Parquet

Solutions

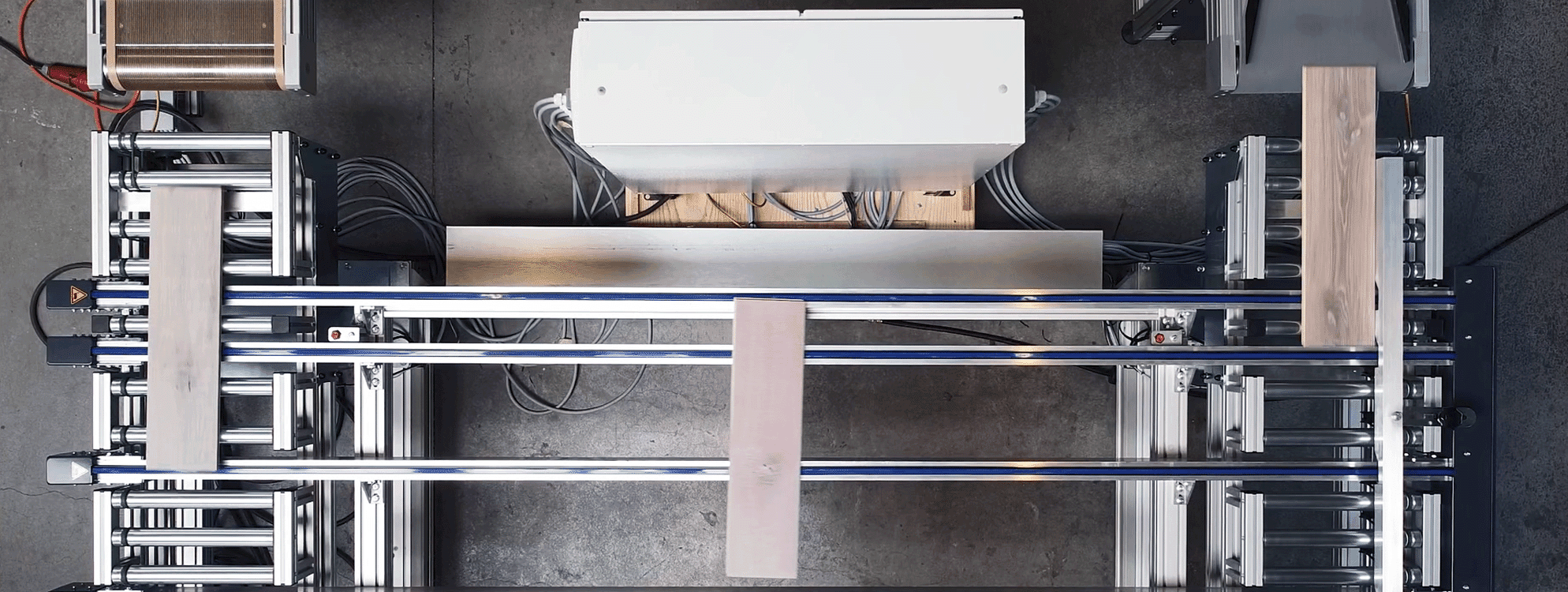

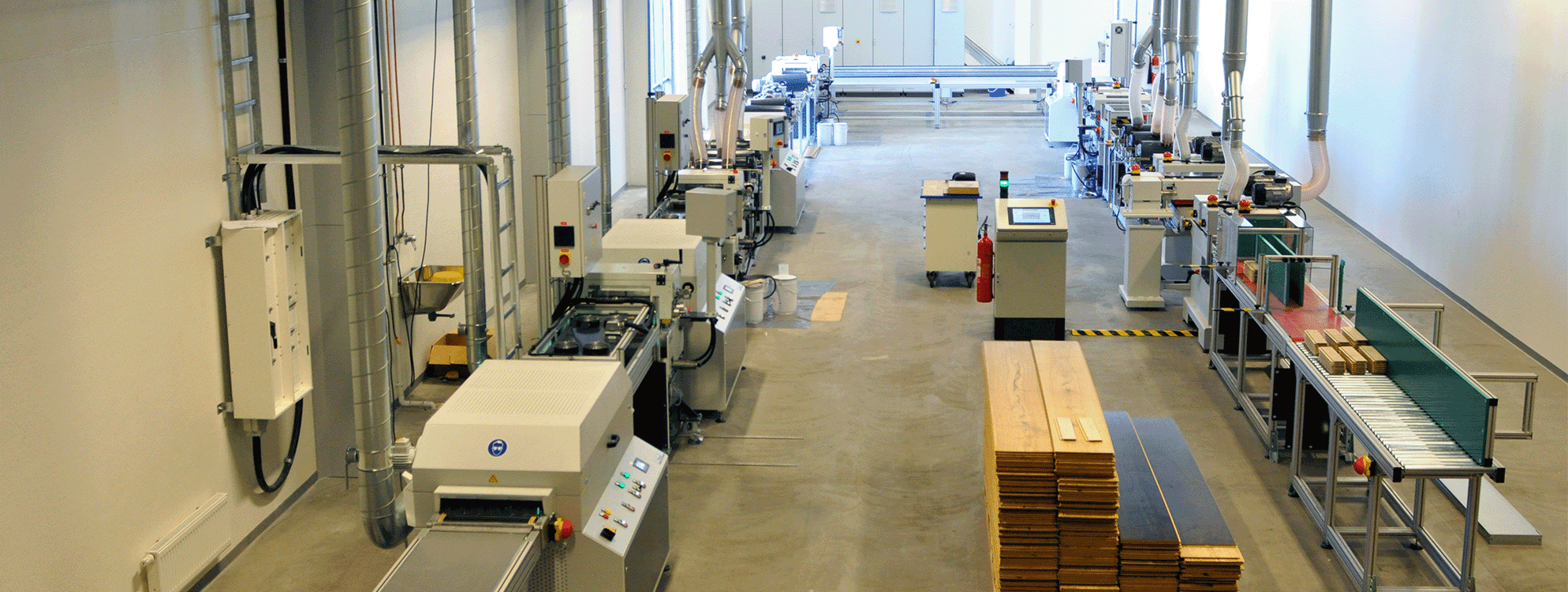

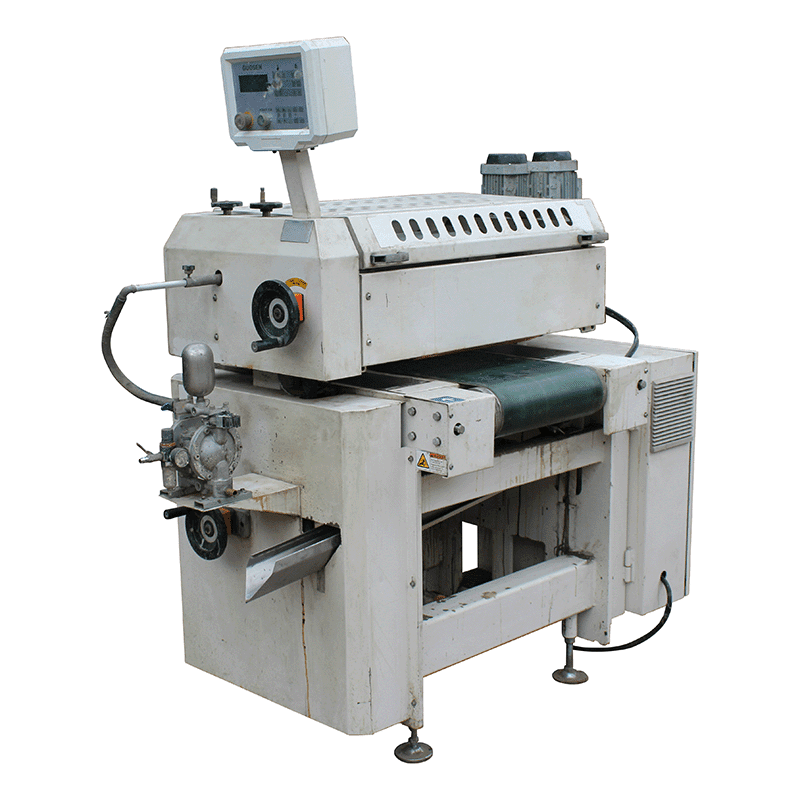

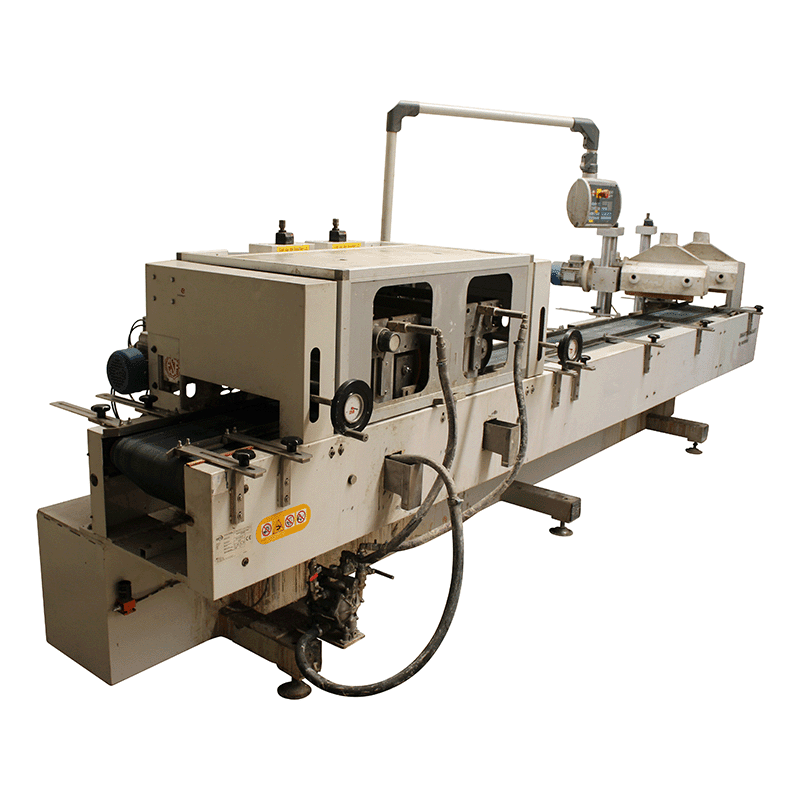

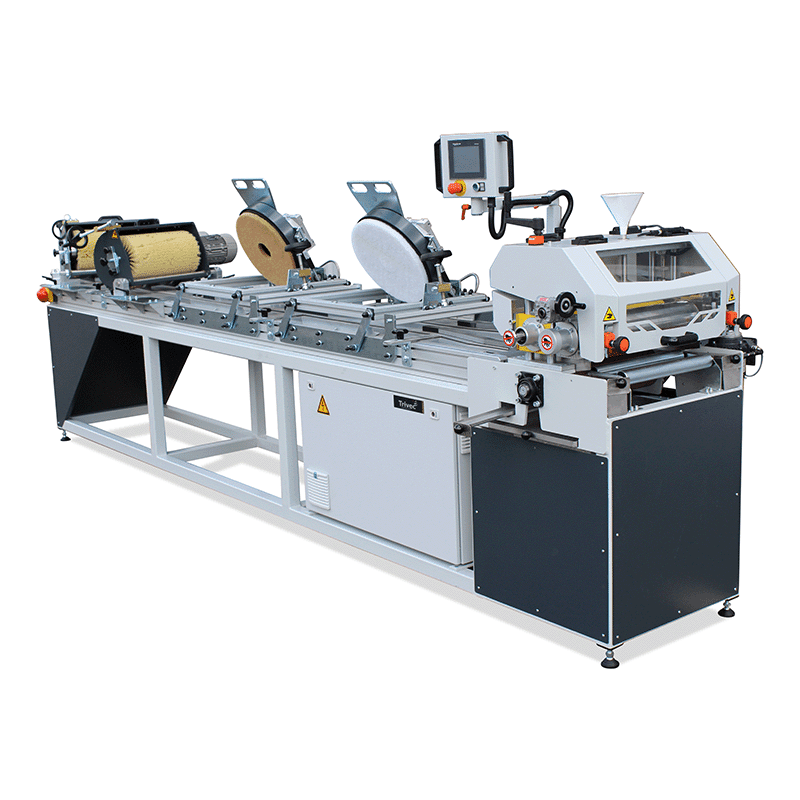

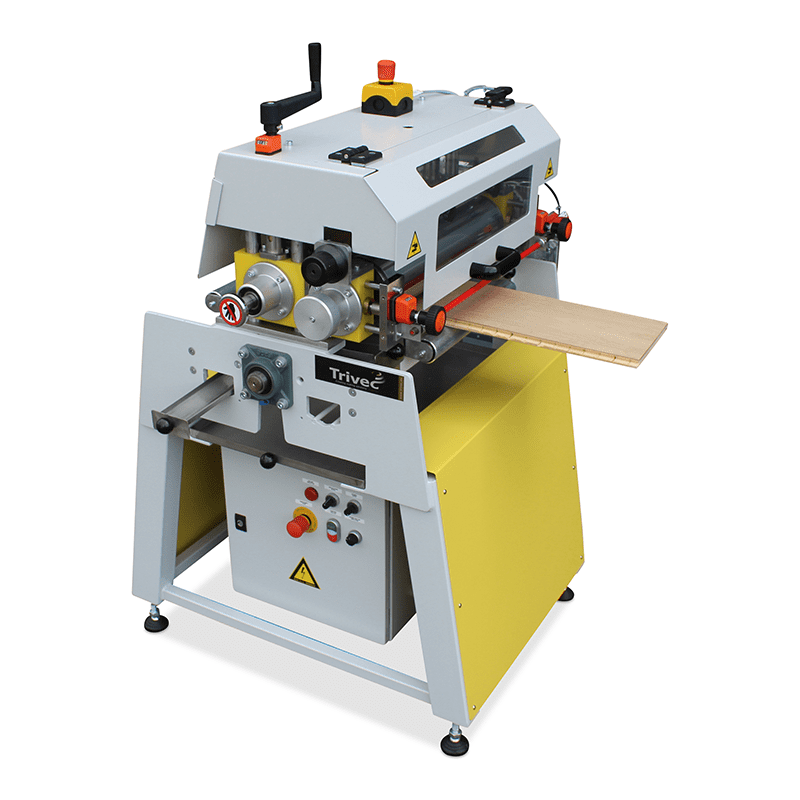

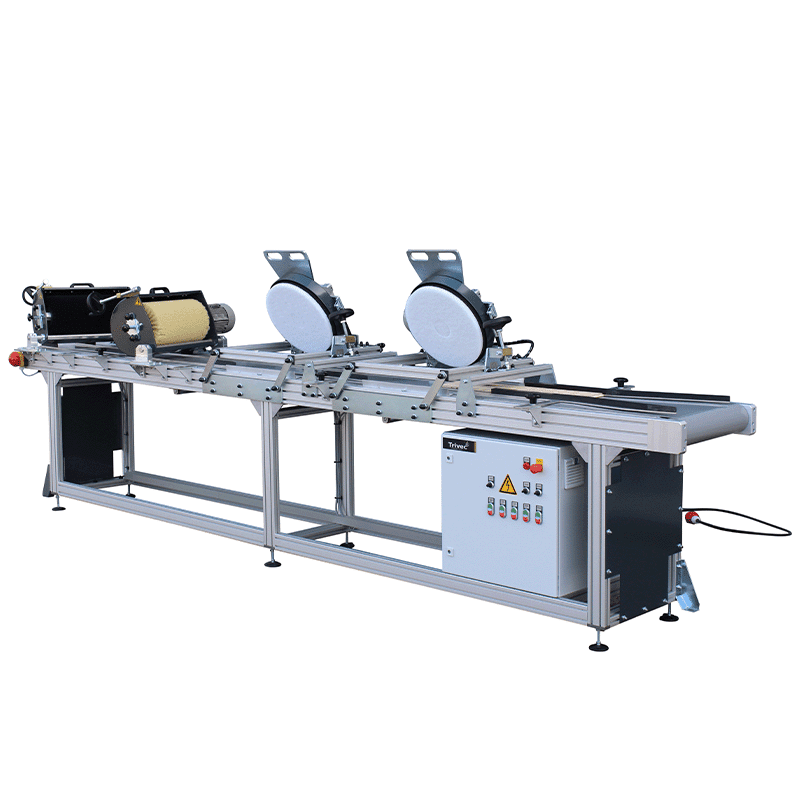

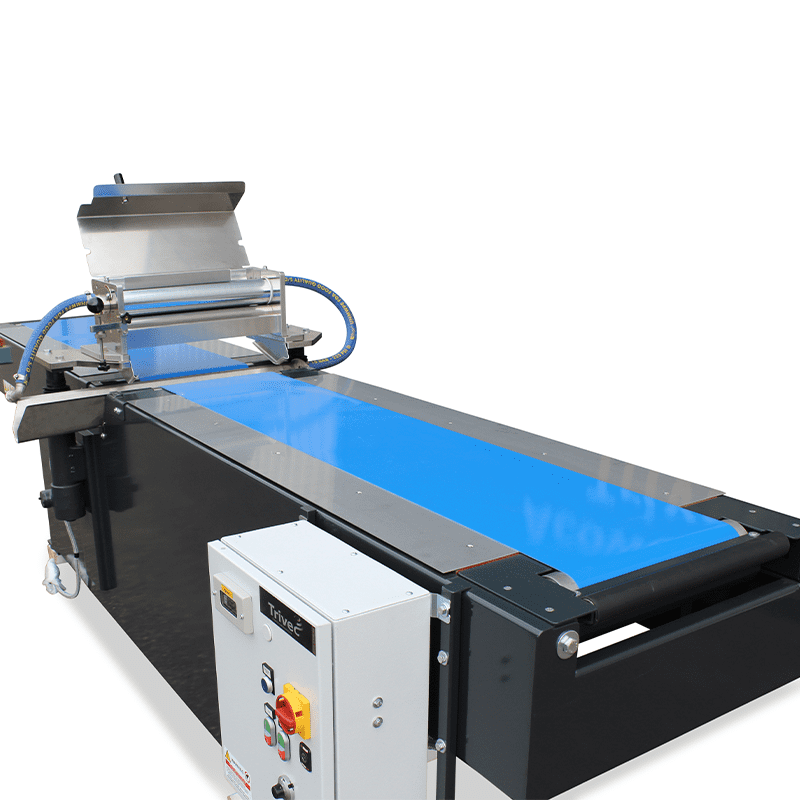

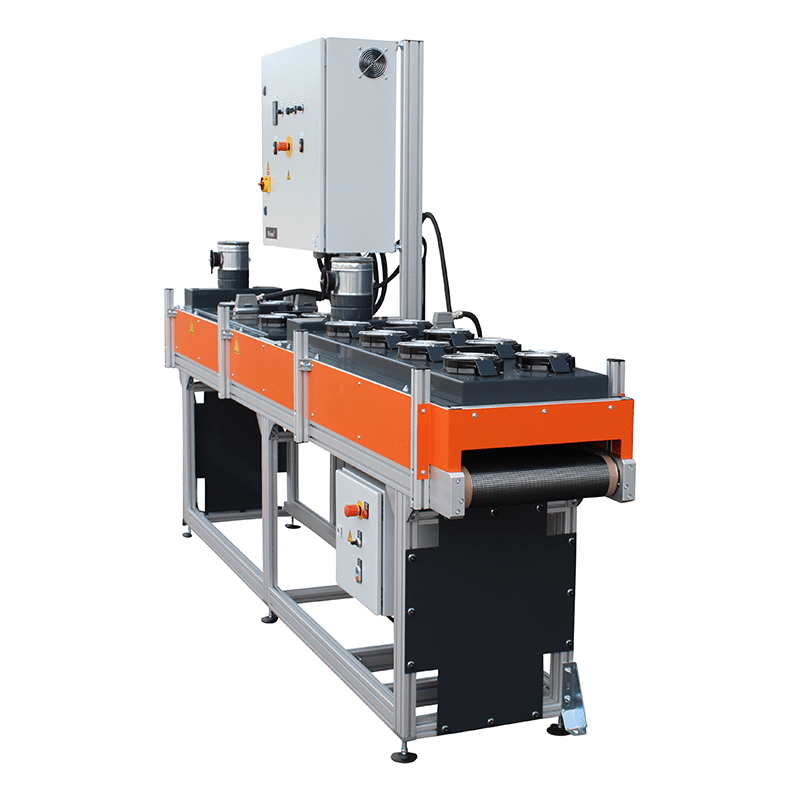

