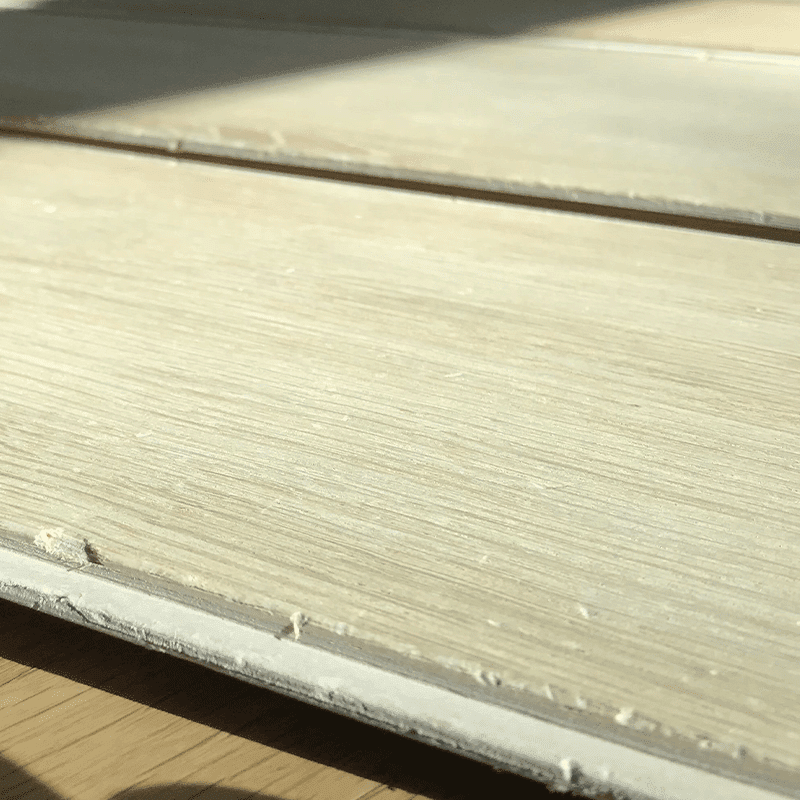

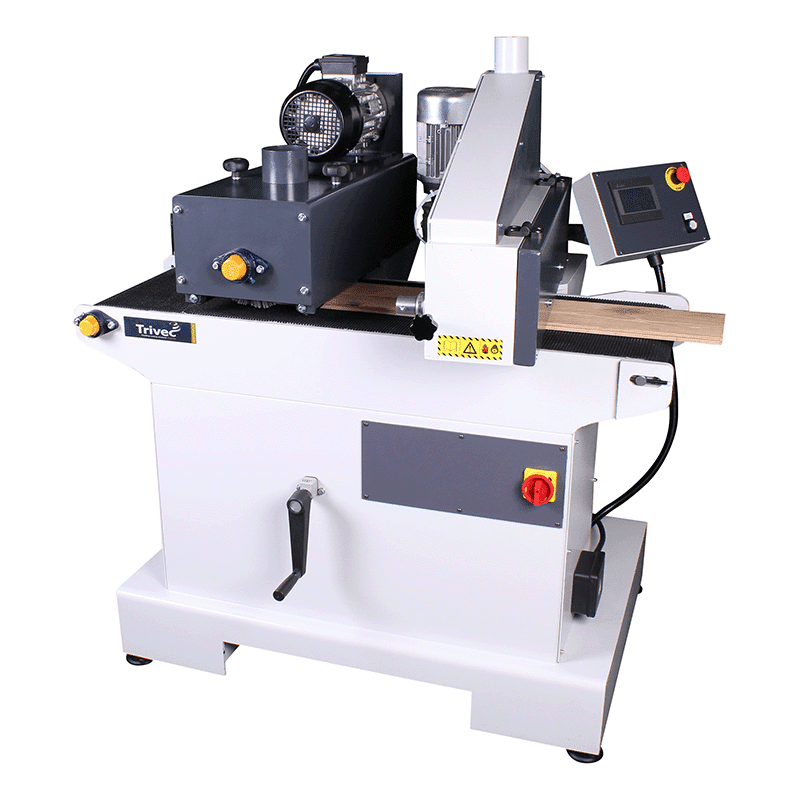

The aging floors effect depends on the material that is added to the drum together with the floorboards this material could be, nuts, bolts, pebbles or special Trivec Tumbler stones. Old fashioned tumbling still remains the best method for creating natural looking aging effects for any type of wood.