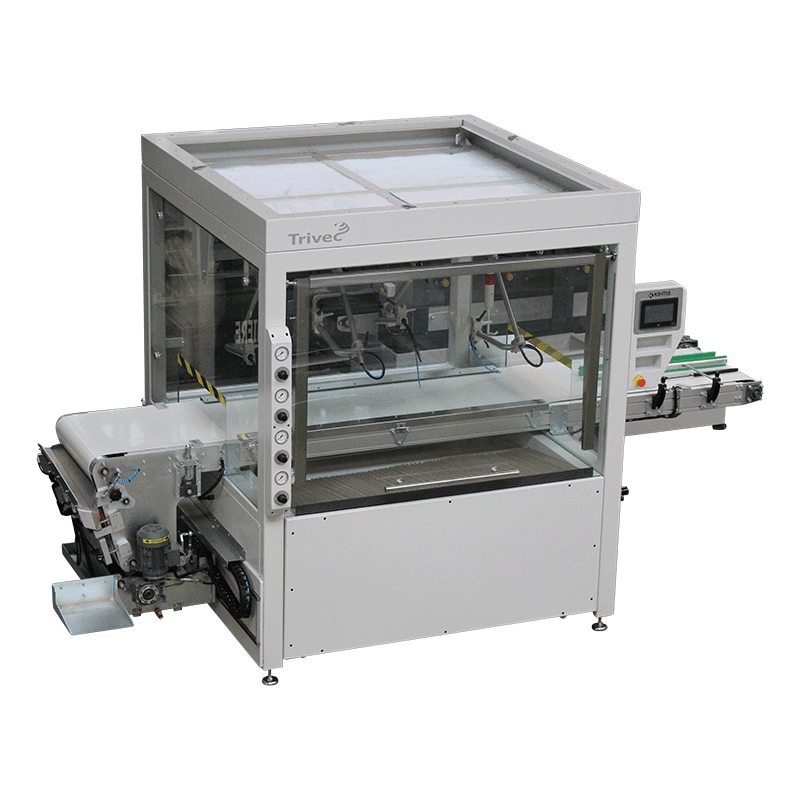

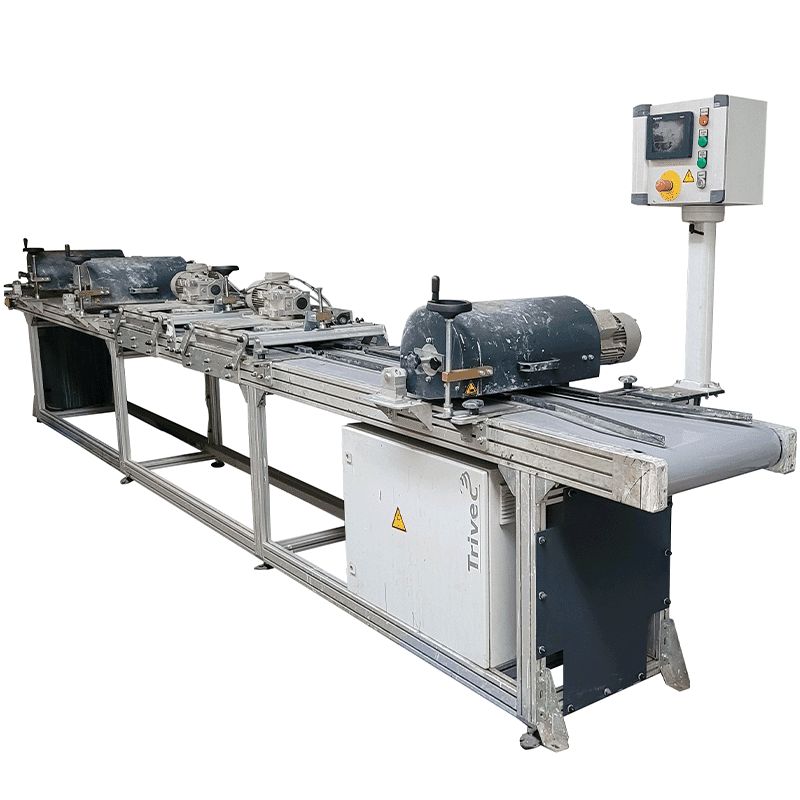

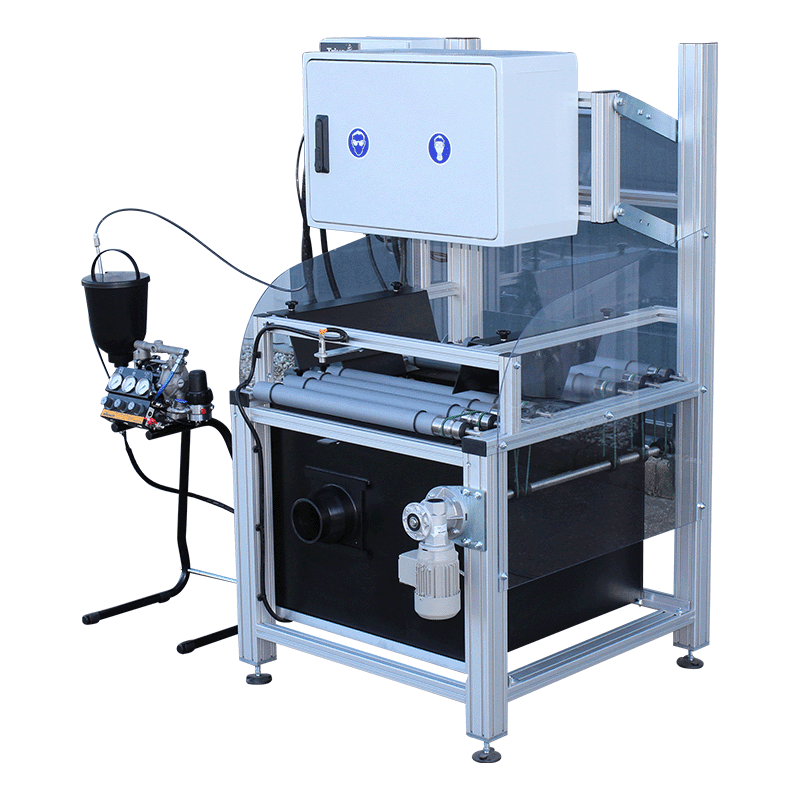

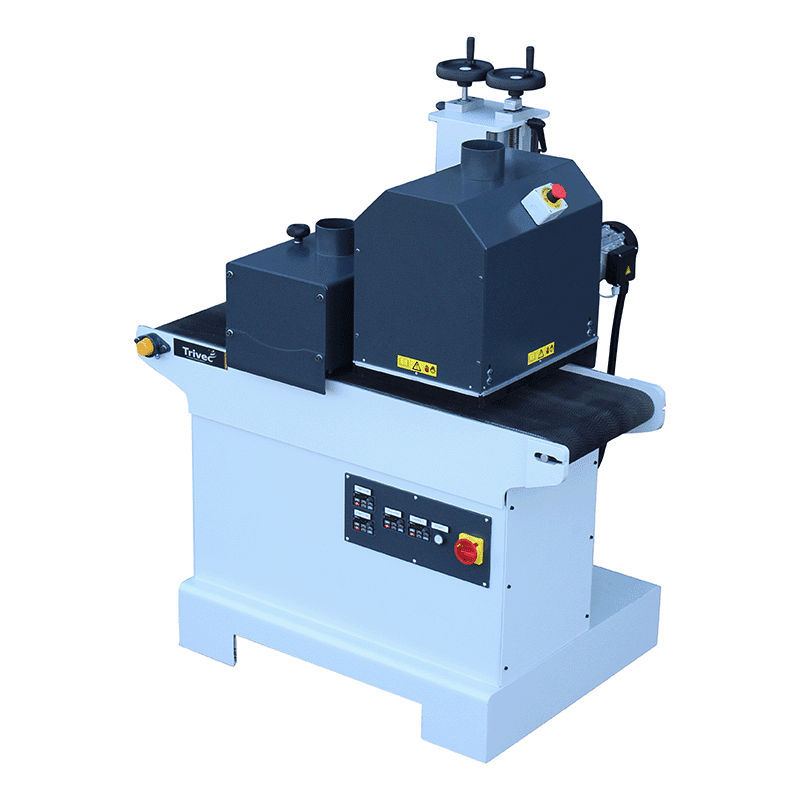

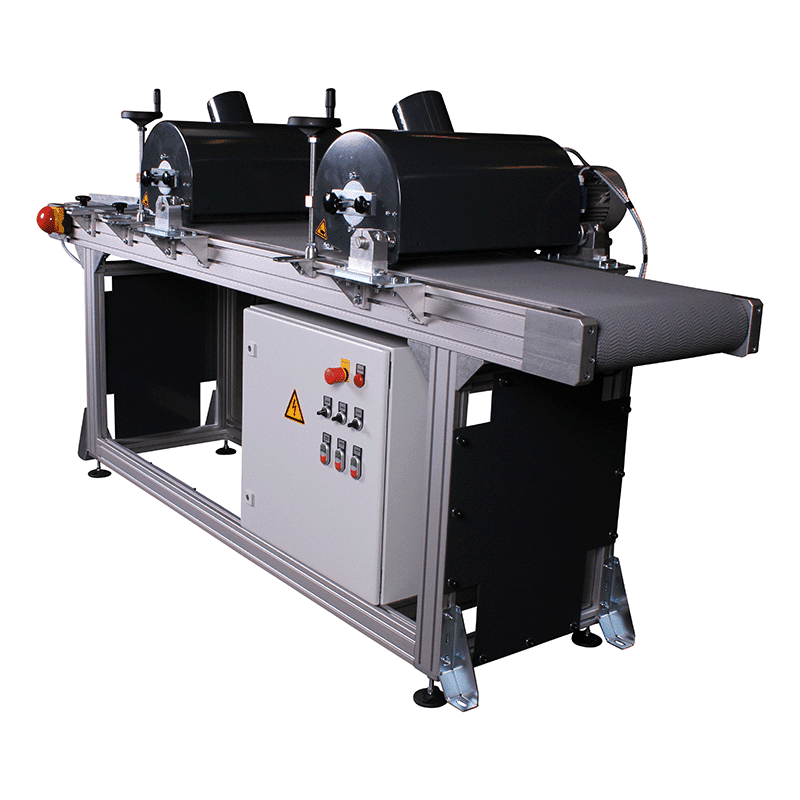

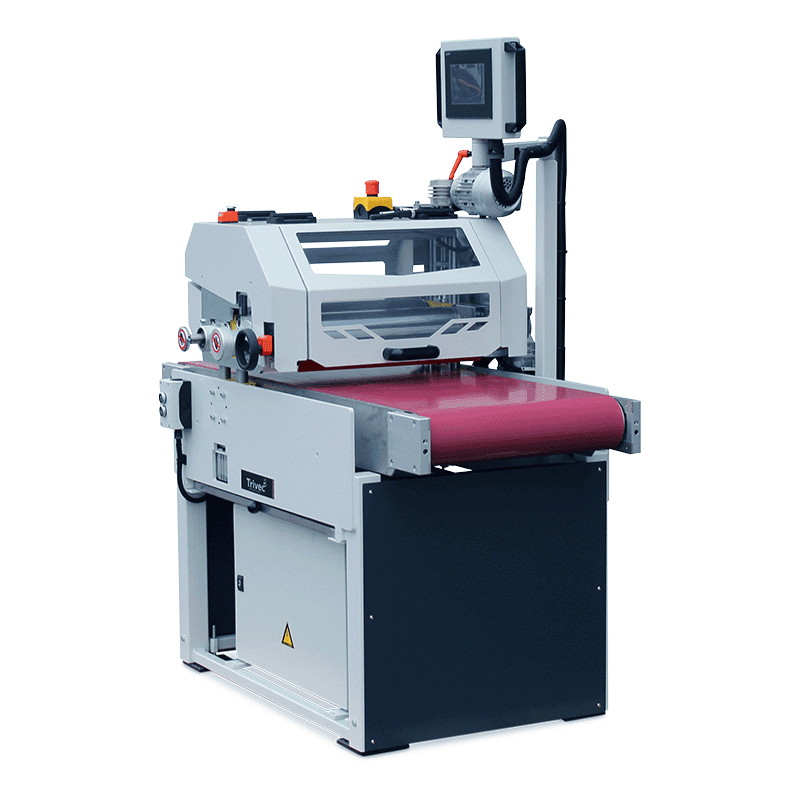

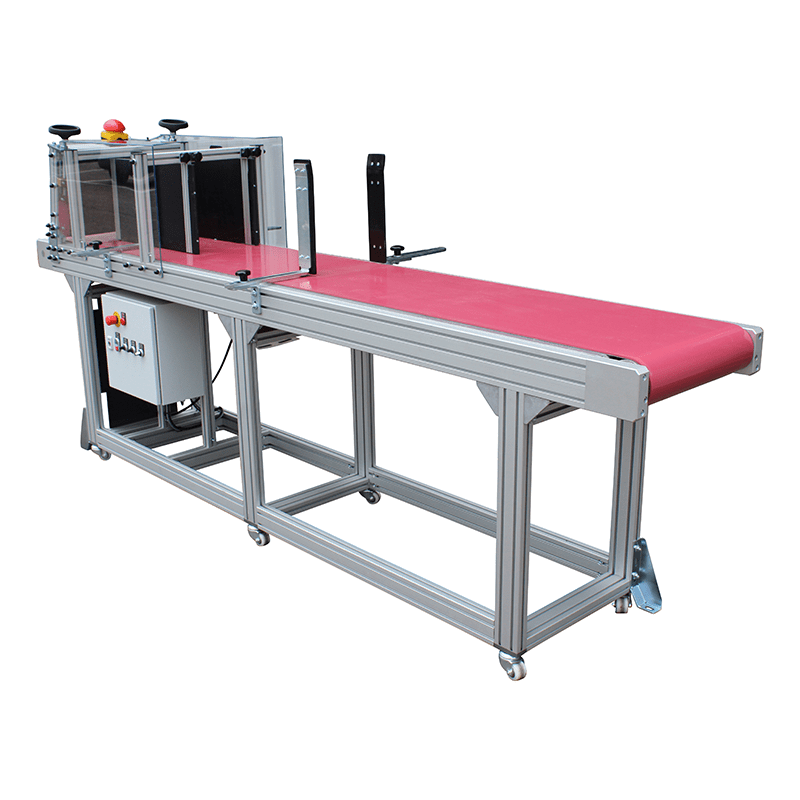

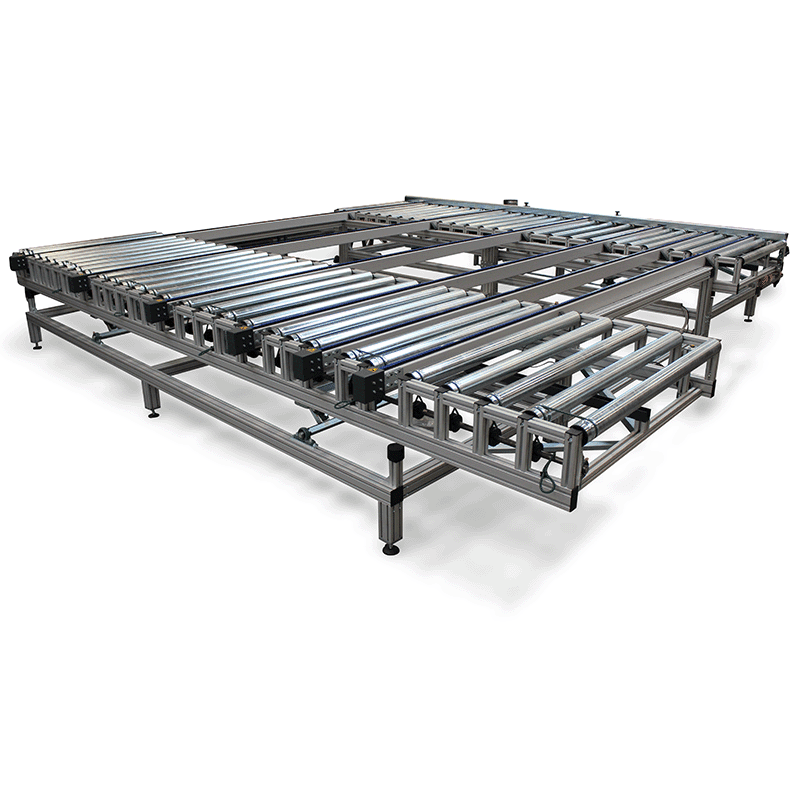

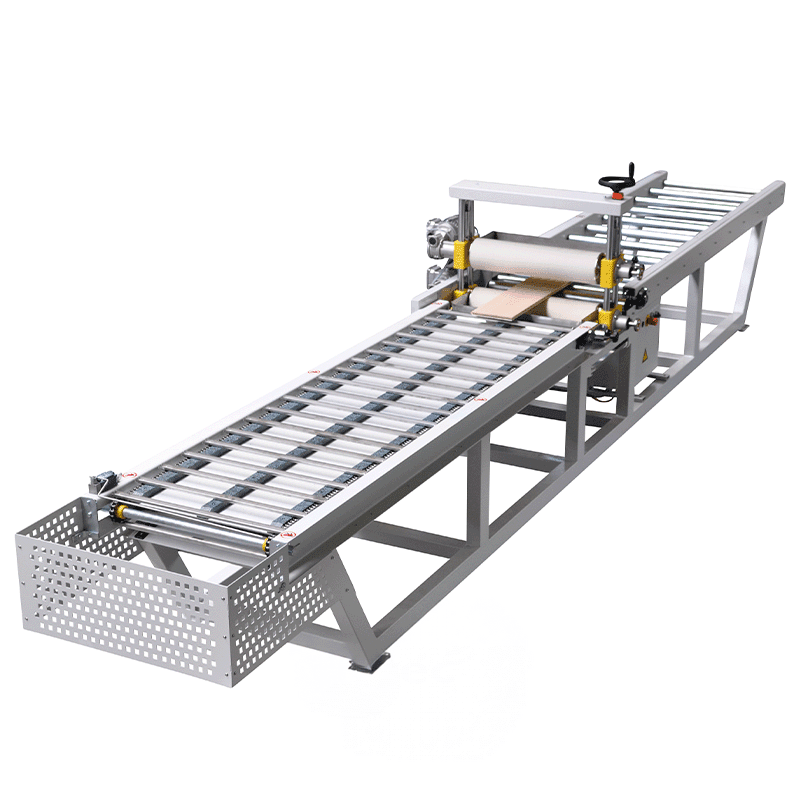

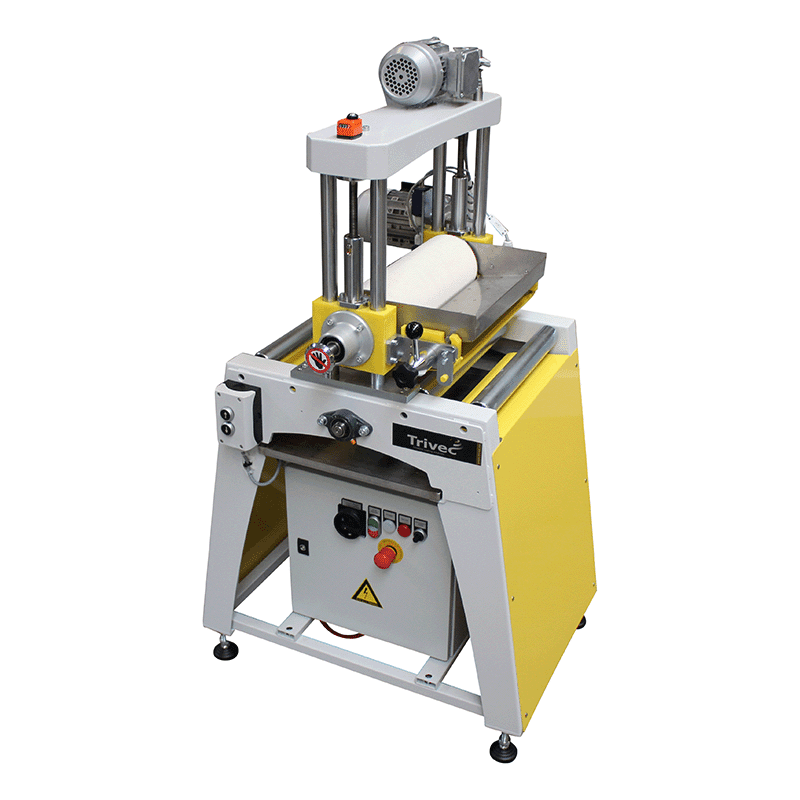

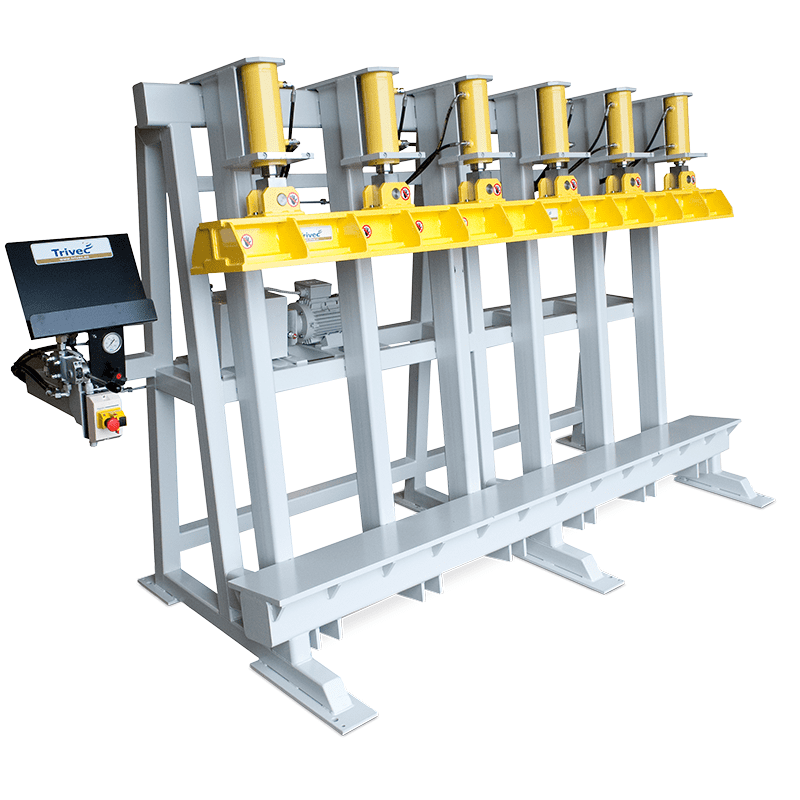

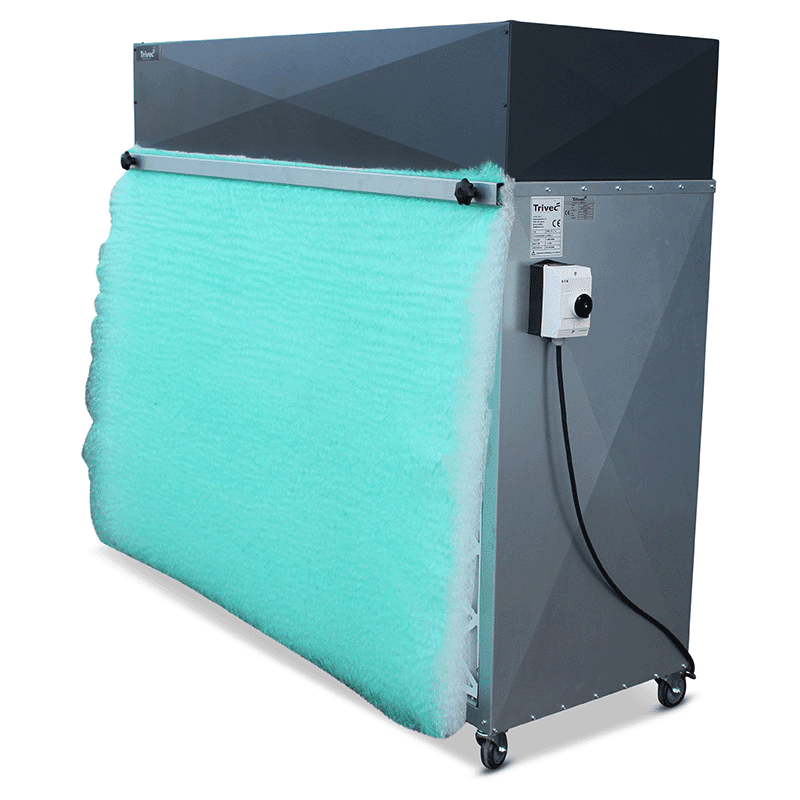

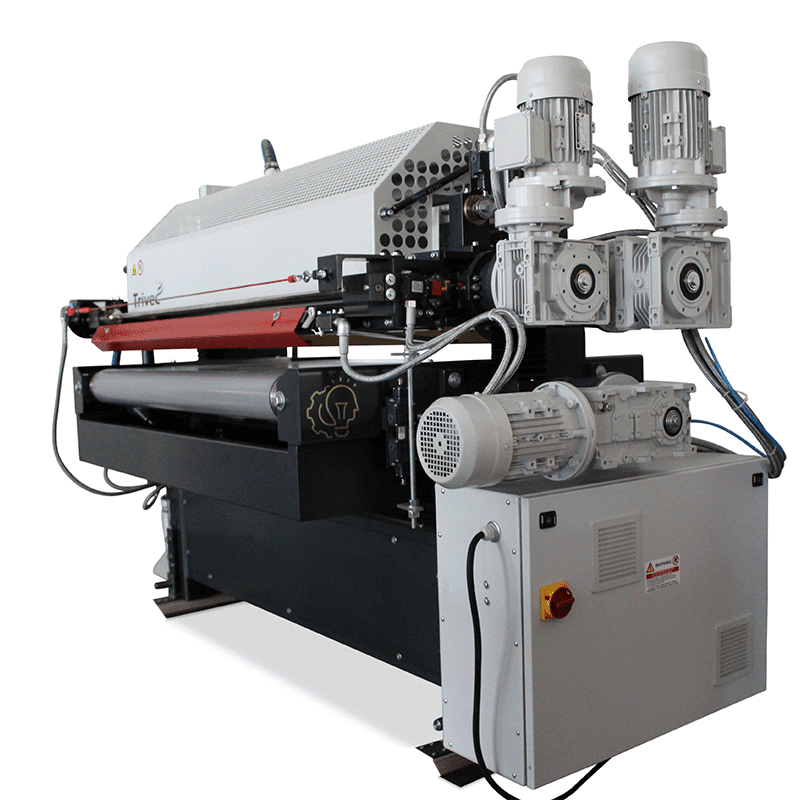

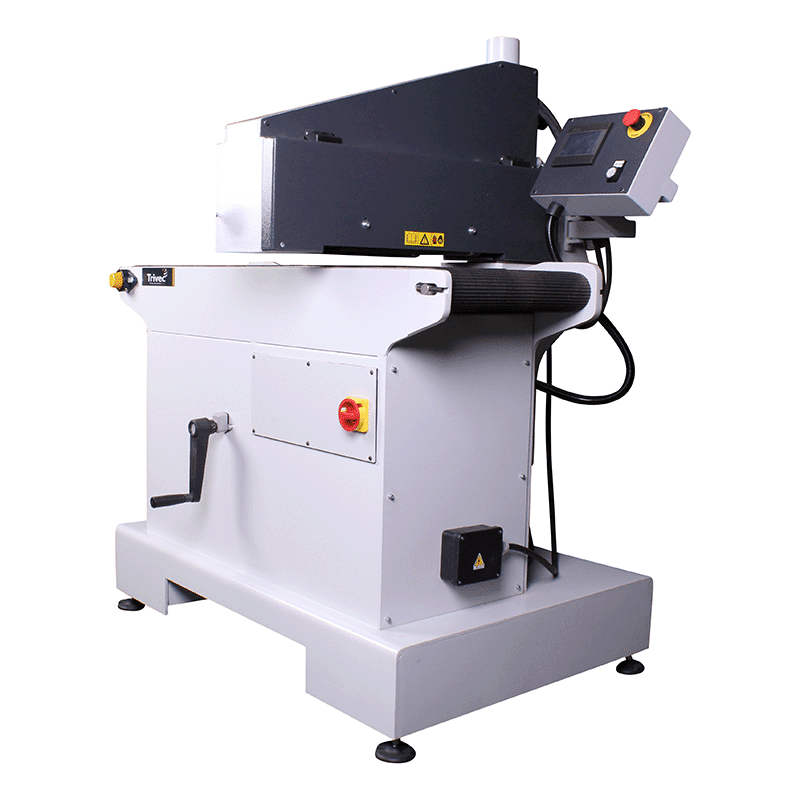

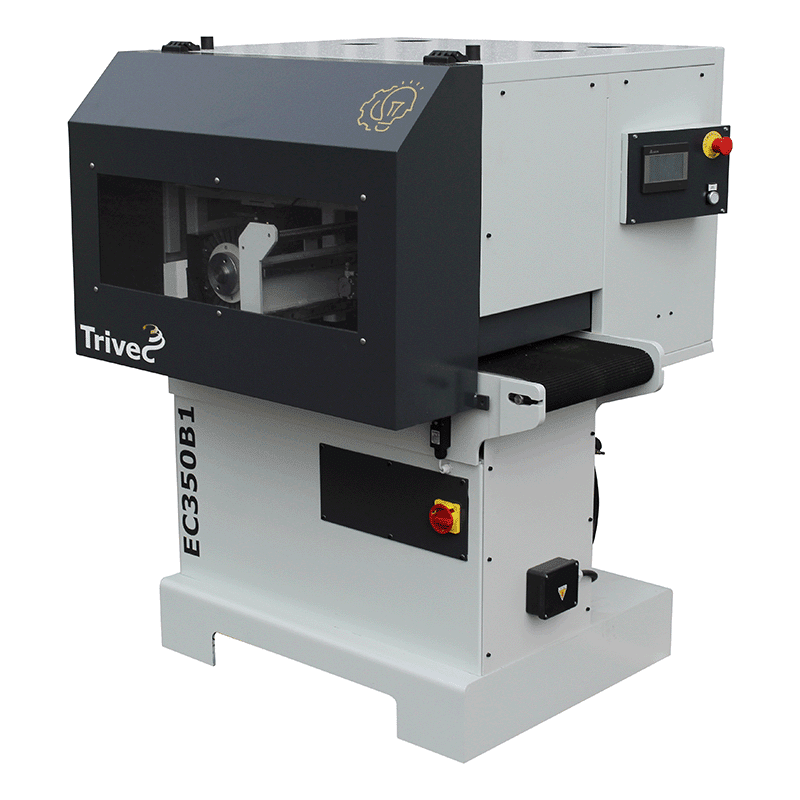

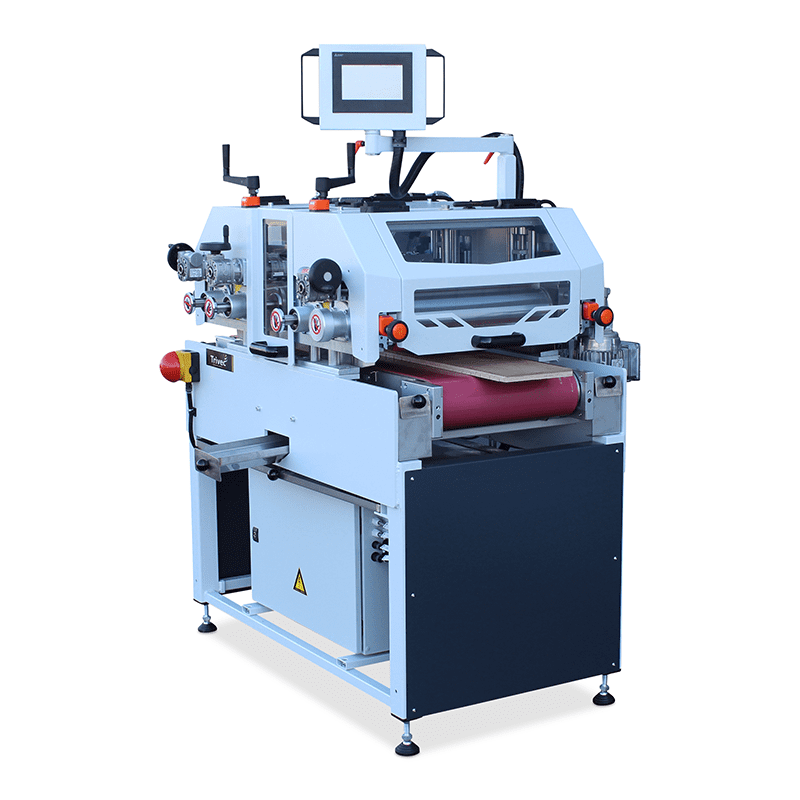

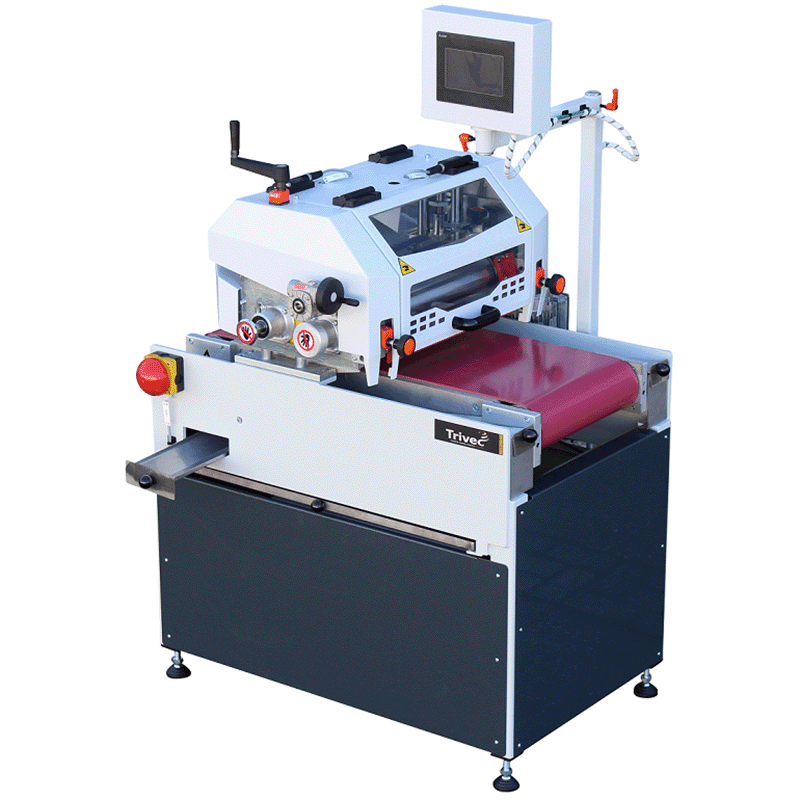

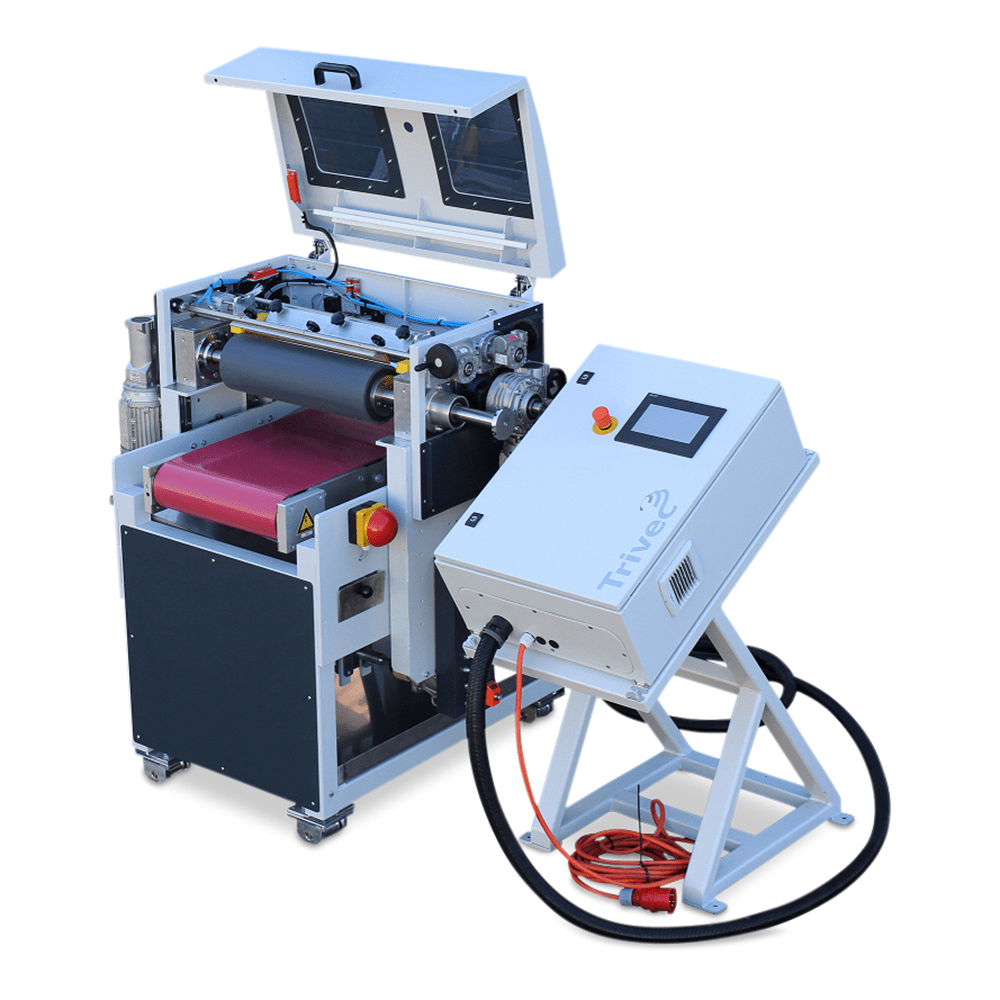

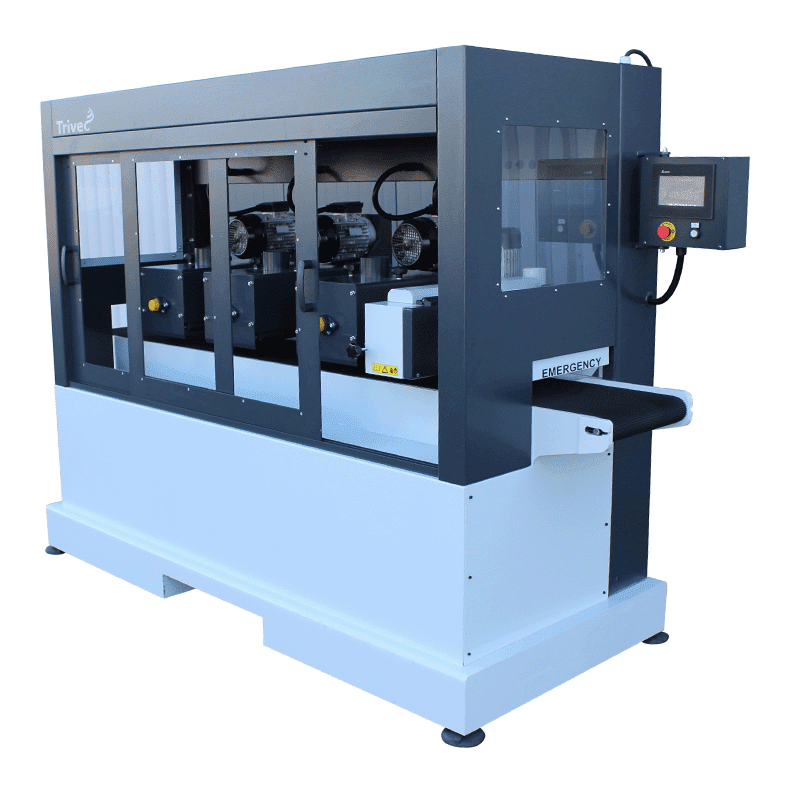

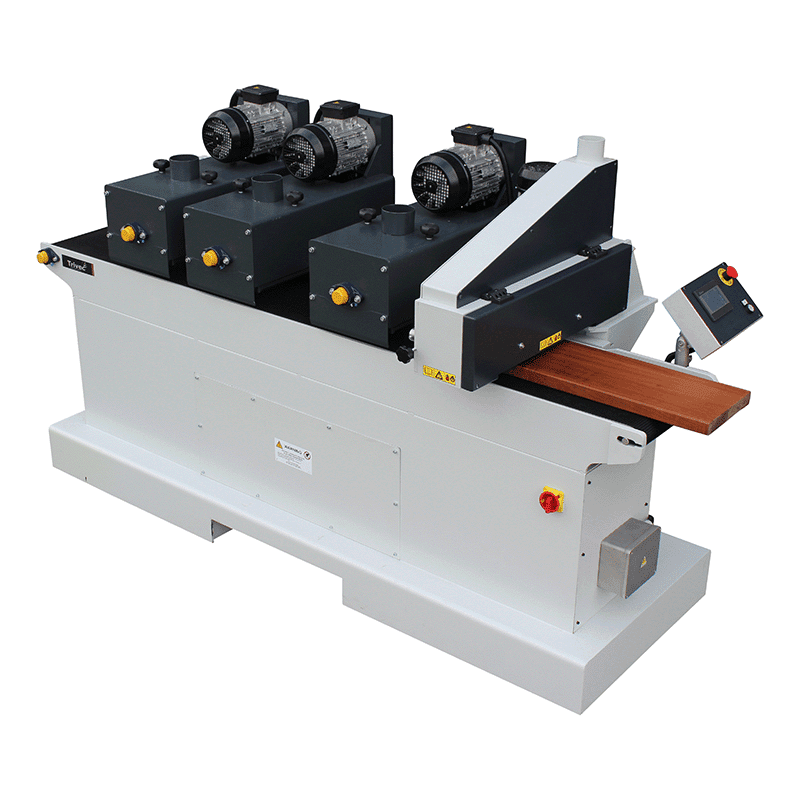

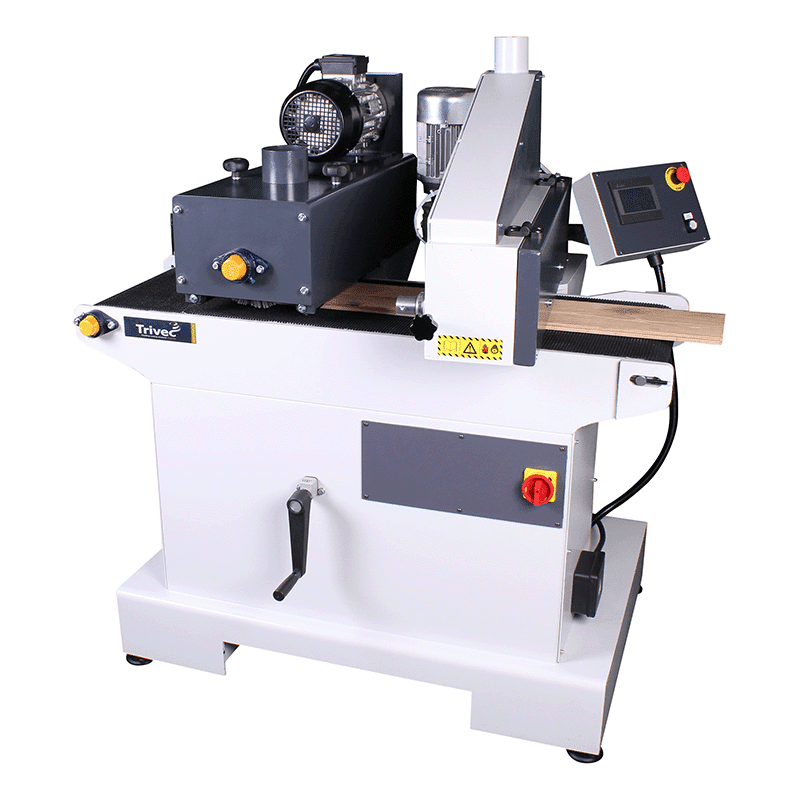

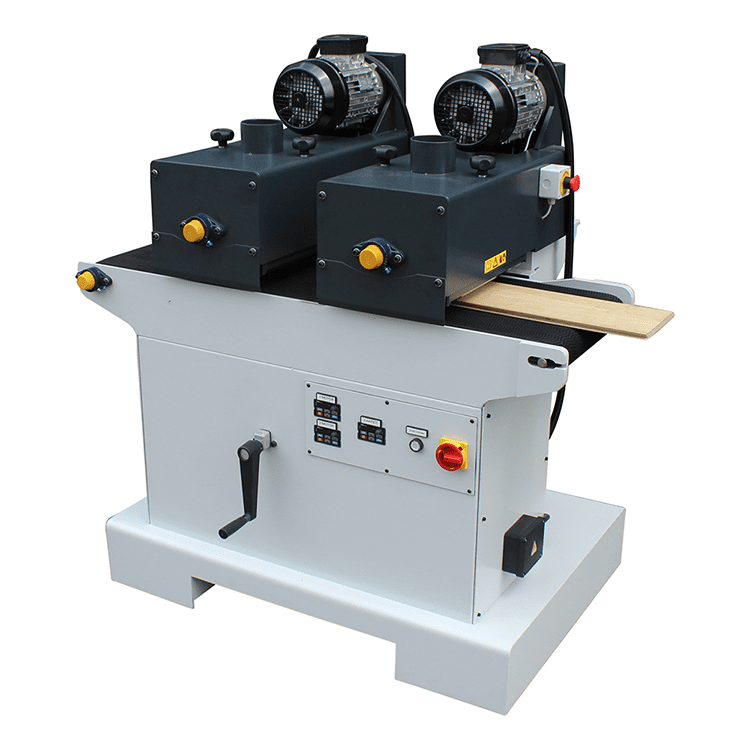

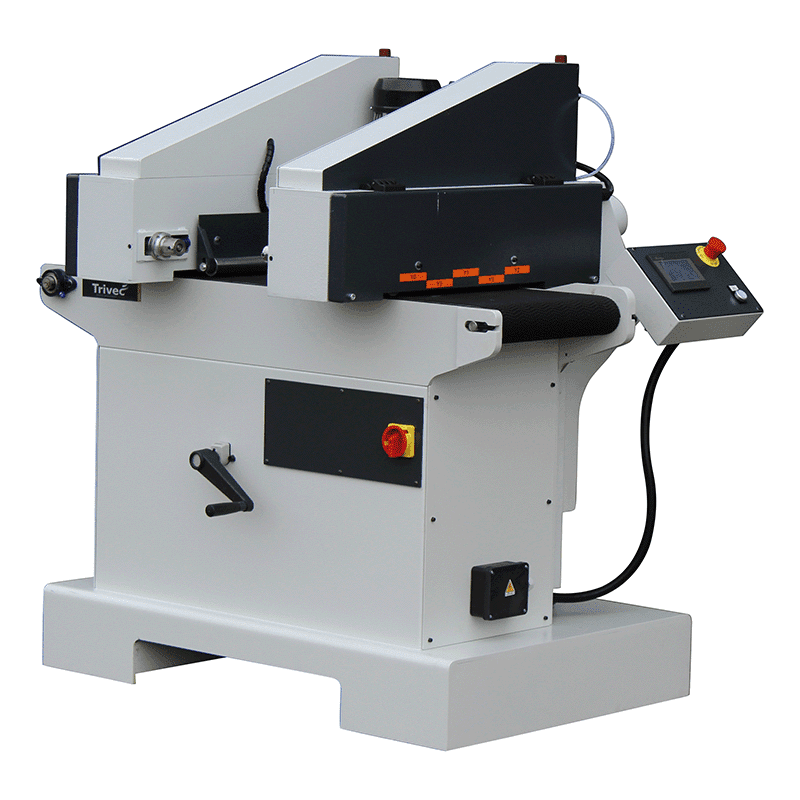

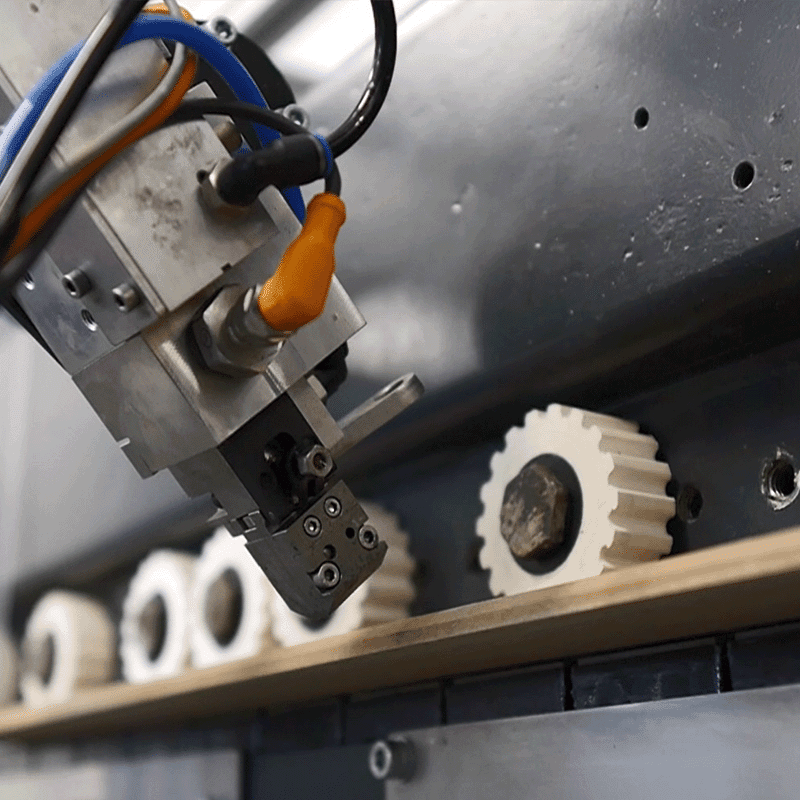

Trivec’s machine lines revolutionize parquet production with modular, high-performance solutions.

They boost efficiency, cut costs, and deliver superior finishes.

- Automate brushing, coating, and drying to reduce production time by up to 50%.

- Precise coating and energy-efficient UV/LED drying minimize material waste and energy costs.

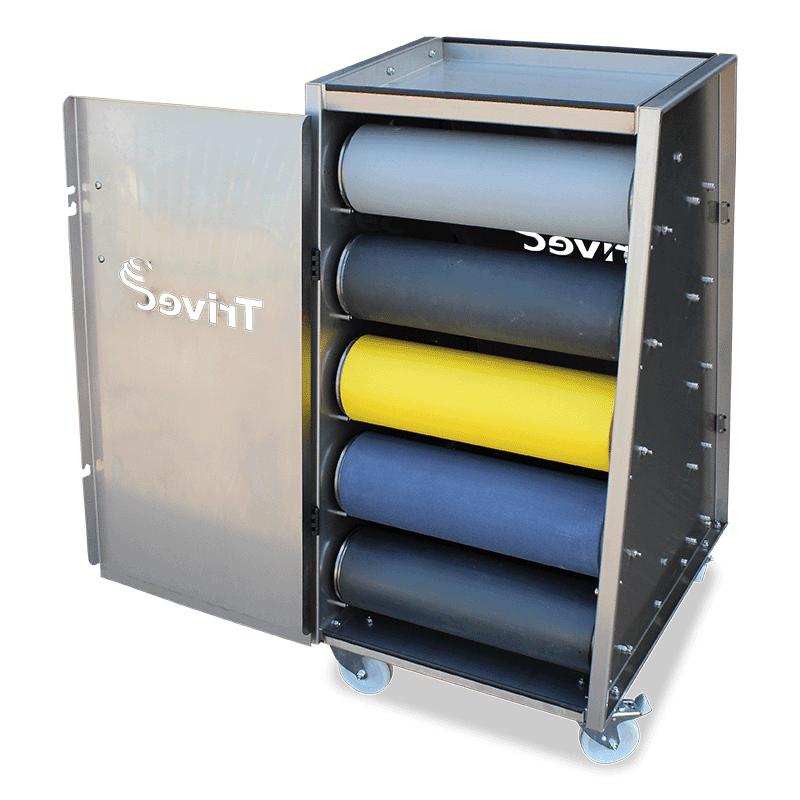

- Modular, scalable designs allow easy adjustments or expansions without disrupting workflows.

- Intuitive touchscreen controls and robust engineering ensure consistent, high-quality results and simple operation.

Explore our standard machine lines below to find the perfect solution for your production needs.

Frequently Asked Questions

Frequently asked questions about our parquet finishing machines

Is the machine line scalable for future expansion?

Can I test the machines first or see a demo?

How much space does a complete machine line require?

What is the lifespan of a machine line?

How easy are the machines to maintain?

What is the ROI (return on investment) of a machine line?

Parquet

Featured projects

How a parquet wholesaler established its own high-quality UV-oil finishing line.

Trivec was approached with a challenging request: help develop the finishing options.

Parquet based on technology

Parquet with different finishes

Go to our parquet machines

Navigate to our parquet machines

Other industries

We specialise in providing machinery solutions for surface finishing and treatment for a variety of industries. Explore how we support your branche or sector with our innovative approach and expertise.

Looking for something else?

Contact us for more information about our solutions and services or how we can help you with your challange or question!